Yes. The replacement piece. Slow going for sure!So the piece you're working on is the replacement roof panel. You're trying to peal the skin off of the structure to ready it for the grafting process. I guess it will take some time and patience, but it will be worth it. Thanks for sharing the pics.

roof rot malibu

- Thread starter malibujustin

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Thanks for the tips!!!!As for the clips that hold trim you need 5 for the top trim.

If your Dad was a welder then he might know how to shrink metal to get it straight again, a lot of body shops do it. Simple but takes hours, heat it with a torch then with a wet rag with ice cubes in it put it directly on the spot you just heated up, you do this after the seam is completely welded of course.

Also it will help if you put a lap joint in the new connecting metal to slide under the old existing roof, it will help with both the welding an to help keep it straight. There is a tool that goes on the end of a air hammer that makes the little channel, its cheap.

Once your done welding it together put a layer of Metal bondo(Aluminum grindings) stuff gets rock hard even against a grinder, so just a thin layer an then finish off with normal bondo if needed.

Just some ideas for you !

Now I got to take the skin off car. Ughh. Got trim off windshield. Now going to take off drip rail moulding. Windshield is cracked already, so I'm going to have to get new windshield. Where is a good place to order one from? Thanks

I would first try your local auto glass dealer...I don't mean Safelite either. Make sure you get a good brand. I've used PPG on my car to replace a PPG windshield that was on there previously. I'm sure other guys will chime in to give you their recommendations.

Here's a brief thread that you might find helpful in removing your old windshield.

https://gbodyforum.com/threads/windshield-removal-on-a-1979-mailbu.56948/#post-480341

Here's a brief thread that you might find helpful in removing your old windshield.

https://gbodyforum.com/threads/windshield-removal-on-a-1979-mailbu.56948/#post-480341

I have a windshield removal tool from hf that I bought several years ago to remove windshield from my 66 malibu. Worked ok for that one. Gonna try it on this one. Thanks for the link. My dad used a piano wire to remove his windshield on his 66 super sport. I have looked online at windshield and see eckler for 144 and npd for 142. Shipping would probably kill me. Will check with a couple of local places. Thanks again

That tool works well, but using a 3" putty knife works well from the inside. Sharpen putty knive so to use it to cut, tape/fasten a 12" piece to the handle so you can push with 2 hands, then just walk the putty knife around window cutting the urethane sealer, then use your HF tool in outside, done deal.

I have used diamond wire for dehorning cattle an yes guitar strings too, but years ago. But takes 2 people.

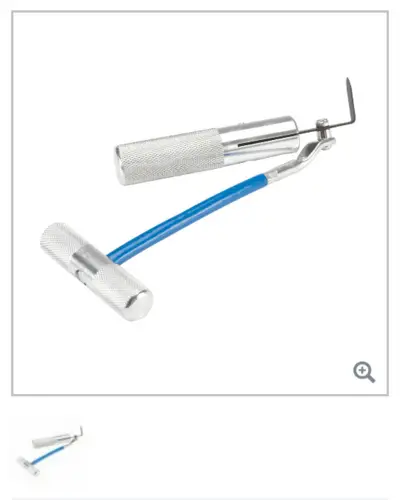

I have windshield tool like this one. HF

I have used diamond wire for dehorning cattle an yes guitar strings too, but years ago. But takes 2 people.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 109

- Replies

- 10

- Views

- 354

- Replies

- 12

- Views

- 158

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.