Happy New Year from The Skunkworks everyone! Gonna start off the New Year with another little update.

Before I get too far ahead, some of the credit for this goes out to HAFROD for posting something similar a couple years back and putting the idea in my head.

Something that’s been bothering me about the car since I bought it has been the hard plastic seat backs on the bucket seats. As is typical for many of these cars and parts all these years later, they were getting to be pretty badly sun damaged and faded, and the plastic itself was starting to break down.

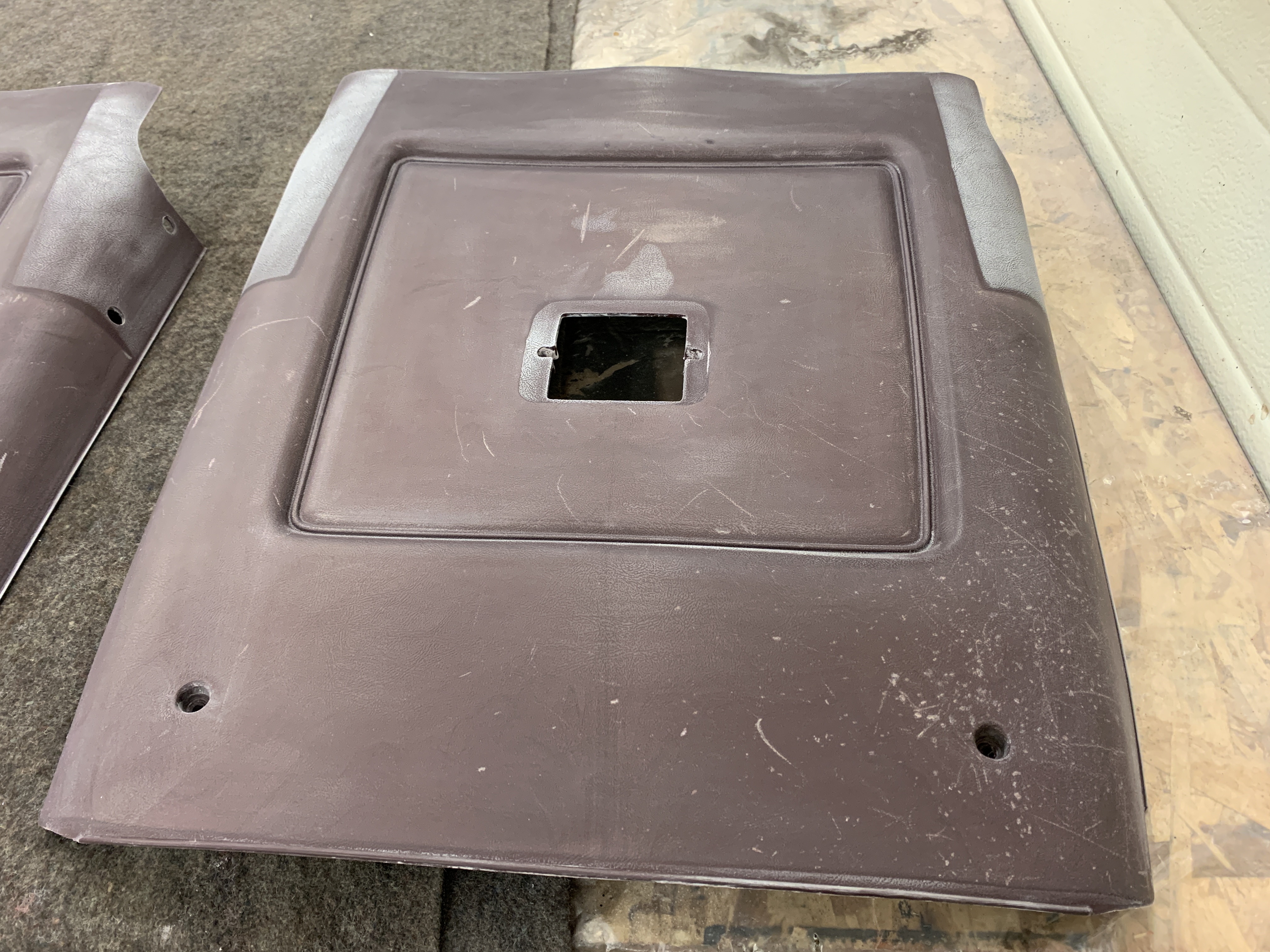

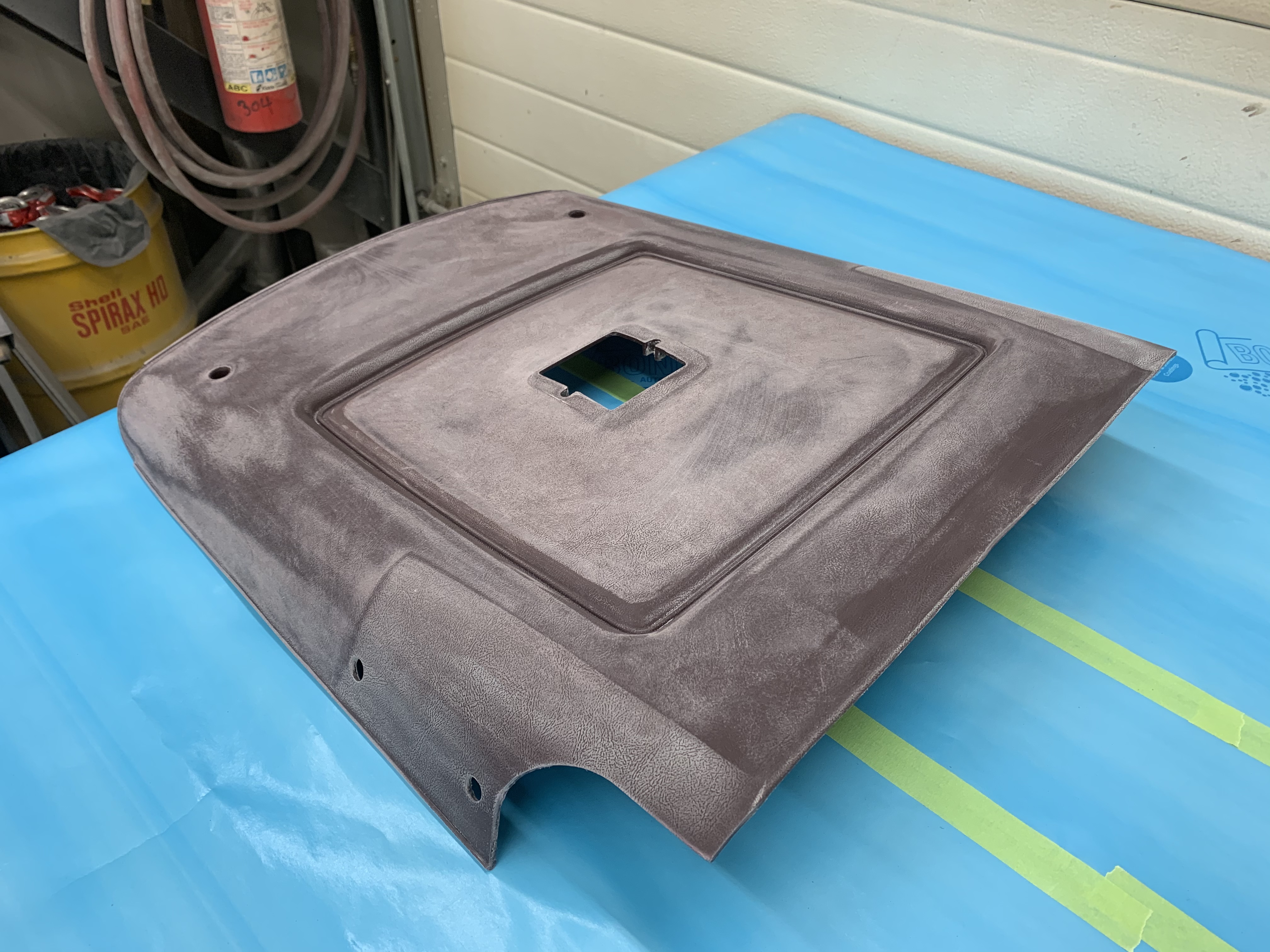

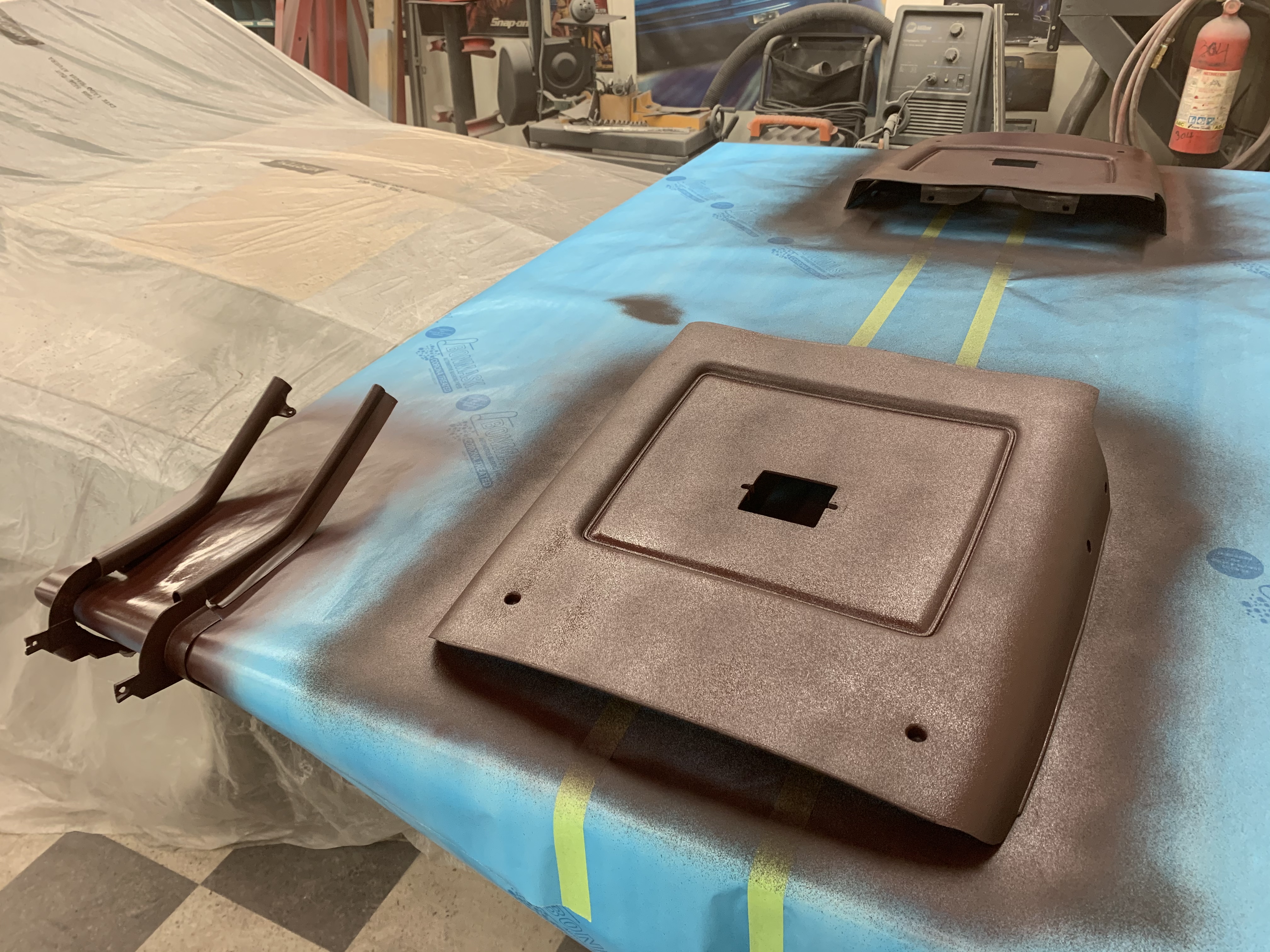

So to begin this little project, I removed the seat backs from the seats in the car, and laid them out on the temporary work bench.

I removed the (now opaque) chrome trim from around the perimeter, and the chrome hinge covers from the sides and give them a real good cleaning with Fantastik and some wax and grease remover. Now you can start to see how rough they were getting:

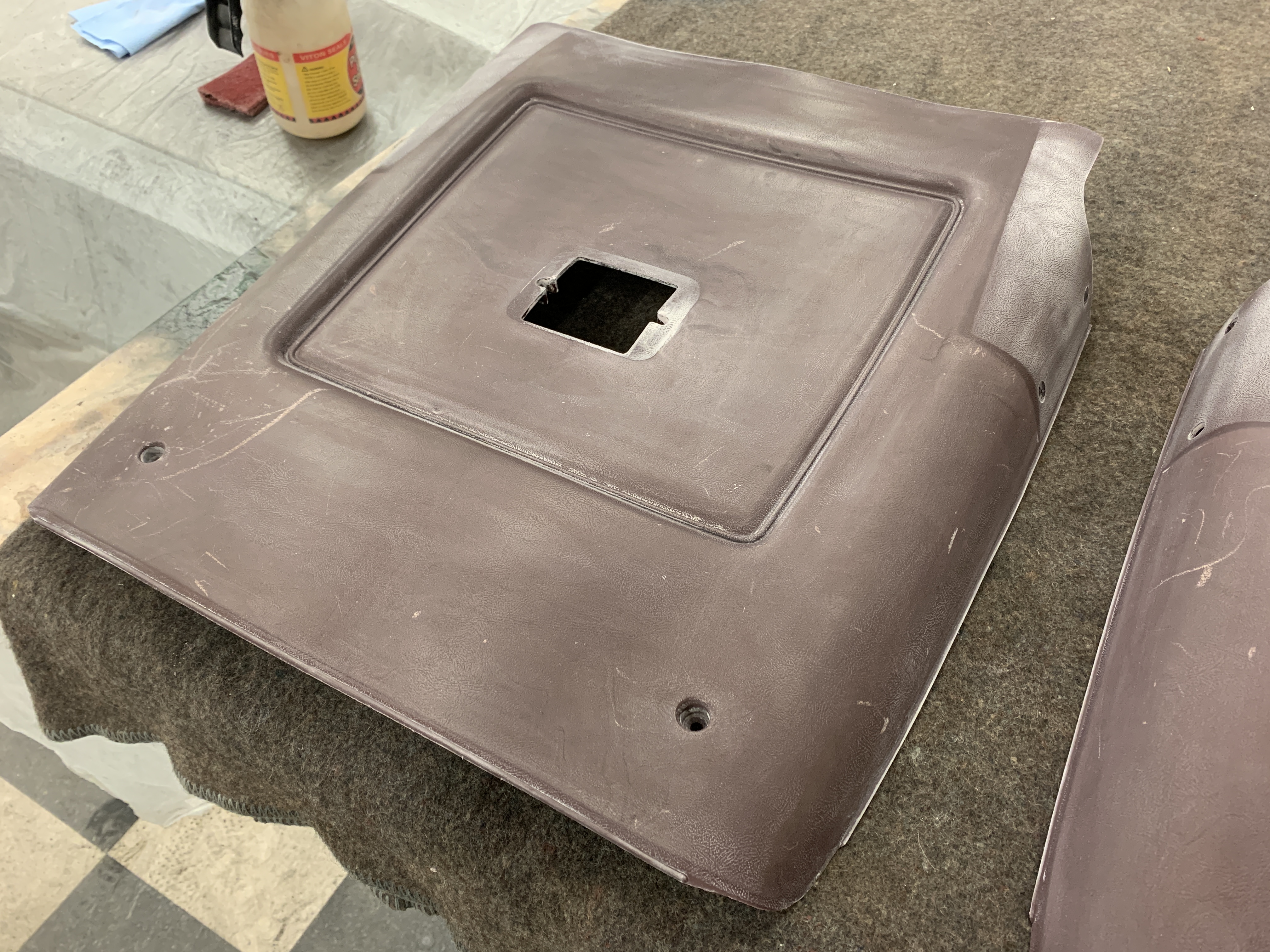

They don’t look too bad in the above pictures other than being pretty faded, but on closer inspection you can see how chalky and degraded they were getting, and how deep some of the scratches were:

Pretty typical really, especially for these darker colors due to their susceptibility to UV damage.

Although I had a plan to restore the textured grain pattern to the plastic, I knew it wouldn’t cover up or hide some of the more heavily damaged areas. Some sanding would be necessary to feather out these spots. I tried some 320 grit on the DA sander to begin with, but this proved to be too fine a grit and just clogged up the paper very quickly. 220 actually proved to be the Goldilocks choice for most of it, with 120 even being necessary for the worst areas.

Looking pretty gnarly here, but they always gotta get worse before they get better:

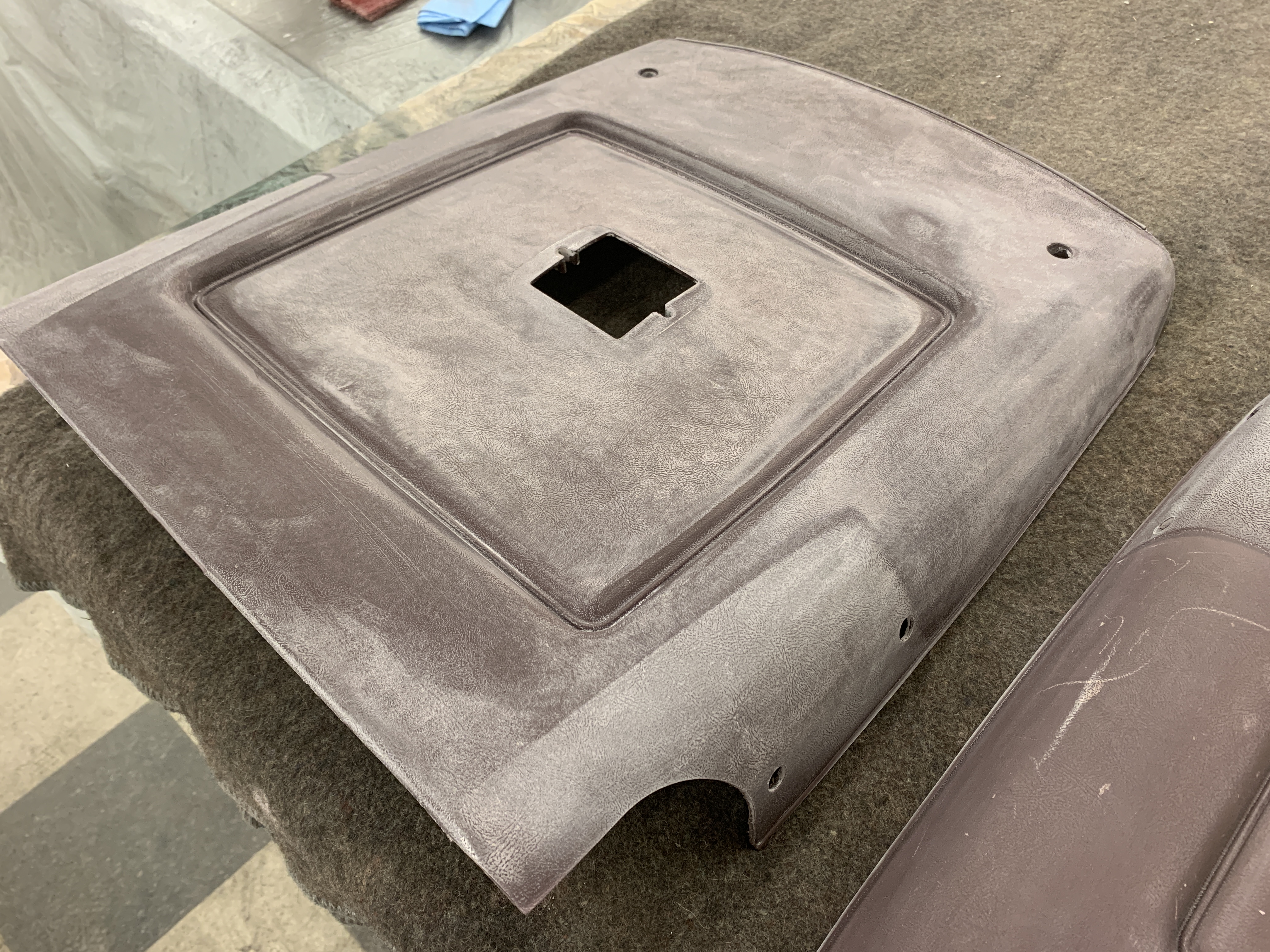

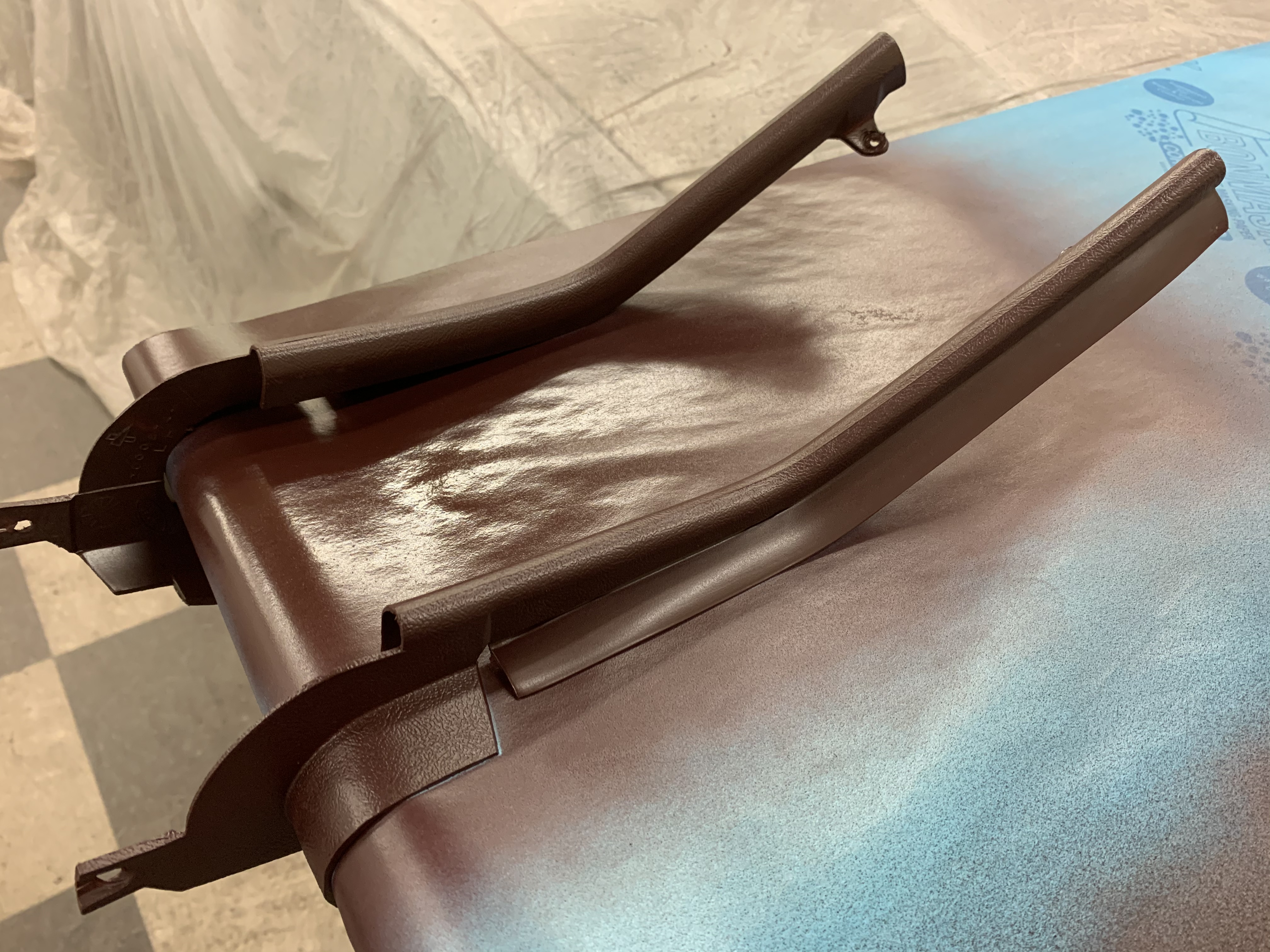

More rounds of sanding and cleaning to check the progress, until the entire surfaces looked smooth and blemish free:

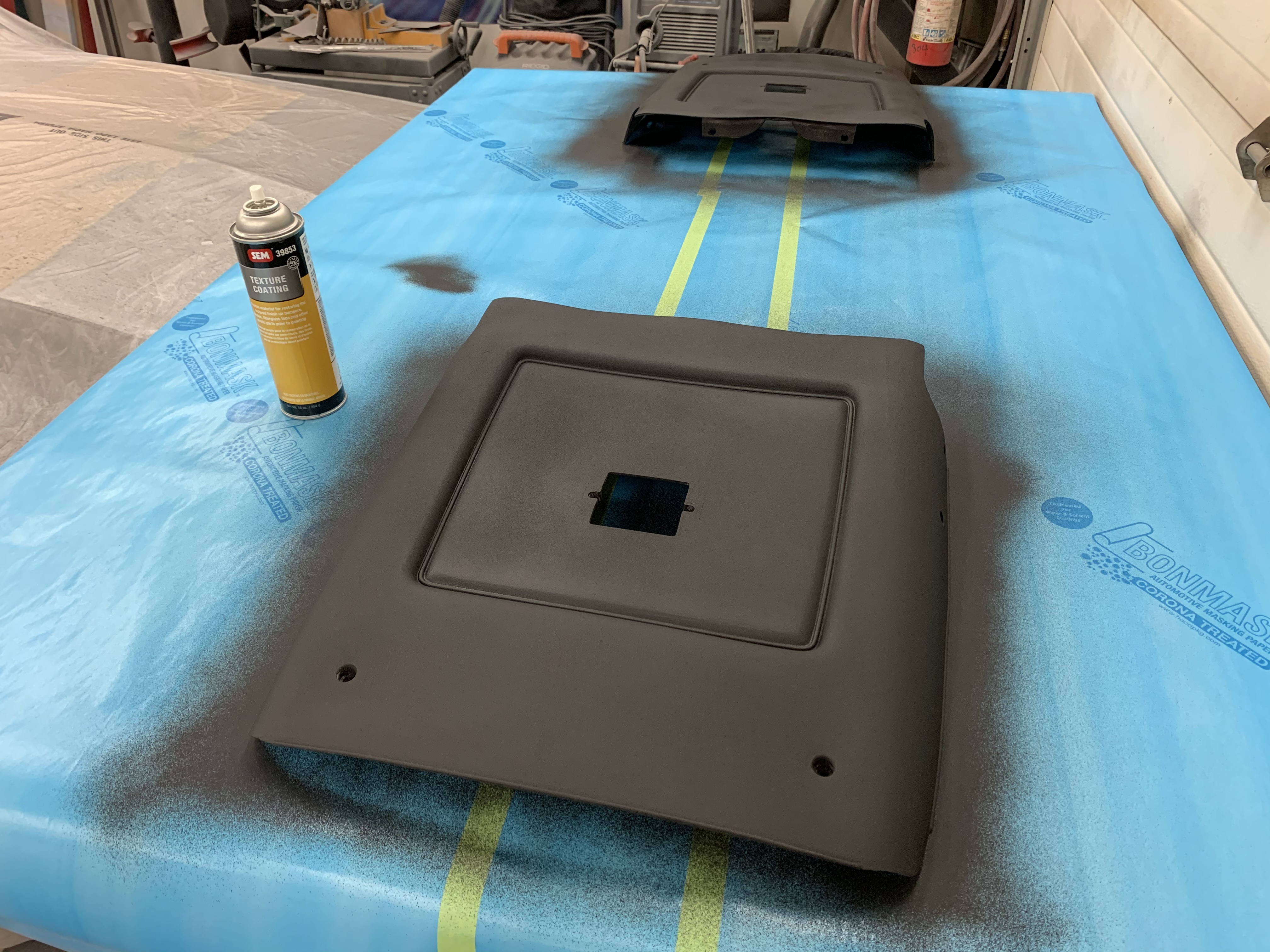

After one last really thorough cleaning, they were ready for some product. SEM makes a product called Texture Coat, and it’s intended for applications like this. It doesn’t exactly match the original grain and pattern, but it’s very very close. Especially to those who aren’t that familiar with how it looked to begin with.

I first became aware of this product back in the mid nineties, when a coworker of mine plastic welded in a piece to fill the remote mirror escutcheon on the door panel when I shaved the mirrors on The Juggernaut, and we needed to replicate the grain pattern.

SEM Texture Coat:

The instructions call for 1-4 very light coats at 18-24” away, and they’re not joking. The closer you are to the work piece, the heavier the texture will be. I followed their recommendations to the letter, and after only 2 light coats I was rewarded with a satisfactory, factory appearing finish:

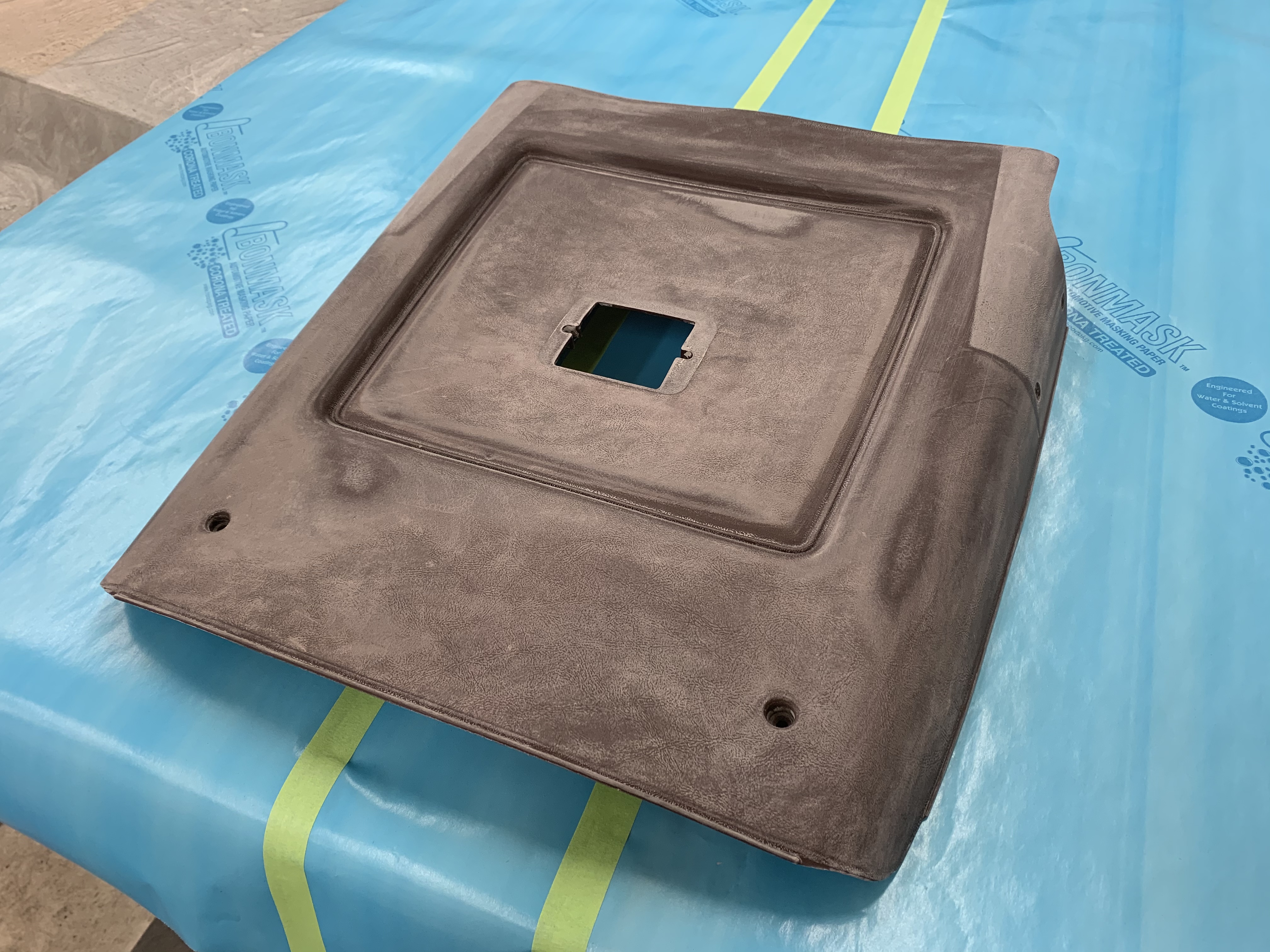

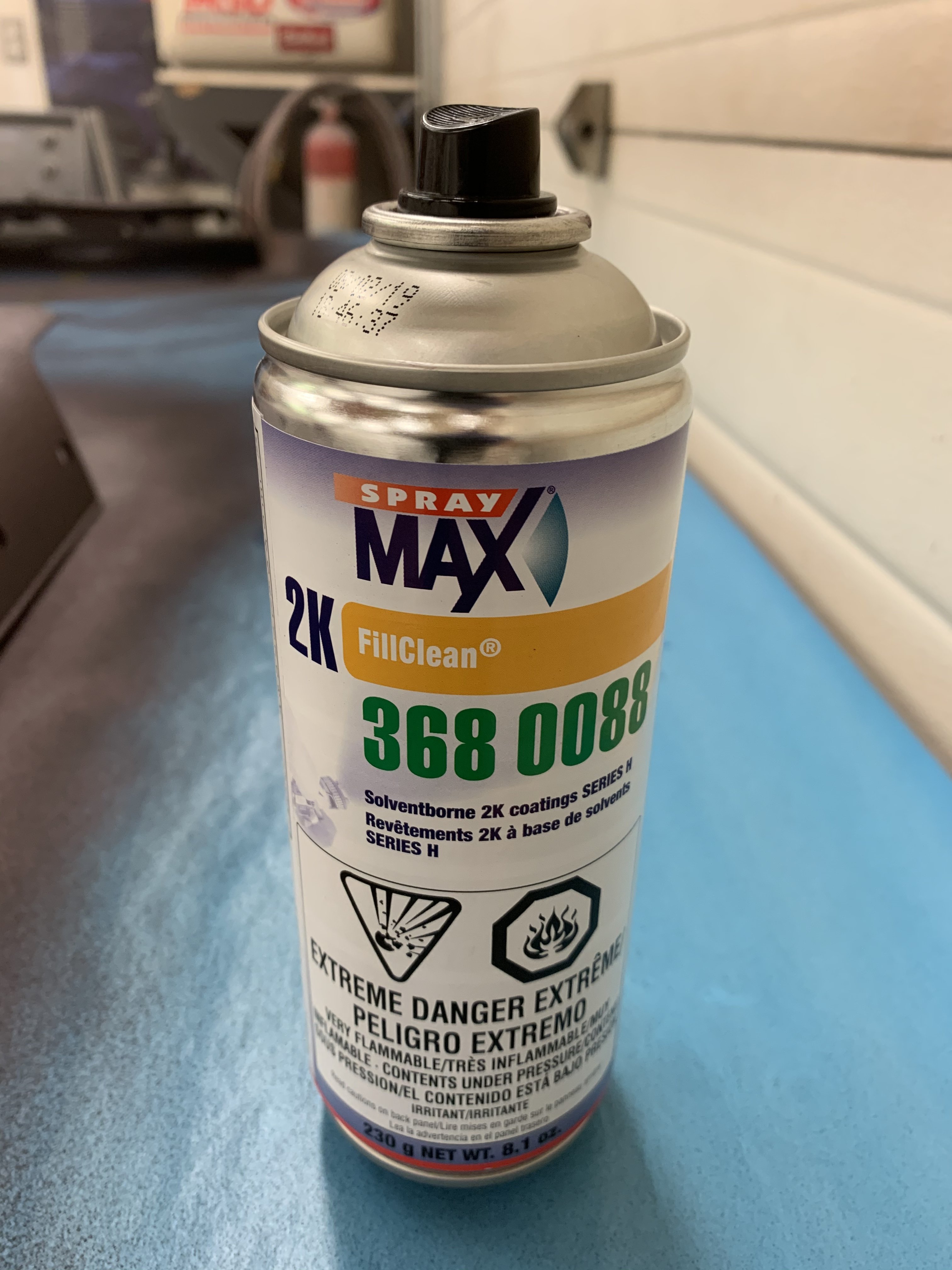

Time for some color. The interior paint code for my Cutlass is GM code 79, Dark Claret. However, upon trying to get my local supplier to find this in their system, I found that the same color code was renamed Code 79 Dark Ruby Red, and was also used in GM’s from 1996-2005 or so. Taking a chance, I had some mixed up and put into a couple of 2K catalyzed spray cans.

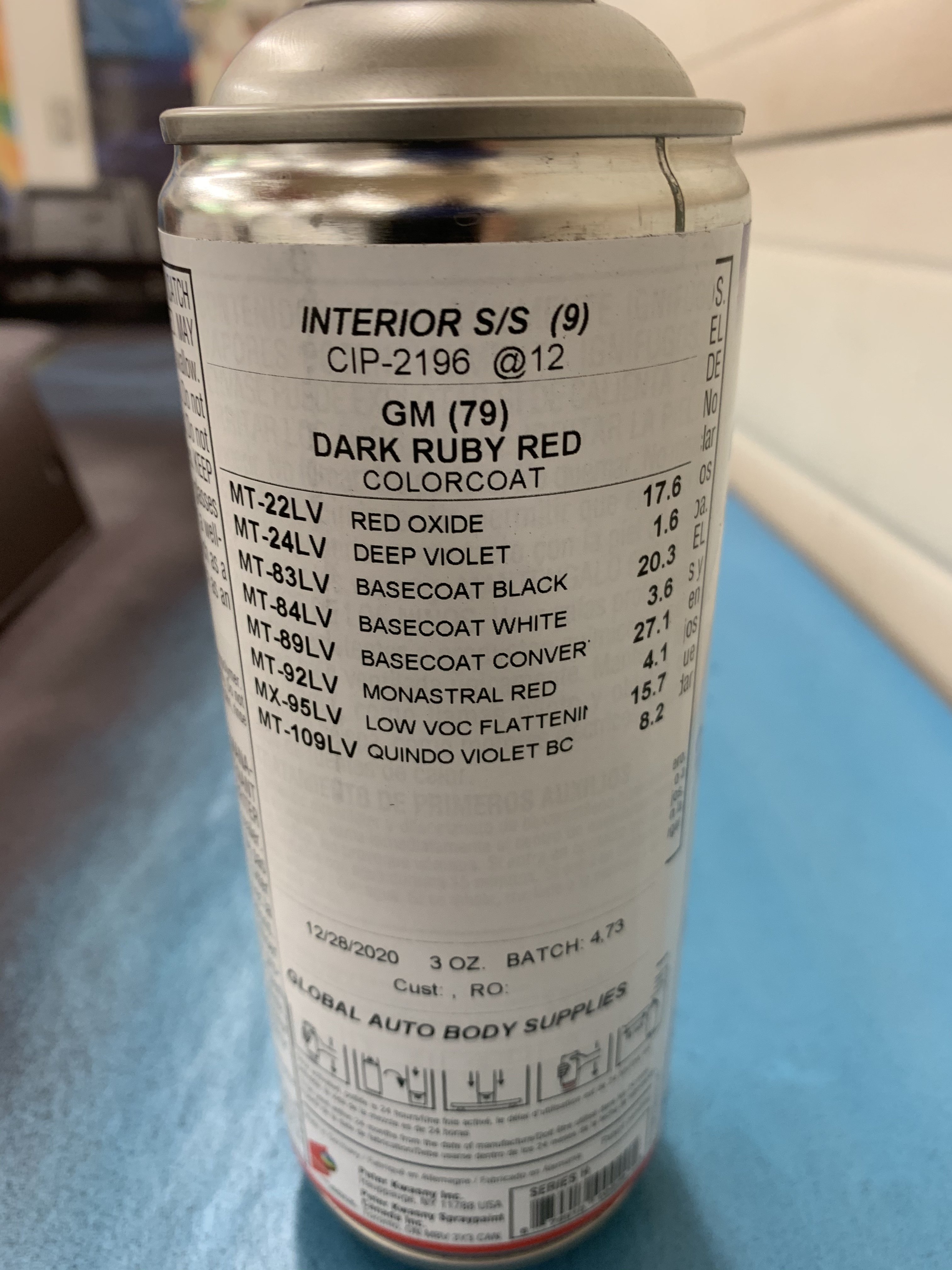

Here’s the ingredient list for this color, for anybody that’s interested:

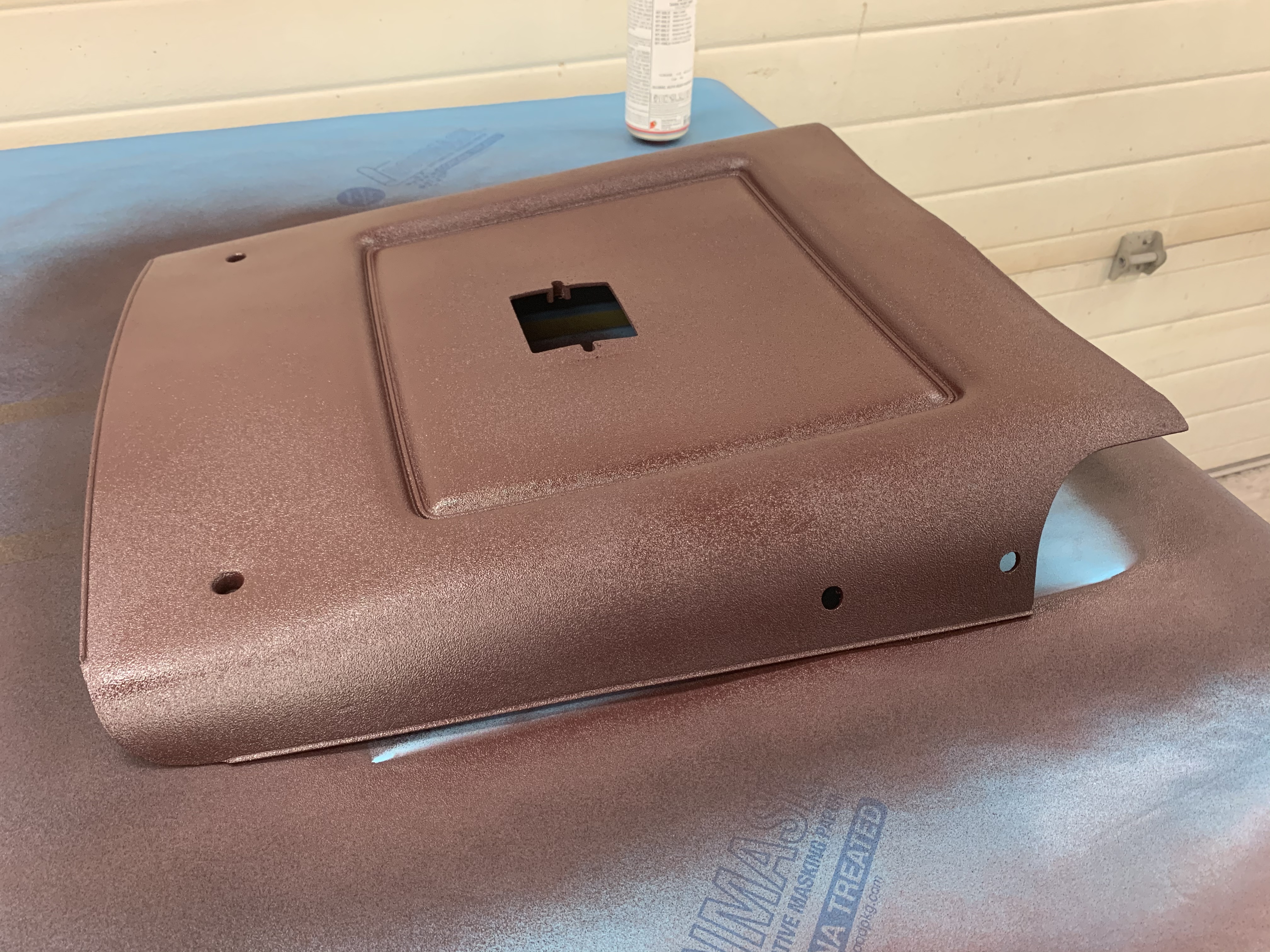

First coat going on:

I also had these dash filler pieces that were pretty faded, so I tried out the color on them first:

Much to my surprise and delight, the color was damn near a bang-on match so I continued on.

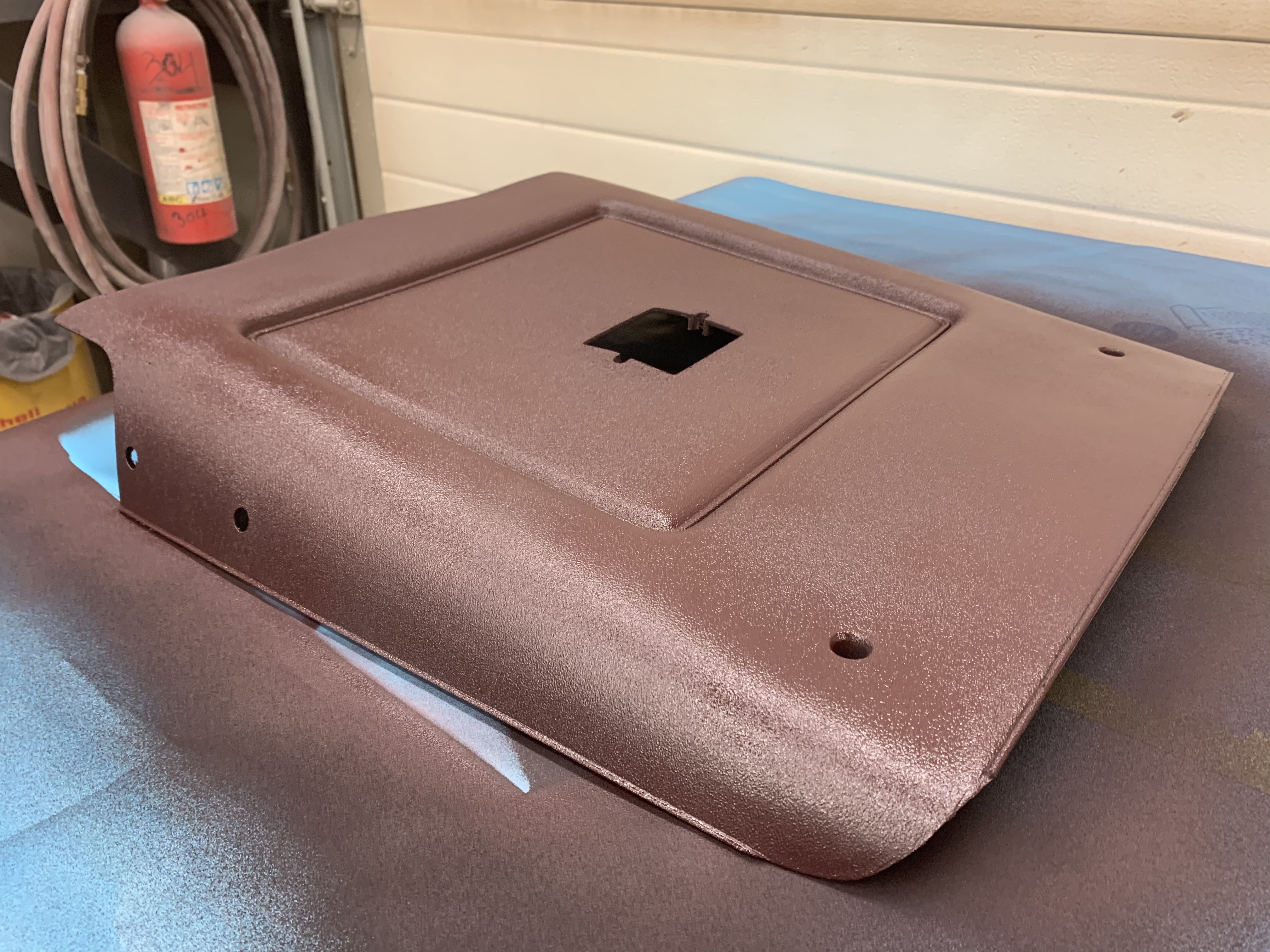

Three medium coats later, they were done.

Turned out very well in my opinion:

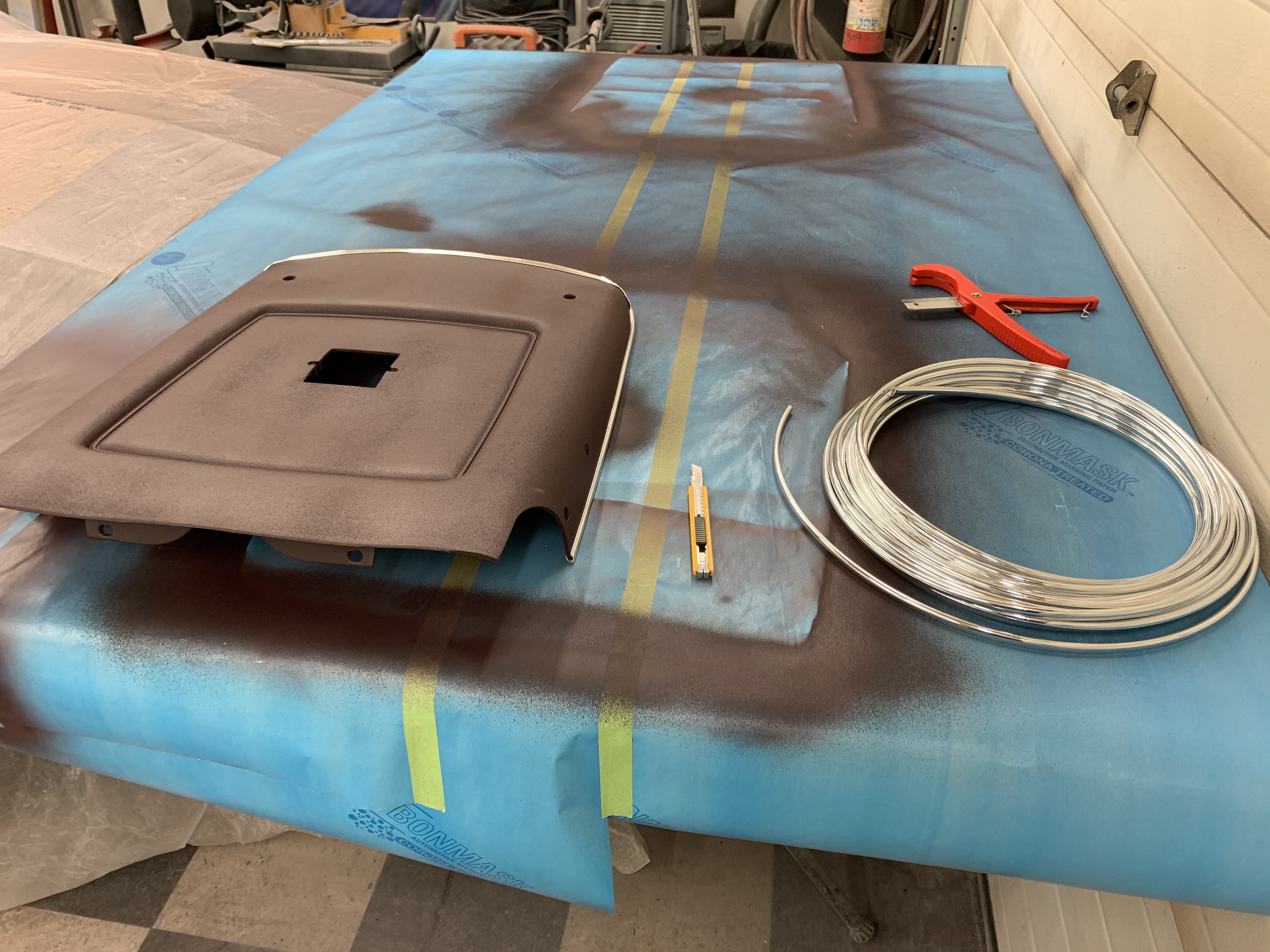

After letting them cure overnight, I began the reassembly process by framing them out with some new chrome trim. This is just basic chrome door edge protective trim that you can find at almost any automotive parts stores.

With the perimeter trim on and the hinge covers reattached, they were really starting to come together!

Nothing to do now but put them back on the seats.

Fully installed and finished, what a world of difference!

The color match is extremely good when compared to the original vinyl right beside it:

And of course I didn’t forget about the smaller chrome trim pieces that finish out the seat bottoms, these got replaced with new stuff to match as well:

(Yes I know the driver’s seat side has a tear in it, it’s on the list of things to get fixed eventually too).

More payoff pics of the drivers side:

I’ve said it before, but I wish you guys could see it in person, in natural light. They look sooo much better, the camera just doesn’t do them justice.

For those of you considering tackling this project for your own cars, this was an extremely simple job. A couple hours labor and around a $100 in materials is all it took to get these results. I give it about a 3 out of 10 on the difficulty scale, yet the results are more than worth it. Best part is, once you have all the materials and the experience, it can be applied to any and all of the rest of the interior plastics in our cars.

Amazing what a little paint and time can do.

D.