I don't think I've ever been disappointed by a Lisle tool. I sure am glad I put headers on my 5.3 in my truck early on with stainless ARP bolts.Good movie I haven't seen in forever, feel like that is my life now though

And for future reference/other guys as well this was really helpful, no idea why its making it load sideways as the original it would be easy to read

View attachment 171792

Olds ticket to 9s... LS swap adventure.

- Thread starter Northernregal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Been slugging away in the trenches, so to speak.

I have been working on this part of the process, kinda on the side, planning for the next step and making wiring diagrams. There is a fair amount of stuff that is going in this time. Ugrading to a dominator opens a LOT of doors for tuning options.

Since the weather has warmed up I took advantage and flushed out the fuel tank. I flushed it around several times, filled and drained, rotated, flushed and filled for the night on a stand. No leaks on the welds, so I drained it today and rinsed it a couple more times for good measure.

I welded in a couple more bungs on the aluminum piping, for pre-intercooler data collection. Starting to get the hang of welding aluminum, These welds don't look terrible. Sloppy but not terrible.

I also welded out the pie cuts. This turned out pretty nice. I need to learn some patience, let things cool a bit and I think I could instagram some welds.

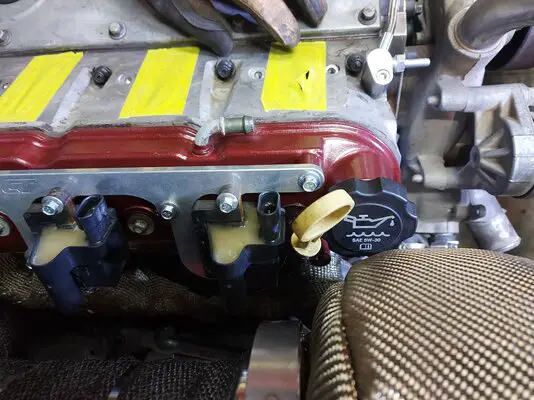

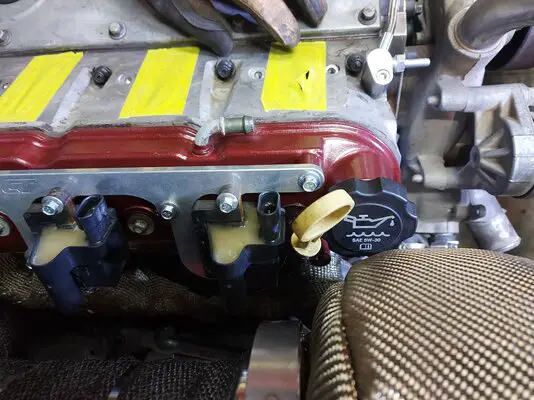

Got this also. El- Cheapo Amazon china war whistle blankey. Mocked up for potential oil fill insulation potential. I think its going to work. Its actually very nice, we shall see how it holds up to real heat and torture.

I also cleaned up the garage. which really needed it. It is time to get some stuff re-assembled so I can wire and put the dash back together. The dash is proving to cause me some stress.

I have been working on this part of the process, kinda on the side, planning for the next step and making wiring diagrams. There is a fair amount of stuff that is going in this time. Ugrading to a dominator opens a LOT of doors for tuning options.

Since the weather has warmed up I took advantage and flushed out the fuel tank. I flushed it around several times, filled and drained, rotated, flushed and filled for the night on a stand. No leaks on the welds, so I drained it today and rinsed it a couple more times for good measure.

I welded in a couple more bungs on the aluminum piping, for pre-intercooler data collection. Starting to get the hang of welding aluminum, These welds don't look terrible. Sloppy but not terrible.

I also welded out the pie cuts. This turned out pretty nice. I need to learn some patience, let things cool a bit and I think I could instagram some welds.

Got this also. El- Cheapo Amazon china war whistle blankey. Mocked up for potential oil fill insulation potential. I think its going to work. Its actually very nice, we shall see how it holds up to real heat and torture.

I also cleaned up the garage. which really needed it. It is time to get some stuff re-assembled so I can wire and put the dash back together. The dash is proving to cause me some stress.

It is 4 solid states in one. All 20 amp continuous, or 50 amp surge. Plus you can run channels together for extra load. So 80amp single, 40 amp dual, etc...Keep us updated on how you like the MSD relay brick. It's pretty darn cool. Is it solid state?

I will keep you updated but its pretty well recommended already.

Update... Exhaust time!!!

So first order of business was to install the O2 sensor bung.

I mocked up the downpipe and measured the distance to the turbine and this spot was 9". So I drilled a pilot and let the step bit eat.

Because I bough soe generic Vibrant bungs I used the flap disc to contour the bung to the exhaust tube, as this is easier to weld.

I got my instagram welder settings ready and sent this one right to the hall of fame.

And just like a regular instagram "influencer". What was off camera was a dumpster fire. lol. Whatever, its stuck together.

Then the pie cut mockup for the bottom began.

I wanted a little bit tighter fit to the underside to hopefully hide the leaf blower. So I trimmed the down pipe until it was just right. It is damn near level with the stock 4L80e pan. Which is about level with the front cross member.

I tacked it together and mocked up the pipe again to fit the cut out.

I think this is going to work very nicely...

Its pretty straightforward from here. WELD WELD WELD!!!

I am actually starting to get a lot better with the tig. I have learned to let the piece cool frequently and be more patient. It has helped my final product immensely. But I am very happy with this downpipe, almost too bad its going to be covered in heat wrap...

So first order of business was to install the O2 sensor bung.

I mocked up the downpipe and measured the distance to the turbine and this spot was 9". So I drilled a pilot and let the step bit eat.

Because I bough soe generic Vibrant bungs I used the flap disc to contour the bung to the exhaust tube, as this is easier to weld.

I got my instagram welder settings ready and sent this one right to the hall of fame.

And just like a regular instagram "influencer". What was off camera was a dumpster fire. lol. Whatever, its stuck together.

Then the pie cut mockup for the bottom began.

I wanted a little bit tighter fit to the underside to hopefully hide the leaf blower. So I trimmed the down pipe until it was just right. It is damn near level with the stock 4L80e pan. Which is about level with the front cross member.

I tacked it together and mocked up the pipe again to fit the cut out.

I think this is going to work very nicely...

Its pretty straightforward from here. WELD WELD WELD!!!

I am actually starting to get a lot better with the tig. I have learned to let the piece cool frequently and be more patient. It has helped my final product immensely. But I am very happy with this downpipe, almost too bad its going to be covered in heat wrap...

Never having used a cutout, is yours setup how all of them are? Meaning the cutout is off to an angle from exhaust flow? I had assumed that the cutout should be on the other discharge. (Asking for a friend)

Basically it's a Y. It "should" be the straight flow exit to be ideal but I feel confident that this will work.Never having used a cutout, is yours setup how all of them are? Meaning the cutout is off to an angle from exhaust flow? I had assumed that the cutout should be on the other discharge. (Asking for a friend)

Knocked off a few items today. I wanted to get the fuel tank out of the way so I started by cleaning the bottom with wax and grease remover and giving it a good scuff with 180 grit to prep for some POR-15. Once it was wiped down for a third time and rags were coming out clean it got a brushed coat of POR-15. It will be getting a coating of undercoat rolled on after this dries, I kinda like this method because it leaves a bit of a textured finish and its matted down nicely. I won't POR15 the top, its getting rubber between it and the body with undercoating and will be fine I think. I really just wanted to protect the welded area as it is well know for rusting once sumped.

Mounted the pump on the hanger so it is ready for install. SO MUCH EASIER WITH JUST ONE!

Now that the downpipe is done I wrapped it in the itching wrap. Then mounted to look at clearances with the turbo blanket on. I think I am going to put a hanger on the dump because this is going to make plug changes a PAIN...

To continue cold side mockup and getting everything in place to start measuring everything for wiring.

I tried to put on the hot side crossover and there is some interference with the down pipe, So I think I am going to redo it in stainless. There are some things I am not happy with on the hot crossover, it hangs WAY too low, its too close to my brake lines for my happiness and I want to put the flex cover in. Might as well do it now...

Mounted the pump on the hanger so it is ready for install. SO MUCH EASIER WITH JUST ONE!

Now that the downpipe is done I wrapped it in the itching wrap. Then mounted to look at clearances with the turbo blanket on. I think I am going to put a hanger on the dump because this is going to make plug changes a PAIN...

To continue cold side mockup and getting everything in place to start measuring everything for wiring.

I tried to put on the hot side crossover and there is some interference with the down pipe, So I think I am going to redo it in stainless. There are some things I am not happy with on the hot crossover, it hangs WAY too low, its too close to my brake lines for my happiness and I want to put the flex cover in. Might as well do it now...

Inner fender?!?!Is the discharge of the turbo clocked where it will stay? It looks like it would interfere with inner fender etc. Because turbo BIG. 😆

No, it's not clocked, but probably very close.

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 80

- Replies

- 5

- Views

- 342

- Replies

- 13

- Views

- 425

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.