What was the urgency on buy the Tig now?

Fluxcore welding slag down my pants rolling around my *ss crack?

What was the urgency on buy the Tig now?

The flowmaster was still more money. I have a 10lbs of 309L rod that came with some stuff I bought years ago so it was free.I just bought a couple of discounted Flowmaster Cummins exhaust systems for my 4" pipes, lots of handy-dandy bends.

I was looking at this before you made me buy a TIG:

https://www.amazon.ca/dp/B07CPM9GV5/?tag=rippca-20

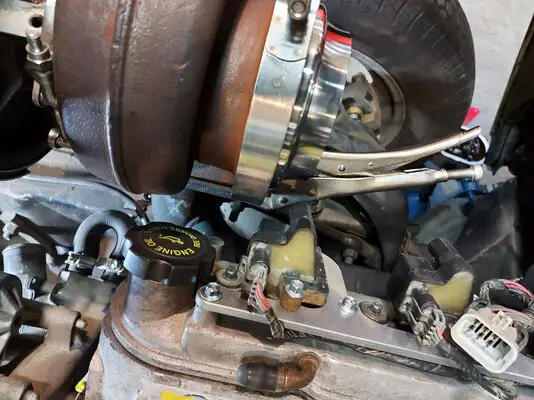

Now I am building the aluminum exhaust I really wanted... once I learn how to weld that material.

He thinks you stop being burnt when you tig weld... lol, it just finds new ways to hurt you.What was the urgency on buy the Tig now?

The flowmaster was still more money. I have a 10lbs of 309L rod that came with some stuff I bought years ago so it was free.

Just wait until you watch more of this guys videos....

But seriously, price out mandrel bent 409 from Lyells, they are DECENT for price.

He thinks you stop being burnt when you tig weld... lol, it just finds new ways to hurt you.

My preferred technique is setting the hot soldering gun right on my leg. Did that while wiring my brother's car. I had a silhouette scar for years.You haven't lived until you've smelled a part of yourself cooking.

This is my old favorite, and why I have embraced crimp connections.My preferred technique is setting the hot soldering gun right on my leg. Did that while wiring my brother's car. I had a silhouette scad for years.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.