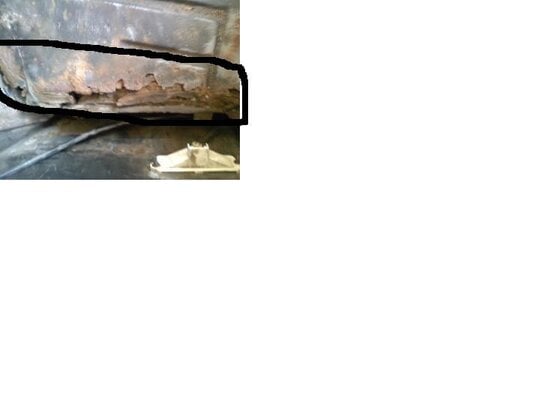

Past all the rust to clean metal. I've found it easier to replace a large section alltogether rather than trying to cut and patch irregular pieces. For example, I had some rot in my wheelwells. I just cut a big oval shaped hole which included all the rusty spots. Forming an oval shaped patch was easy, and once welded in, was as strong as the original. Same with floorboards. Why mess with little holes peppering the panel when a whole section can be cut out and replaces so much easier? Your trunk where the wheelwells intersect look like they will need serious surgery. Be prepared to go as far back as needed so when you weld in the new panels you won't be hitting more rusty metal.