The fill spout isn't an issue in that location, or at least not the one I am worried about, there is room for a blanket and that will insulate the filler just fine. PCV? Lol, thats plugged, no issue. The coil however is my concern, and I can tilt the flange a couple of degrees, add some space and mount a heat shield and some insulation. I think this will work. I already have insulators for the plug wires, that should help.'It's not a full day until I'm bleeding' used to be my motto lol.

Nice burnt finger shot though!!! 🙂 I have two fingeers that are numb on the outside (reattached about 3 decades ago), I smell them burning before I feel it, and if the burn is bad enough it takes about a minute for me to start feeling burning sensation closer to the bone (and that really sucks). I've developed an acute sense for the smell of burning flesh lol.

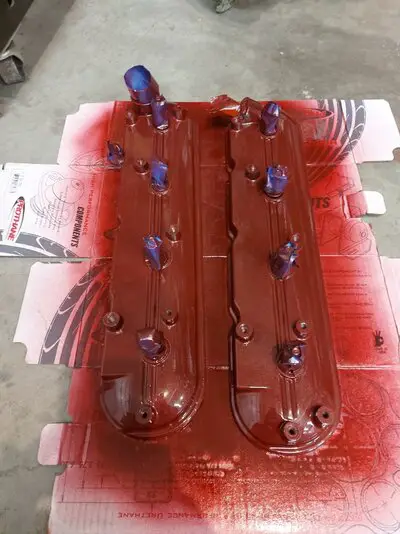

I feel your pain with the coil pack clearance issue. I made that mistake once, and my solution is the pedastal mount on the frame rail - no more hanging T6 turbos on the manifold bolts for me. You can swap the valve covers side to side and deal with PCV/vent hole, but you'll need an extenion on the filler to clear the brake booster, hydroboost or whatever you have to get oil in it. If you roll with that setup, then you've just made putting oil in the motor mission impossible with the added benefit of melting plug wires/boots.

I'm being somewhat of a wise *ss, but I'm allowed - it's my name 😉. Seriously though, I'd strongly encourage you to revamp that flange to provide for an extra inch of clearance to the fill/pcv and coil.

I've seen bigger turbos hung on log manifolds, I think itll be alright. Especially since I have ARP bolts. 😉