BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

hi Donovan, Sure good to see you back in the shop, nothing like some sanding time to numb the senses a bit. Seeing you reference some high spots that mysteriously manifested, I just wanted to share a little thing we ran into while blocking the front fenders on my Monte. The inner fender wells were not installed at this stage because why would you. Once the guys started to block sand, the fenders started flexing, causing the bodyman to become somewhat agitated (pissed off). Installed inner fenders and flex problem disappeared. Kind of the same type of issue when blocking the cowl hood. When the hoods are built, foam (goop) is placed in the spaces between the inner and outer skins of the hood for support. Ever so slightly these spots can push up a bit more than other welded spots (pulled down). This will be evident when you first start sanding the hood. The shiny bare metal spots lined up directly above the foam placement under the hood. Thin metal can play lots of tricks on you. Once again, good to see you back at it!

I’ve been a production painter for years and we use an ez edger to fold 3/4 masking tape for door jambs. When you put the tape in there properly it gives a softer edge than the foam. Sometimes the foam can leave a jagged edge from the paint build up. Some prep guys I know can fold the tape this way with their hands but unfortunately I can’t.

https://www.amazon.com/dp/B00BD455NE/?tag=gbody-20

I’m familiar with that method as well, and if done correctly it can yield very good results. But if done incorrectly, it can turn out pretty ugly.

I too lack the skill set to do it that way properly most of the time too unfortunately, I absolutely despise masking at the best of times. I’m more of a “get through it as quickly as possible and move on” kinda guy that way.

Thanks for the link, but it’s highly unlikely that I’m going to purchase one just for hobby/home work.

Get some REST man!

Your killing me......I can't keep up this pace.

That’s the one thing I can’t do. I’ve got an upcoming deadline for use of a state of the art paint booth that I’m striving hard to make, and slowing down isn’t in the realm of possibility.

In fact if anything I’m finding my pace to be maddeningly slow as it is!

hi Donovan, Sure good to see you back in the shop, nothing like some sanding time to numb the senses a bit. Seeing you reference some high spots that mysteriously manifested, I just wanted to share a little thing we ran into while blocking the front fenders on my Monte. The inner fender wells were not installed at this stage because why would you. Once the guys started to block sand, the fenders started flexing, causing the bodyman to become somewhat agitated (pissed off). Installed inner fenders and flex problem disappeared. Kind of the same type of issue when blocking the cowl hood. When the hoods are built, foam (goop) is placed in the spaces between the inner and outer skins of the hood for support. Ever so slightly these spots can push up a bit more than other welded spots (pulled down). This will be evident when you first start sanding the hood. The shiny bare metal spots lined up directly above the foam placement under the hood. Thin metal can play lots of tricks on you. Once again, good to see you back at it!

Thanks Brian.

I’m very familiar with the factory applied adhesive “dots” that are between the inner structure and outer hood skin. I had to cut through all of them to separate the hood skin when I built the custom hood for The Juggernaut. And yes you’re absolutely right, having adequate support for all the panels in place is a necessity before you start block sanding. Another reason Olds Cool will be as assembled as possible before blocking out the high build and painting.

Managed to put some work in on the car this weekend.

Sunday I put Mike to task on stripping all the old paint off of the front bumper filler panel. He has already completed doing the same to the fender to bumper fillers, so this was the next logical progression. It’s all gotta be done at some point anyways. He got a decent start on it, but I finished it up for him later that evening.

I’ve said it before when I did the rear quarter fillers, but the material these things are made of is really odd. It’s like a rubbery plastic, and sanding it is like trying to sand bubblegum. Not very easy to say the least.

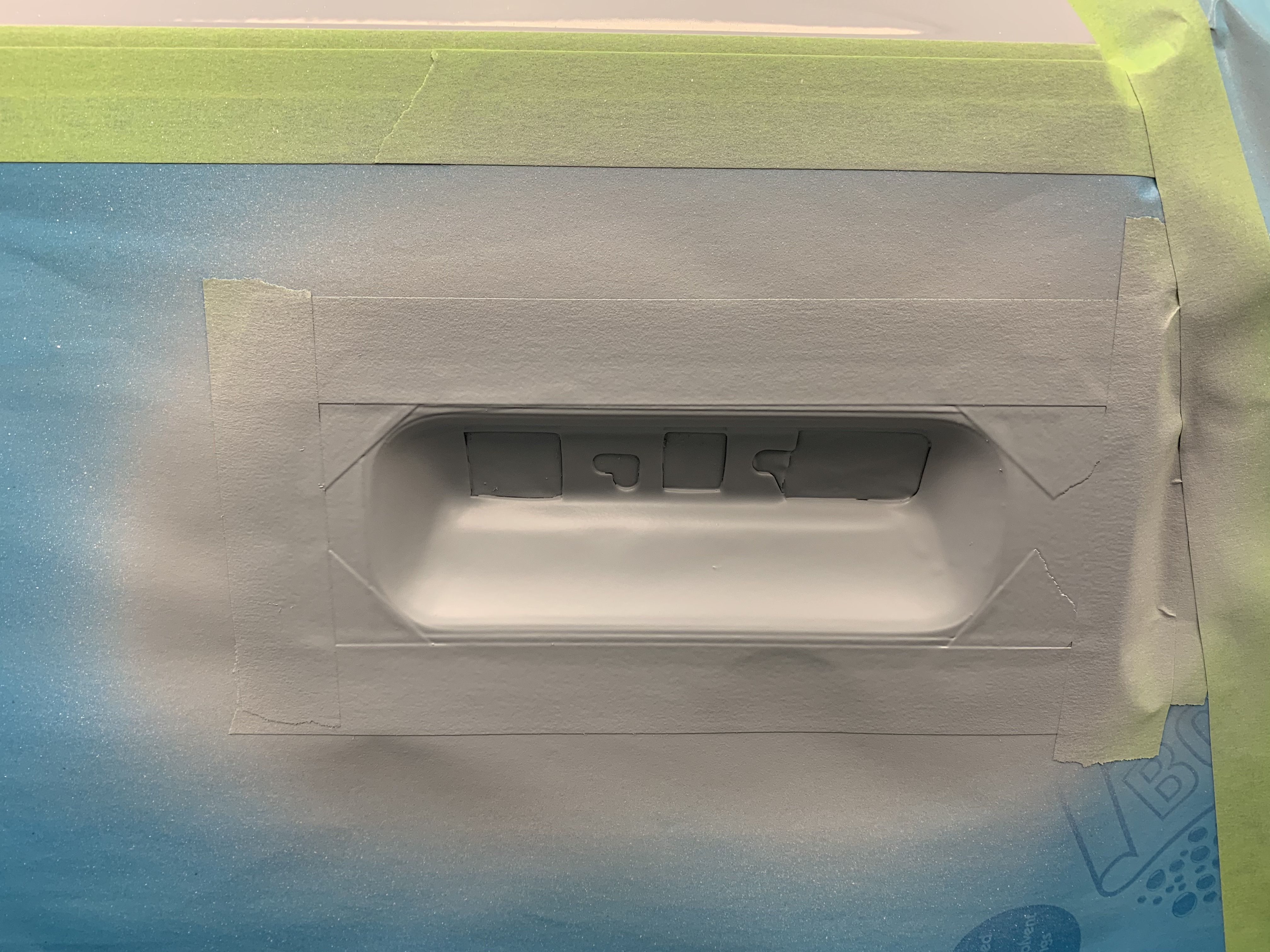

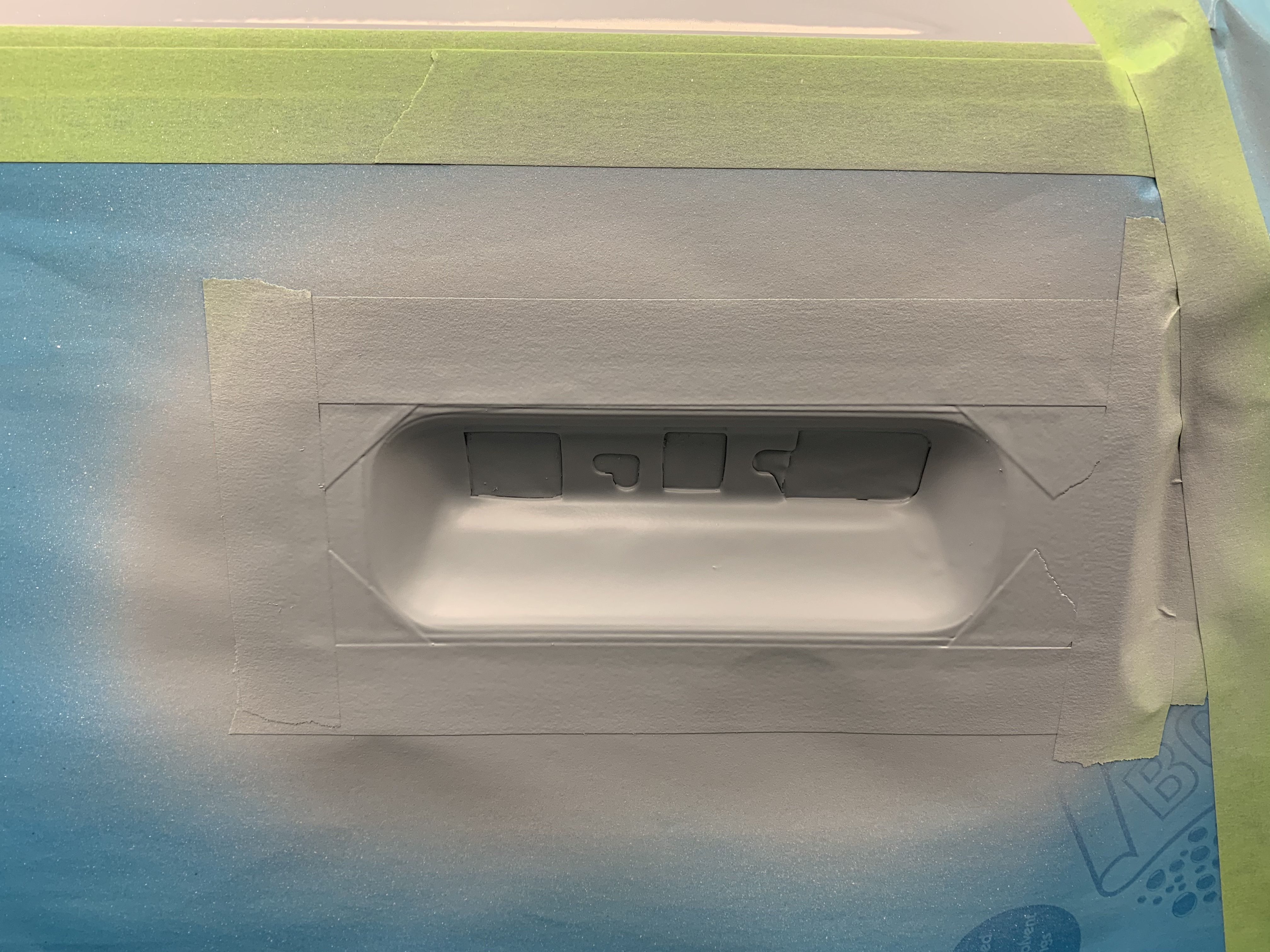

While Mike was doing that, I masked up the top of the driver’s door and shot epoxy and high build primers on the repair and door handle recess:

After letting it cure overnight, Monday morning I blocked it out with 220, 320 and 400 all the way back into the unrepaired section. It all went extremely well.

Repair? What repair??

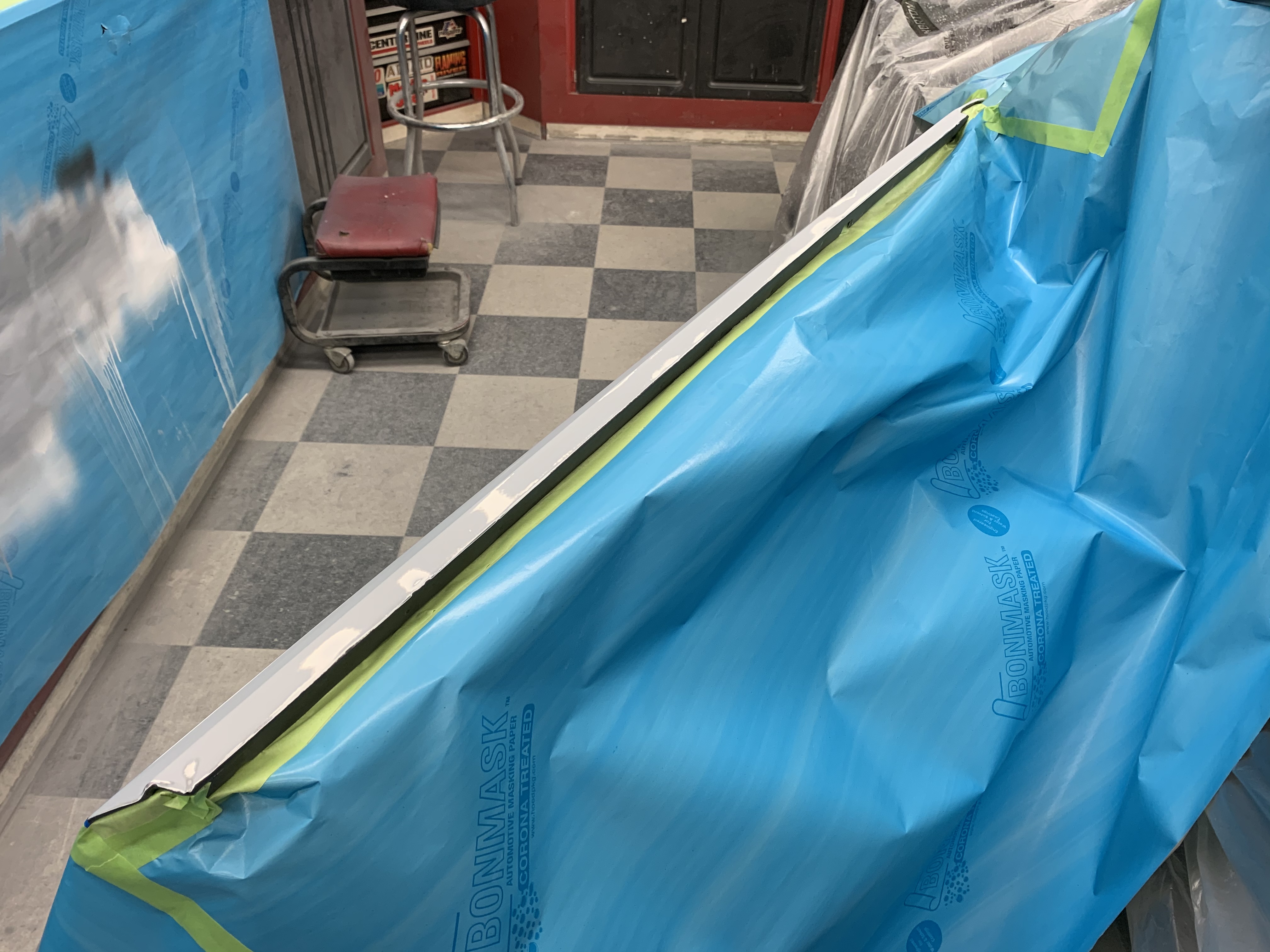

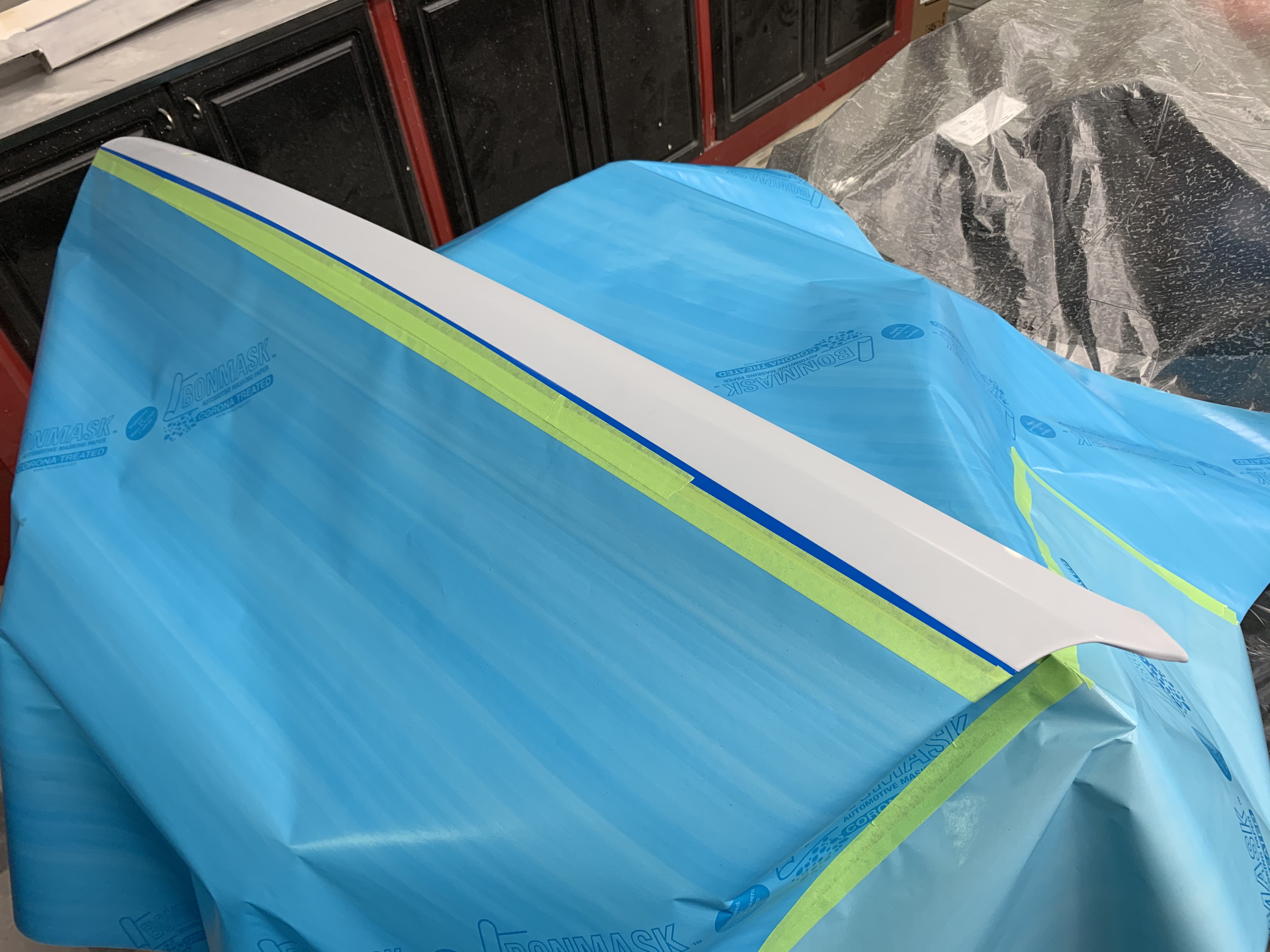

Once that was completed, I set about masking it up once more, done this time a little differently for paint:

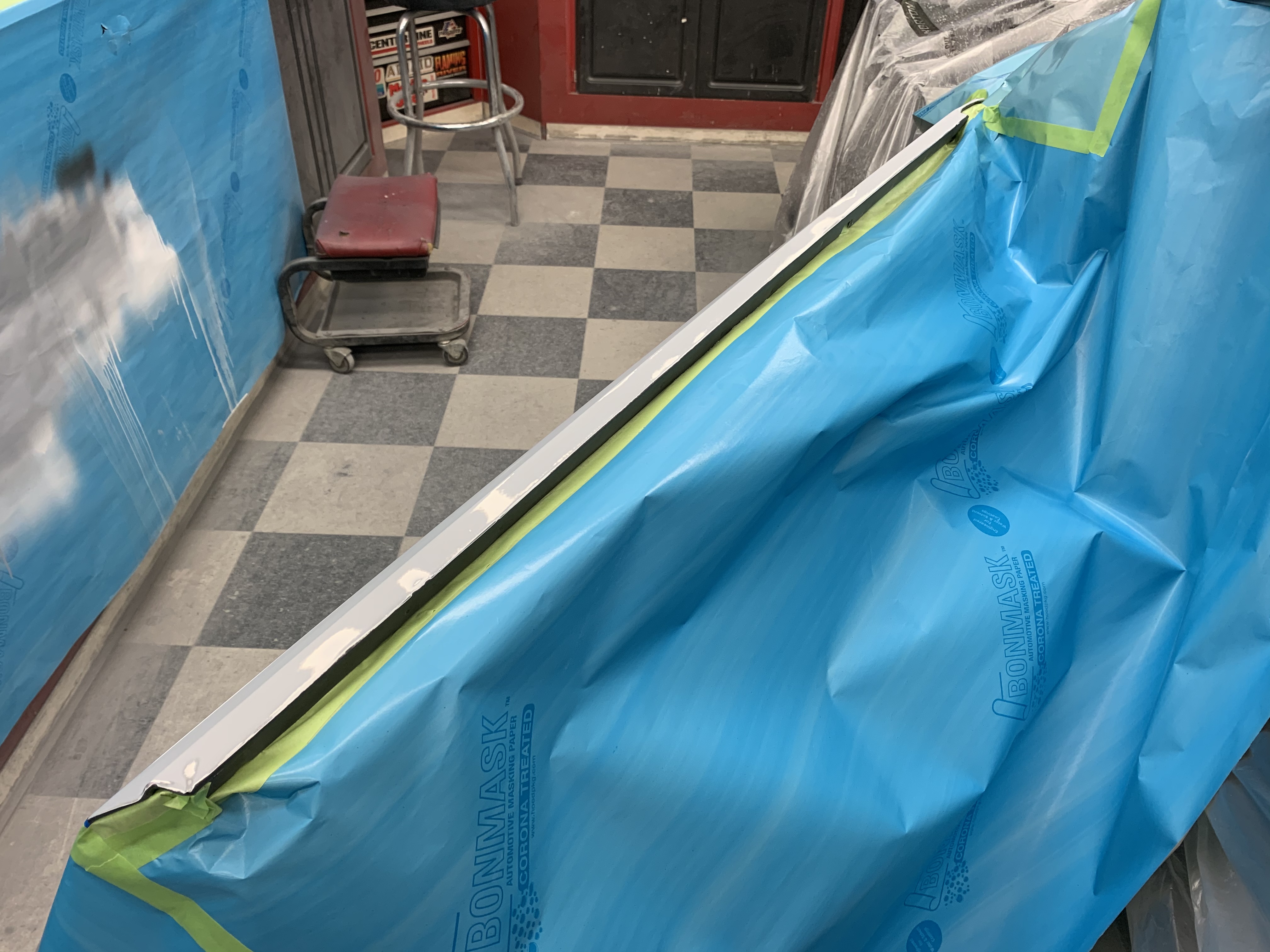

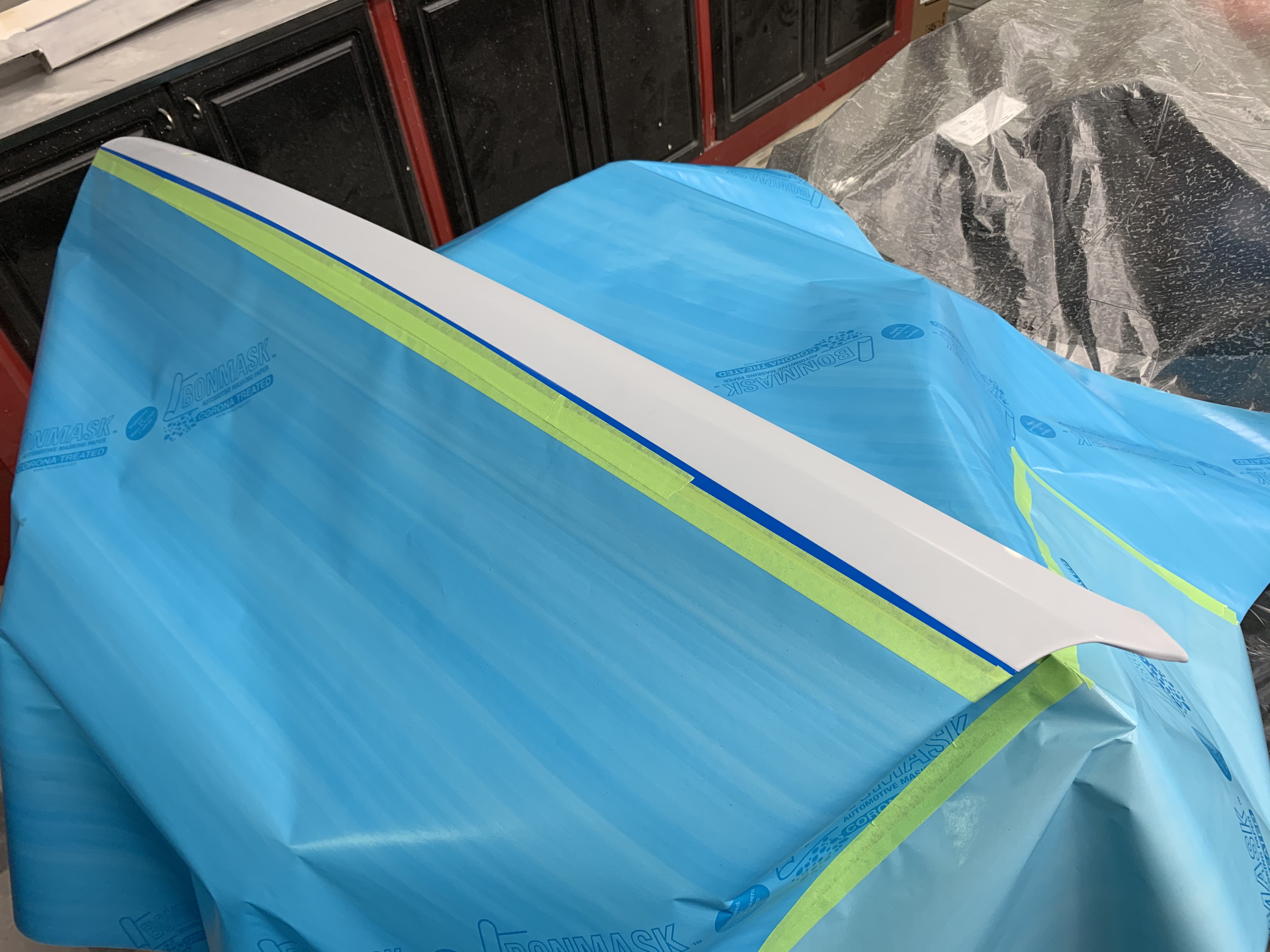

The fender needed the same treatment, and it occurred to me that you guys probably don’t see what goes into taping off all these difficult areas I complain so much about. So here’s a couple of pics as I was going about this tedious chore:

Once I had all the holes and voids covered over and the perimeter taped off, papering the rest was relatively easy in comparison. All the masking for the upper two tone on the door and fender are now done.

Tomorrow after dinner, I’ll give these one last wipe down with wax and grease remover, and a light once over with the tack rag. Then it’ll be time to play amateur chemist and mix up some Sterling grey and get these shot.

We’re back on track again gents!

Until then,

D.

Sunday I put Mike to task on stripping all the old paint off of the front bumper filler panel. He has already completed doing the same to the fender to bumper fillers, so this was the next logical progression. It’s all gotta be done at some point anyways. He got a decent start on it, but I finished it up for him later that evening.

I’ve said it before when I did the rear quarter fillers, but the material these things are made of is really odd. It’s like a rubbery plastic, and sanding it is like trying to sand bubblegum. Not very easy to say the least.

While Mike was doing that, I masked up the top of the driver’s door and shot epoxy and high build primers on the repair and door handle recess:

After letting it cure overnight, Monday morning I blocked it out with 220, 320 and 400 all the way back into the unrepaired section. It all went extremely well.

Repair? What repair??

Once that was completed, I set about masking it up once more, done this time a little differently for paint:

The fender needed the same treatment, and it occurred to me that you guys probably don’t see what goes into taping off all these difficult areas I complain so much about. So here’s a couple of pics as I was going about this tedious chore:

Once I had all the holes and voids covered over and the perimeter taped off, papering the rest was relatively easy in comparison. All the masking for the upper two tone on the door and fender are now done.

Tomorrow after dinner, I’ll give these one last wipe down with wax and grease remover, and a light once over with the tack rag. Then it’ll be time to play amateur chemist and mix up some Sterling grey and get these shot.

We’re back on track again gents!

Until then,

D.

Now that tape work is the finest OCD work I've seen done. That will be the separation between getting it done & getting it done right.

Donovan you must have the patience of a saint. Your taping is a work of art

So, when can I drop off my 78?

Bring ‘er on by on the eleventeenth.

I see what you mean by tedious Donovan. You must use alot of tape and masking paper.

Similar threads

- Replies

- 25

- Views

- 2K

- Replies

- 15

- Views

- 1K

- Replies

- 1

- Views

- 378

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.