Thank you! I’ve got quite a bit more to update everyone on already, I’ve just gotta find some time to do it.

BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thank you! I’ve got quite a bit more to update everyone on already, I’ve just gotta find some time to do it.

You started back on the Juggernaut?

You started back on the Juggernaut?

Nein, nada, nyet.

When I do, those will be posted in The Juggernaut build thread.

Nein, nada, nyet.

When I do, those will be posted in The Juggernaut build thread.

Hey a girl can dream can't she?

Update time. Hoo wee, where to begin?

A lot has transpired since the last, what was it? Oh right, chrome hinge covers.

Since then, I’ve received the highly anticipated decal package from 69hurstolds, and they were definitely well worth the wait. But I’ll post more about those later.

Since the car is basically 99% complete, I’ve been spending the time still chasing after all the niggling little details, you know, the piddly shjt that irritates a guy, but he never seems to address. Like a squeaky passenger door hinge for example. Picked up some heavy duty clear silicone spray and took care of that and a few other moving parts on the car.

Things like the upper seatbelt mounts that were binding after the headliner install. The original headliner had pockets molded into it for the mounts, but the aftermarket one did not. When the bolts and hangers and their covers were installed, they crushed into the headliner preventing them from letting the belts move smoothly through them. They wouldn’t even retract when the doors were opened, you would have to manually feed them back into the retractors.

Talk about a PITA.

I brought the issue to the attention of the manufacturer/supplier/distributor, but got basically blown off so I knew I was on my own.

So I en-gan-nerd a solution. Found the thread pitch of the original bolts, then picked up some metric 10.9 all-thread and a couple of matching nuts along with some aluminum pipe to custom make my own “shoulders” for the all-thread. It took a while to find just the right combination of all-thread and spacer length to space the hangers out far enough, but once I did I welded the nuts on flush with the ends of the all-thread. Presto, instant custom length 10.9 metric bolts. Installed them with the correct length aluminum spacers to act as the bolt shoulders with a little Loctite, and boom.

No more binding and they work as they should again:

When that was done, I next dove into the second last blend repair area. I had a couple of burn throughs on the driver’s side of the hood:

Same procedure here as you’ve seen me do a couple of times now, knock it down with 1000 grit dry, and blend prep the transition areas, then mask...

...and dust in the base and slather on 3 coats of clear. The only obvious difference here versus the white I’ve done before is this grey is metallic. Metallics are extremely tricky to blend properly. The air pressure, mix ratio, distance from the panel, number of coats, ALL have to be as close as possible to how it was originally sprayed. Otherwise it’ll lay down differently and not look right.

After it had cured for a bit, I gave it the same paint correction steps and polishing as the rest of the car to eliminate the orange peel and dust nibs. Turned out very well, the grey base dust-in is all but invisible, and the clear blend is as well.

While all this was going on, 3 weekends ago I took the $100 swap meet G body headers I picked up a few years back over to my new powder coat guy and dropped them off. Told him to work his magic and call me when they were done.

Bye, nasty old crap!:

Hello, pretty new finish, picked them up on Tuesday of last week.

I went with a flat, dark grey CeraKote ceramic powder called Glacier Grey on these, I wanted something subtle and understated for under the hood of Olds Cool. Brilliant lustre silver would’ve stuck out like a sore thumb with the rest of the underhood components being mostly black and Corporate Blue. I’m very happy with them, and pleased that they weren’t too rusty or beat up. A big shout out to Jay at Powder Works in Calgary for hooking me up and making these look good.

Which then brings us to this weekend, but first I have to give y’all a little back story on the exhaust.

When I bought Olds Cool several years back, the exhaust was rotted away on it. Like gas you out of the car unless you had the windows down kind of bad. So within the first week of owning it, I got it into the exhaust shop to get some new pipes on it. I knew already that I was going to want dual exhaust on it eventually, so I had them build 2 new pipes and run them down the passenger side of the car (because single hump crossmember). I told them I wanted 2 1/2” diameter, but this posed a problem when attaching them to the exhaust manifolds. The manifolds are 2 1/4” stock, and won’t accept a 2 1/2” pipe.

So they did a bit of hackery to accommodate my wishes, but still be functional. This is what 2 1/4” head pipes look like welded into the rest of a 2 1/2” system:

The exhaust shop was able to build me a new head pipe up to the passenger’s side manifold, but not the crossover pipe to the driver’s side. Hence the rusty old original pipe there. As you can obviously see, the system was functional, but faaar from efficient for a potentially 350 horse 350. I knew I was leaving a lot on the table with this bastardized system and manifolds, but then again, I knew I’d eventually be correcting it. Hence the headers.

Ok, back to the current state.

Yesterday, Mike came over and we got right to cutting, ripping and tearing. The head pipes got cut off just south of the sweged and welded areas, and the manifolds came off. We decided to tackle the passenger side first as I’ve read many horror stories on here about how tough it can be with the a/c box in place.

They weren’t wrong.

The battery was disconnected and the starter pulled, along with the flywheel dust cover, the plugs, the dipstick, and the dipstick tube. The engine mount bolt had to be pulled, the engine jacked up, then the clamshell removed from the block. This still wasn’t enough room, so then the top 2 engine mount bolts on the crossmember needed to be pulled, and the mount rotated off to the side:

Once we were finally able to finagle it in from the topside (there was no way in hell it would’ve gone in from the bottom), it bolted up perfectly and everything was reassembled.

The driver’s side went quite a bit better, but still required a lot. The plugs were pulled on this side as well, then the steering box was unbolted from the frame so we could easily disconnect the Jeep steering shaft without having to compress it. The oil pressure sending unit had to go and get plugged, then the engine mount bolt had to be removed and the engine jacked up on this side too. Oil filter had to come off, along with the temperature gauge wire. We managed to fish this one in from the bottom, I’m still not quite sure how we did it TBH, but I’ll take the win.

But like the passenger’s side, once it was in place it fit perfectly. Then it was just a matter of reassembling everything again.

All in all, I’m pretty pleased so far. The 3” collectors sit up nice and tight to the floor, don’t interfere with the backdrive linkage, and don’t hit or rub on anything. I was able to retain the temp gauge sender and wire by simply bending the spade over and reattaching the wire.

The oil pressure sending unit will have to be relocated and tee’d in with the idiot light sender at the back of the engine by the distributor, but I can handle that easily enough.

On the passenger’s side, I was able to keep and utilize the dipstick and tube even. I’ll need to change the plug wire ends to 90’s most likely, but that should be about it. The headers are currently just being held in place with temporary bolts, I have some nice black oxide ARP’s on the way for the final assembly.

On the underside of the car, the “2 pipes run down the passenger side” nonsense is going away. It will be a true dual exhaust, one down each side as it should be, I’m still just working on a solution to the double hump crossmember issue. The Jegster crossmembers are sold out and back ordered, and I’m not paying the astronomical prices they want for the G Force ones. Does anyone know if Iceman is still selling his? If not, I’ll likely end up notching the factory one. I should have enough exhaust pipe to cut/splice/and weld to the new desired configuration, and header reducers are on their way as well. They and the header bolts should be here Wednesday.

Anyways, that’s it for now guys. I’m beat and the fingers are cramping up from all this typing. Ya can’t say I’ve been sitting idle at least!

Till next time,

D.

A lot has transpired since the last, what was it? Oh right, chrome hinge covers.

Since then, I’ve received the highly anticipated decal package from 69hurstolds, and they were definitely well worth the wait. But I’ll post more about those later.

Since the car is basically 99% complete, I’ve been spending the time still chasing after all the niggling little details, you know, the piddly shjt that irritates a guy, but he never seems to address. Like a squeaky passenger door hinge for example. Picked up some heavy duty clear silicone spray and took care of that and a few other moving parts on the car.

Things like the upper seatbelt mounts that were binding after the headliner install. The original headliner had pockets molded into it for the mounts, but the aftermarket one did not. When the bolts and hangers and their covers were installed, they crushed into the headliner preventing them from letting the belts move smoothly through them. They wouldn’t even retract when the doors were opened, you would have to manually feed them back into the retractors.

Talk about a PITA.

I brought the issue to the attention of the manufacturer/supplier/distributor, but got basically blown off so I knew I was on my own.

So I en-gan-nerd a solution. Found the thread pitch of the original bolts, then picked up some metric 10.9 all-thread and a couple of matching nuts along with some aluminum pipe to custom make my own “shoulders” for the all-thread. It took a while to find just the right combination of all-thread and spacer length to space the hangers out far enough, but once I did I welded the nuts on flush with the ends of the all-thread. Presto, instant custom length 10.9 metric bolts. Installed them with the correct length aluminum spacers to act as the bolt shoulders with a little Loctite, and boom.

No more binding and they work as they should again:

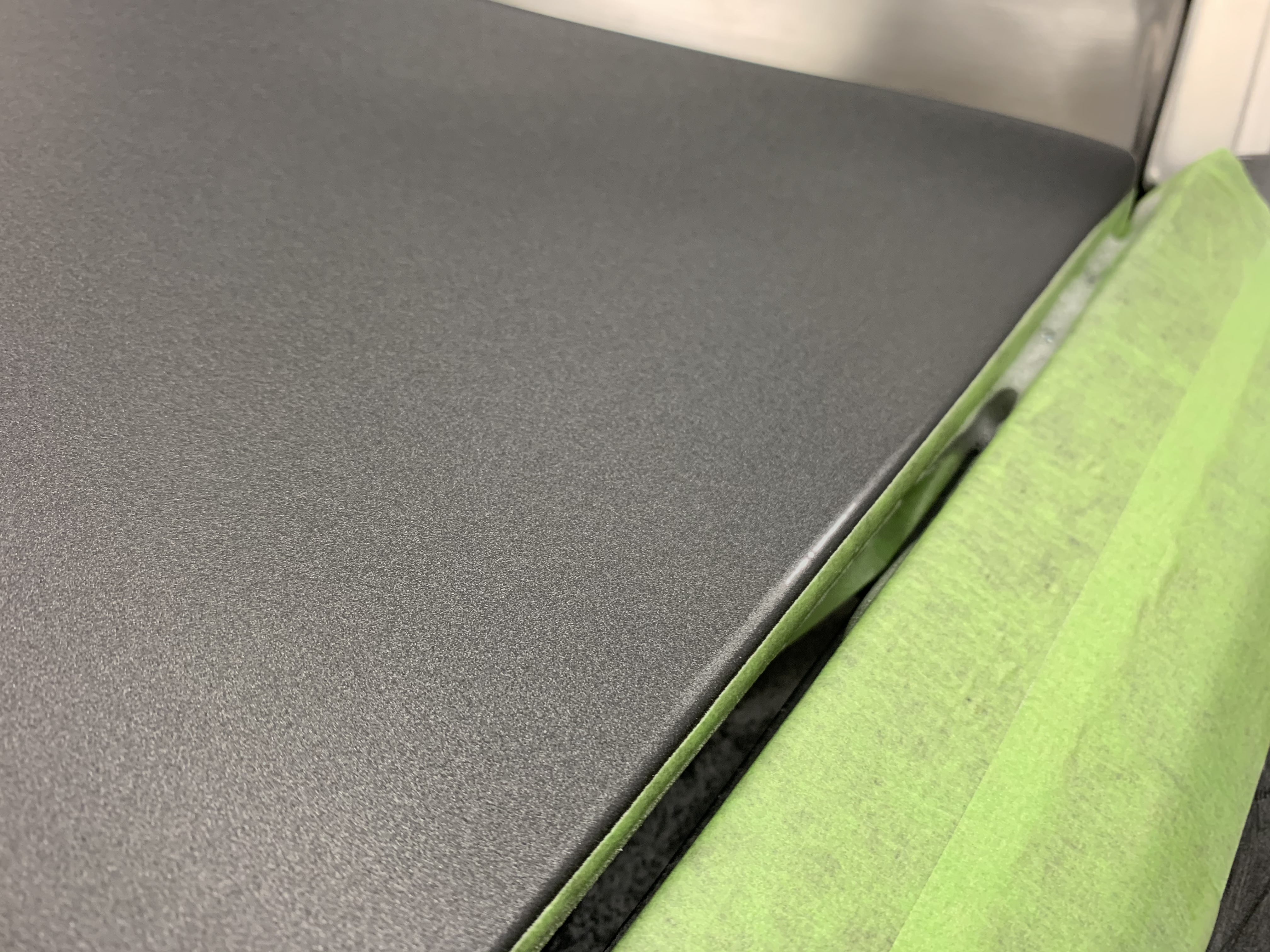

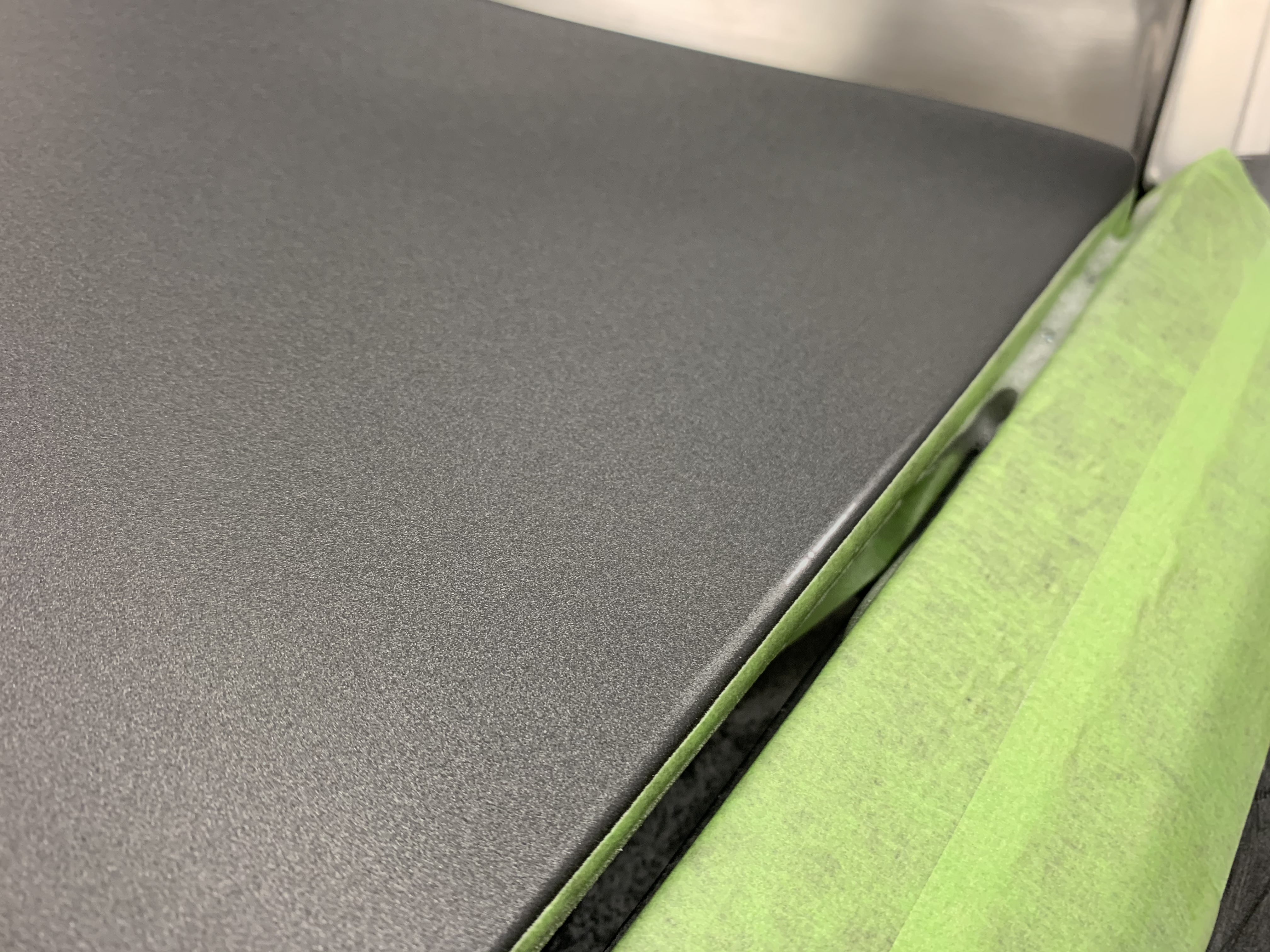

When that was done, I next dove into the second last blend repair area. I had a couple of burn throughs on the driver’s side of the hood:

Same procedure here as you’ve seen me do a couple of times now, knock it down with 1000 grit dry, and blend prep the transition areas, then mask...

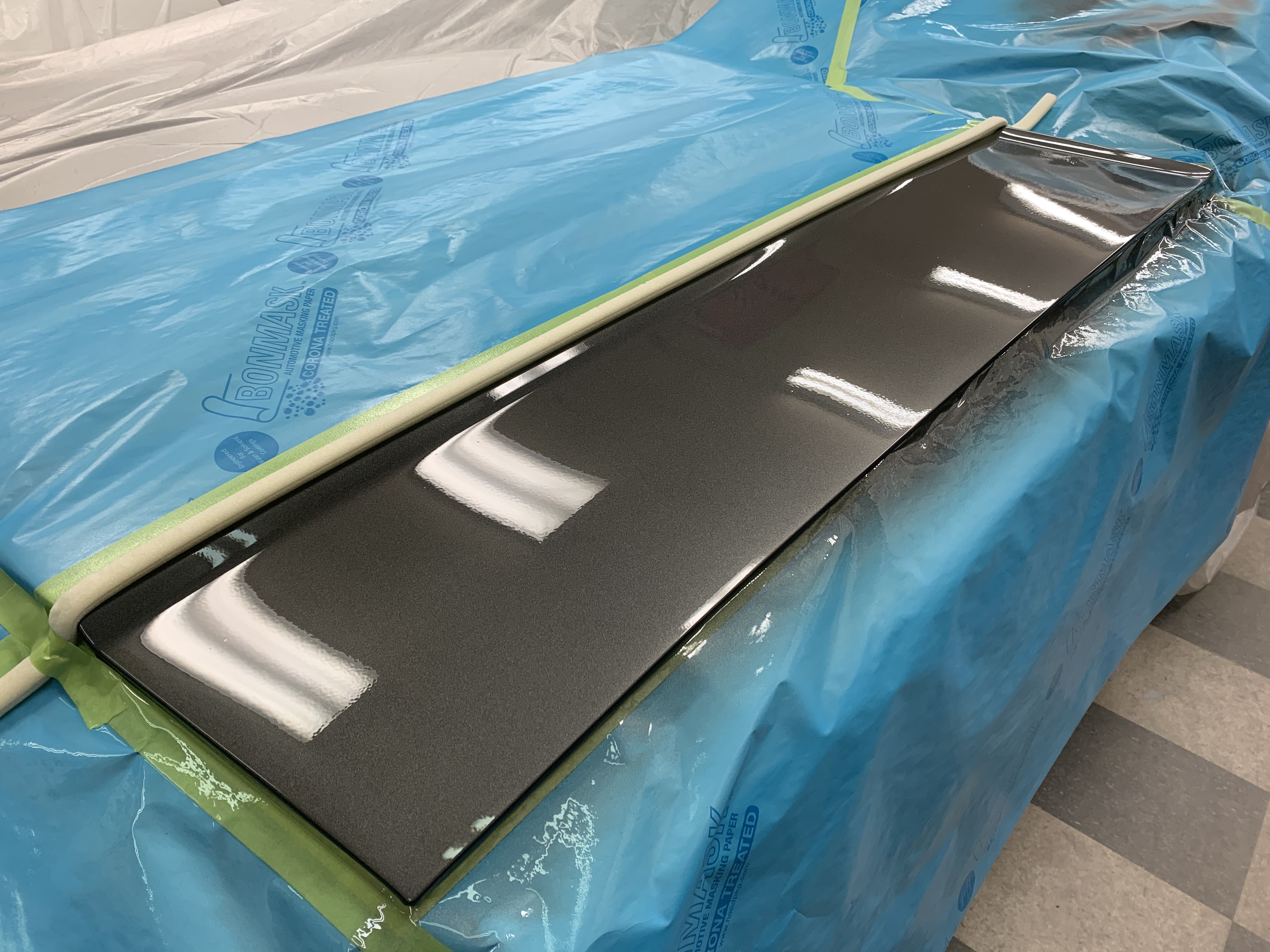

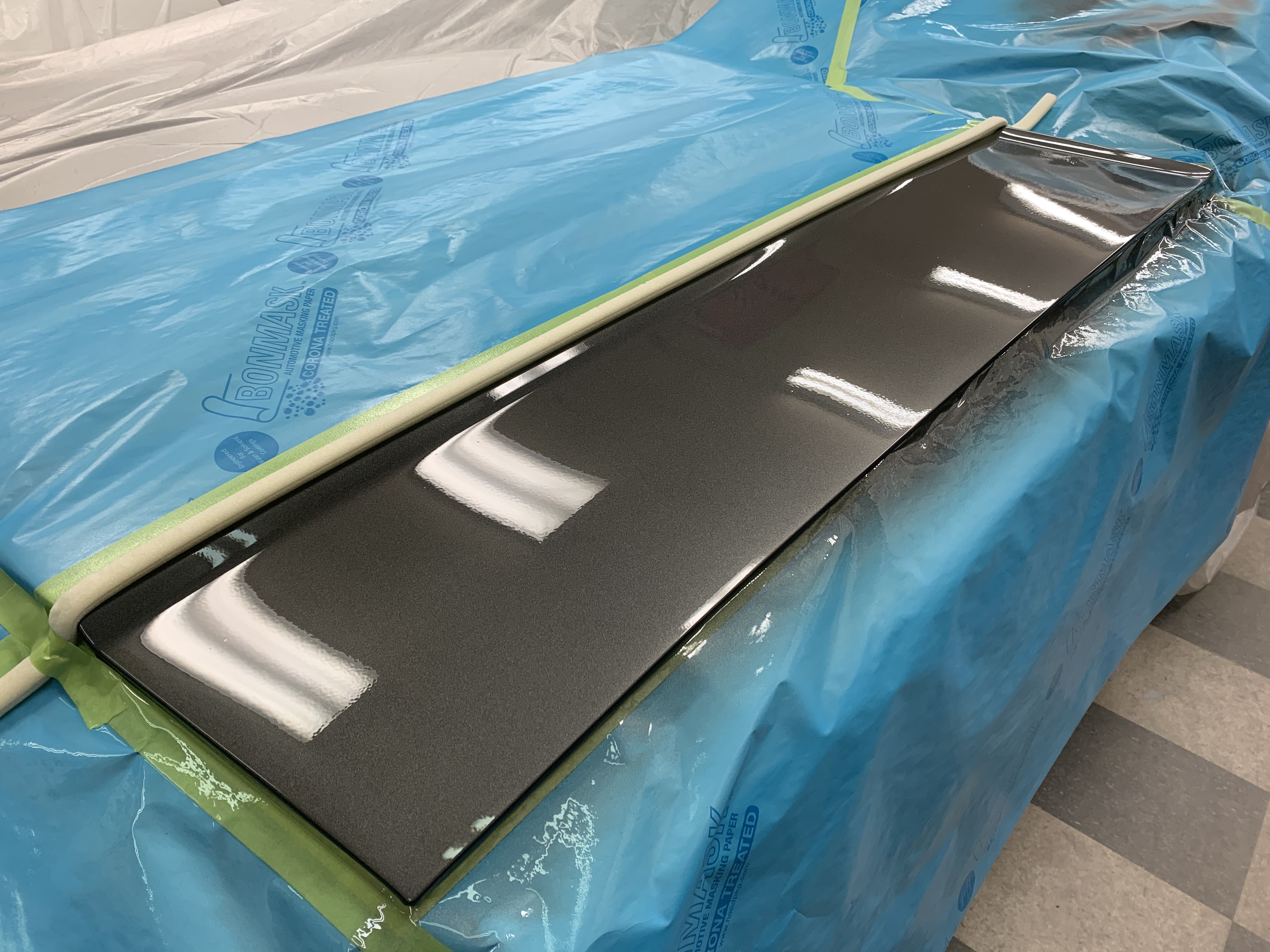

...and dust in the base and slather on 3 coats of clear. The only obvious difference here versus the white I’ve done before is this grey is metallic. Metallics are extremely tricky to blend properly. The air pressure, mix ratio, distance from the panel, number of coats, ALL have to be as close as possible to how it was originally sprayed. Otherwise it’ll lay down differently and not look right.

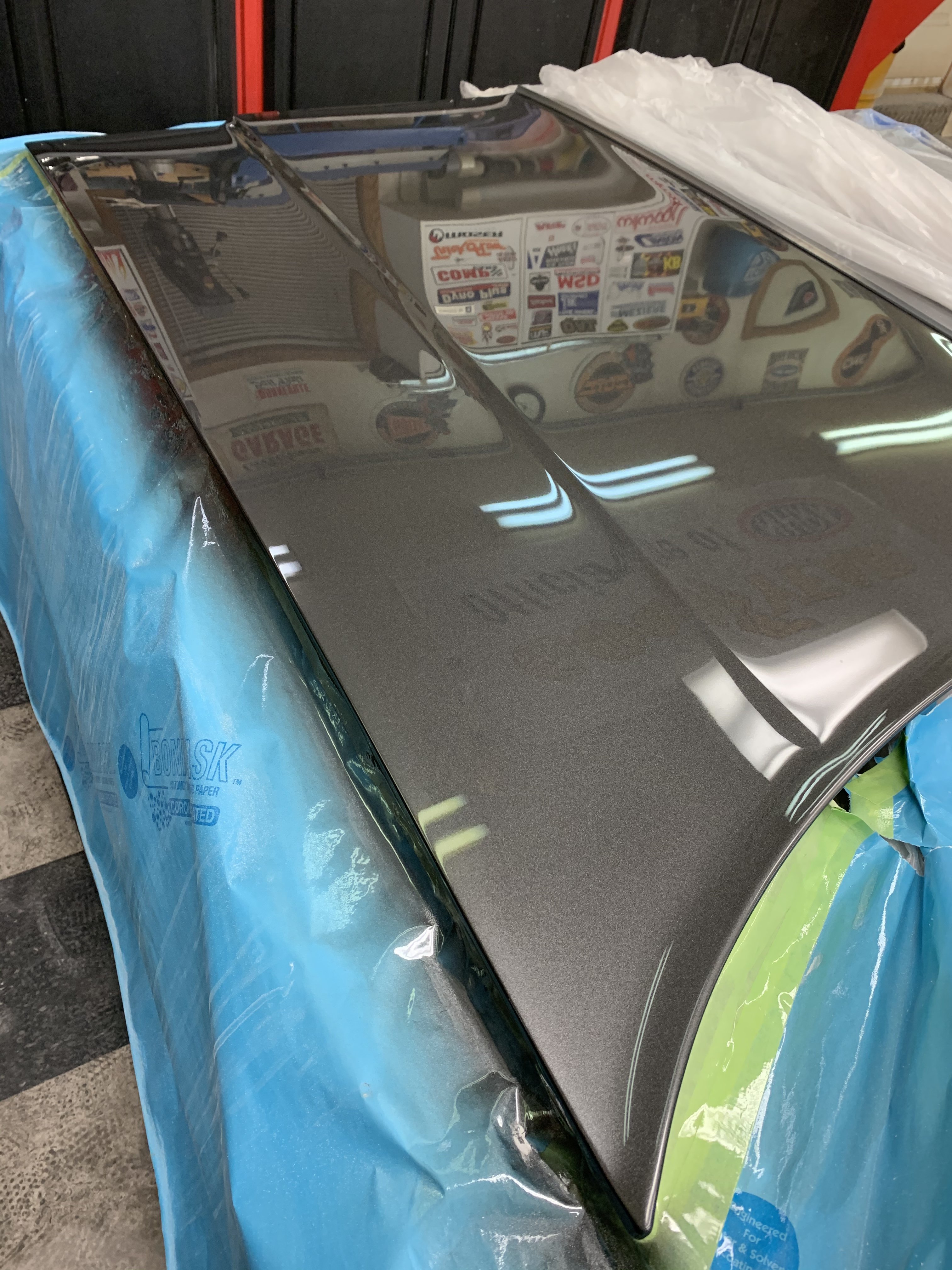

After it had cured for a bit, I gave it the same paint correction steps and polishing as the rest of the car to eliminate the orange peel and dust nibs. Turned out very well, the grey base dust-in is all but invisible, and the clear blend is as well.

While all this was going on, 3 weekends ago I took the $100 swap meet G body headers I picked up a few years back over to my new powder coat guy and dropped them off. Told him to work his magic and call me when they were done.

Bye, nasty old crap!:

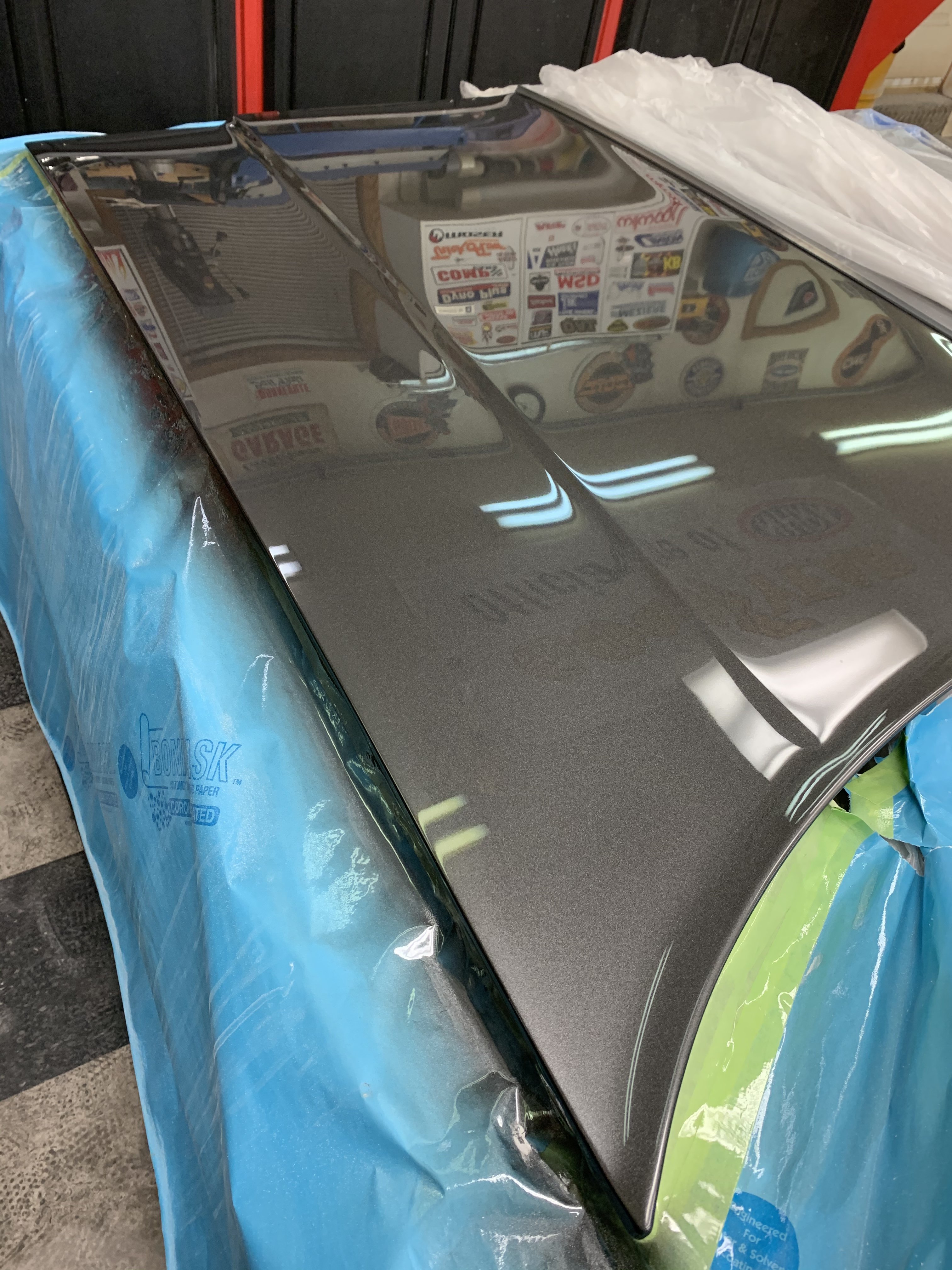

Hello, pretty new finish, picked them up on Tuesday of last week.

I went with a flat, dark grey CeraKote ceramic powder called Glacier Grey on these, I wanted something subtle and understated for under the hood of Olds Cool. Brilliant lustre silver would’ve stuck out like a sore thumb with the rest of the underhood components being mostly black and Corporate Blue. I’m very happy with them, and pleased that they weren’t too rusty or beat up. A big shout out to Jay at Powder Works in Calgary for hooking me up and making these look good.

Which then brings us to this weekend, but first I have to give y’all a little back story on the exhaust.

When I bought Olds Cool several years back, the exhaust was rotted away on it. Like gas you out of the car unless you had the windows down kind of bad. So within the first week of owning it, I got it into the exhaust shop to get some new pipes on it. I knew already that I was going to want dual exhaust on it eventually, so I had them build 2 new pipes and run them down the passenger side of the car (because single hump crossmember). I told them I wanted 2 1/2” diameter, but this posed a problem when attaching them to the exhaust manifolds. The manifolds are 2 1/4” stock, and won’t accept a 2 1/2” pipe.

So they did a bit of hackery to accommodate my wishes, but still be functional. This is what 2 1/4” head pipes look like welded into the rest of a 2 1/2” system:

The exhaust shop was able to build me a new head pipe up to the passenger’s side manifold, but not the crossover pipe to the driver’s side. Hence the rusty old original pipe there. As you can obviously see, the system was functional, but faaar from efficient for a potentially 350 horse 350. I knew I was leaving a lot on the table with this bastardized system and manifolds, but then again, I knew I’d eventually be correcting it. Hence the headers.

Ok, back to the current state.

Yesterday, Mike came over and we got right to cutting, ripping and tearing. The head pipes got cut off just south of the sweged and welded areas, and the manifolds came off. We decided to tackle the passenger side first as I’ve read many horror stories on here about how tough it can be with the a/c box in place.

They weren’t wrong.

The battery was disconnected and the starter pulled, along with the flywheel dust cover, the plugs, the dipstick, and the dipstick tube. The engine mount bolt had to be pulled, the engine jacked up, then the clamshell removed from the block. This still wasn’t enough room, so then the top 2 engine mount bolts on the crossmember needed to be pulled, and the mount rotated off to the side:

Once we were finally able to finagle it in from the topside (there was no way in hell it would’ve gone in from the bottom), it bolted up perfectly and everything was reassembled.

The driver’s side went quite a bit better, but still required a lot. The plugs were pulled on this side as well, then the steering box was unbolted from the frame so we could easily disconnect the Jeep steering shaft without having to compress it. The oil pressure sending unit had to go and get plugged, then the engine mount bolt had to be removed and the engine jacked up on this side too. Oil filter had to come off, along with the temperature gauge wire. We managed to fish this one in from the bottom, I’m still not quite sure how we did it TBH, but I’ll take the win.

But like the passenger’s side, once it was in place it fit perfectly. Then it was just a matter of reassembling everything again.

All in all, I’m pretty pleased so far. The 3” collectors sit up nice and tight to the floor, don’t interfere with the backdrive linkage, and don’t hit or rub on anything. I was able to retain the temp gauge sender and wire by simply bending the spade over and reattaching the wire.

The oil pressure sending unit will have to be relocated and tee’d in with the idiot light sender at the back of the engine by the distributor, but I can handle that easily enough.

On the passenger’s side, I was able to keep and utilize the dipstick and tube even. I’ll need to change the plug wire ends to 90’s most likely, but that should be about it. The headers are currently just being held in place with temporary bolts, I have some nice black oxide ARP’s on the way for the final assembly.

On the underside of the car, the “2 pipes run down the passenger side” nonsense is going away. It will be a true dual exhaust, one down each side as it should be, I’m still just working on a solution to the double hump crossmember issue. The Jegster crossmembers are sold out and back ordered, and I’m not paying the astronomical prices they want for the G Force ones. Does anyone know if Iceman is still selling his? If not, I’ll likely end up notching the factory one. I should have enough exhaust pipe to cut/splice/and weld to the new desired configuration, and header reducers are on their way as well. They and the header bolts should be here Wednesday.

Anyways, that’s it for now guys. I’m beat and the fingers are cramping up from all this typing. Ya can’t say I’ve been sitting idle at least!

Till next time,

D.

With all that effort, reconsider the ARP black oxide hardware as is. It will rust. I used their BBC kit (studs + 12pt nuts) for my dually & within months all of the nuts were rust coated. I had to pull everything back apart, clean the studs & spray them w/some rattle can black hi-temp & used SS fine thread nuts. The replacement combo has been in place since & still looks good (<1k miles for the as-is ARP coating; >6k miles on my revised set-up)....... I went with a flat, dark grey CeraKote ceramic powder called Glacier Grey on these, I wanted something subtle and understated for under the hood of Olds Cool. Brilliant lustre silver would’ve stuck out like a sore thumb with the rest of the underhood components being mostly black and Corporate Blue. I’m very happy with them, and pleased that they weren’t too rusty or beat up. A big shout out to Jay at Powder Works in Calgary for hooking me up and making these look good.

On the passenger’s side, I was able to keep and utilize the dipstick and tube even. I’ll need to change the plug wire ends to 90’s most likely, but that should be about it. The headers are currently just being held in place with temporary bolts, I have some nice black oxide ARP’s on the way for the final assembly.

ARP hardware is an investment in quality fasteners. They REALLY need to have a better 'black/dark' coating vs. the black-oxide finish to reflect that investment. I was very disappointed.

With all that effort, reconsider the ARP black oxide hardware as is. It will rust. I used their BBC kit (studs + 12pt nuts) for my dually & within months all of the nuts were rust coated. I had to pull everything back apart, clean the studs & spray them w/some rattle can black hi-temp & used SS fine thread nuts. The replacement combo has been in place since & still looks good (<1k miles for the as-is ARP coating; >6k miles on my revised set-up).

ARP hardware is an investment in quality fasteners. They REALLY need to have a better 'black/dark' coating vs. the black-oxide finish to reflect that investment. I was very disappointed.

I agree wholeheartedly. I have ARP black oxide head bolts on my 455, and not painted they developed surface rust very quickly. I’ve since painted them the same color as the engine block, and am much happier with them now. I’ll be repeating the process on the header bolts when they arrive with some VHT Satin Black.

Also agree that ARP’s are an investment in quality, no one makes a finer fastener IMO. Although, I seriously considered using Stage 8 locking header bolts instead (like on my 455 as well), but they don’t offer them in anything but a shiny finish.

The Jegster crossmembers are sold out and back ordered, and I’m not paying the astronomical prices they want for the G Force ones. Does anyone know if Iceman is still selling his?

Couldn't you make a jig using the existing crossmember? That way you could modify the existing one or even build a new one from scratch. All it would take is some heavy gauge steel and a metal glue gun.

That's my 2 cents anyway.

Either way, great work as per usual Donovan!!

Hutch

Similar threads

- Replies

- 14

- Views

- 597

- Replies

- 10

- Views

- 437

- Replies

- 319

- Views

- 17K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.