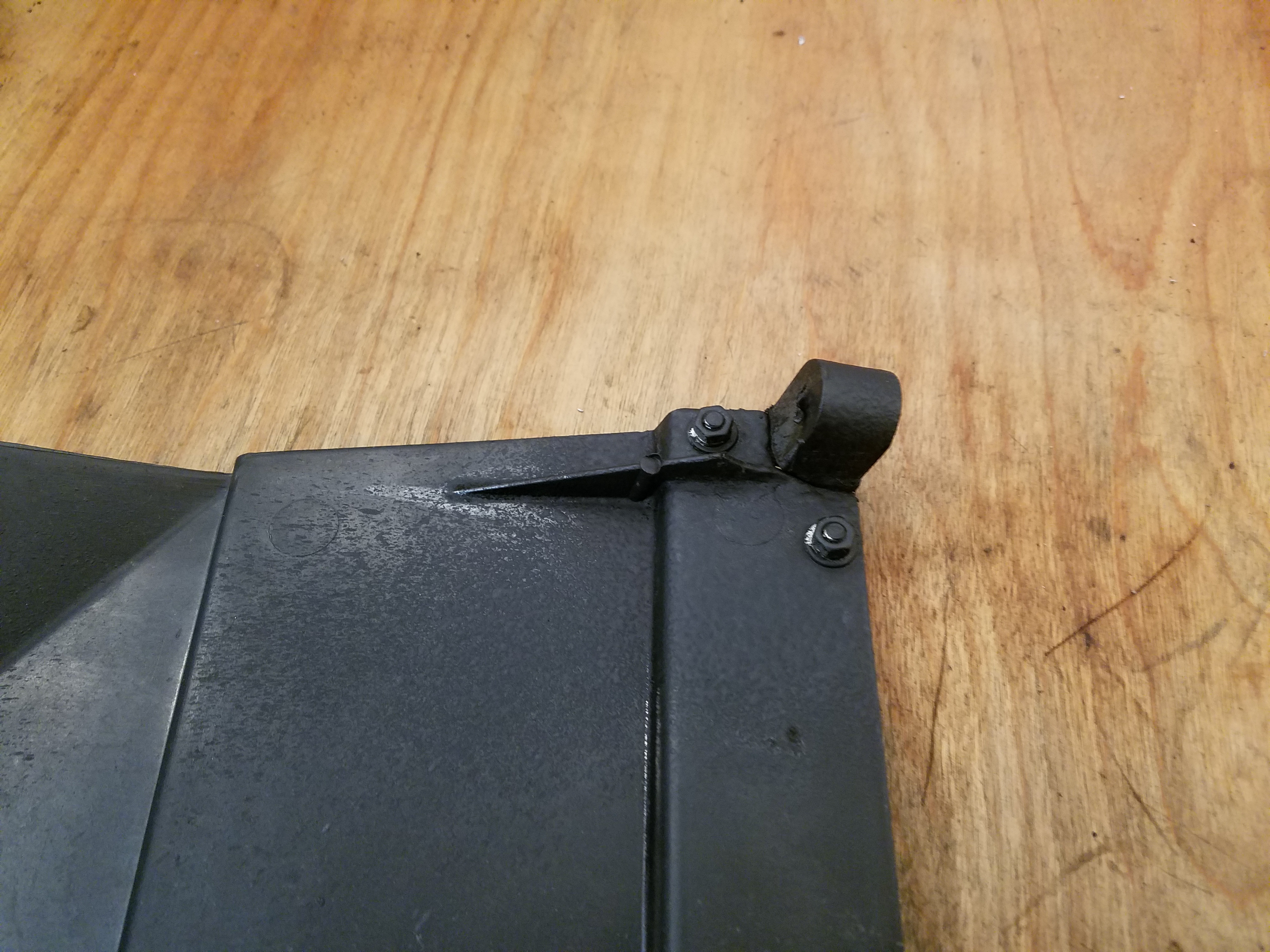

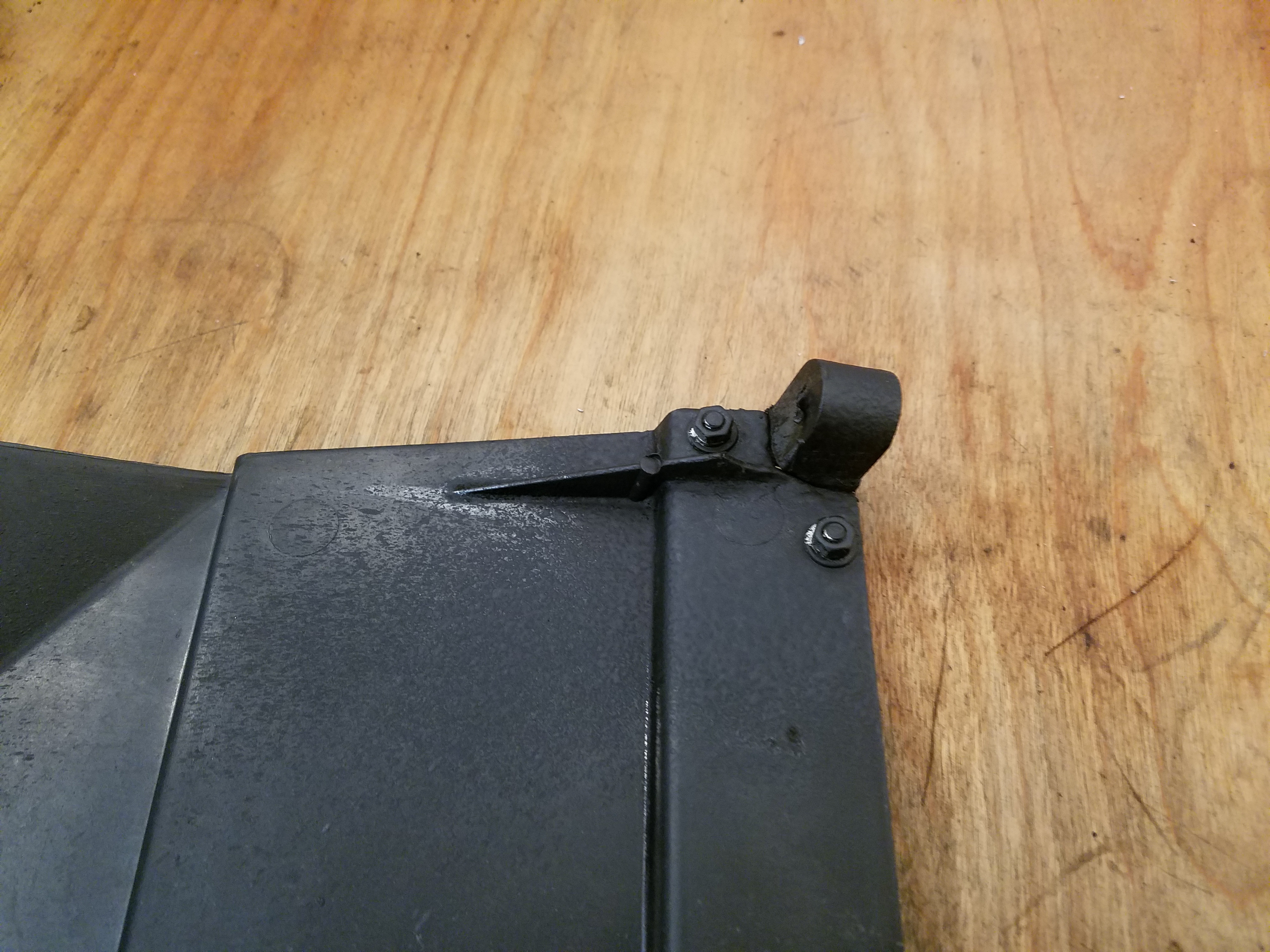

Friday morning I returned to the storage to put on my repaired passenger inner fender extension and to correct my incorrectly installed clutch linkage rod (from the clutch pedal to the equalizer). Here are a couple of pictures of the repaired fender extension on the car. The repair is strong and you would have to get out your microscope to even see that it has even been fixed. I'm really proud to have this piece on the car. Donovan, thanks for the help buddy, This means something to me....

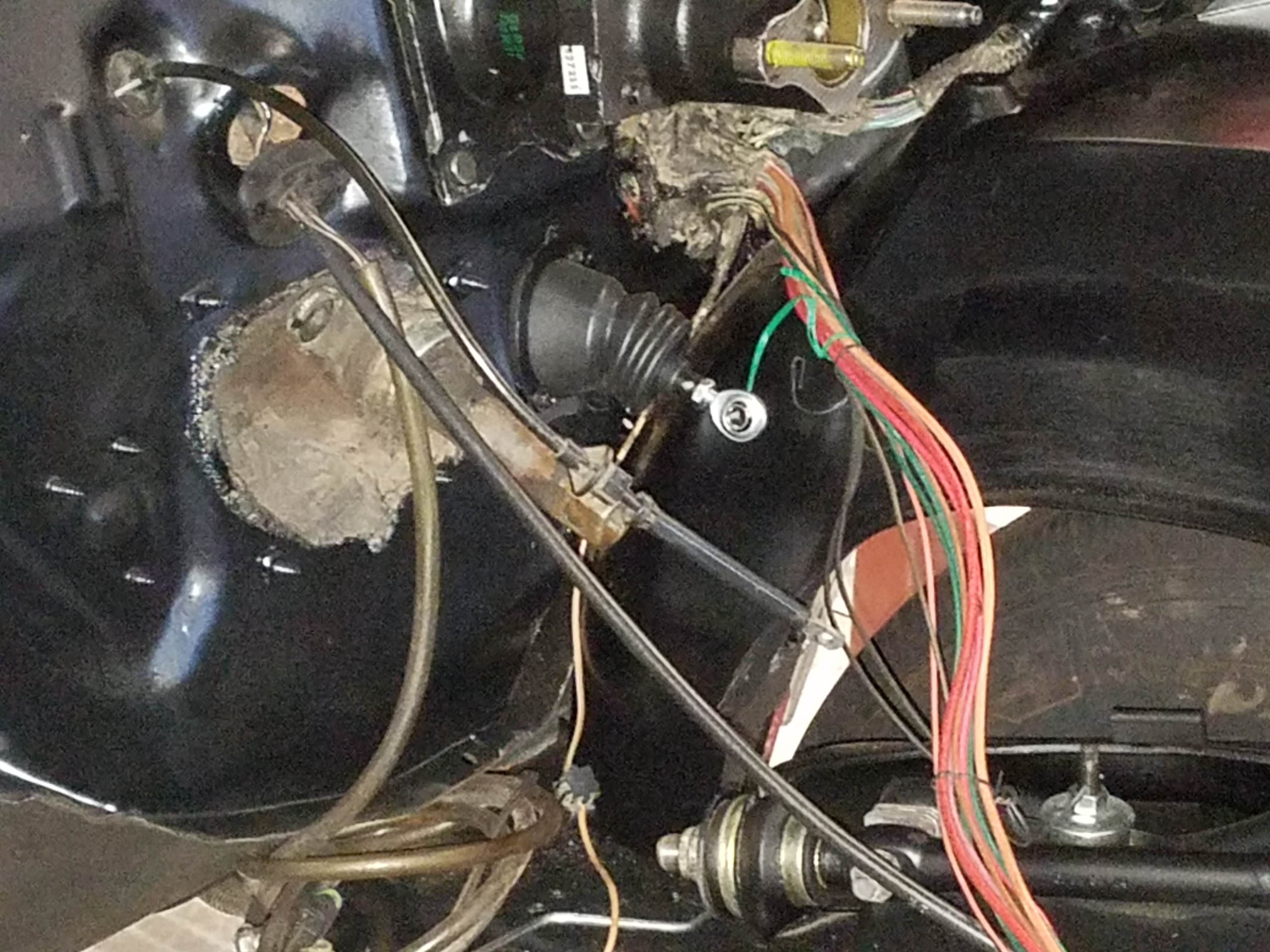

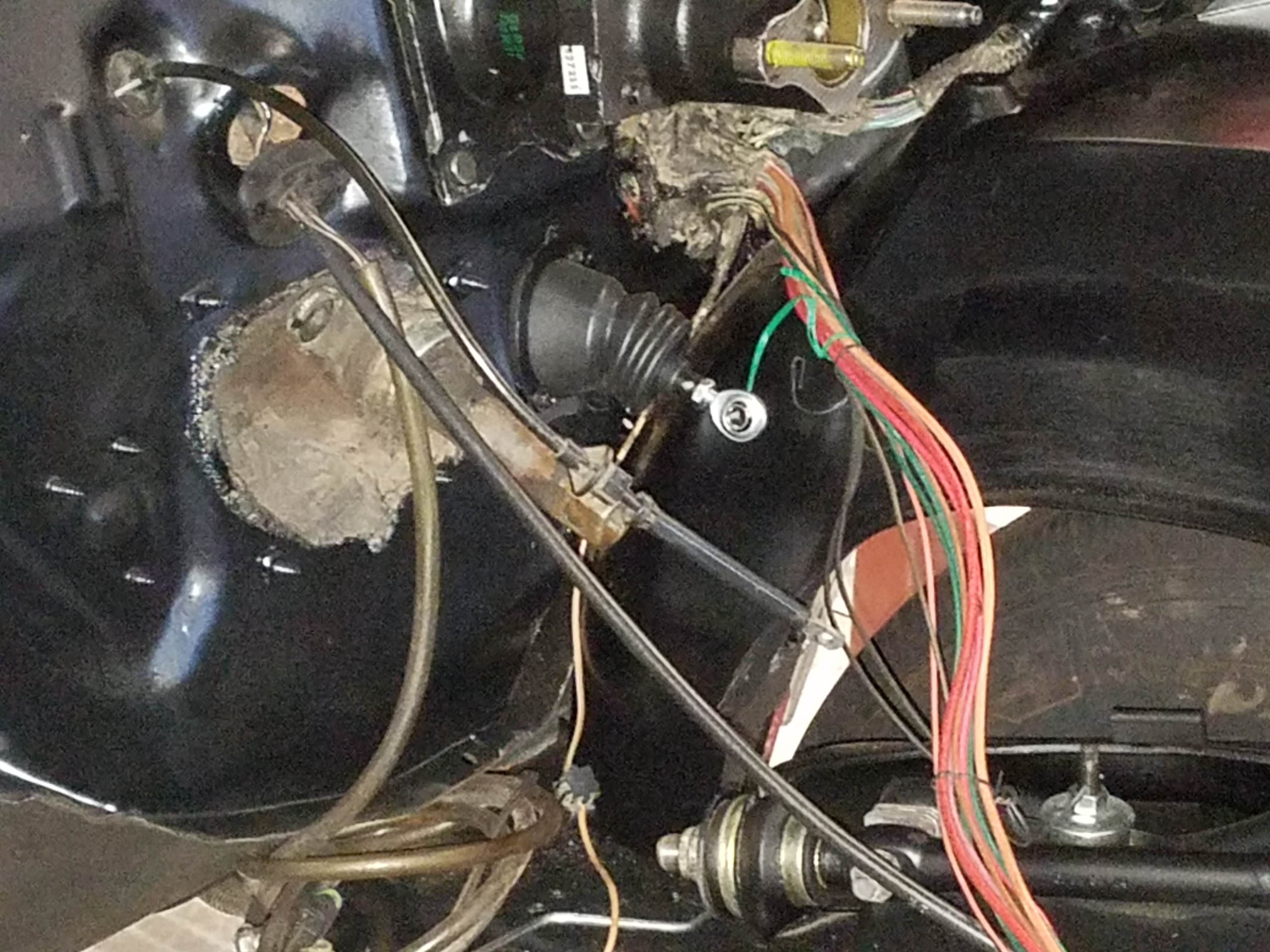

After I got the repaired inner fender extension installed, I moved to correct the wrongly installed clutch linkage rod. Not only was the rod installed backwards, it was bolted on the wrong side of the pedal. I'm pretty sure the hack previous owner had the rod in backwards (what I replicated) and that's why he can-openered the firewall. I also didn't have the new rod adjusted quite right length-wise relative to the original linkage. I got this squared away and then I went ahead and installed the retainer for the clutch rod boot on the firewall that I fabbed on Thursday. I don't think the boot is clocked correctly. I used the dimples in the firewall as a guide for where to drill the firewall but the boot is pointing down and outboard which doesn't seem right to me. No matter. I think it will be functional and it is way better than the no boot, can-opener firewall I inherited....

After I finished up with the clutch rod boot, I started working on reconfiguring the storage to get the car off of the wall on the driver's side. Now that the antenna was done, there was no need for it to be pushed so far over and the future progress needed it to be back over towards center. About the time I finished with that Sean showed up.

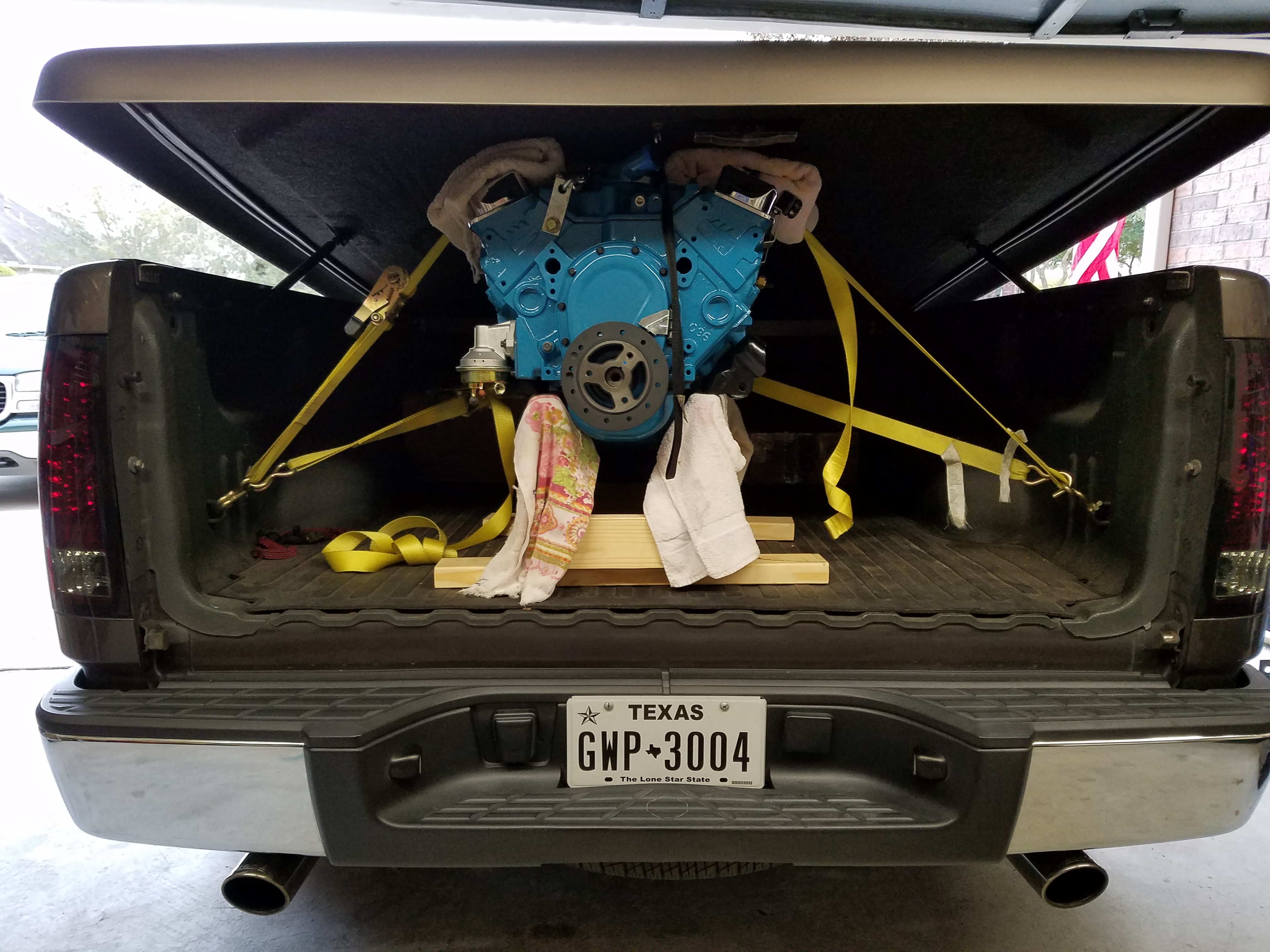

Being done at the storage for the time being, we went back to the house and started looking at what it would take to transport the engine for the GP over to the storage. We took some measurements, made a list and then went to the Home Depot to buy some lumber.

We built a wooden cradle to set the 350 on. We got the cradle built, pulled the tailgate off my truck (because the baby hoist at the house is so limited with its depth) and got the engine loaded in the back of my truck....

We got the engine transported over to the storage, unloaded and rolled up the hill into the storage bay. That's where we ended Friday...

There's nothing baby about the hoist in the picture above. That's a real deal, made in USA hoist that my dad bought in the early 90's. He recently gave it to me and I'm proud to own it. We've done a lot of engines with that hoist, including some stupid heavy stuff.

This morning Sean, Dad and I went to breakfast like we do every Saturday. From there, we went to the storage to put that SBC in the GP. We started out with confirming the pilot bushing in the crank was what we wanted, and then we installed the new GM flywheel. Then we double checked the gear mesh of the starter. Then we picked it up and set it in there as easy as you please. We didn't even pull the hood....

For those of you that don't know, that's my brother Sean and my Dad, Dwain. Once the engine was down and bolted to the mounts, Sean and I moved forward with installing the clutch disc and pressure plate. It turns out the clutch kit I had bought for the Saginaw was wrong for it and right for the T5. The Saginaw is 10 spline and the T5 is 26 spline. I had bought a clutch disc earlier this week for the T5 but when I opened up the kit for the "Saginaw" it had a 26 spline disc in it. I'm glad to be able to send that extra $200 disc back.

We got the clutch installed, followed by my 1983 only Camaro only T5 only bellhousing, followed by the T5. Everything was moving right along. This is when you know something is about to happen and it did, though it was small.

Sean got the G-Force crossmember unboxed while I put the mount on the transmission. We jacked the transmission up until the tower for the shifter was solidly up against the transmission tunnel and there was no way the mount was going in with the crossmember. It's obvious that the new hole in the tunnel has to be cut before the transmission will go on its mount. Also painfully obvious is the fact that the T5 is not going to work with the Granny-Pillow-Top bench seat.

I had myself deluded into thinking the T5 was going to line up with the existing hole in the floorboard. Yeah right.

So where it stands is the transmission is just sitting on the crossmember with no mount. The Granny-Bench has to go now. I don't know where I'll put it. The tired Monty SS buckets I bought off of Craig's List a few years ago in Deer Park are going to have to go in sooner rather than later. My next move is Granny-Bench removal.

I wanted the engine and trans sitting on the mounts today and the headers "fitted", but still it was a good day. I can't thank my brother enough for the help. I wouldn't be where I am without it. Thanks for tuning in guys. Here are some pics. Major milestone....