I understand the process and have done this on big blocks many times. However with these new fangled LSx's I thought that the crank and cam sensor took care of all that nonsense. Then you adjust timing electronically. What am I missing? I will be using Holley's terminator so maybe guys with stock computers need to do this especially with boost? I was under the impression that once you line up the timing dots on the gears you were good to goVery interested to see what occurred. I think it's below the head and above the rod. But what do I know, that could be as simple as a failed push rod, lifter or rocker as well. It would be nice to know if the timing was correct or not before you take it apart as well.

Good luck - Jim.

Tony - verifying timing on an LS is easily done erroneously with a piston stop if the valves aren't backed off on #1 cylinder when using a piston stop. Reason being that the valve, exhaust I believe, contacts the piston stop giving the feeling that the piston is hitting it rather than the valve, thus causing an erroneous TDC mark on the balancer. Sloppy Mechanics' Matt Happel repeatedly blew up motors in his Colorado due to this issue, until he figured it out. It can be found in his YouTube videos. It caused him t have the timing advanced somewhere in the area of 12-15 degrees IIRC.

Olds ticket to 9s... LS swap adventure.

- Thread starter Northernregal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Aren't valvetrainy things half engine speed?

You can true up your timing in the Holley software. I was just looking to verify it was close. Trying to do something good to rule out problems later.I understand the process and have done this on big blocks many times. However with these new fangled LSx's I thought that the crank and cam sensor took care of all that nonsense. Then you adjust timing electronically. What am I missing? I will be using Holley's terminator so maybe guys with stock computers need to do this especially with boost? I was under the impression that once you line up the timing dots on the gears you were good to go

Very interested to see what occurred. I think it's below the head and above the rod. But what do I know, that could be as simple as a failed push rod, lifter or rocker as well. It would be nice to know if the timing was correct or not before you take it apart as well.

Good luck - Jim.

Tony - verifying timing on an LS is easily done erroneously with a piston stop if the valves aren't backed off on #1 cylinder when using a piston stop. Reason being that the valve, exhaust I believe, contacts the piston stop giving the feeling that the piston is hitting it rather than the valve, thus causing an erroneous TDC mark on the balancer. Sloppy Mechanics' Matt Happel repeatedly blew up motors in his Colorado due to this issue, until he figured it out. It can be found in his YouTube videos. It caused him t have the timing advanced somewhere in the area of 12-15 degrees IIRC.

I watched his video after and had a slack jawed " oh no" moment.

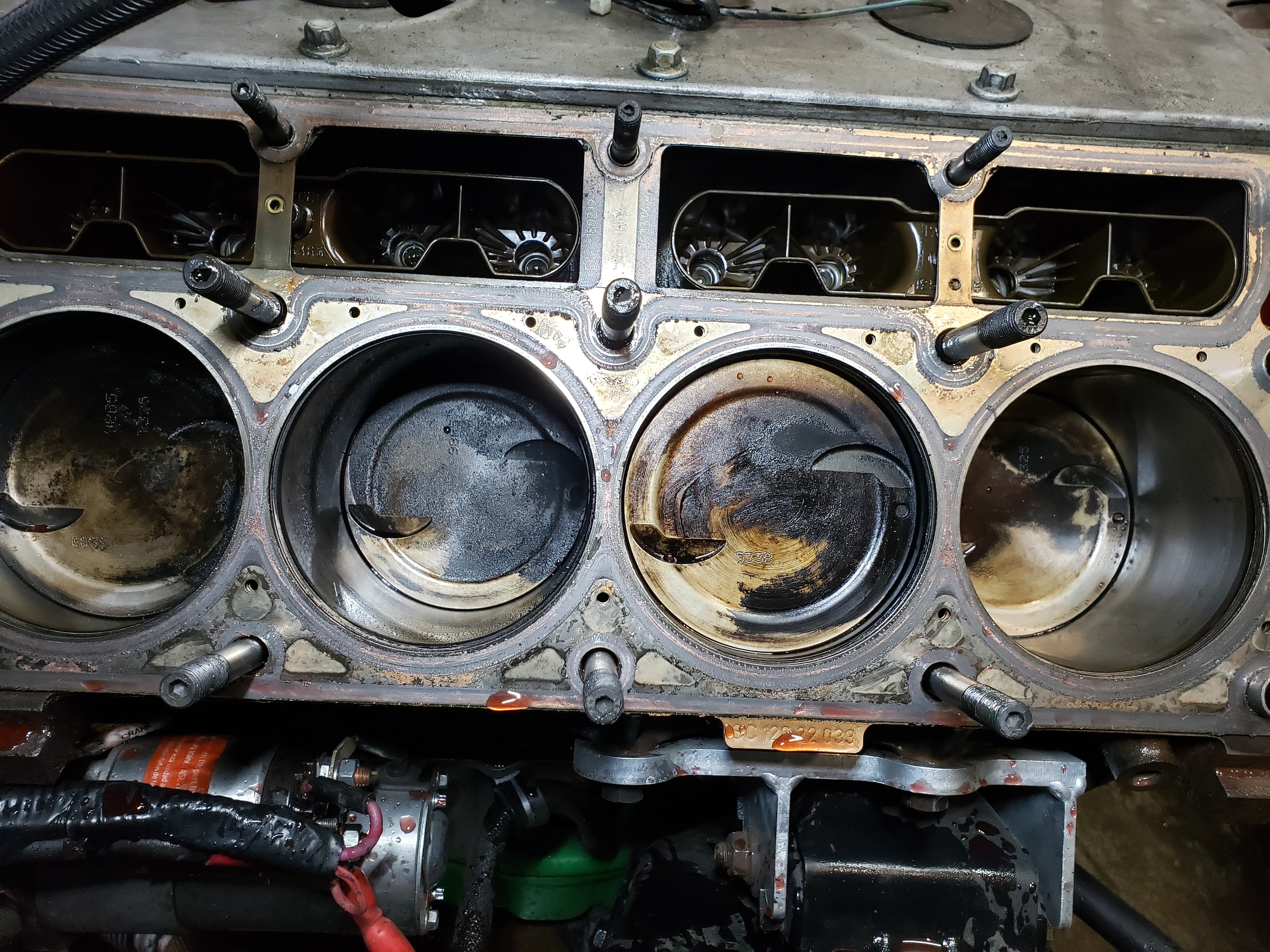

After the video I pulled the valve cover and plugs again, looking over #1 timing events all happen as they should on rockers and nothing is loose or "odd". It also doesn't tick when turning over with the starter, or at least its not audible. I jammed my Chinese imitation fiber optic in all the plug holes and only saw a mark on the #1 piston top. So hopefully just an exhaust valve tweak.

But I have 3 different plans. And I'll have a direction as soon as I get the head off and see what I've done.

True... but its still not supposed to make that noise.Aren't valvetrainy things half engine speed?

Got a quick update from today's adventures.

Hauled the Regal to my unsuspecting parents garage, "for the winter"...

Cleaned out the garage and moved the cutlass in.

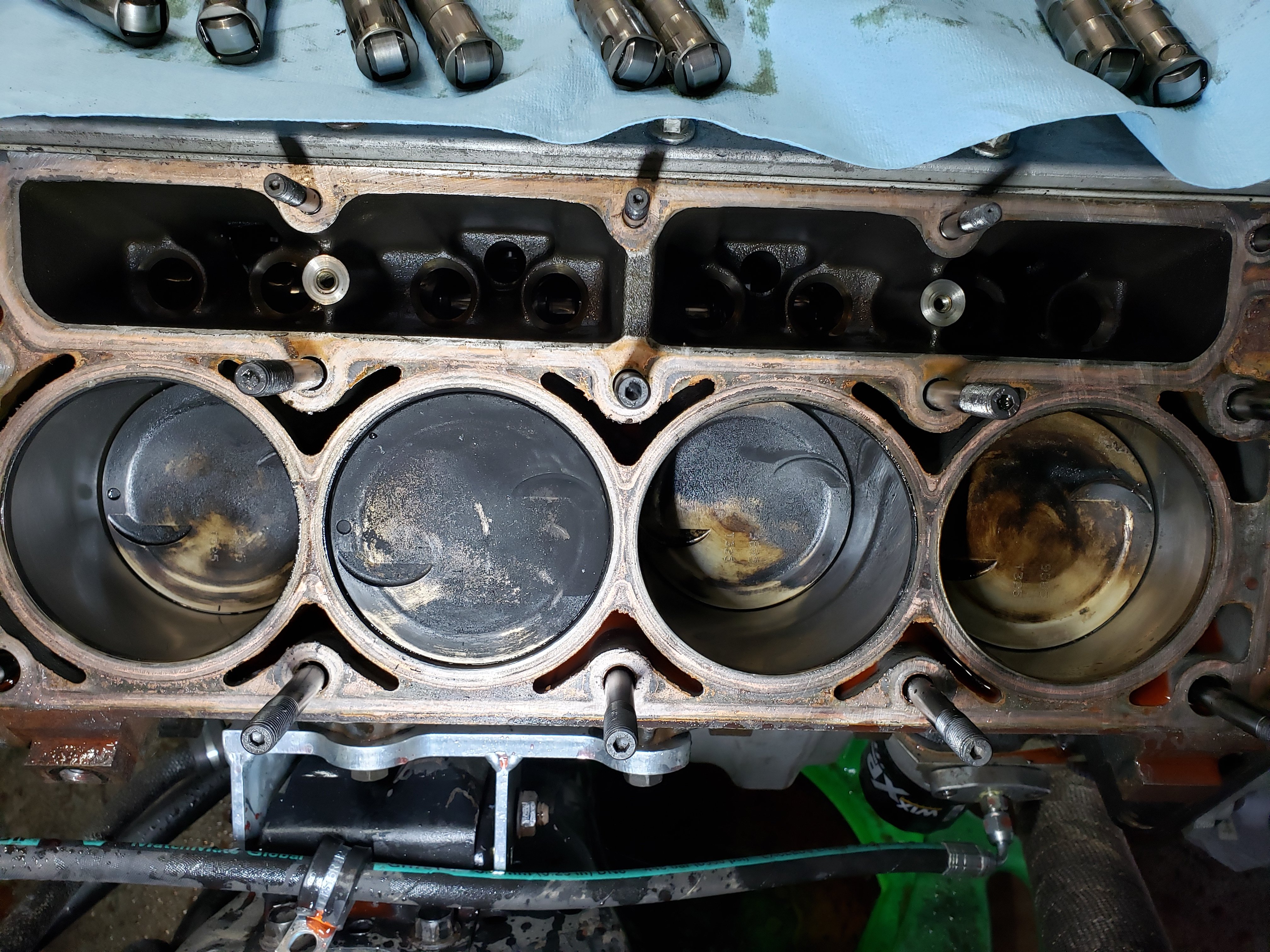

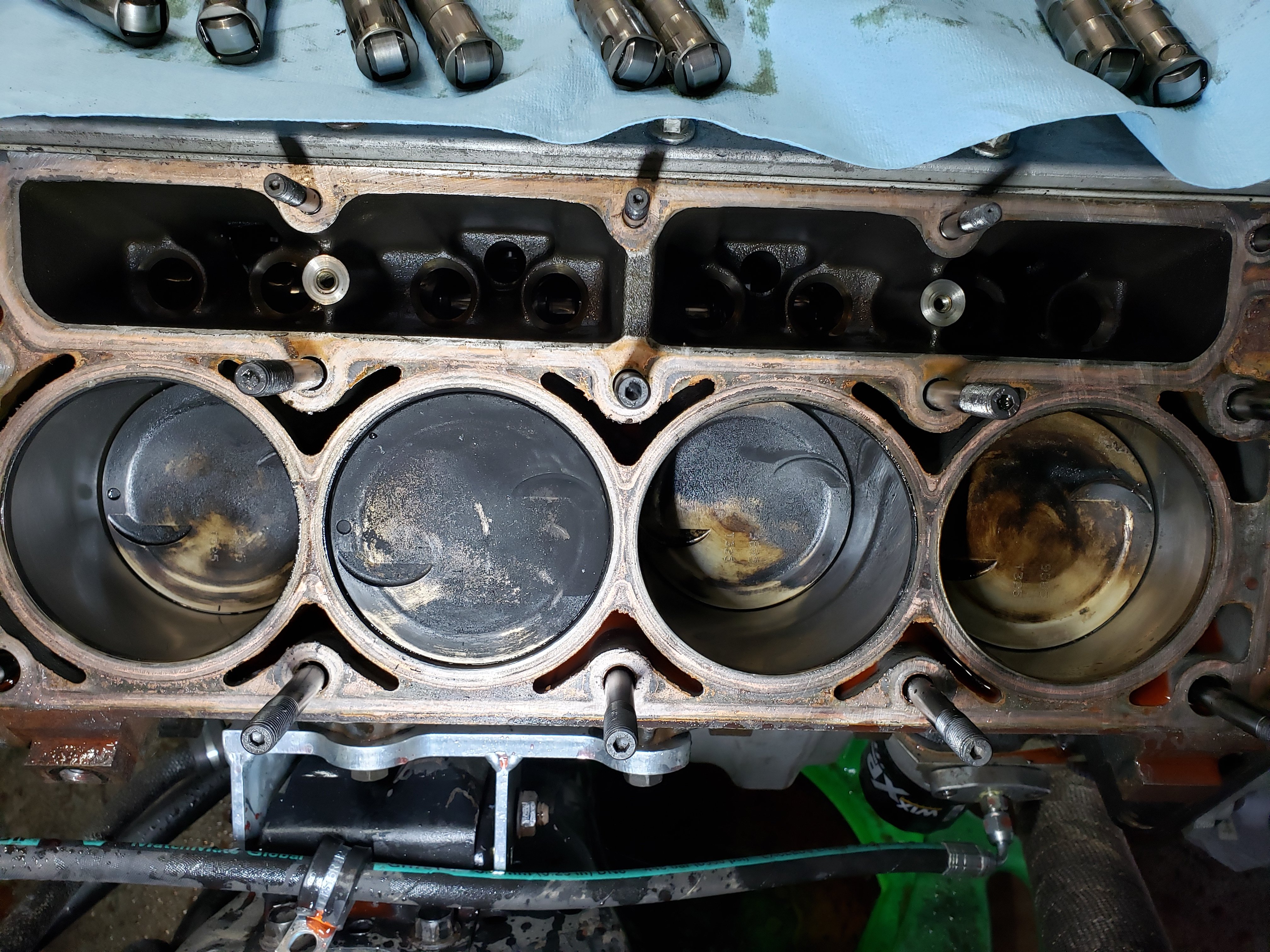

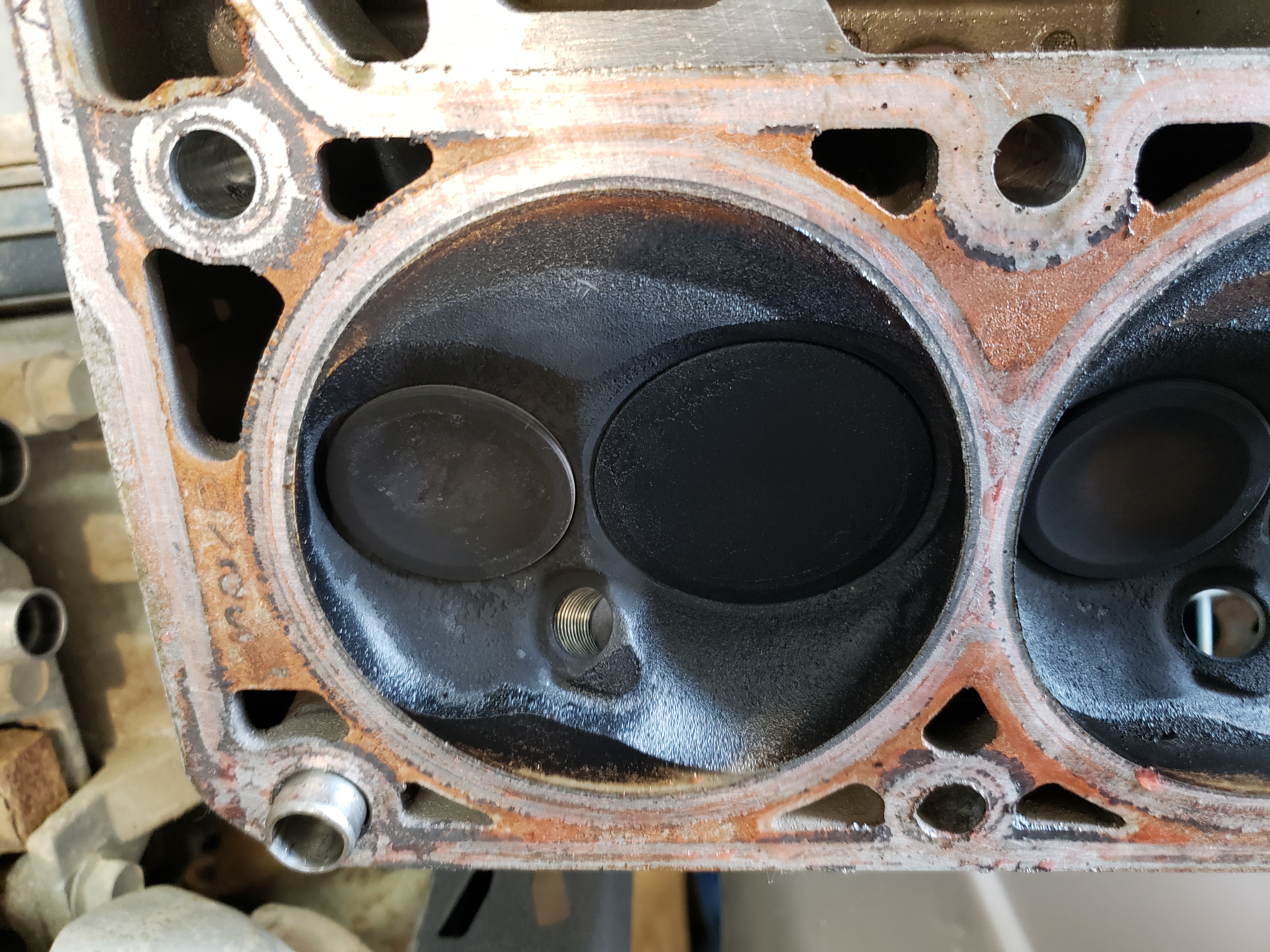

Pulled the head on d-side. And I didn't find anything. Very slight mark in the face of #1 from the piston stop, but superficial at best.

D-side lifters looked and felt like new. Some very mild scuffing on the circumference but pretty much as new. All rollers were in great shape and none were collapsed.

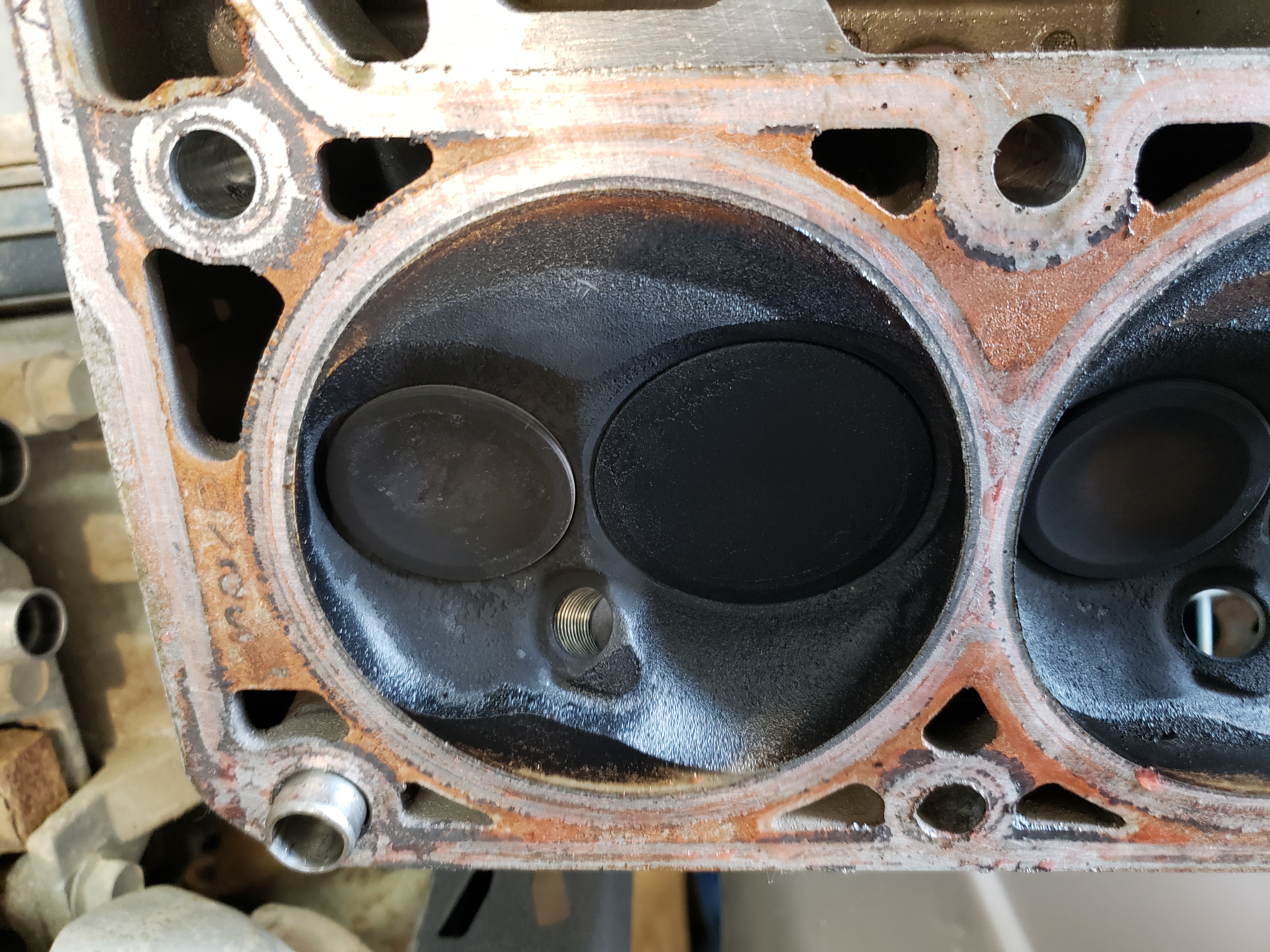

The head and #1 combustion chamber were perfect.

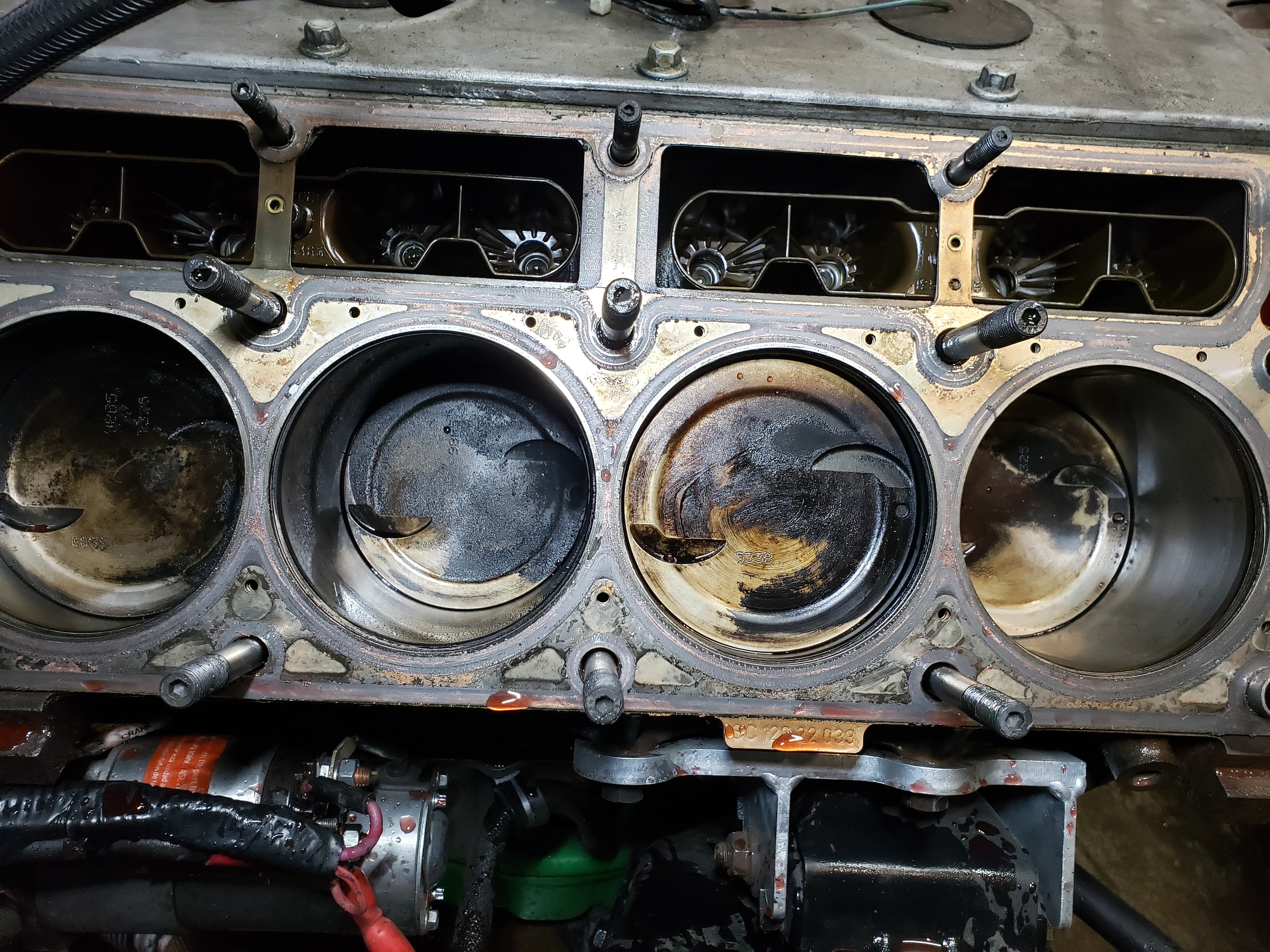

I was pretty concerned that I found nothing at this point so I pulled the p-side head. Again I found nothing.

And the head itself were flawless.

And the head itself were flawless.

I have yet to pull the lifters from the passenger side, tomorrow will hopefully find something as this is concerning.

Looking into the cam tunnel from the driver side i didn't see any marks on it so I have high hopes its fine.

I am wondering if I didn't crack a plug insulator causing a leak when it was running. As much as I don't want to find carnage, I think I'd feel better if I did.

Hauled the Regal to my unsuspecting parents garage, "for the winter"...

Cleaned out the garage and moved the cutlass in.

Pulled the head on d-side. And I didn't find anything. Very slight mark in the face of #1 from the piston stop, but superficial at best.

D-side lifters looked and felt like new. Some very mild scuffing on the circumference but pretty much as new. All rollers were in great shape and none were collapsed.

The head and #1 combustion chamber were perfect.

I was pretty concerned that I found nothing at this point so I pulled the p-side head. Again I found nothing.

I have yet to pull the lifters from the passenger side, tomorrow will hopefully find something as this is concerning.

Looking into the cam tunnel from the driver side i didn't see any marks on it so I have high hopes its fine.

I am wondering if I didn't crack a plug insulator causing a leak when it was running. As much as I don't want to find carnage, I think I'd feel better if I did.

I think your right, I didn't mention it.I don't know if you mentioned but how was your oil pressure while running?

Both mechanical and digital were 48-45psi cold.

I'm with Turbolq4 would say a lifter. Should have investigated and isolated the cylinder before teardown.

I shall know by noon today hopefully. I hope I find somethiing.

Very interested to see what occurred. I think it's below the head and above the rod. But what do I know, that could be as simple as a failed push rod, lifter or rocker as well. It would be nice to know if the timing was correct or not before you take it apart as well.

Good luck - Jim.

Tony - verifying timing on an LS is easily done erroneously with a piston stop if the valves aren't backed off on #1 cylinder when using a piston stop. Reason being that the valve, exhaust I believe, contacts the piston stop giving the feeling that the piston is hitting it rather than the valve, thus causing an erroneous TDC mark on the balancer. Sloppy Mechanics' Matt Happel repeatedly blew up motors in his Colorado due to this issue, until he figured it out. It can be found in his YouTube videos. It caused him t have the timing advanced somewhere in the area of 12-15 degrees IIRC.

Install stop and pointer, rotate clockwise, mark pulley, rotate counterclockwise, mark pulley, split difference between the marks to get TDC. Also, consider pinning the crank/pulley to ensure it doesn't move.

I think your right, I didn't mention it.

Both mechanical and digital were 48-45psi cold.

Cold at idle? That's not bad... neither high or low. My cars are much higher cold at idle.

I am still wondering why the bearings needed to be touched. The more we do the wider the margin for error grows.

I shimmed the pump, from watching your 4.8 build. I'm like 35 psi hot and 80psi @ 6k too, right about perfect.Cold at idle? That's not bad... neither high or low. My cars are much higher cold at idle.

I am still wondering why the bearings needed to be touched. The more we do the wider the margin for error grows.

What bearing are you referring to? Bottom end when i put the motor together?

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 192

- Replies

- 1

- Views

- 116

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.