Alrighty.

So, as I alluded to in the previous post, I believe I finally have a plan of attack. Or rather 2 plans of attack.

After grinding off the clip mounting studs on the car tonight, I was able to get better access and be able to more thoroughly clean up the vertical part of the front channel.

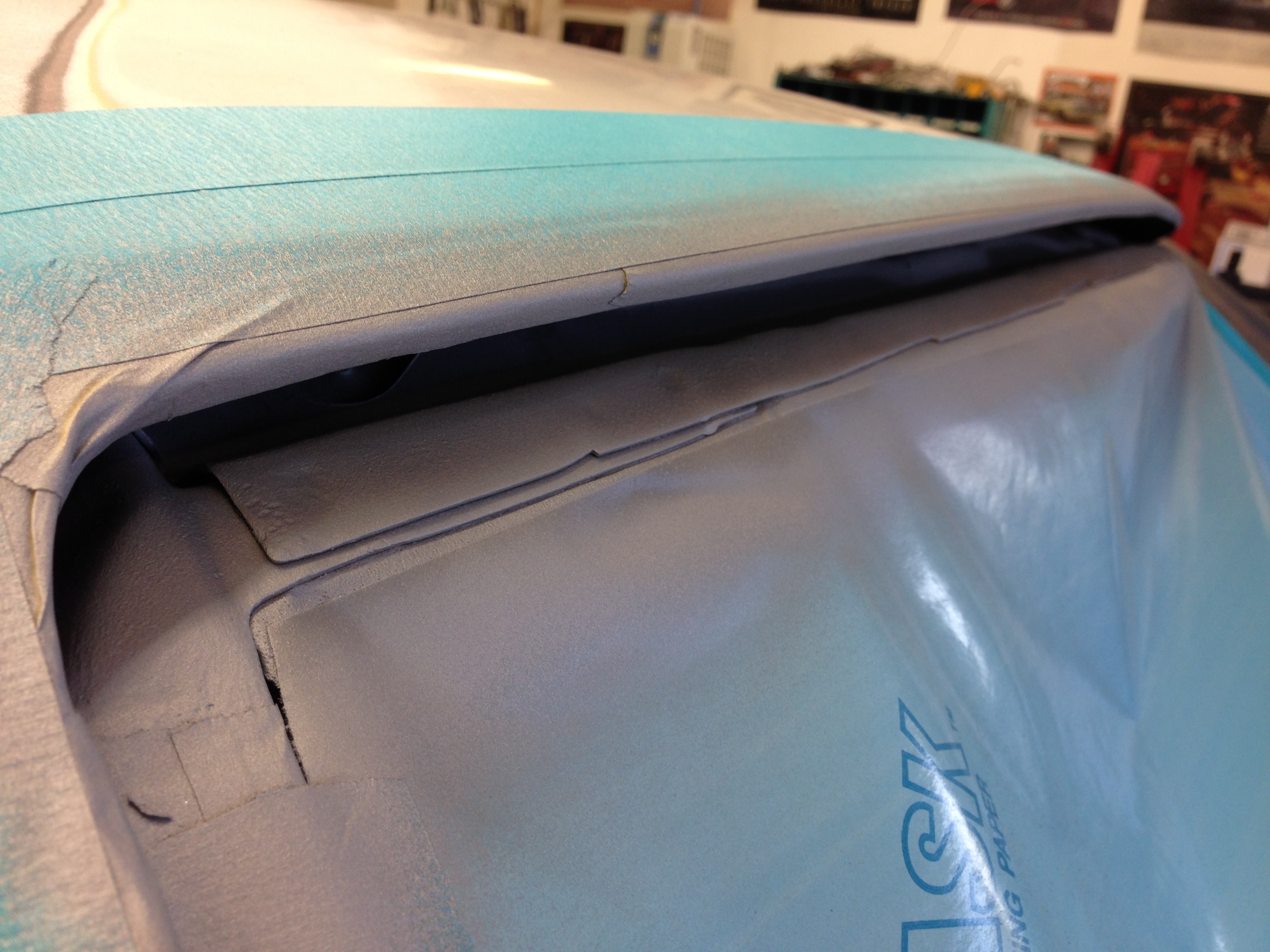

I've got a solid 1/4" of good un-rusted metal from the roof skin body line down into the channel. I will use this small section to overlap the new piece. This will retain the shape and strength of the roof skin without too much worry of warping once I start welding. Yep, I think I'm gonna weld here. It just seems a smarter idea given the structural stresses this area of the car sees.

I don't necessarily even have to fully weld it the entire length, because it'll be overlapped, I can do several small plug welds and achieve the same strength and result. When it's permanent, but before paint, I will carefully seam seal up the edge.

Another advantage to doing it this way is that because the new piece will be underlapped, there will never be the possibility of water working its way down into the seam.

We will call this "Plan A", and it's the most desirable way to do it in my opinion. It keeps the repair confined to within the channel, and won't require making the repair any larger or complicated than it needs to be.

IF Plan "A" doesn't work out, I'll fall back to "Plan B".

"Plan B" entails flanging either the existing roof skin or the new patch, and panel bonding that joint along with the standard plug welds on the horizontal surface. I'd prefer not to go this route due to the fact that I'd then be getting back into the roof skin. I'd like to try and avoid that if at all possible.

The beauty of having these two plans is that if the first one doesn't work out for whatever reason, I'm not hooped and can still use the second plan.

🙂

Ok, so now that you're all aware of "The Master Plan(s)", here's tonight's progress and pics.

After grinding off the clip studs and cleaning up the top 1/4", I laid out a strip of 1/4" masking tape in the channel flush with the roof edge.

This will be my cutting guide.

Once that was done, I had to remove the lead from the corners. This was done using the same melting it out method as I used on the new patch.

I had to do a little further tear down before I could proceed with this, the weatherstrip, mouldings for them, and the chrome "A" pillar pieces had to be removed first.

I've only done the driver's side so far, but the lead removal process will be repeated again once I get over to the passenger's side.

I don't know if it's like this on other G bodies, but it's actually quite shocking to see just how little actual metal there is in this location once all the lead's gone!

😱

After a little cleanup of the burnt paint, it looks much better:

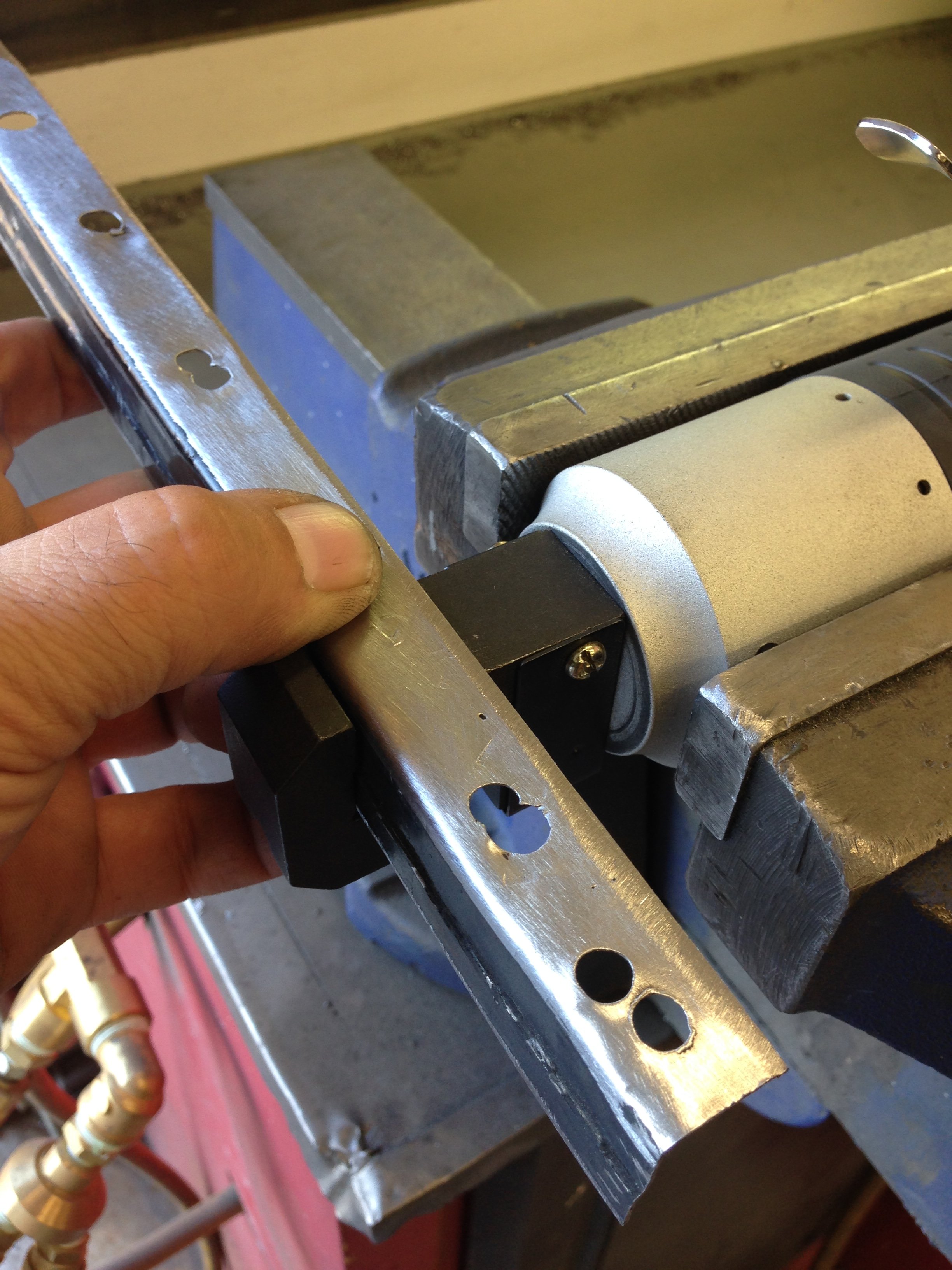

With the lead gone, I used the body saw (to eliminate any chance of putting additional heat into this area) to cut along the bottom of my tape line:

I ground down and ground out the metal and the braze where it overlaps in the corner:

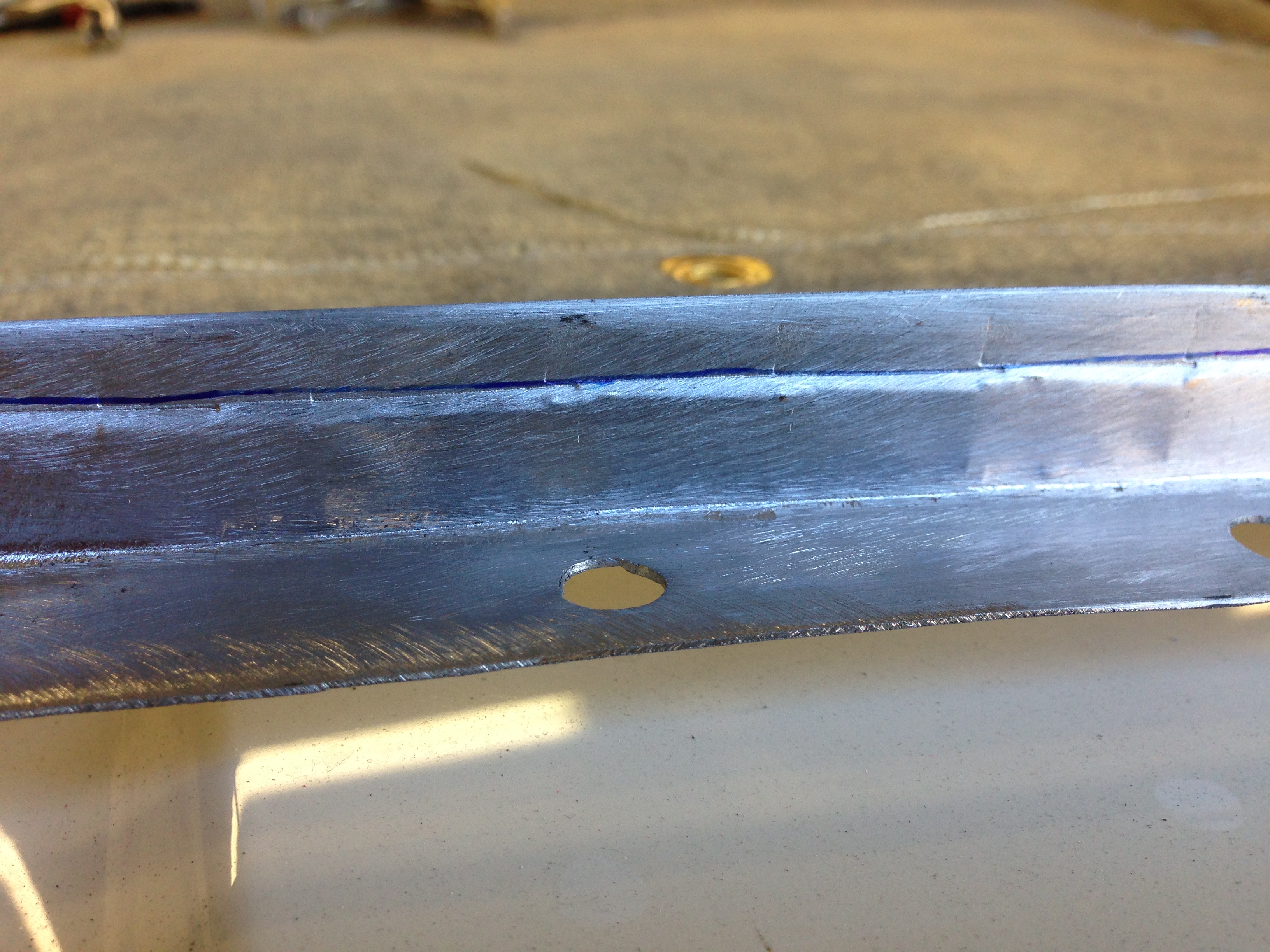

After that, I made a second cut in the vertical section near flush to the pinch weld flange. This lets me remove the thin strip of metal in there and make it easier to get the spot welded portion out.

Here's the area as I'm going along, grinding out the spot welds and stripping the rusty crap out:

And that's where I'm at for tonight. I'll continue removing the last remnants of rusty flange in this manner until I'm done tomorrow night.

There may not have been much actual progress tonight, but I sure feel a whole lot better and more confident now that I have a direction and plan. I have a good feeling about this, I think it'll work out great.

Thanks very much everyone for the encouragement, confidence, suggestions, and ideas. You guys truly are the best.

Donovan

So, as I alluded to in the previous post, I believe I finally have a plan of attack. Or rather 2 plans of attack.

After grinding off the clip mounting studs on the car tonight, I was able to get better access and be able to more thoroughly clean up the vertical part of the front channel.

I've got a solid 1/4" of good un-rusted metal from the roof skin body line down into the channel. I will use this small section to overlap the new piece. This will retain the shape and strength of the roof skin without too much worry of warping once I start welding. Yep, I think I'm gonna weld here. It just seems a smarter idea given the structural stresses this area of the car sees.

I don't necessarily even have to fully weld it the entire length, because it'll be overlapped, I can do several small plug welds and achieve the same strength and result. When it's permanent, but before paint, I will carefully seam seal up the edge.

Another advantage to doing it this way is that because the new piece will be underlapped, there will never be the possibility of water working its way down into the seam.

We will call this "Plan A", and it's the most desirable way to do it in my opinion. It keeps the repair confined to within the channel, and won't require making the repair any larger or complicated than it needs to be.

IF Plan "A" doesn't work out, I'll fall back to "Plan B".

"Plan B" entails flanging either the existing roof skin or the new patch, and panel bonding that joint along with the standard plug welds on the horizontal surface. I'd prefer not to go this route due to the fact that I'd then be getting back into the roof skin. I'd like to try and avoid that if at all possible.

The beauty of having these two plans is that if the first one doesn't work out for whatever reason, I'm not hooped and can still use the second plan.

🙂

Ok, so now that you're all aware of "The Master Plan(s)", here's tonight's progress and pics.

After grinding off the clip studs and cleaning up the top 1/4", I laid out a strip of 1/4" masking tape in the channel flush with the roof edge.

This will be my cutting guide.

Once that was done, I had to remove the lead from the corners. This was done using the same melting it out method as I used on the new patch.

I had to do a little further tear down before I could proceed with this, the weatherstrip, mouldings for them, and the chrome "A" pillar pieces had to be removed first.

I've only done the driver's side so far, but the lead removal process will be repeated again once I get over to the passenger's side.

I don't know if it's like this on other G bodies, but it's actually quite shocking to see just how little actual metal there is in this location once all the lead's gone!

😱

After a little cleanup of the burnt paint, it looks much better:

With the lead gone, I used the body saw (to eliminate any chance of putting additional heat into this area) to cut along the bottom of my tape line:

I ground down and ground out the metal and the braze where it overlaps in the corner:

After that, I made a second cut in the vertical section near flush to the pinch weld flange. This lets me remove the thin strip of metal in there and make it easier to get the spot welded portion out.

Here's the area as I'm going along, grinding out the spot welds and stripping the rusty crap out:

And that's where I'm at for tonight. I'll continue removing the last remnants of rusty flange in this manner until I'm done tomorrow night.

There may not have been much actual progress tonight, but I sure feel a whole lot better and more confident now that I have a direction and plan. I have a good feeling about this, I think it'll work out great.

Thanks very much everyone for the encouragement, confidence, suggestions, and ideas. You guys truly are the best.

Donovan