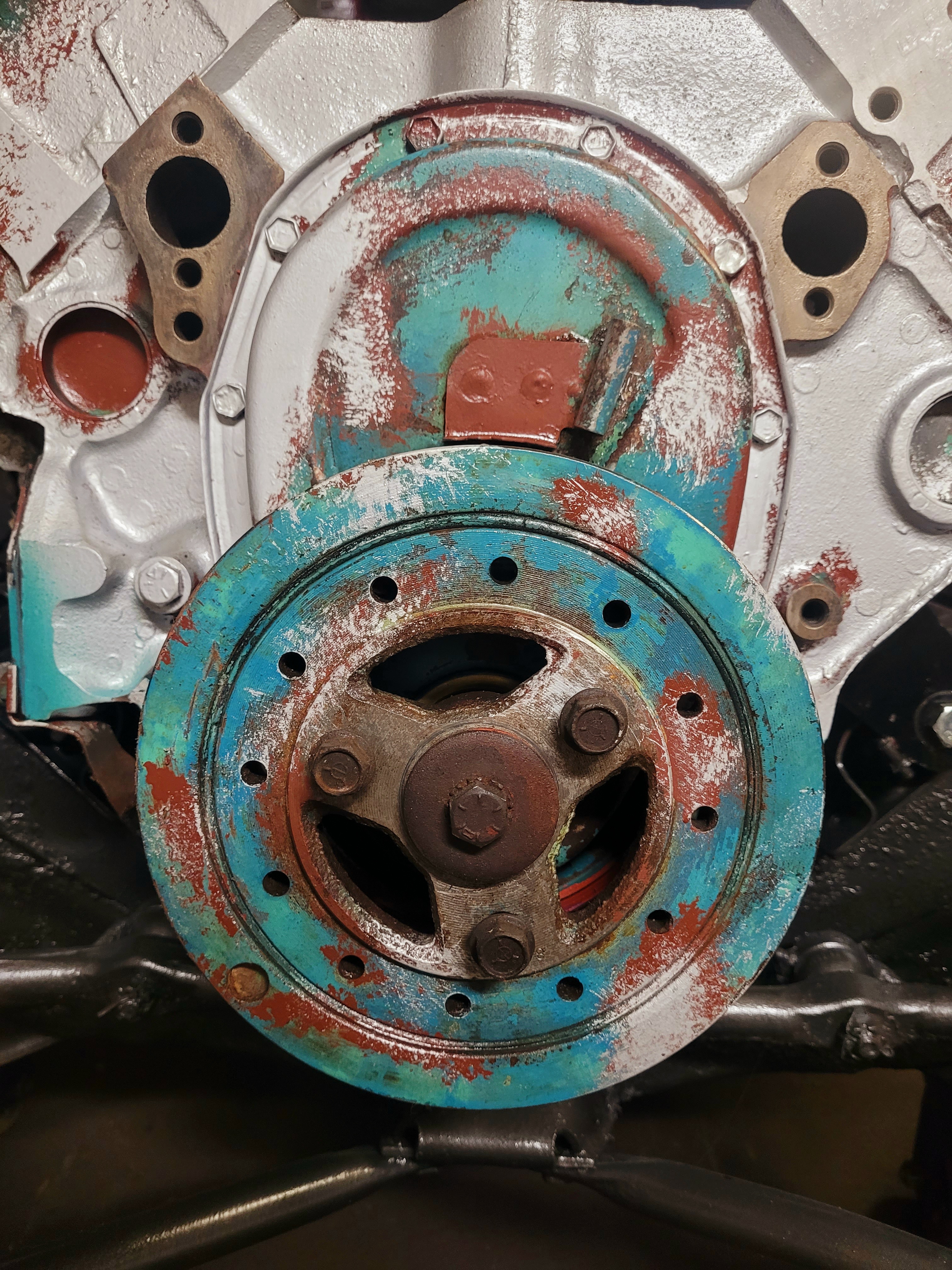

Looks good. I did an older small journal 327 had several rebuilds before I got it and at least 4 paint jobs. I water blasted and degreased it and used a clear coat. It had the original GM red in some spots, then orange, yellow and something like a silver grey. And the bare metal spots as well. Looked good with the gloss clear. I kept the original manifold with the oil fill tube.

I changed out the balancer and pulleys those were gloss black but everything else left it as I got it. Just cleaned it up and clear coat.

Engine was flat tops, studded ARP mains, Crane roller rockers, .488 cam and found some old headman headers old sliver paint and rust, a little beat up but fit the look. Sold to guy doing a rat rod so it fit that look perfect.

I changed out the balancer and pulleys those were gloss black but everything else left it as I got it. Just cleaned it up and clear coat.

Engine was flat tops, studded ARP mains, Crane roller rockers, .488 cam and found some old headman headers old sliver paint and rust, a little beat up but fit the look. Sold to guy doing a rat rod so it fit that look perfect.