I have been in talks with my artistic director, We have a color picked out.

Ummm, I beg to differ. I most definitely was not consulted.

😅

I have been in talks with my artistic director, We have a color picked out.

uh oh....Ummm, I beg to differ. I most definitely was not consulted.

😅

I have gotten static for not cleaning them up and making them pretty....I notice the junkyard universal marking system on your IAC and TPS sensor. Those places must all buy marking pens from the same supplier lol.

Pretty neat though, can't wait to see the dual fuel setup in action.

Me too, trust me!Cant wait to see this thing rip again

Got the motor cleaned up and measured the bores and mains, installed the cam bearings and got the crank in and mains torqued

Cam bearing install. Made sure all oil holes are lined up and going to feed the cam.

View attachment 160797

Bores all measured good for 0.004" piston clearance, exactly what summit calls for. Beauty!

Mains were all 0.002" clearance, tight but within minimum spec.

Torqued are spinning very nicely by hand.

View attachment 160798

Got shut down for candy distribution duty, but the tedious part is behind me.

Yeah, try running .002" and push some RPM on a BBO. This is why almost all stock 455's pushed hard, ended up knocking. My clearances are .0022" rods, 2" journals and .0025" on 2.5" mains on my 330 stroker crank, will see how long it lives with 5500 RPM blasts. Our Olds V8's are 30 to 50+ years old, some made at a very sad time in automotive history. At Fleming decided to try a new failure for the Olds V8, valve destruction. The LS is a very sturdy platform but so is nearly every new design motor. As soon a the warranty is up and the car paid for, my 3.6 Pentastar is getting a Sprintex Supercharger. What are the main and rod sizes on a 6L LS? I would imagine their cranks are also light, forged and in a super stiff bottom end, all helps allow tight clearances. Yeah, G bodies and their wonderful no rust protection, you got off lucky. Put some paint protection on that sh*t. Looking good.Why do you run an LS?

Oh yeah, see my build thread

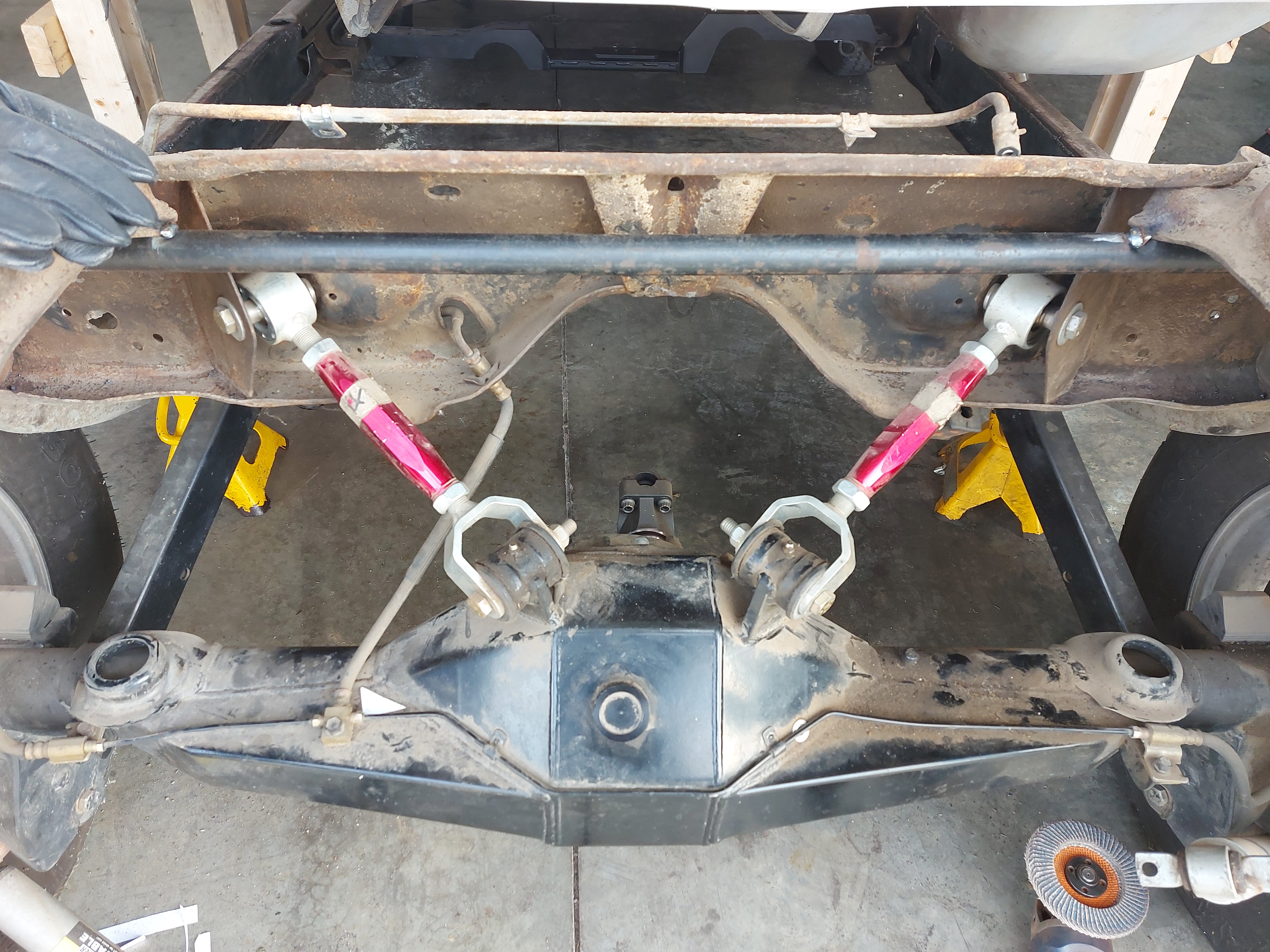

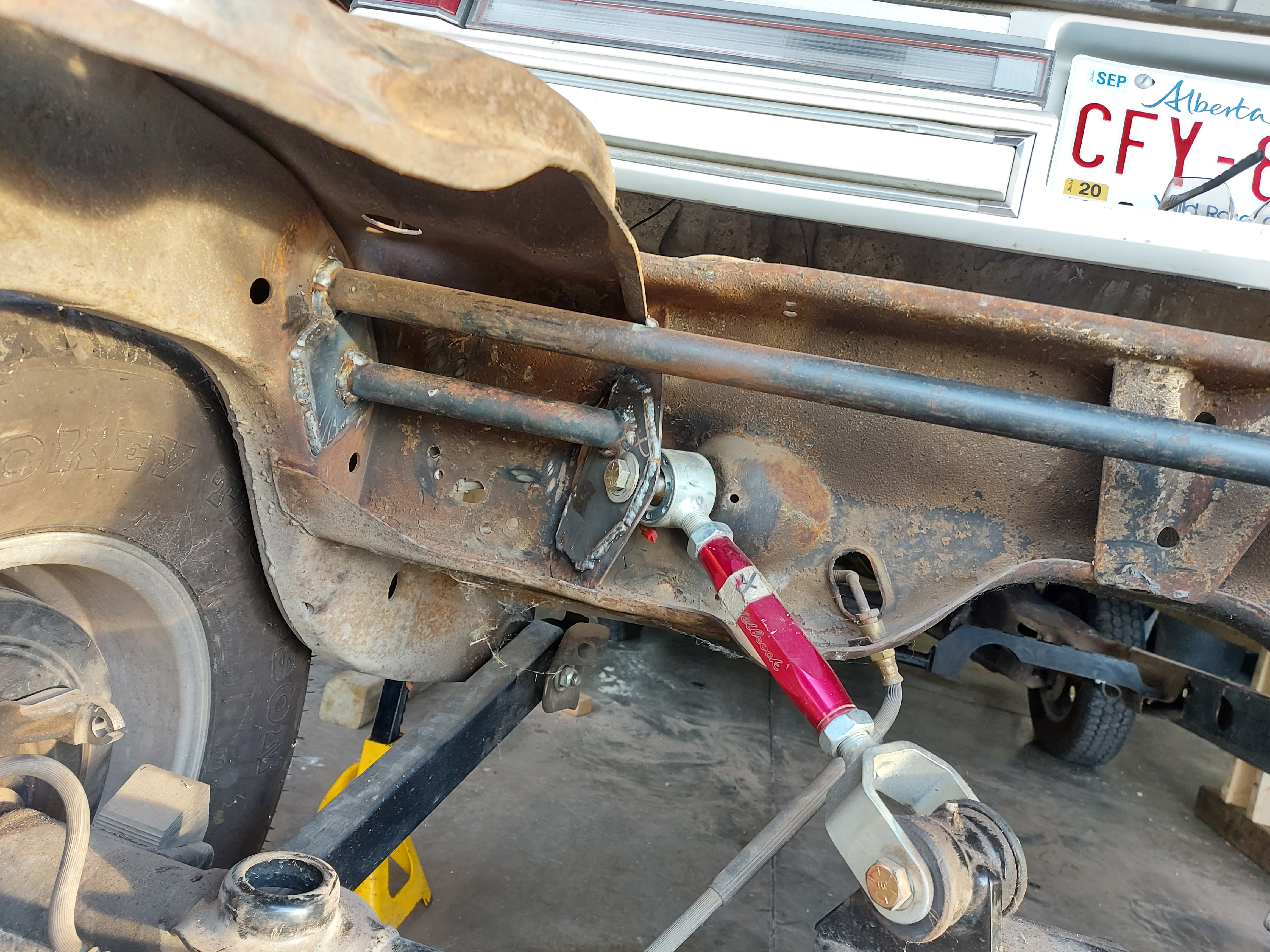

My assistant the Croatian sensation will be back tomorrow for another Fab day.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.