Hey everyone, back with another update.

I'm still hard at work on the car, continuing with filler and blocking work on the driver's side sail panel. It's coming along alright, but I needed a bit of a break from all the dust and mess.

So Tuesday night, I did another massive cleanup and blow out of the car and garage again. This is how the car currently looks after the dust settled (literally!):

Nothing to write home about, but at least its progress.

Thinking to the very near future, and having the luxury of a clean garage again, I decided it was a good time to start making some patch panels to repair the rusty areas around the rear marker lights in the quarter panels before I returned to making more dust.

They're both in poor shape, and in dire need of fixing.

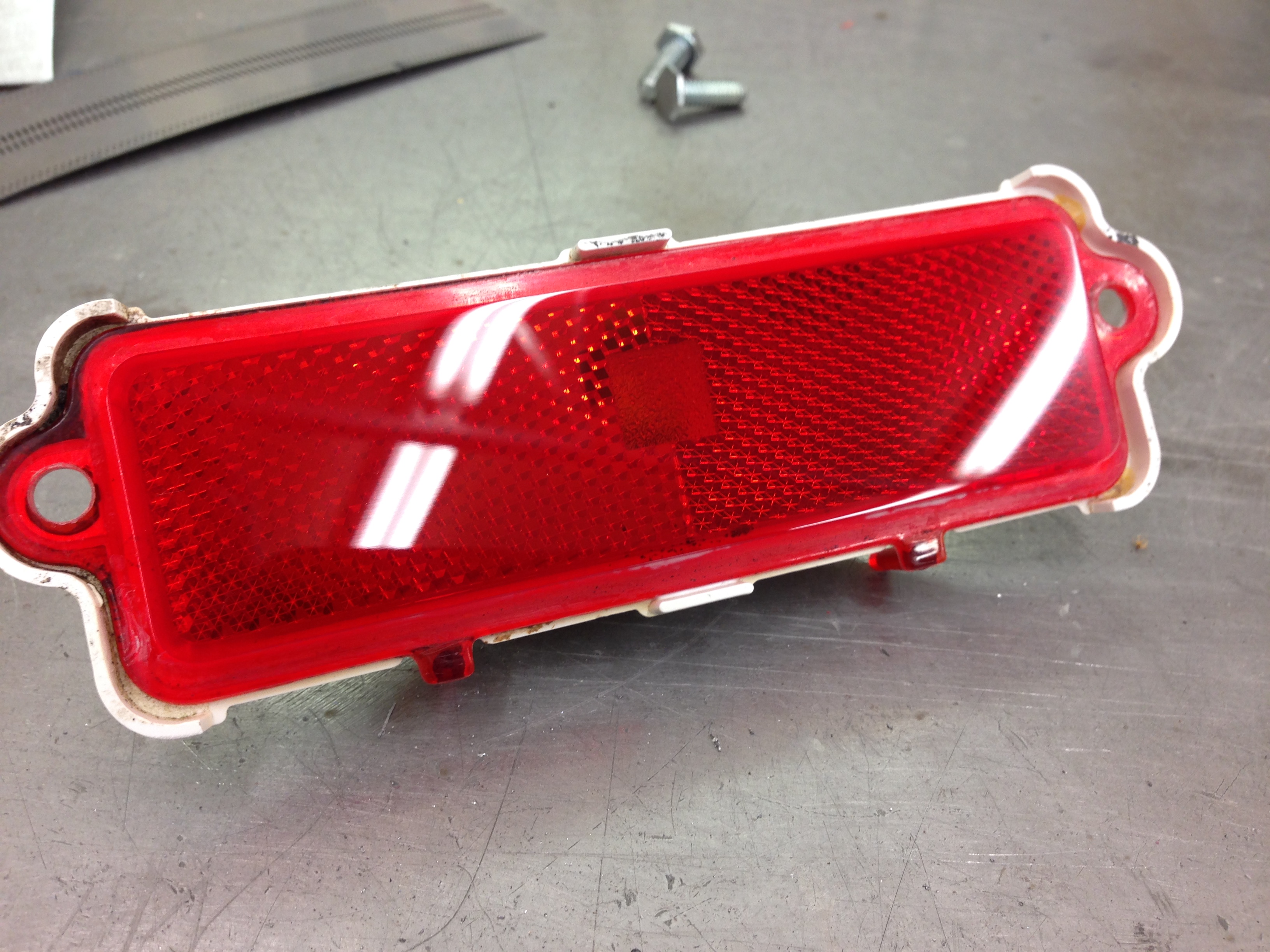

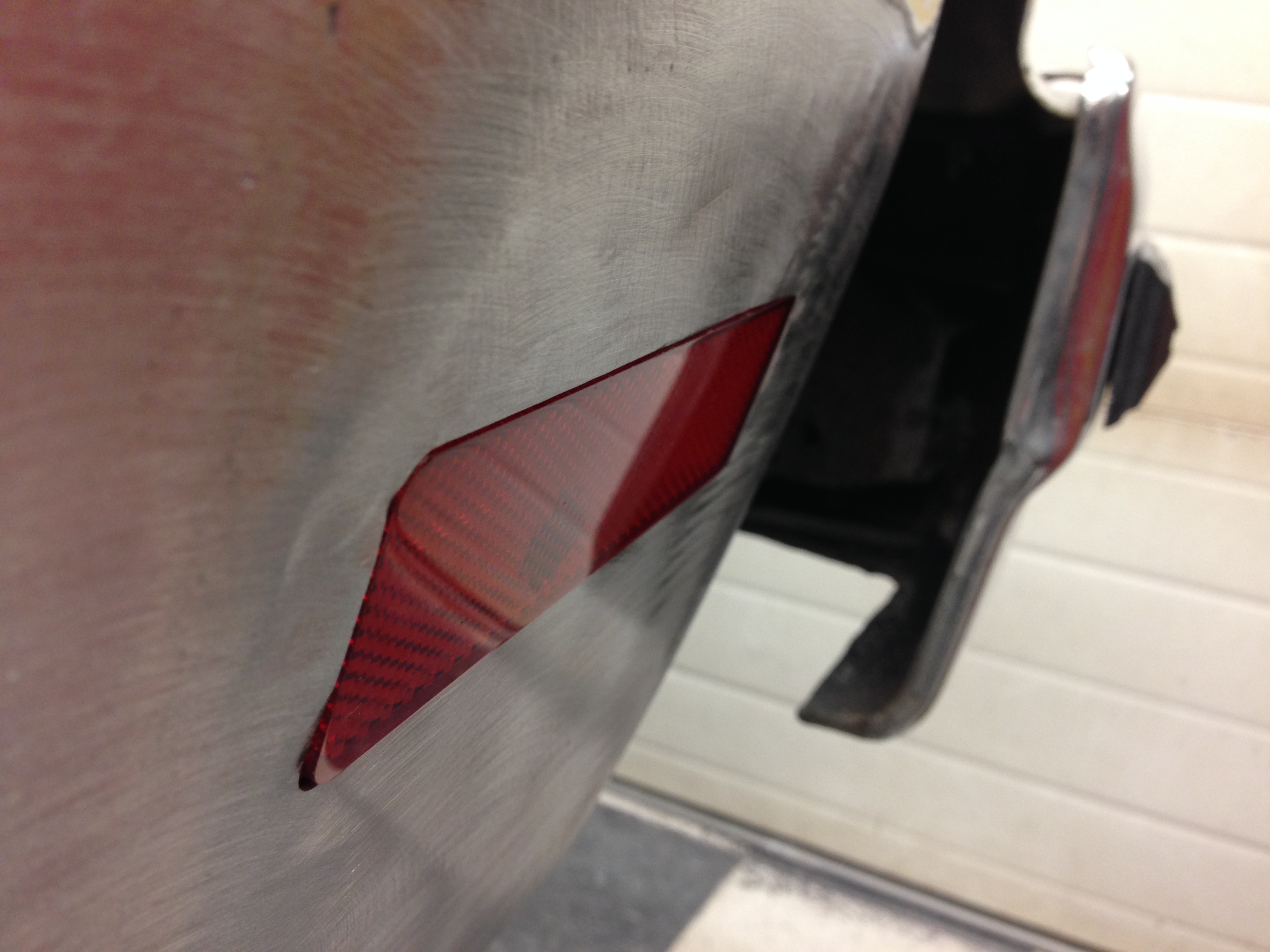

This is the passenger's side...

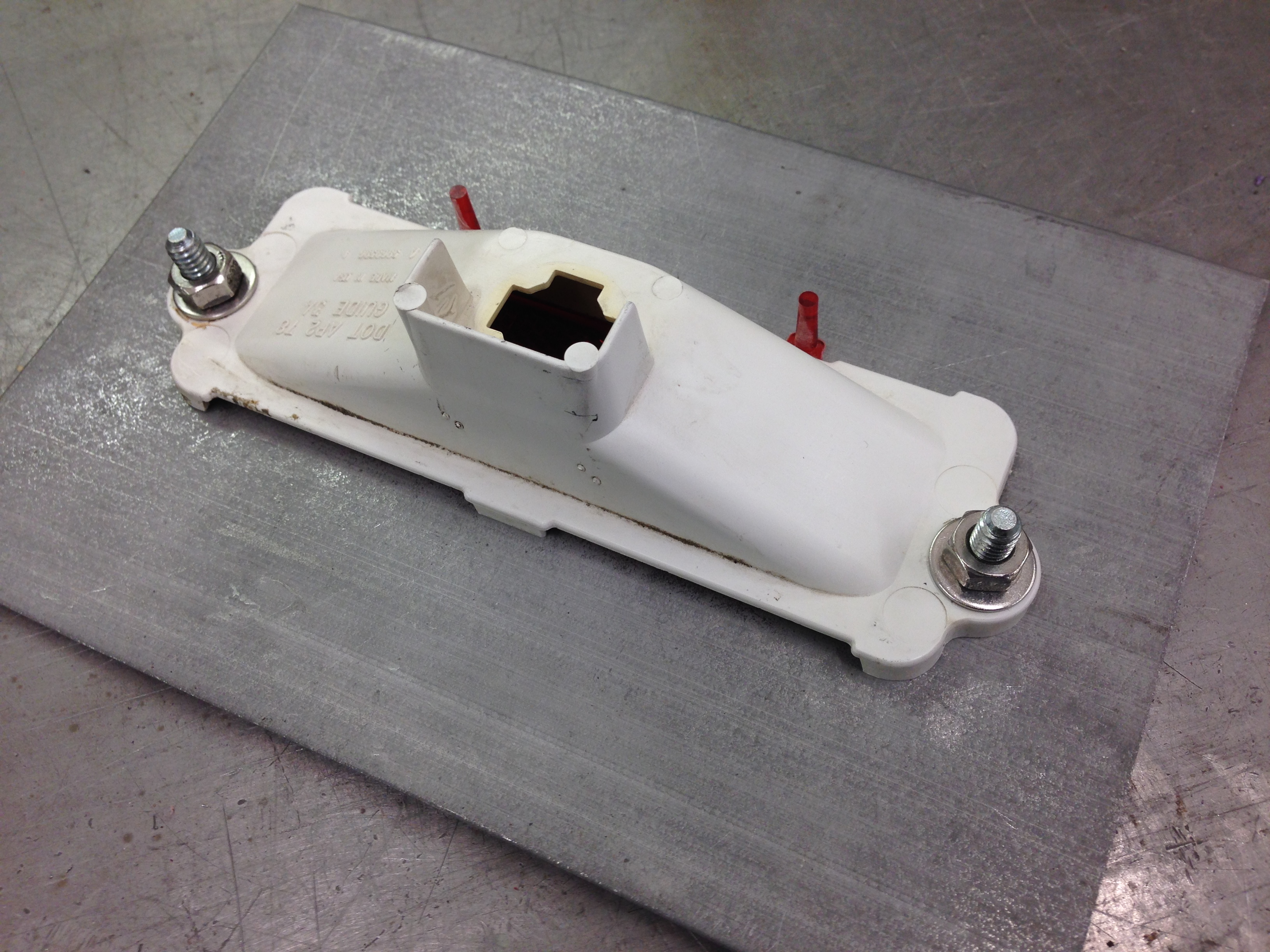

...and this is the driver's with the light and bezel removed:

Like I said, in dire need of fixing. I guess I'm actually fortunate to catch it at this stage, it's not too far gone yet where it's un-repairable.

I know some of you guys dig it when I get into my creative and customizing mode, so I think you're gonna like this.

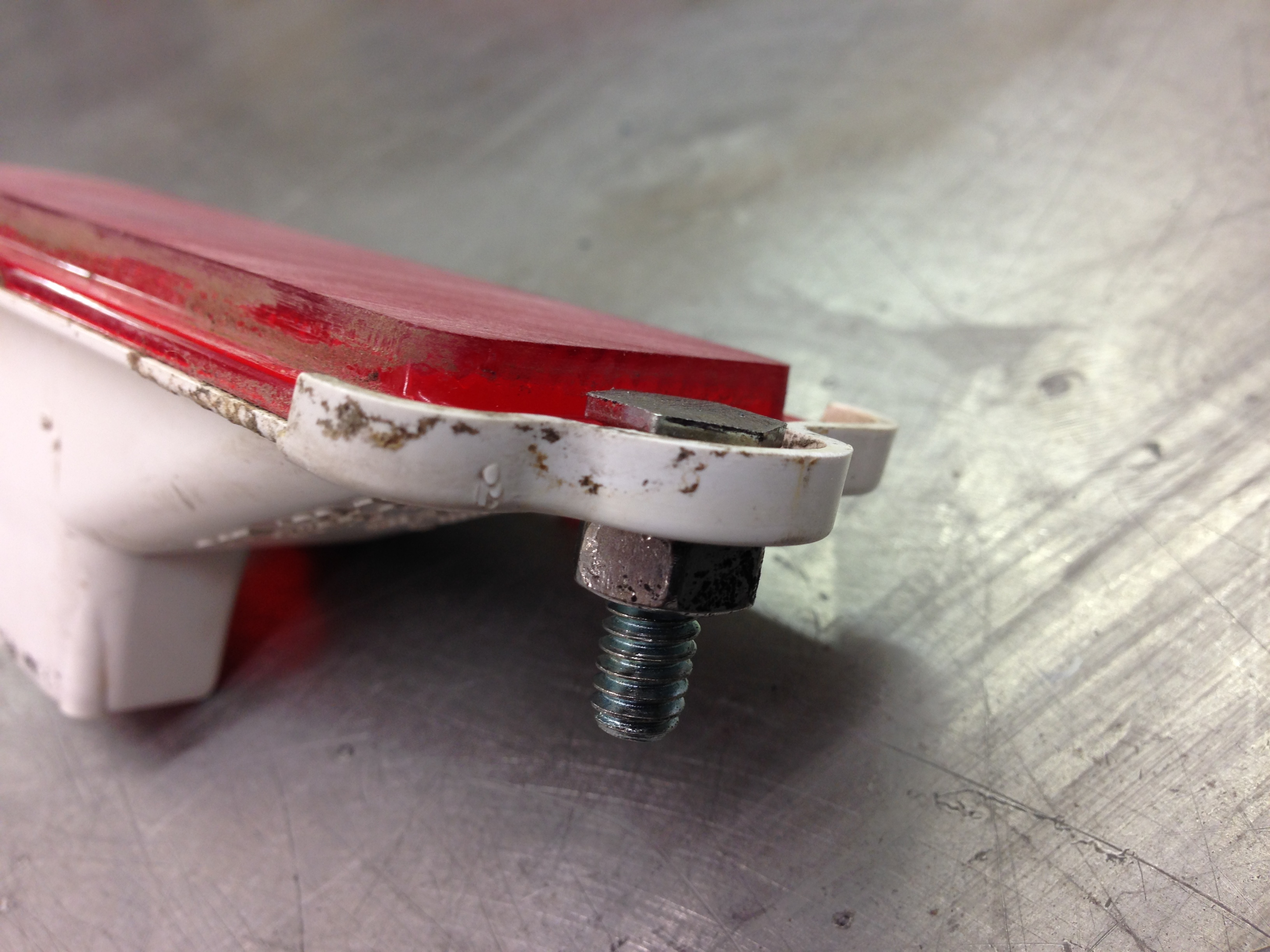

The way the marker lights mount on these "A" body Cutlasses leaves much to be desired. There's a bezel with two studs on the backside that surrounds the light, then the assembly sits in a recess in the quarter panel. Two speed nuts fasten the assembly from inside the trunk, sandwiching the light in between the bezel and quarter panel.

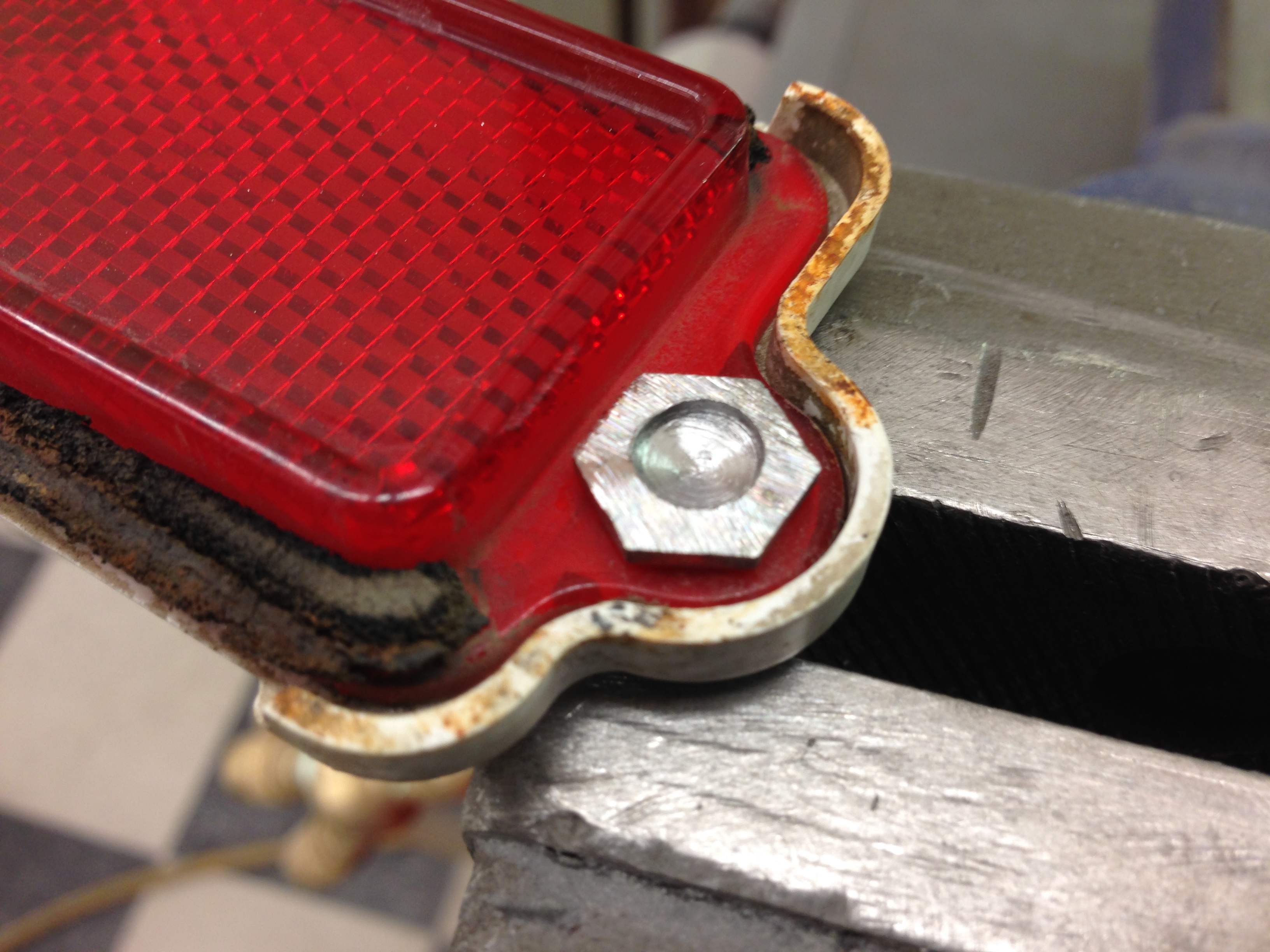

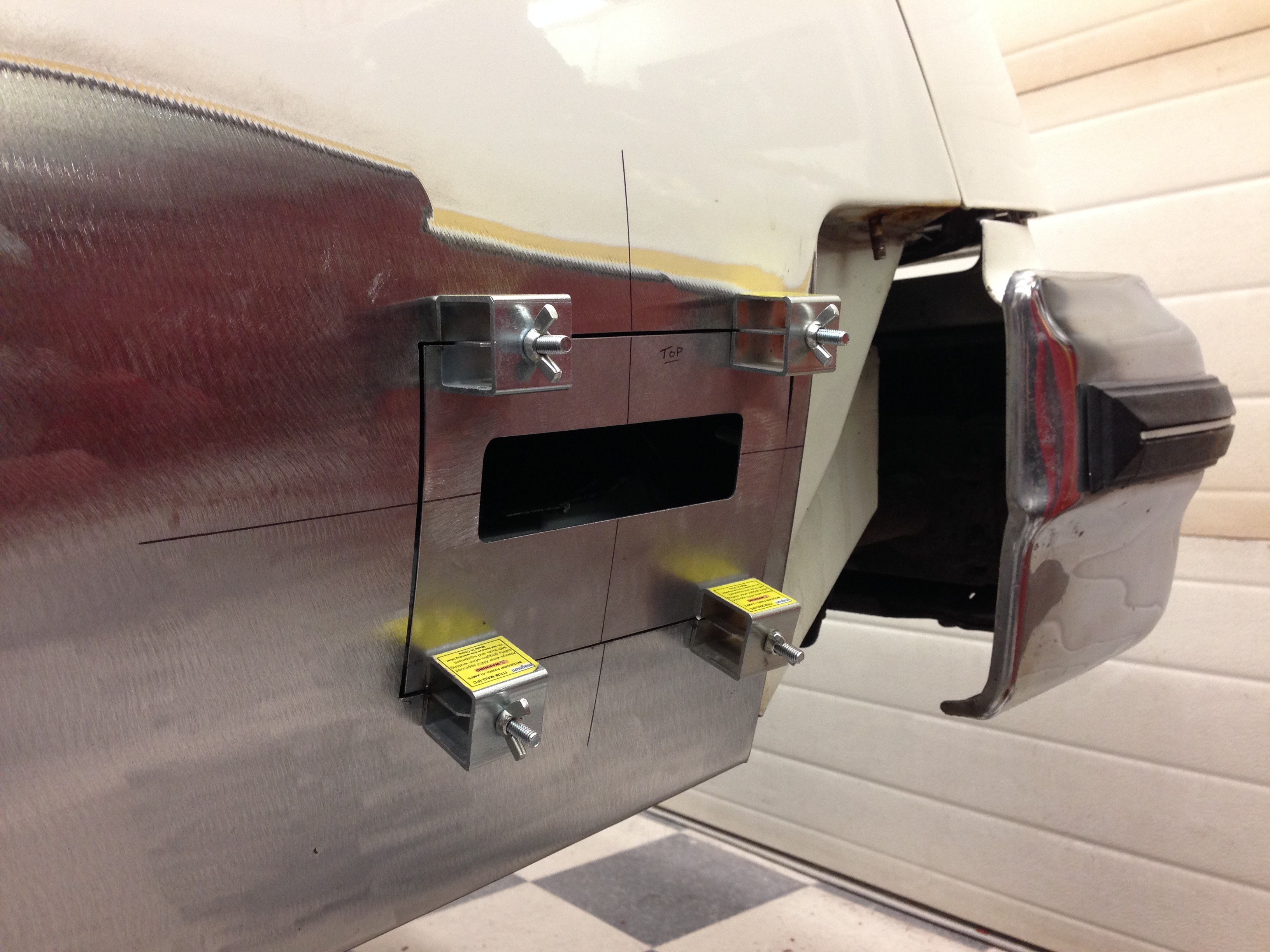

Invariably tho, some ham fisted monkey decides that tight is never really tight enough, cranks it right down, and ends up horseshoeing the bezel:

This is bad not only because it looks terrible, but it also allows water to get underneath the bezel causing the kind of rust damage you see above.

Rather than be satisfied with repairing and duplicating what the factory did, I thought there was a better way that would look nicer. I should mention here too that this is a "stock style" build, so I didn't want to shave them altogether like I did on The Juggernaut. I will likely give this car to my girlfriend after the Juggernaut is done so that we can take both cars to shows so that people can see the difference between "almost stock", and "not at all".

Lol

I also want her to remain legal, so the marker lights have to stay.

Anyways.

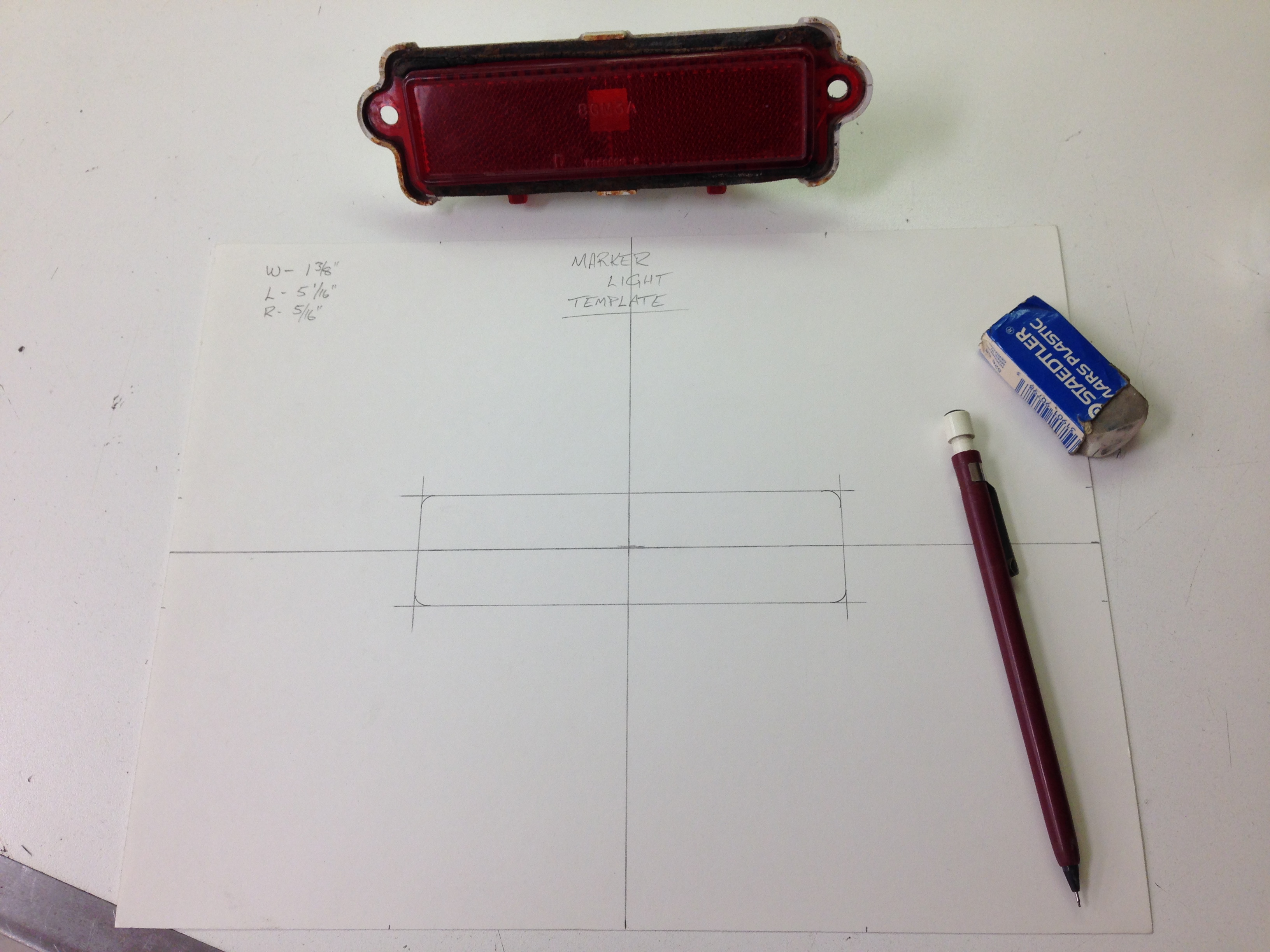

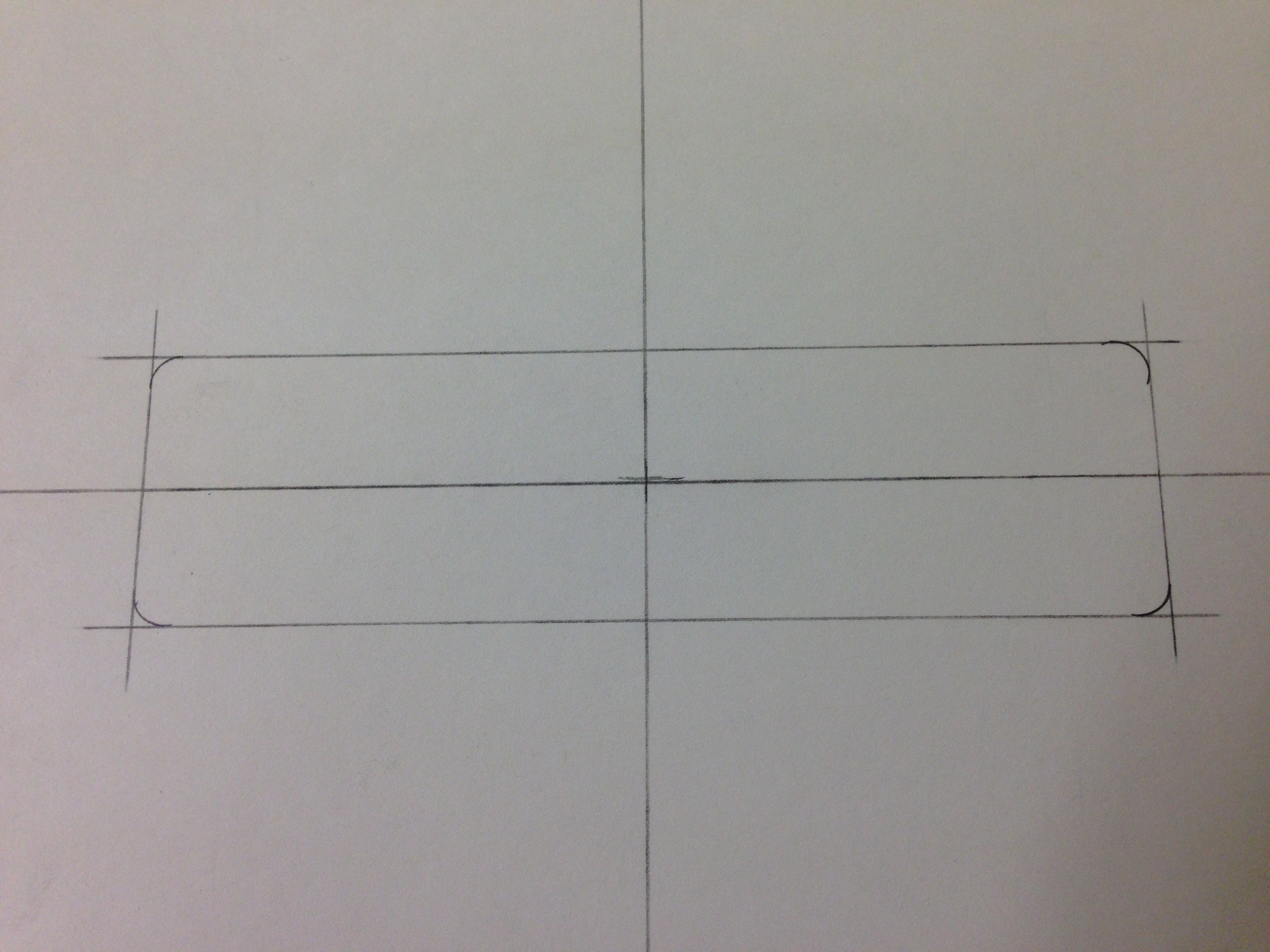

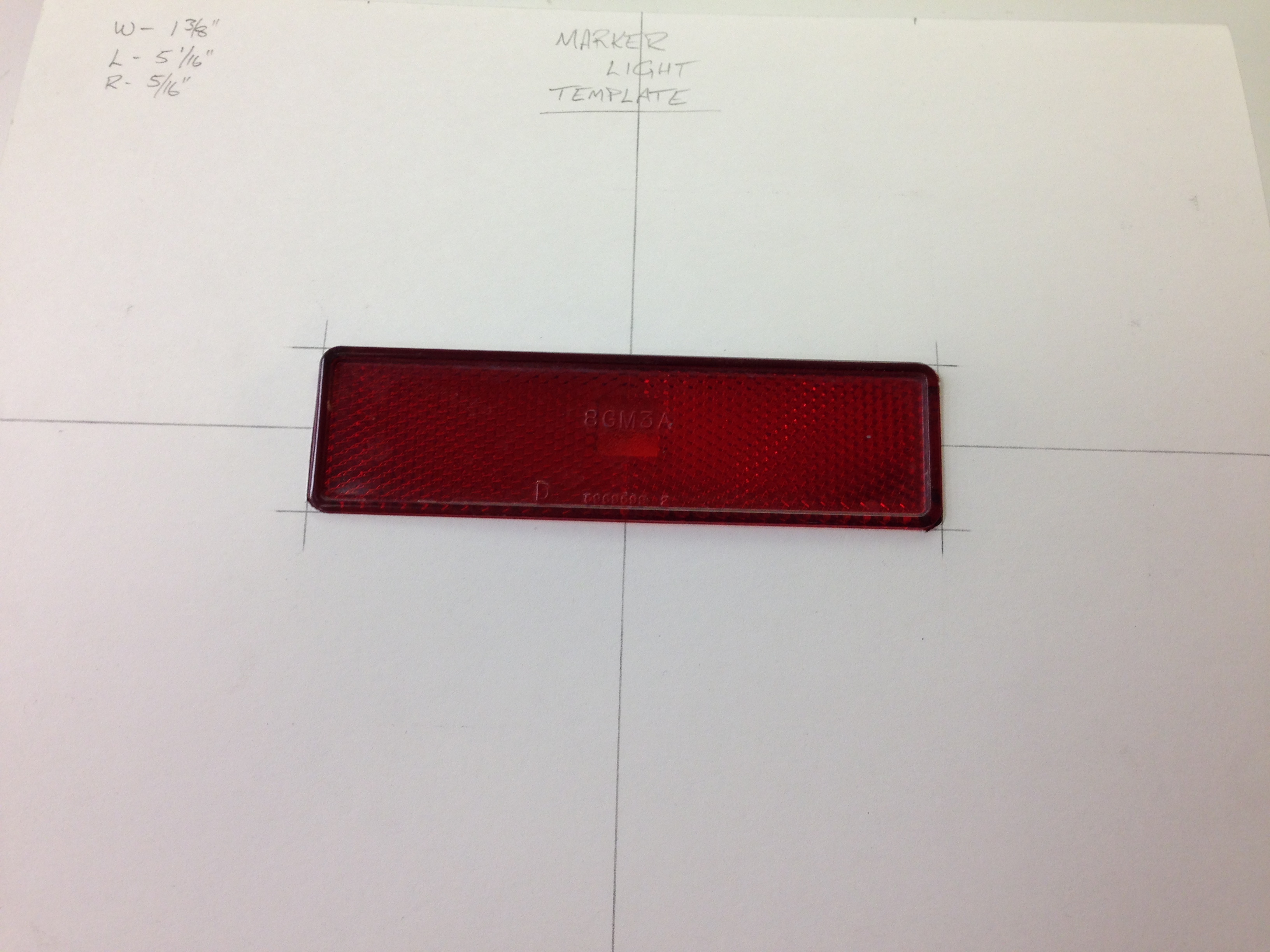

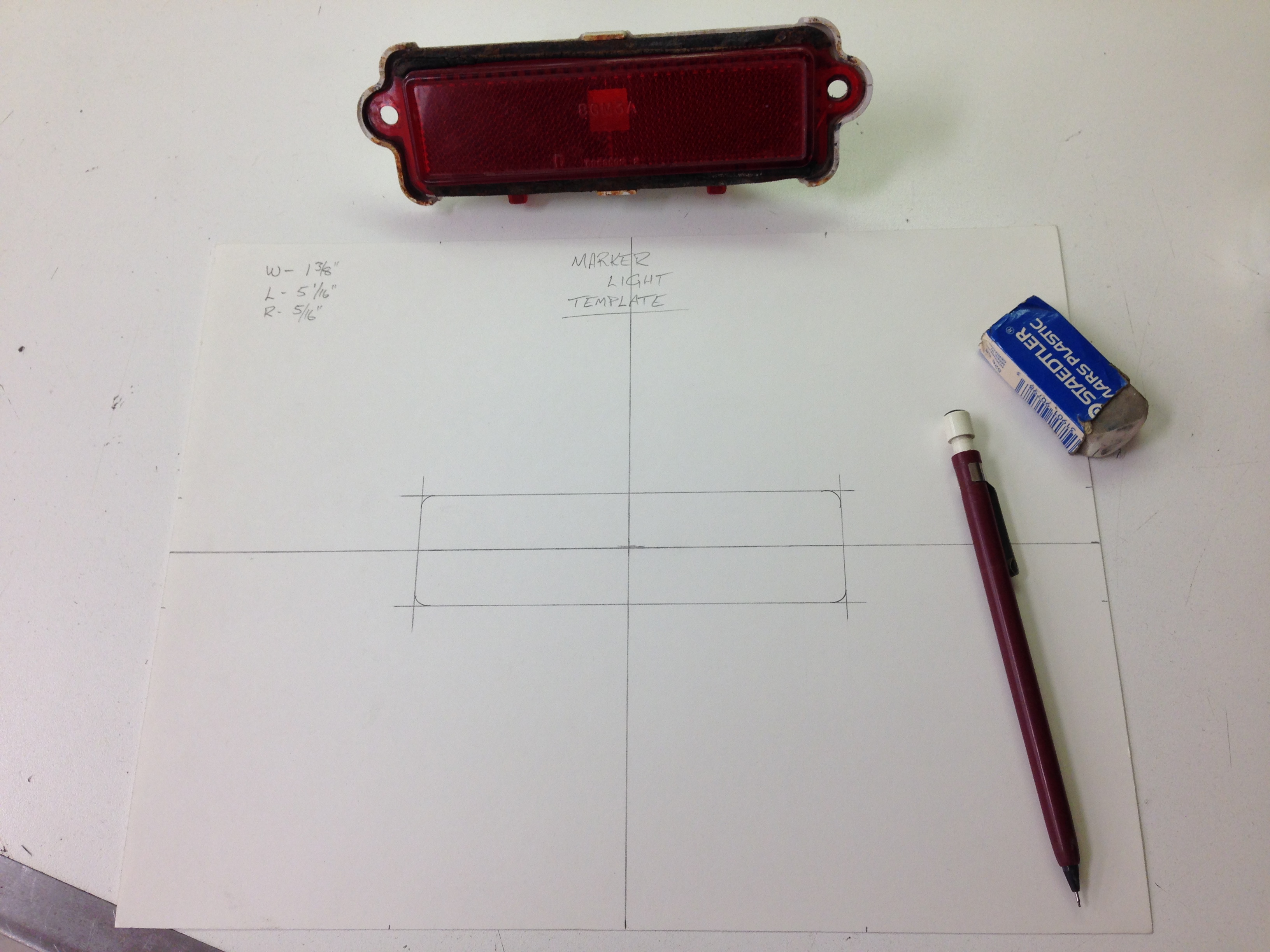

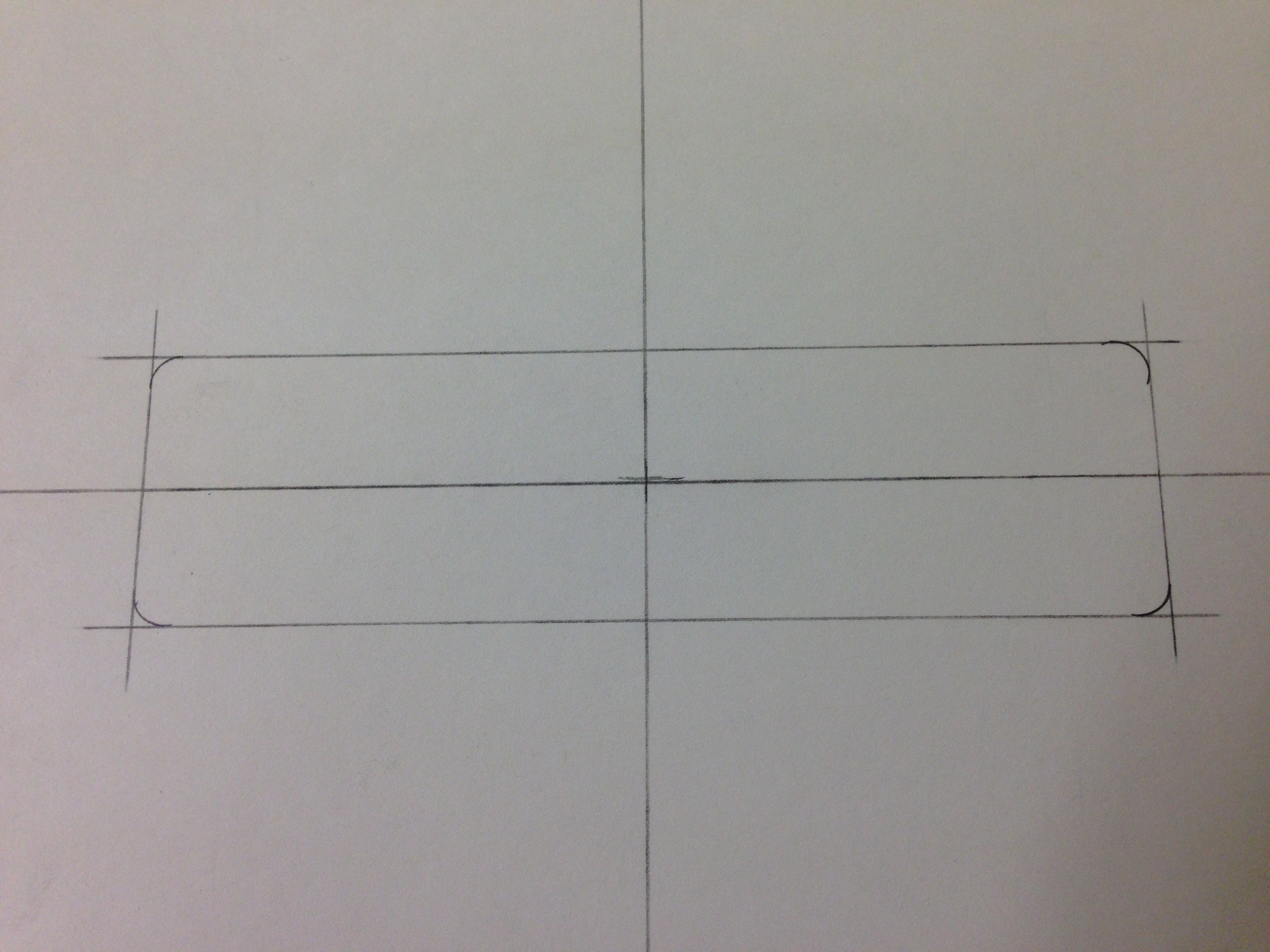

Starting with a fresh sheet of shirt cardboard and the dimensions of the light, I drafted up a template:

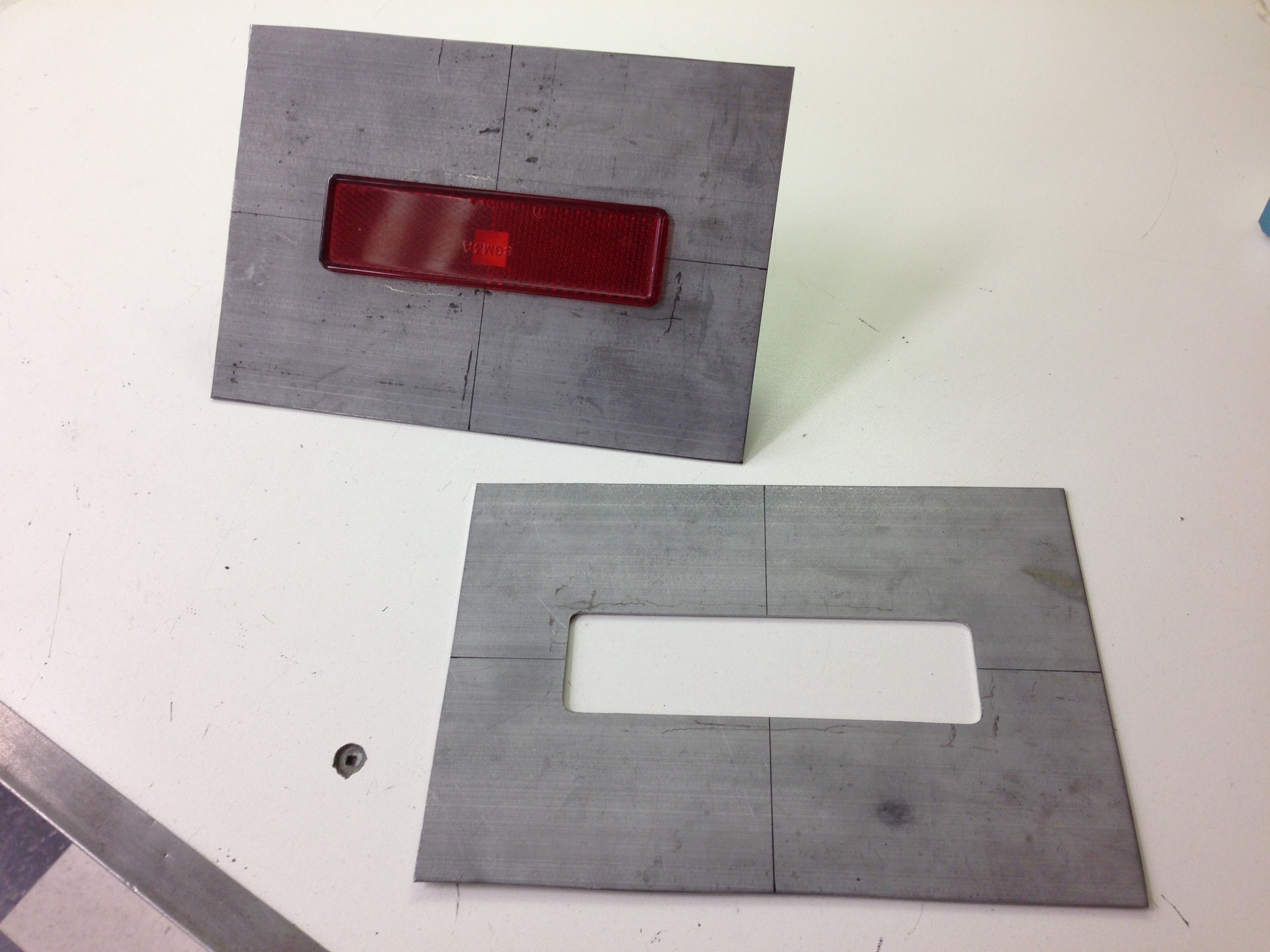

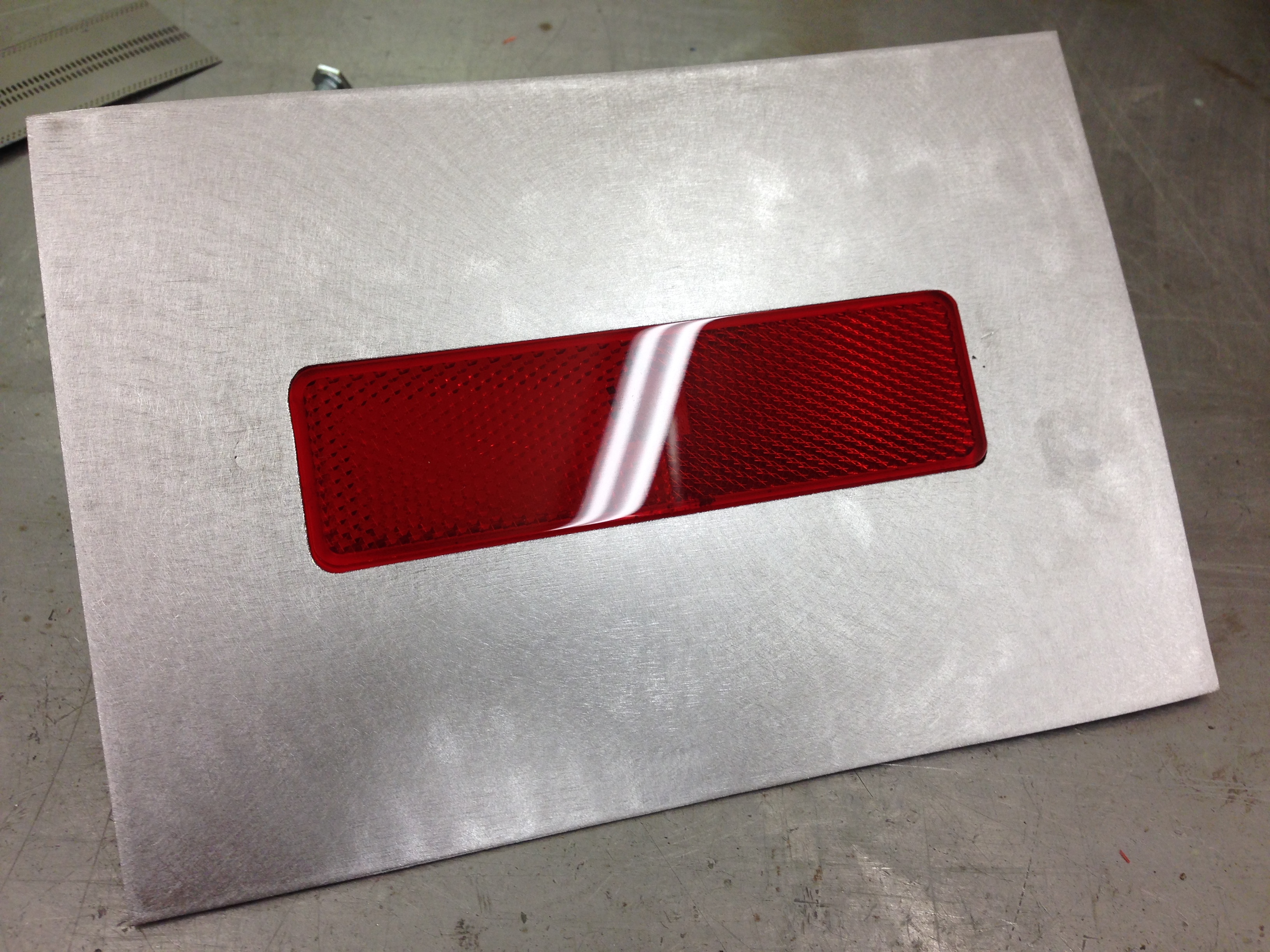

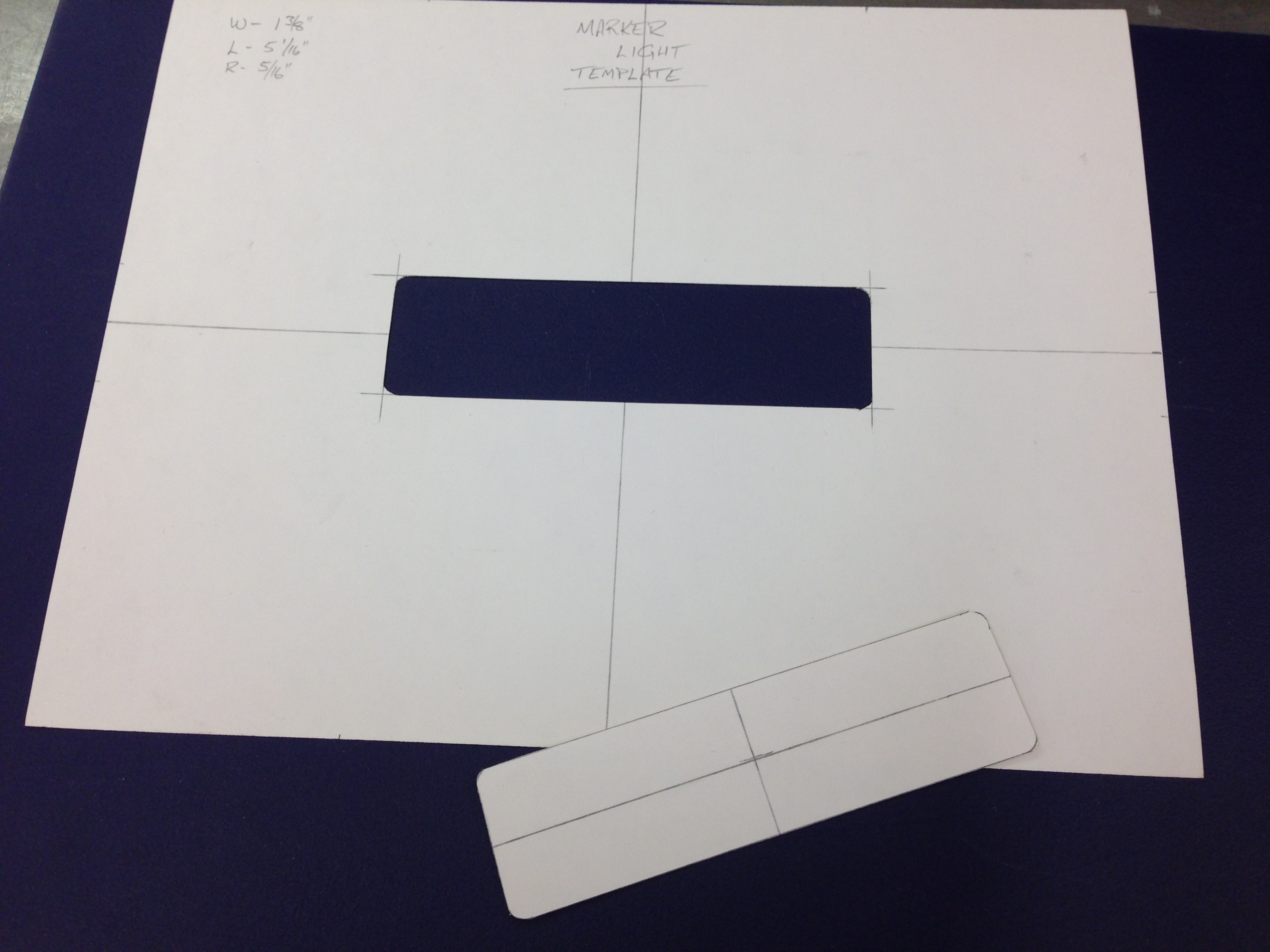

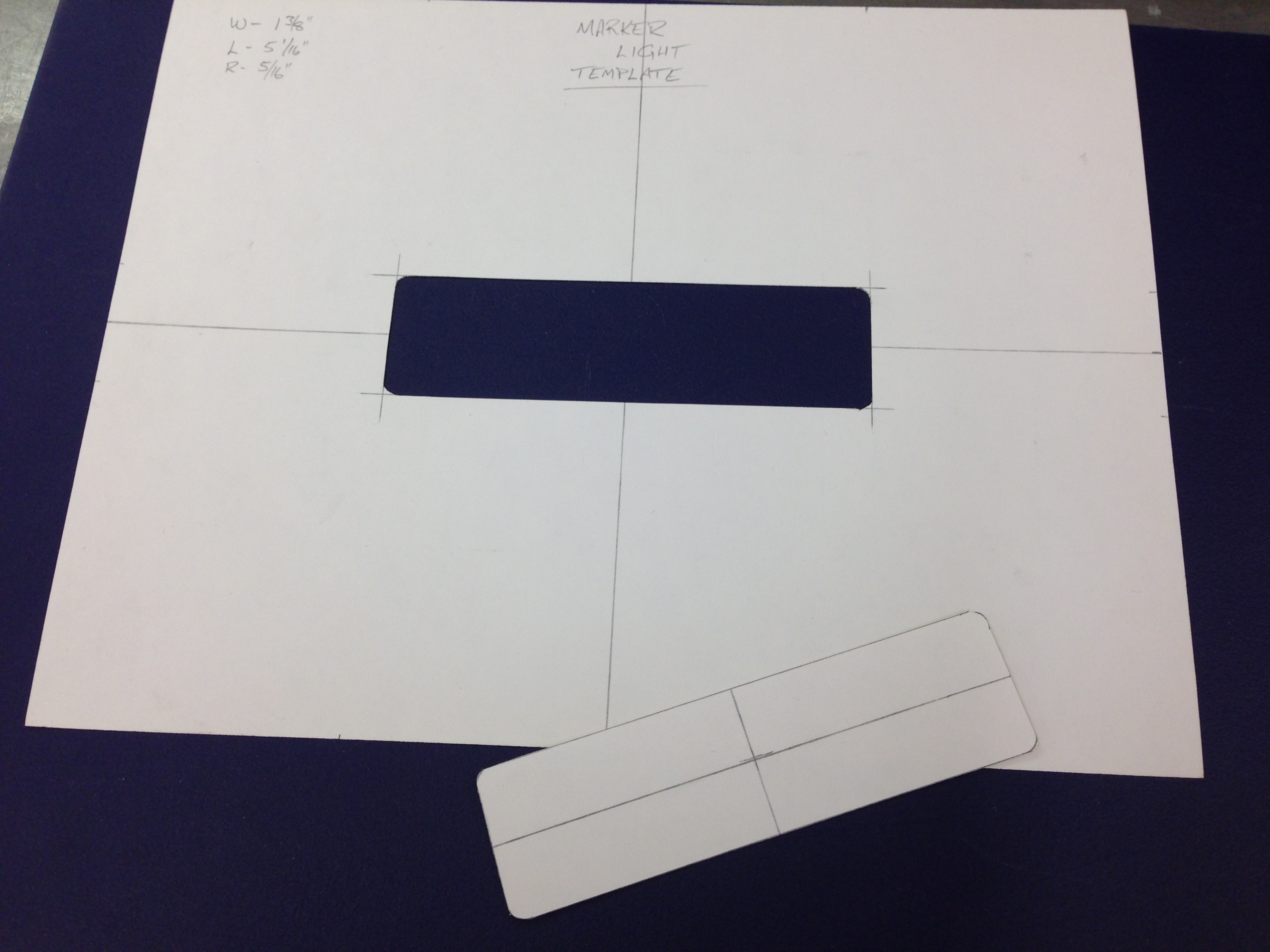

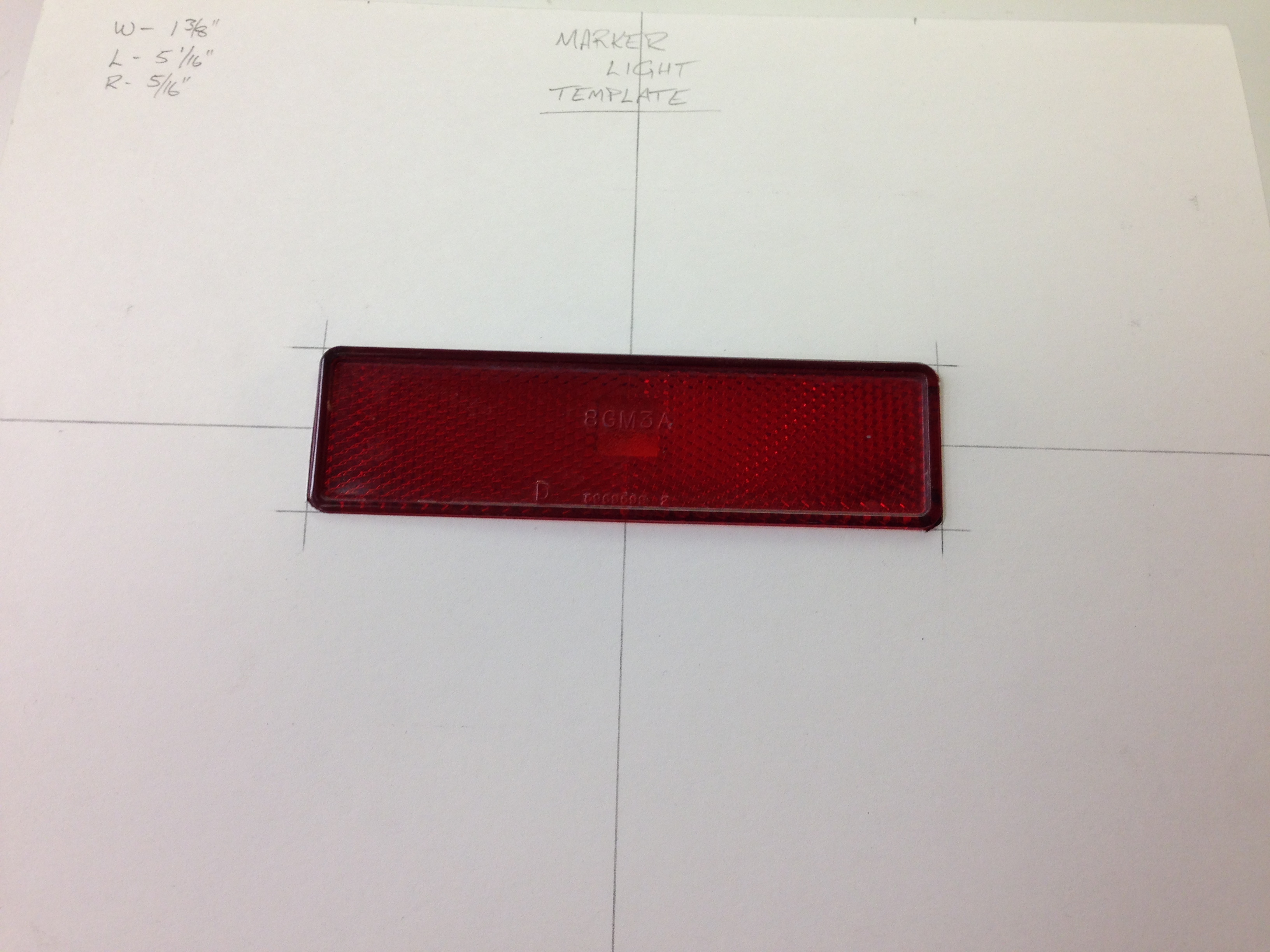

Once drawn up, I cut out the center and test fit the light to ensure it was a good fit:

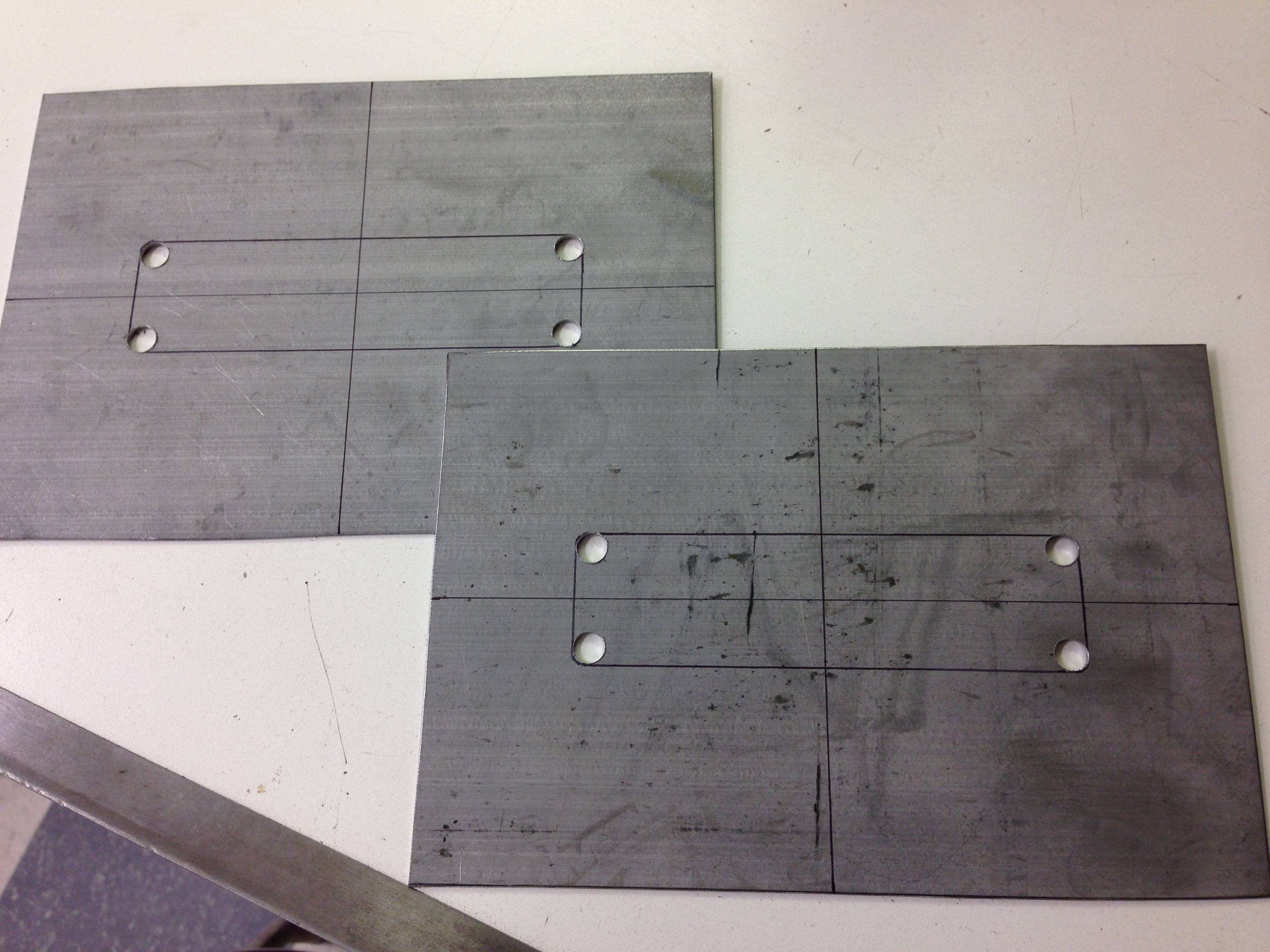

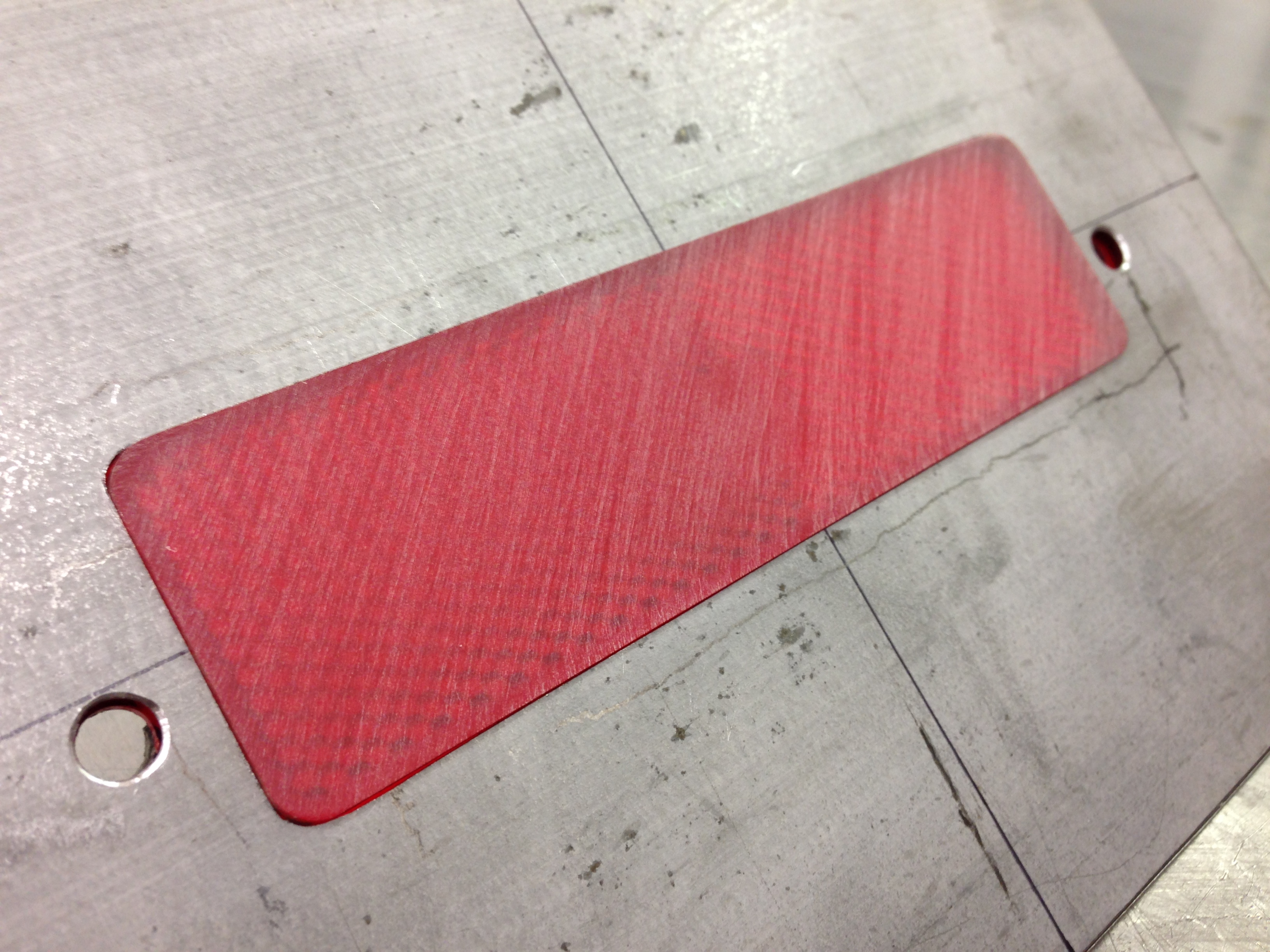

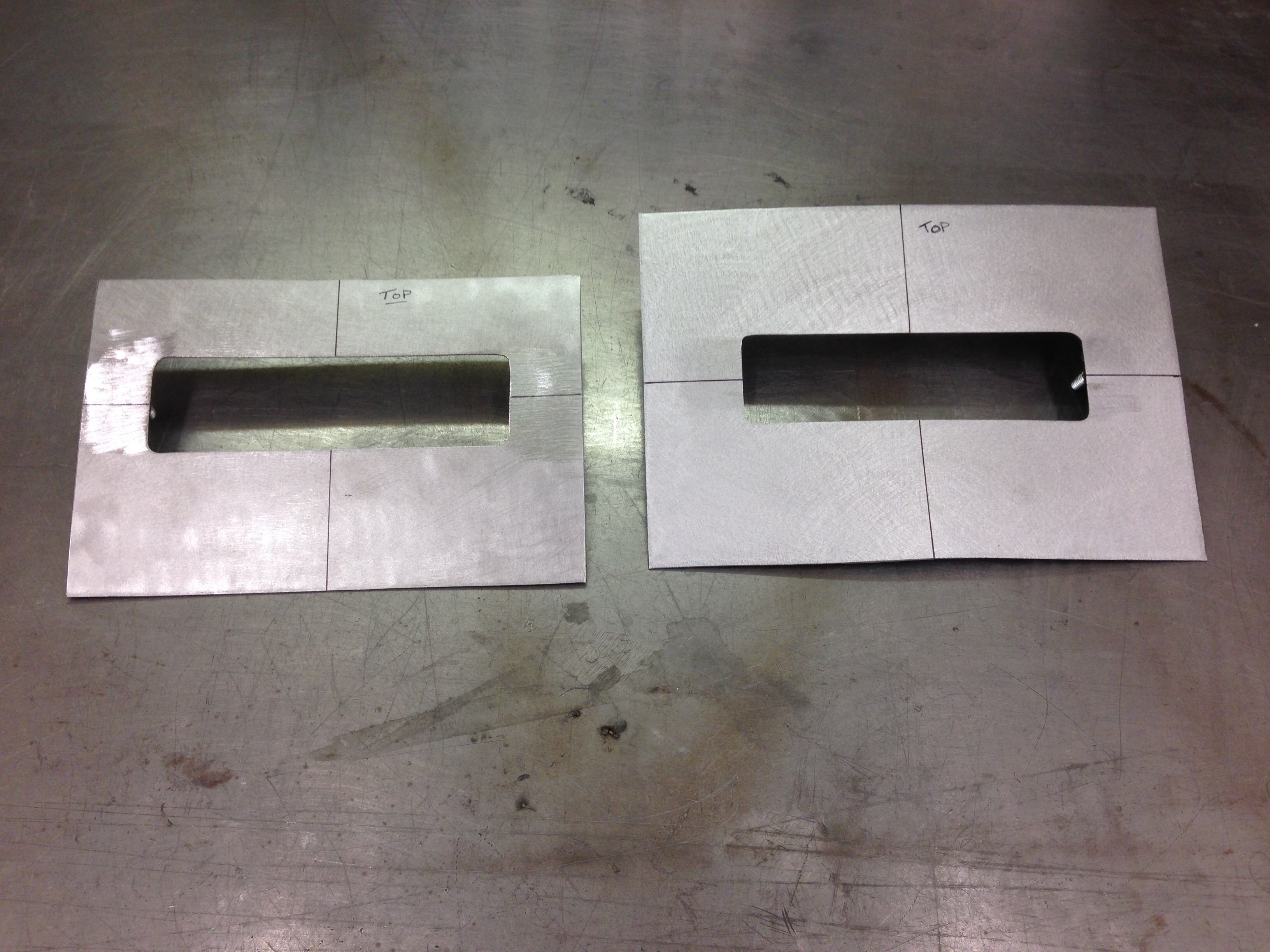

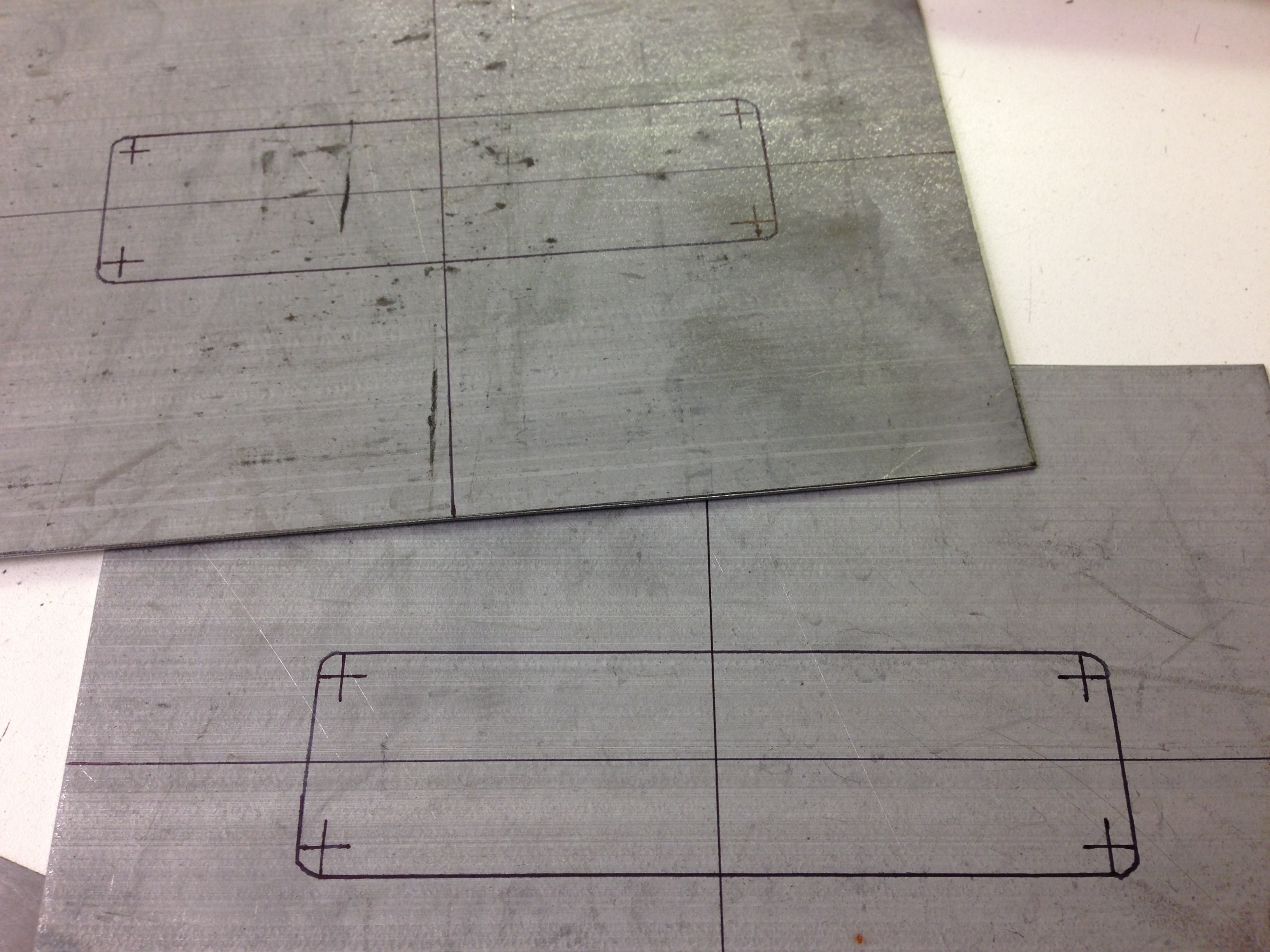

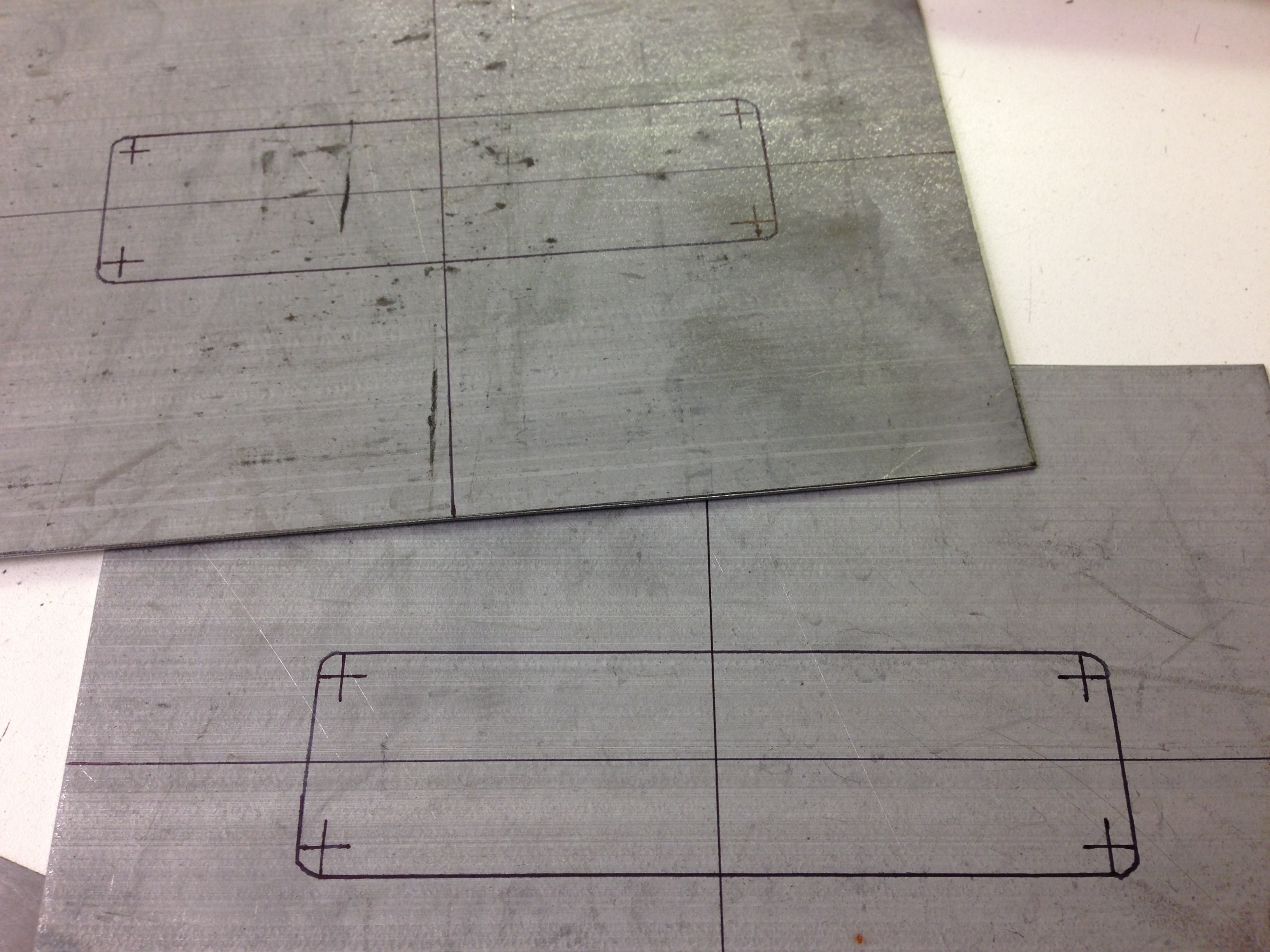

Happy with the fit, I cut two equal sized pieces of 20 gauge sheetmetal, and transferred the opening shape onto them. I also laid out the centers of the holes I'd need to make the radiuses in the corners:

Continued >>>

I'm still hard at work on the car, continuing with filler and blocking work on the driver's side sail panel. It's coming along alright, but I needed a bit of a break from all the dust and mess.

So Tuesday night, I did another massive cleanup and blow out of the car and garage again. This is how the car currently looks after the dust settled (literally!):

Nothing to write home about, but at least its progress.

Thinking to the very near future, and having the luxury of a clean garage again, I decided it was a good time to start making some patch panels to repair the rusty areas around the rear marker lights in the quarter panels before I returned to making more dust.

They're both in poor shape, and in dire need of fixing.

This is the passenger's side...

...and this is the driver's with the light and bezel removed:

Like I said, in dire need of fixing. I guess I'm actually fortunate to catch it at this stage, it's not too far gone yet where it's un-repairable.

I know some of you guys dig it when I get into my creative and customizing mode, so I think you're gonna like this.

The way the marker lights mount on these "A" body Cutlasses leaves much to be desired. There's a bezel with two studs on the backside that surrounds the light, then the assembly sits in a recess in the quarter panel. Two speed nuts fasten the assembly from inside the trunk, sandwiching the light in between the bezel and quarter panel.

Invariably tho, some ham fisted monkey decides that tight is never really tight enough, cranks it right down, and ends up horseshoeing the bezel:

This is bad not only because it looks terrible, but it also allows water to get underneath the bezel causing the kind of rust damage you see above.

Rather than be satisfied with repairing and duplicating what the factory did, I thought there was a better way that would look nicer. I should mention here too that this is a "stock style" build, so I didn't want to shave them altogether like I did on The Juggernaut. I will likely give this car to my girlfriend after the Juggernaut is done so that we can take both cars to shows so that people can see the difference between "almost stock", and "not at all".

Lol

I also want her to remain legal, so the marker lights have to stay.

Anyways.

Starting with a fresh sheet of shirt cardboard and the dimensions of the light, I drafted up a template:

Once drawn up, I cut out the center and test fit the light to ensure it was a good fit:

Happy with the fit, I cut two equal sized pieces of 20 gauge sheetmetal, and transferred the opening shape onto them. I also laid out the centers of the holes I'd need to make the radiuses in the corners:

Continued >>>

Last edited: