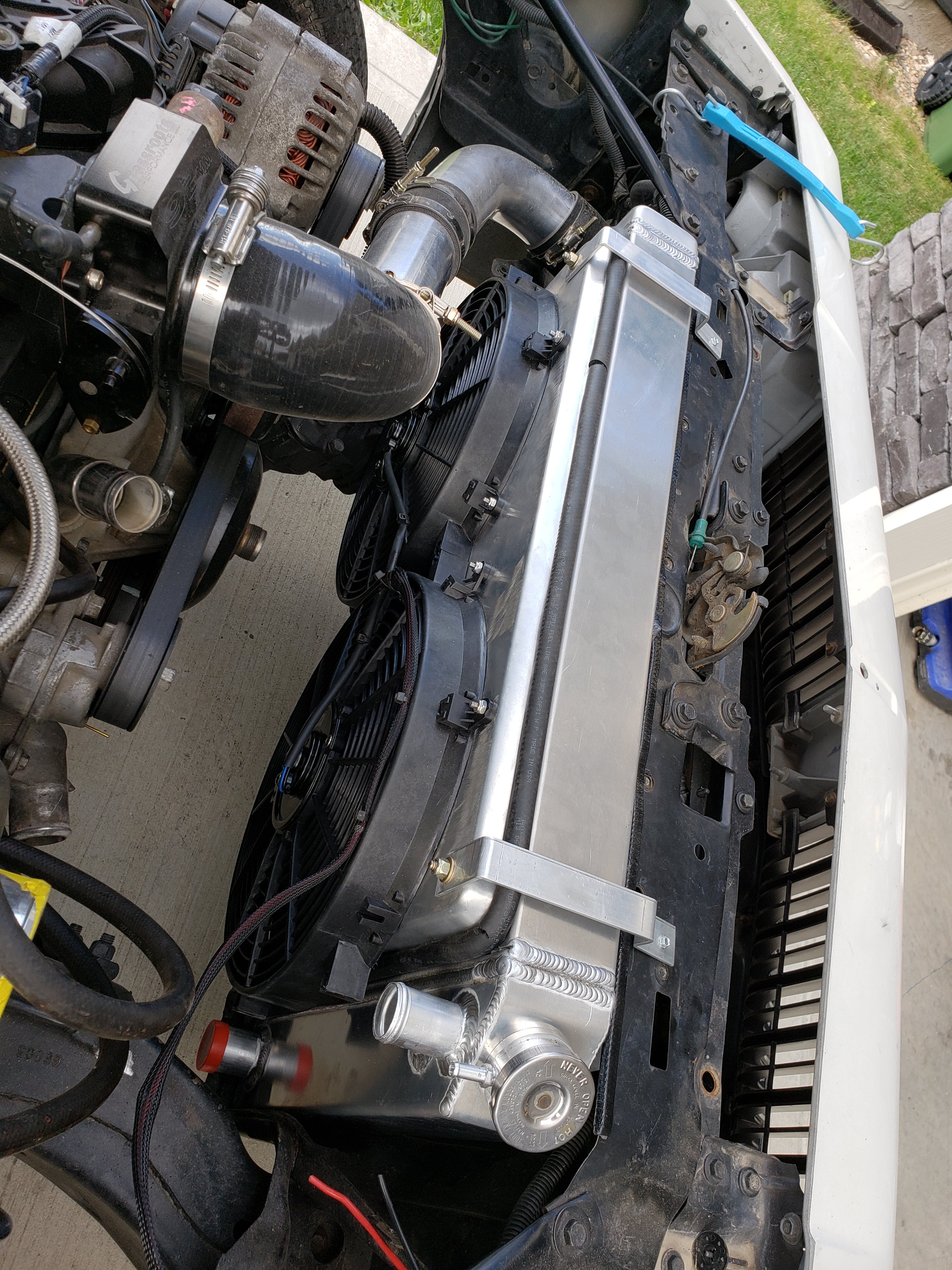

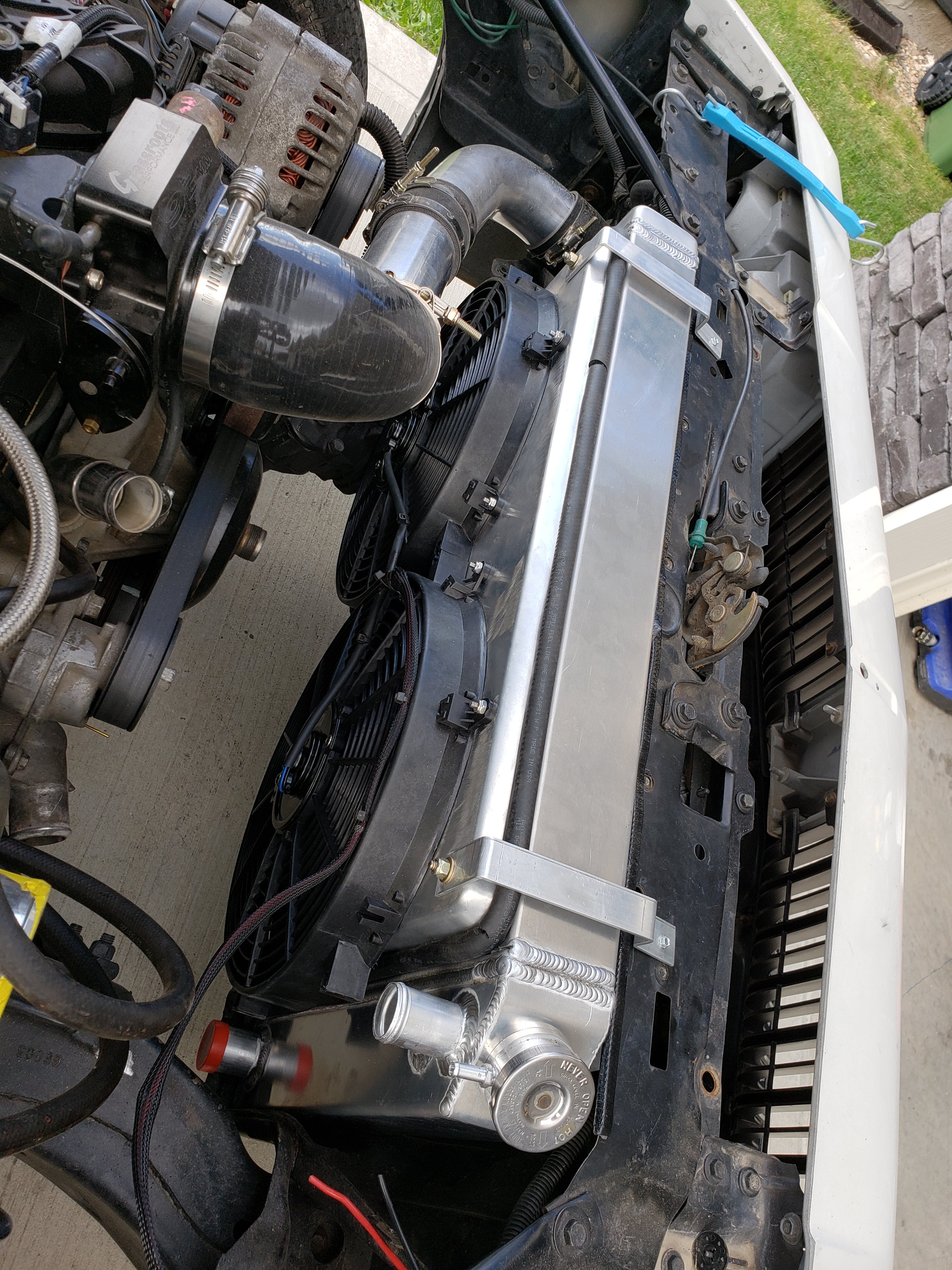

What’s the fuel line for? NHRA rules state no more than 12” of rubber line total. Going to need hard line or braided stainless.Got the rad shroud finish cut for the fans, fans mounted and wrapped the edge of the cookie sheet.... I mean custom rad shroud in 5/16 split fuel line.

Looking pretty much like it's a win in my books.

View attachment 147633View attachment 147634View attachment 147635View attachment 147636View attachment 147637

Custom rad shroud cost.

Full size baking sheet. Amazon. $32 CAD.

China 14" E-fans. Pair. Amazon. $120 CAD.

Classy Stainless hardware. Home Depot. $12

8' 5/16 fuel hose. $12 CAD.

All in. $174 CAD. Or 126.39 USD

I feel like this was a win.

Olds ticket to 9s... LS swap adventure.

- Thread starter Northernregal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Cushion around the shroud. I split it and wrapped it around the cookie sheet lip, seals the shroud to the rad nicely.

Excellent idea!Cushion around the shroud. I split it and wrapped it around the cookie sheet lip, seals the shroud to the rad nicely.

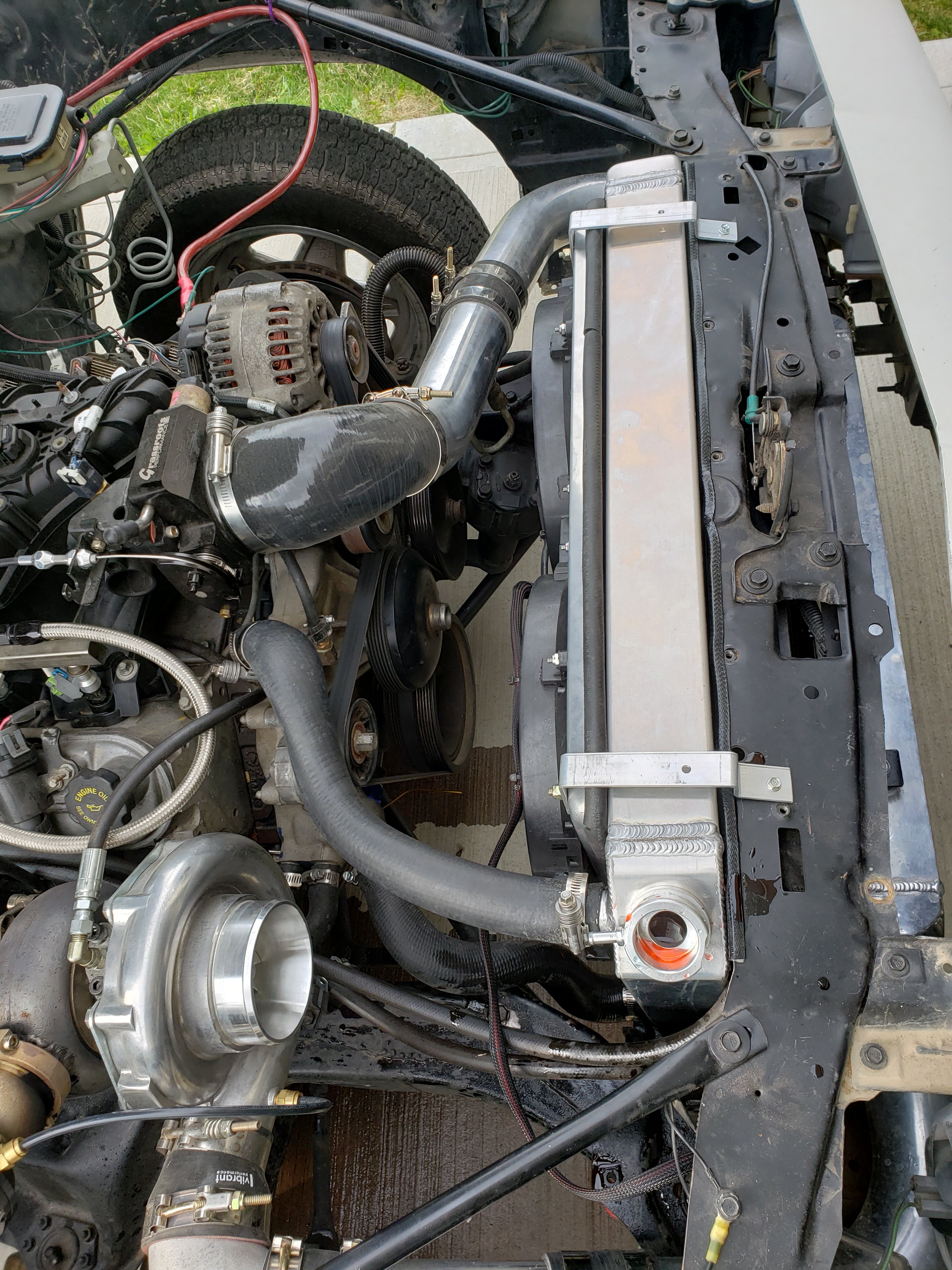

I hate making aluminum rad mounts with chinese tools.

But it runs. And the fans work, nicely I might add.

Working on flex sensor now.

But it runs. And the fans work, nicely I might add.

Working on flex sensor now.

What’s the fuel line for? NHRA rules state no more than 12” of rubber line total. Going to need hard line or braided stainless.

I believe that to be incorrect, but you have me reading now. Is that for a for a 7.50 or 8.50 certification?

Lines: All non-OEM fuel lines (including gauge and/or data recorder lines) must be metallic, steel braided, or NHRA- accepted “woven or woven-pushlock.” A maximum of 12 inches total (front to rear) of non-metallic or non-steel braided hoseI believe that to be incorrect, but you have me reading now. Is that for a for a 7.50 or 8.50 certification?

is permitted for connection purposes only; individual injector nozzle and motorcycle fuel lines are excluded. Fuel lines (except steel braided lines) in the flywheel/bellhousing area must be enclosed in a 16-inch length of steel tubing, 1/8-inch-minimum wall thickness, securely mounted as a protection against fuel- line rupture. Fuel lines may not be routed in the driveshaft tunnel. It is mandatory that fuel lines passing supercharger

drive belts be steel braided, NHRA-accepted woven or woven- pushlock, or be enclosed in protective steel tubing. A current list of NHRA-accepted woven or woven-pushlock fuel lines is available on NHRARacer.com. All NHRA-accepted fuel lines must use ends that are specifically designed for the type of fuel line being used. No hose clamps allowed on NHRA-accepted fuel lines

I guess I won't be doing any NHRA certified drag racing as I ran rubber injection hose through the frame from front to back on my car.This is in the general rules section so it should apply to all vehicles

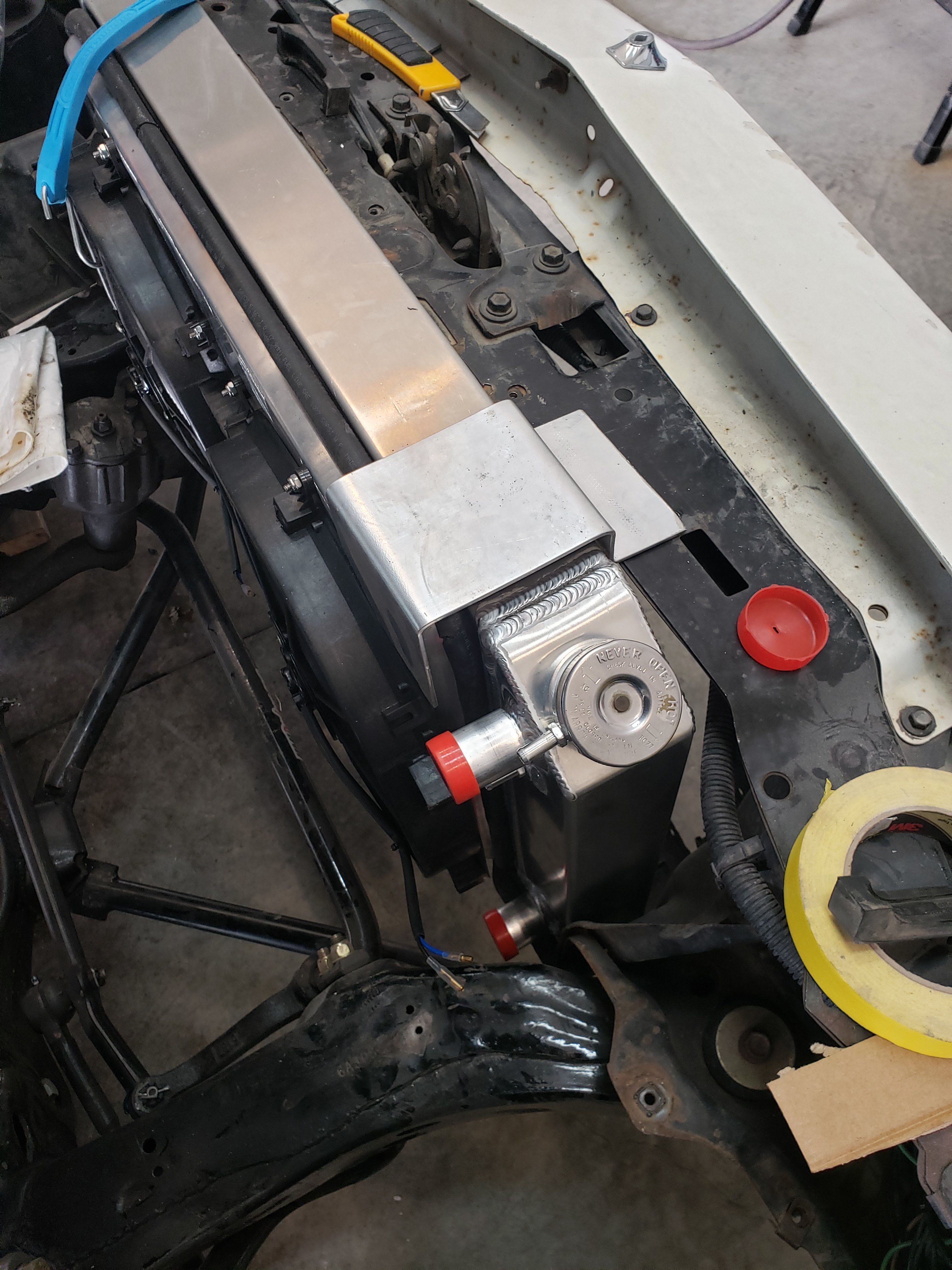

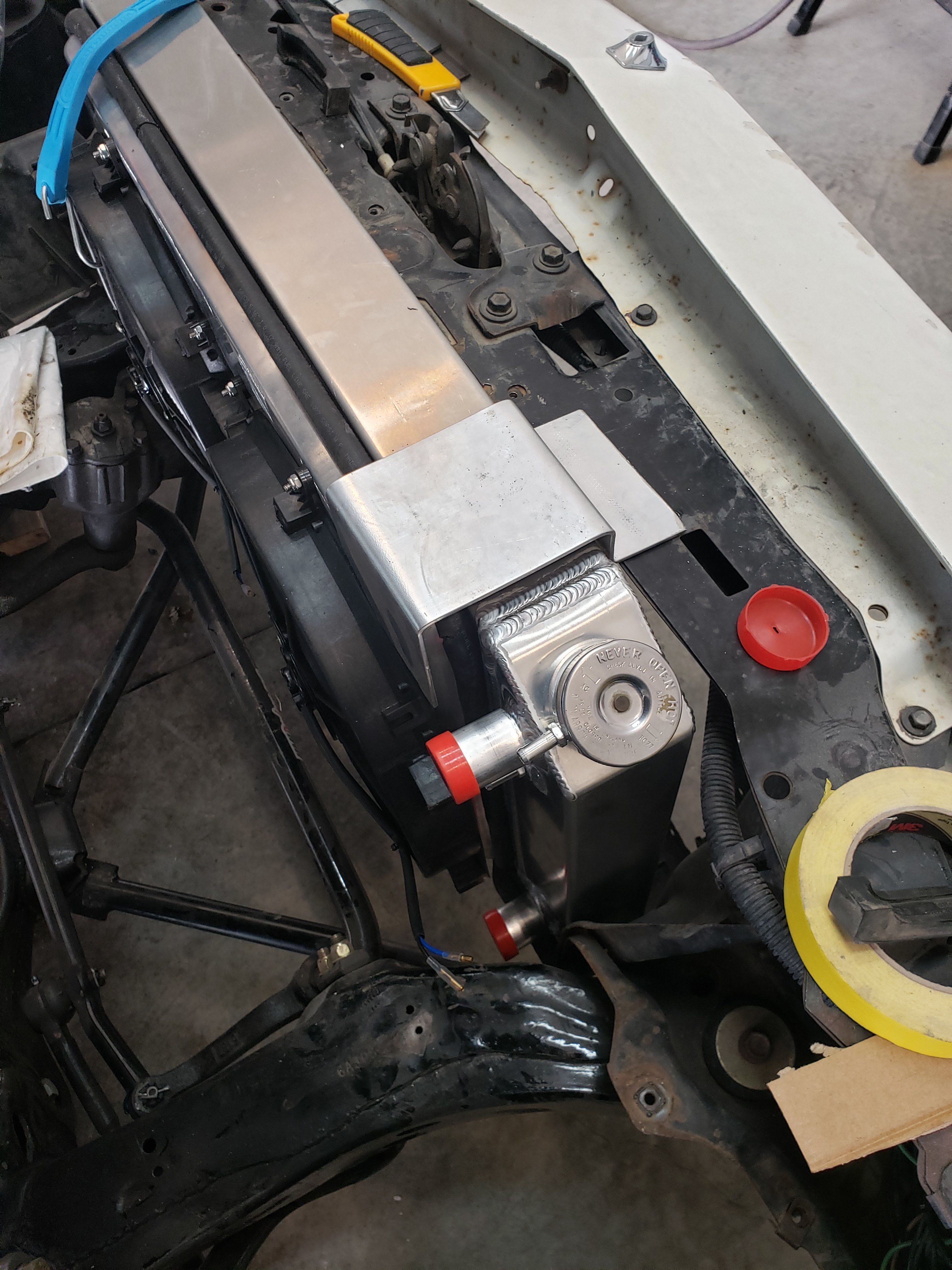

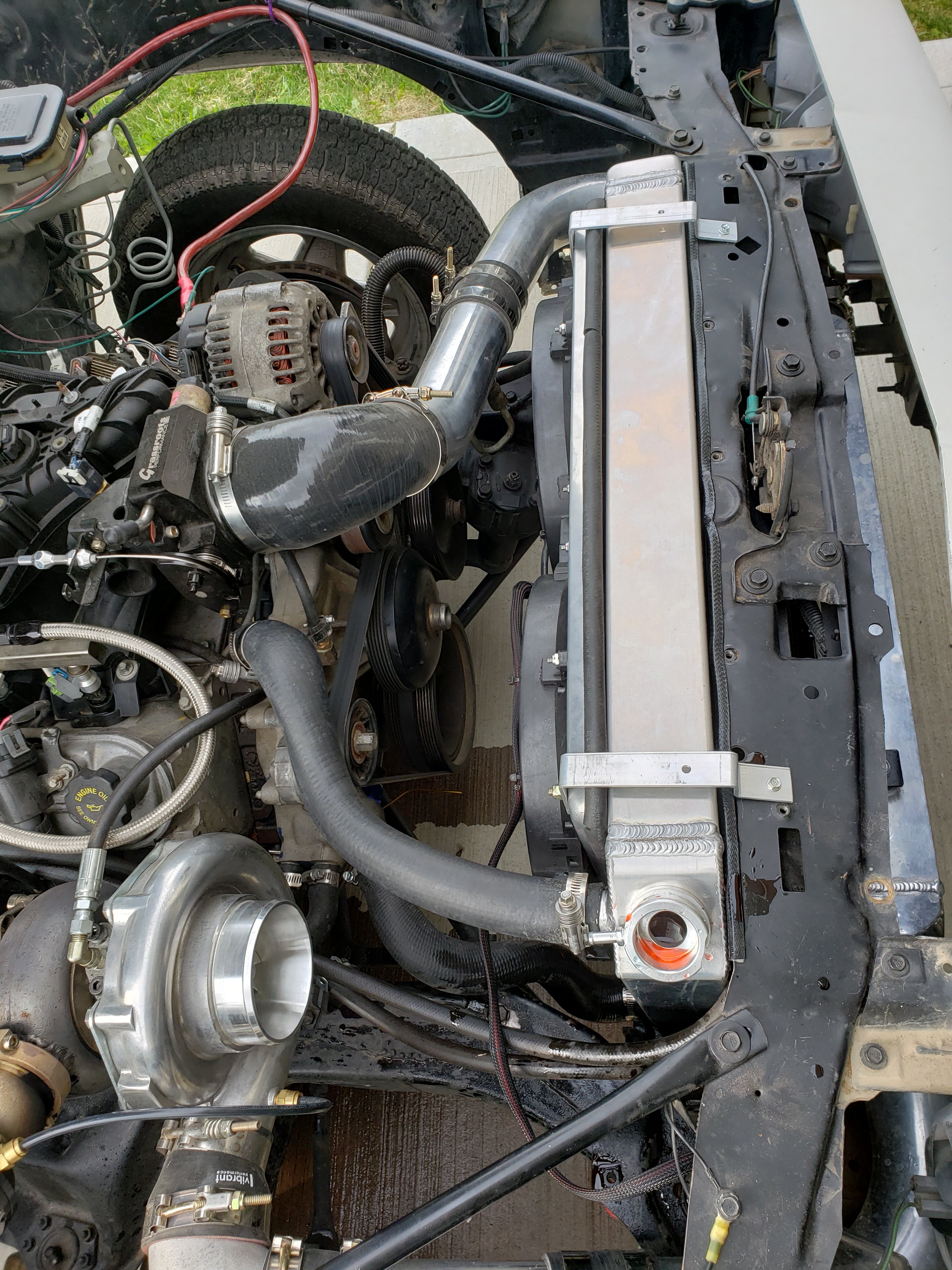

Had a pretty busy week trying to get the rad in and flanged up.

I've been fighting with making the rad support for the sweet, custom cookie sheet rad shroud. I had some aluminum leftover from the cut outside for the fan so I tried them, but I didn't really feel they were going to last. It was just too thin.

Then I tried some 4" wide 14ga aluminum and it was a giant pain to get to bend in my vice. I got one side ok looking but I couldn't get the two bends for the front close enough together to be tight to the rad.

I ended up getting a vice jaw brake set and switching to 1 1/4" 14ga aluminum flat bar. It bent much nicer, held its shape well and wasnt a complete disaster to bend. Made tops and bottom brackets to hold the shroud in.

I cut up the factory truck upper hose I was using to fit the new outlet location for now, not super happy with it but it functional.

Fired her back up and bleed the air back out.

First test was good. Sitting at an idle it holds 186f with the fans on. Already a 10 degree improvement. Fans are pretty quiet, compared to the junkyard mustang fan it had. I HIGHLY doubt they are close to the 2000cfm advertised on Amazon, but they move way more air than before.

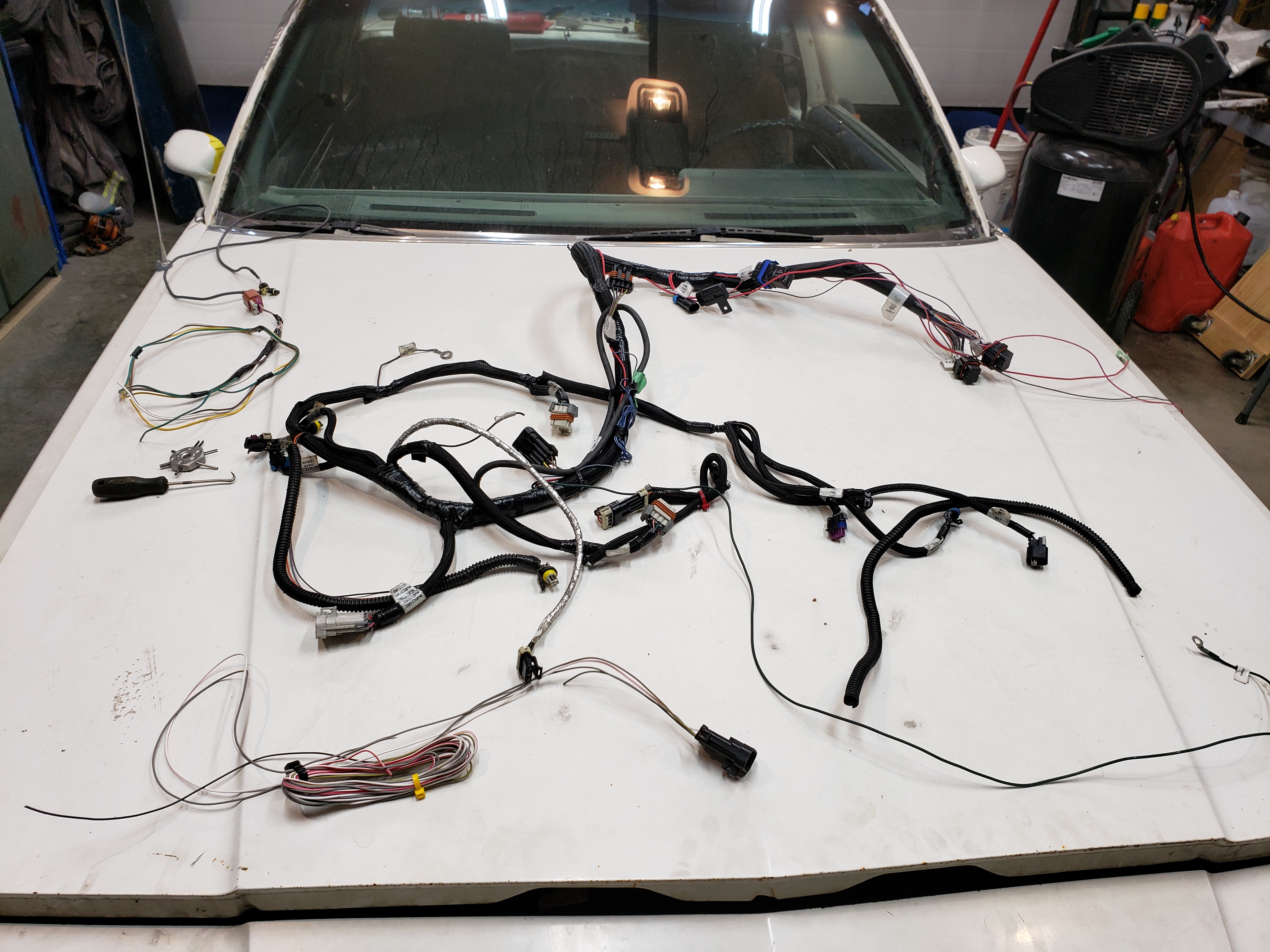

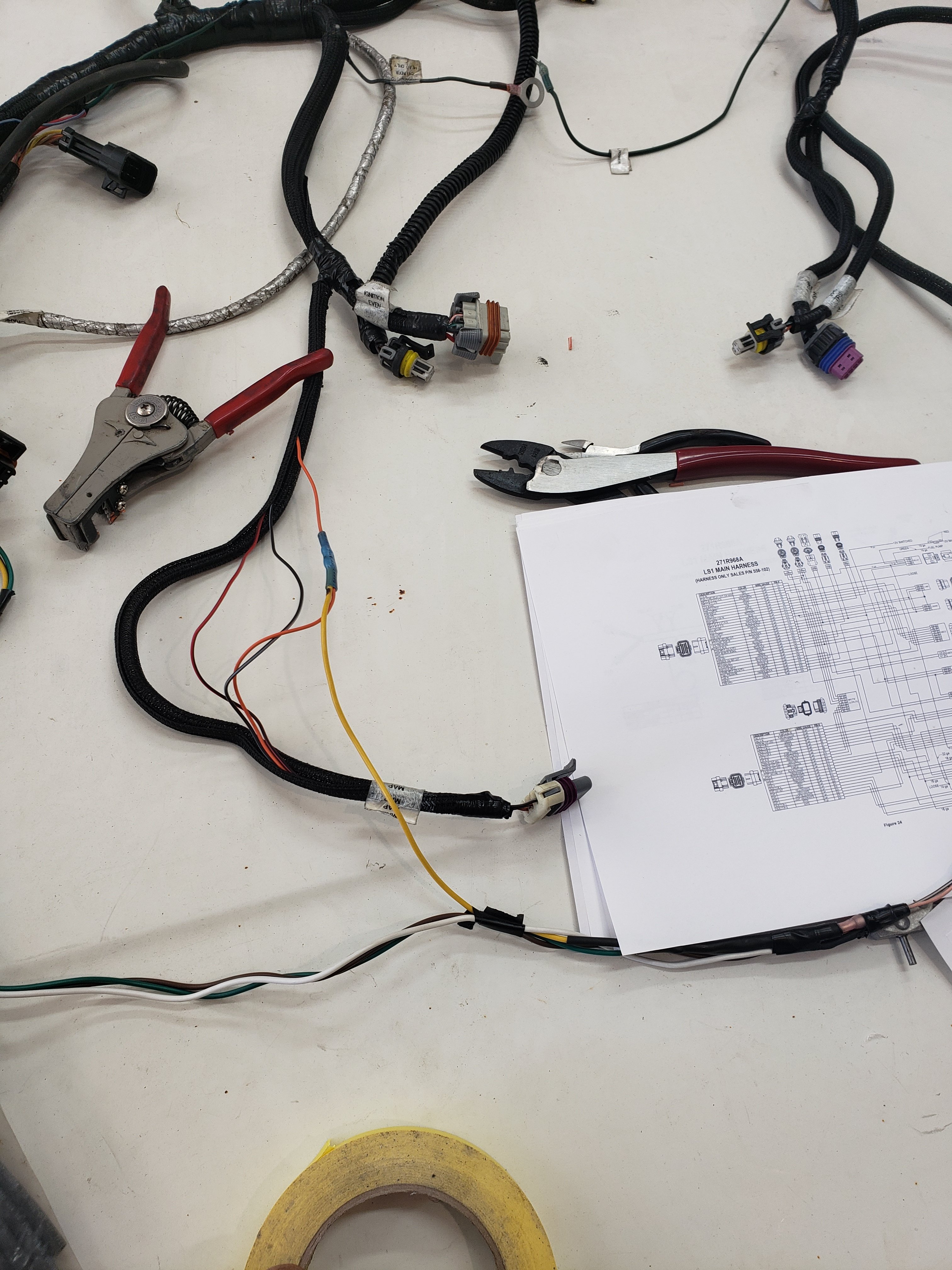

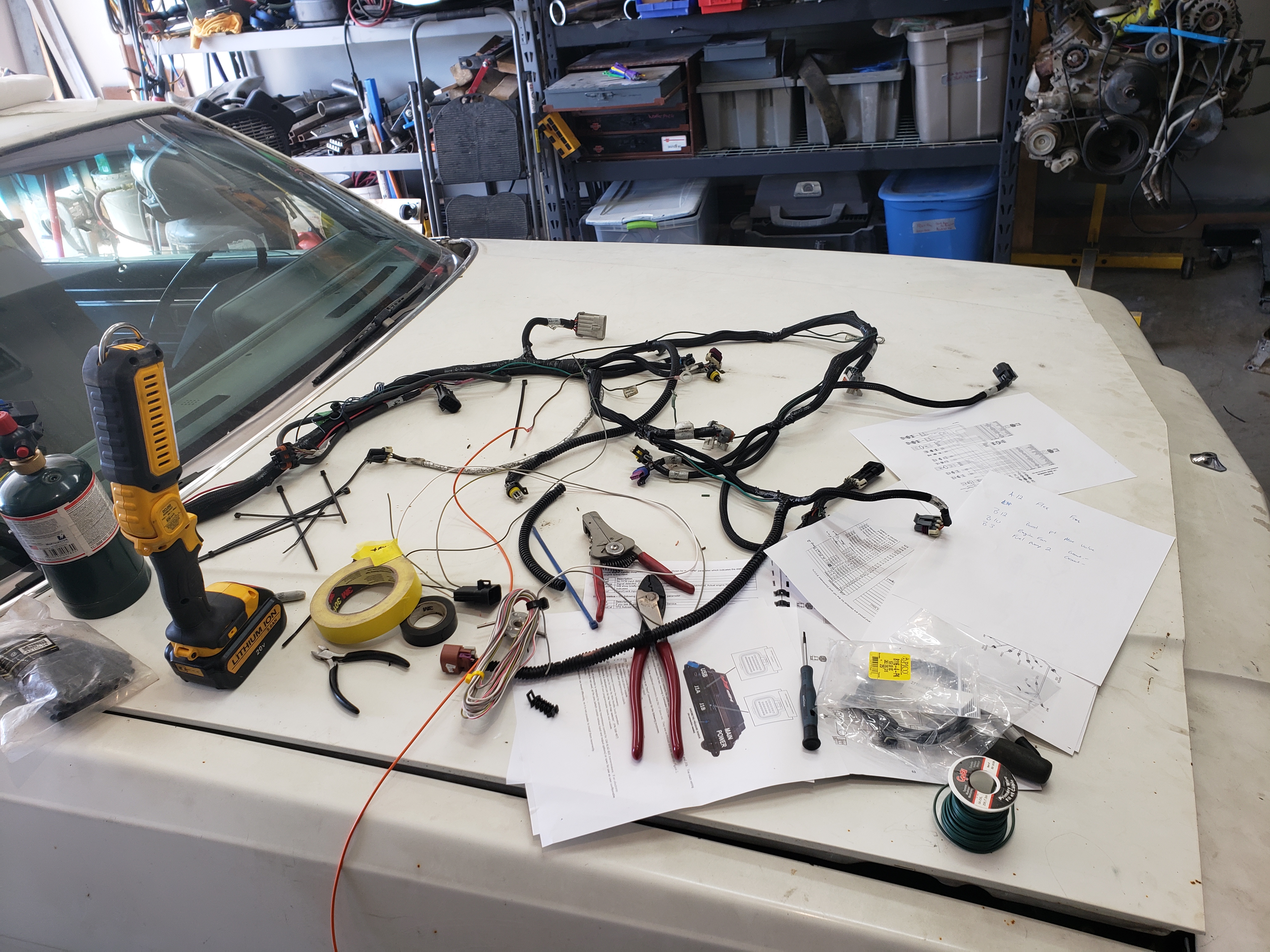

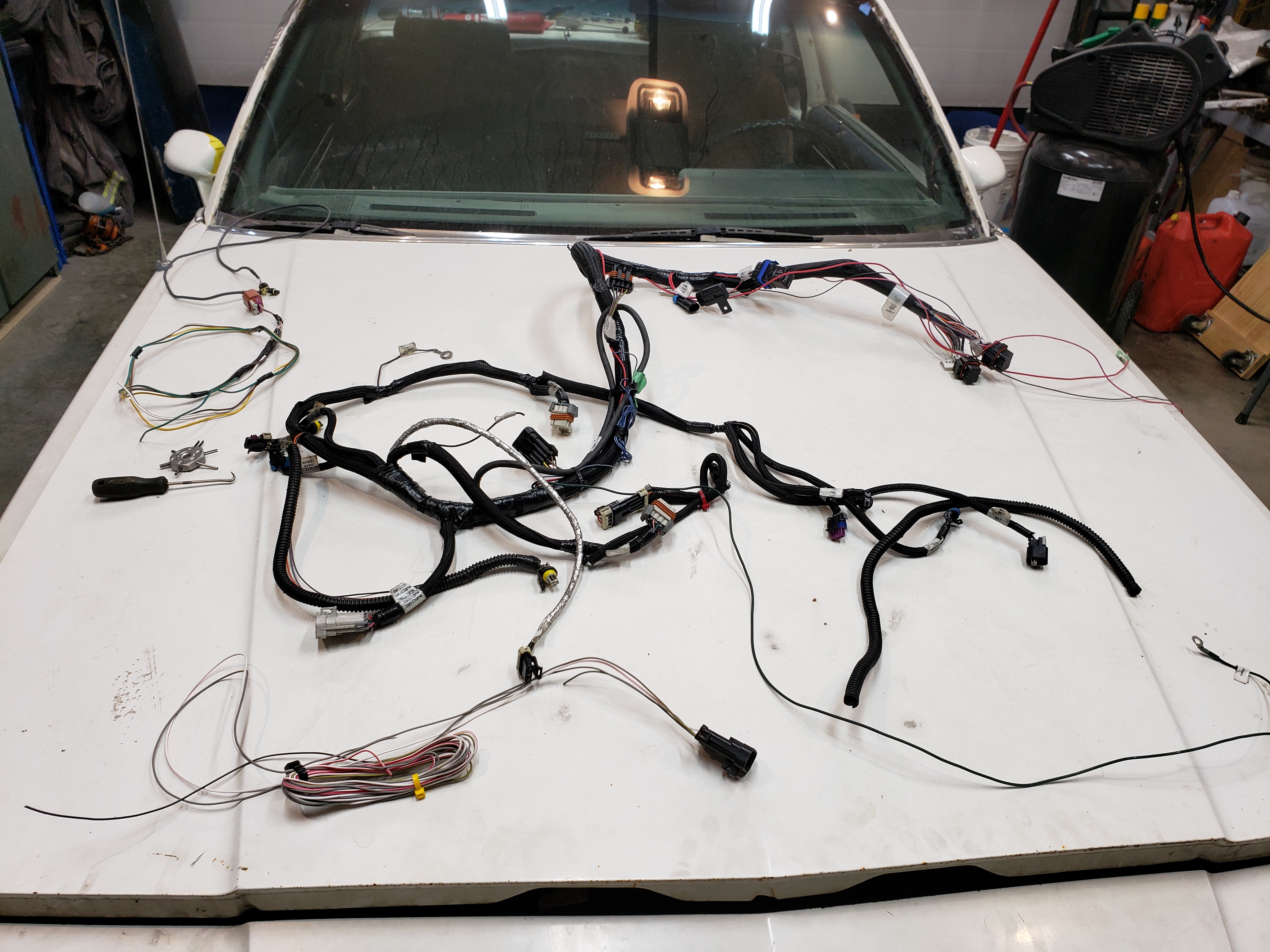

After I was satisfied with that I ripped out the main engine harness.

Time for some moving around.

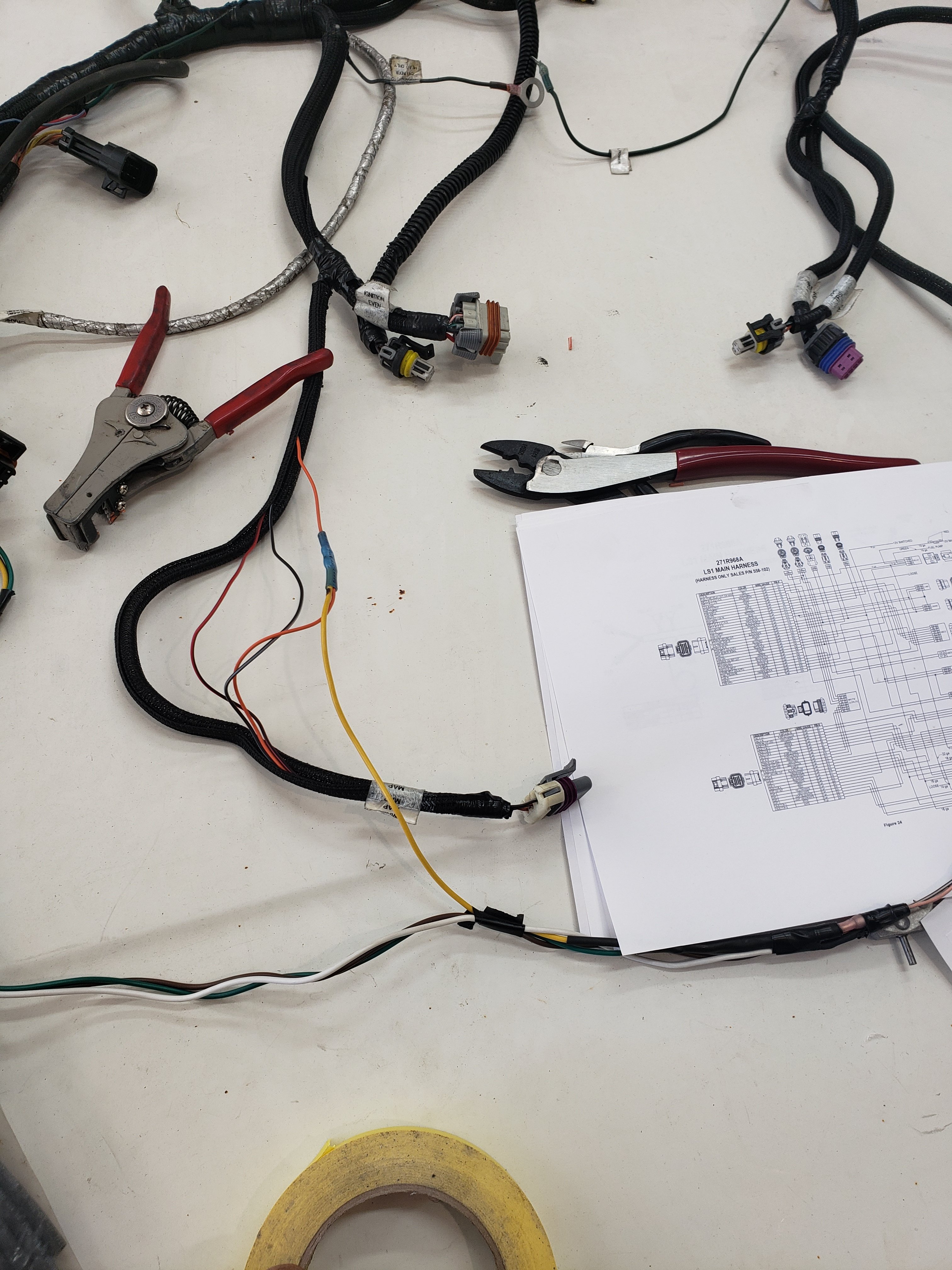

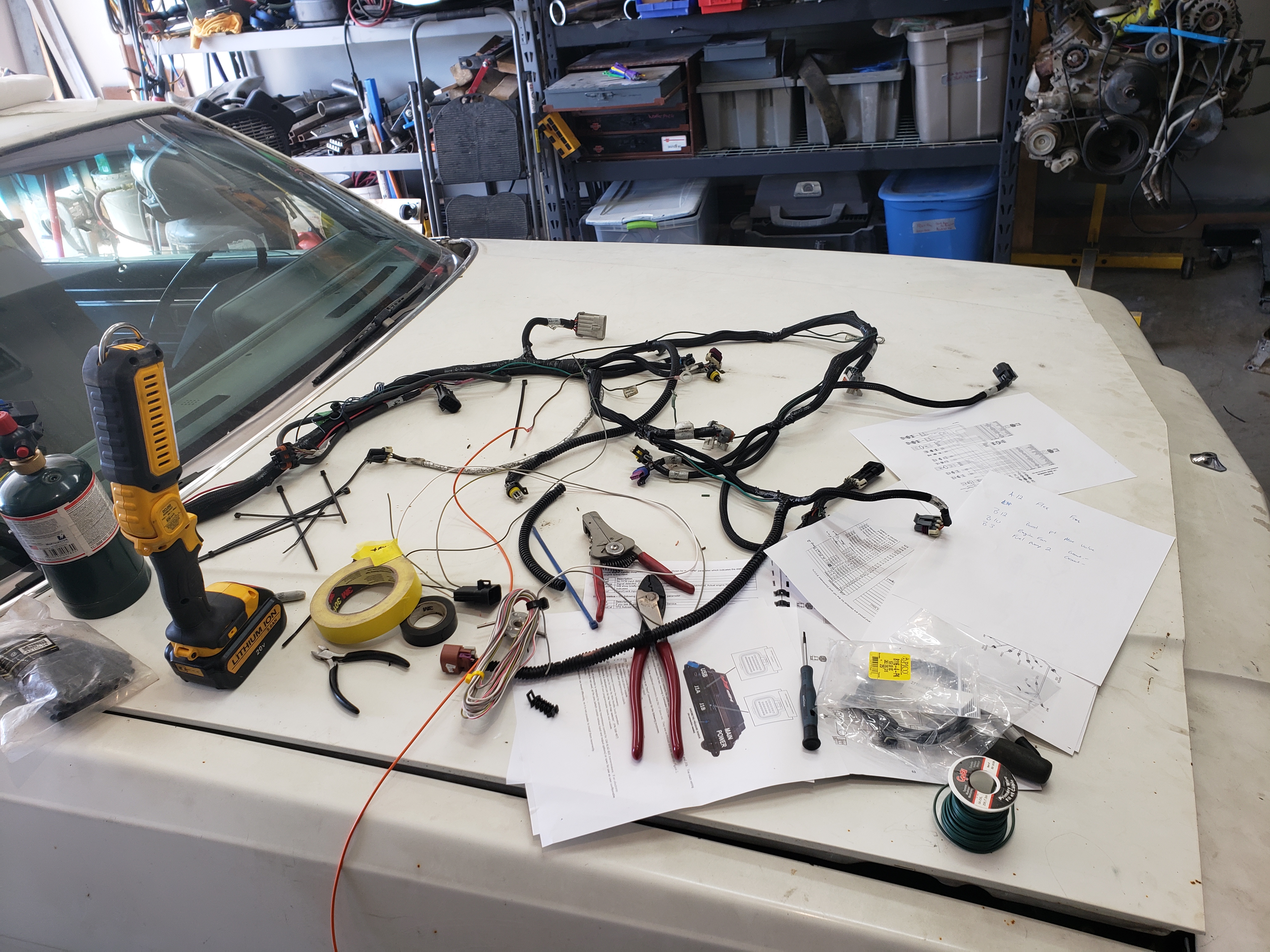

Once laid out on the buick work bench I made. a plan for the flex sensor wiring and locations of the boost control solenoid. I moved some stuff on the harness to better suit my configuration and tapped into the 5v and sensor ground for the flex sensor.

The harness is back in, it's running again but the content sensor isnt reading right. I may have swapped the power and signal lines by accident when I wired it. I hope anyway. I'm off tomorrow so I will find out.

At least the E85 I found here is a win. Tested out the content test bottle I got off Amazon.

So finish off the flex diagnosis, mount and wire the boost solenoid, fab up an air filter solution and a waste gate piping re-do for tomorrow. should have some ethanol testing to do friday. 😃

Oh ya, swap the rear diff in the girlfriend's Infiniti QX60 tomorrow too. Should be fun.

I've been fighting with making the rad support for the sweet, custom cookie sheet rad shroud. I had some aluminum leftover from the cut outside for the fan so I tried them, but I didn't really feel they were going to last. It was just too thin.

Then I tried some 4" wide 14ga aluminum and it was a giant pain to get to bend in my vice. I got one side ok looking but I couldn't get the two bends for the front close enough together to be tight to the rad.

I ended up getting a vice jaw brake set and switching to 1 1/4" 14ga aluminum flat bar. It bent much nicer, held its shape well and wasnt a complete disaster to bend. Made tops and bottom brackets to hold the shroud in.

I cut up the factory truck upper hose I was using to fit the new outlet location for now, not super happy with it but it functional.

Fired her back up and bleed the air back out.

First test was good. Sitting at an idle it holds 186f with the fans on. Already a 10 degree improvement. Fans are pretty quiet, compared to the junkyard mustang fan it had. I HIGHLY doubt they are close to the 2000cfm advertised on Amazon, but they move way more air than before.

After I was satisfied with that I ripped out the main engine harness.

Time for some moving around.

Once laid out on the buick work bench I made. a plan for the flex sensor wiring and locations of the boost control solenoid. I moved some stuff on the harness to better suit my configuration and tapped into the 5v and sensor ground for the flex sensor.

The harness is back in, it's running again but the content sensor isnt reading right. I may have swapped the power and signal lines by accident when I wired it. I hope anyway. I'm off tomorrow so I will find out.

At least the E85 I found here is a win. Tested out the content test bottle I got off Amazon.

So finish off the flex diagnosis, mount and wire the boost solenoid, fab up an air filter solution and a waste gate piping re-do for tomorrow. should have some ethanol testing to do friday. 😃

Oh ya, swap the rear diff in the girlfriend's Infiniti QX60 tomorrow too. Should be fun.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 43

- Replies

- 4

- Views

- 142

- Replies

- 0

- Views

- 93

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.