Day progress update. Had to wonder out to get some supplies, needed some metal primer for the cage, CAULK!! Big white tubes of it, and picked up some stealth materials. SO I think I have a plan to keep her kinda sleepy from the outside.

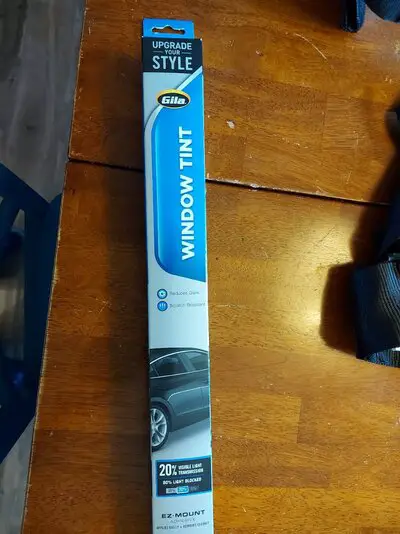

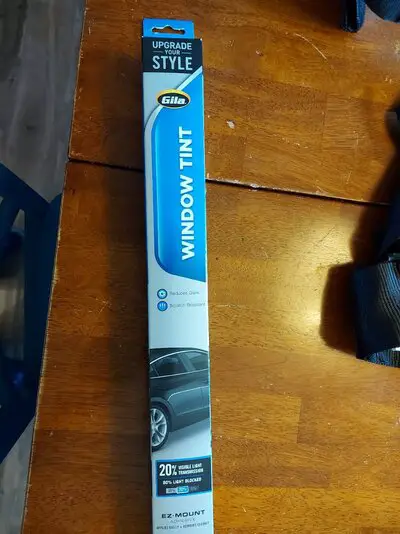

The cheapest 20% self adhesive window film I could find at the ol' Cambodian Tire. I promise to install in a semi-terrible manner so it looks unassuming. Gonna be sweet.

Then I got to some more metal work because I wanted a day off from crawling around the jungle gym.

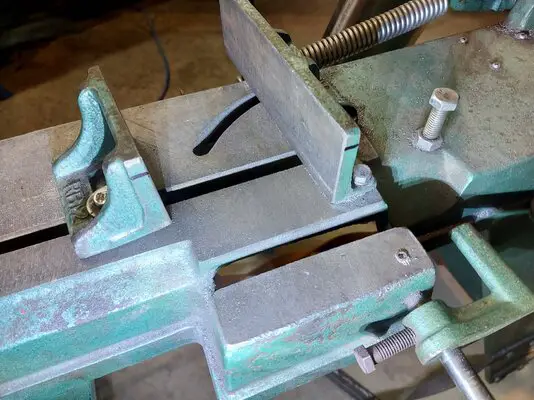

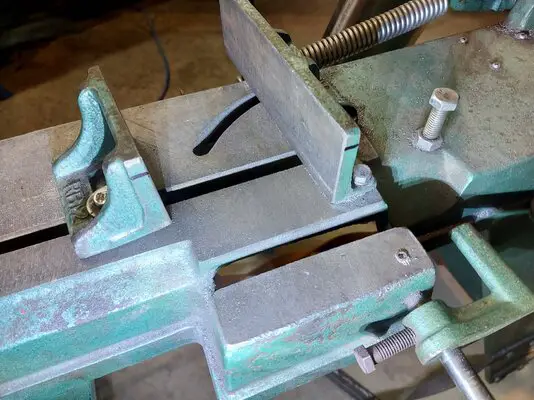

So you wanna make pie cuts for a super sick custom exhaust system? I'm your guy...

First measure the tube half and mark both sides end to end. In my case its super sweet Canukistanian made 4" 409 stainless 16 ga.

Then for a more smooth bend set the band saw to 4.5 degrees. You can do 9 degrees and use less pie cuts, but it looks more choppy. I love tig wleding so much I decided to use 9 degree wedges (4.5 on both sides) and have 10 per 90.

Then I marked the fences on both sides 2" off the table. Basicly once you make the cut, spin your pipe 180 degrees and line up your marks, then cut again.

So once this is set up, let her chew pipe while you do something else to entertain yourself. You will need many many pieces so just keep setting it and forgetting it.

While that was going I started working on the flange for the log manifold. First I cut off the T4 flange.

Then cut off the extra 1/2" I need to be able to close the hood on the car with the S488 beach ball turbo.

Currently in the midst of hogging out the 1/2" T6 flange I am fabricating. It is a slow go as the plasma cutter doesn't like to run hard on 110v. I have blown the fuse about 5 times now and can only really run 16amps consistently. Its almost there, so once I am close I will touch it up with a carbide cutter on the die grinder.

After a couple hours of cutting pie cuts, its starting to look pretty good too. Going to cut some shorter pies to be able to reduce the bend radius, if need be.