What sump did you end up with? Im looking at going to a MF 750 and it says to have a -12 to the pump feed which means the sump would need a 3/4" outlet on the sump. Most i have seen are 1/2".

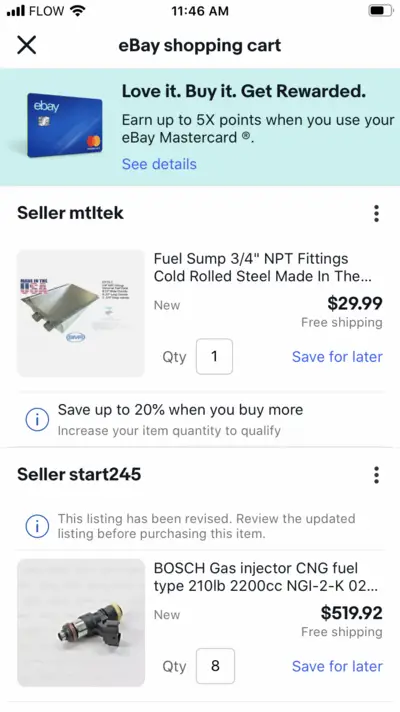

I found a sump on eBay with #12 fittings. The seller was out of Mass. and made them himself.

I have to say that I’m running the stock Fuel

Line for a vent. Seems to be working so far, but I’m running staged pumps.

Hopefully

Both of you guys are pulsing those 4303’s.