Alright, first and foremost I'd like to say that a couple days in the sun and a little time with a roller has eliminated many of the bubbles seen above, and I'll get a picture in the daylight tomorrow. Today's focus, though, was the dust shields. I was able to combine the other 2 shields into one that'll work for my passenger side by repeating the process I'd performed once already. Naturally they don't match because my second one looks better, but most won't notice the difference. I'm combining brake dust shields from different model S10 trucks and Blazers, part numbers 970-097 & 970-098 and 15704499 & 15704500. The 097 and 098 pieces are basically the G Body shields with the addition of a wheel speed sensor.

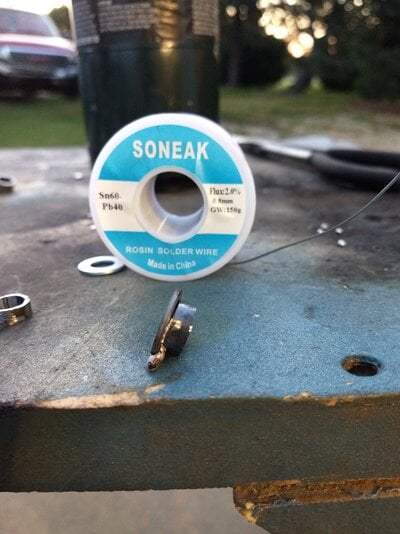

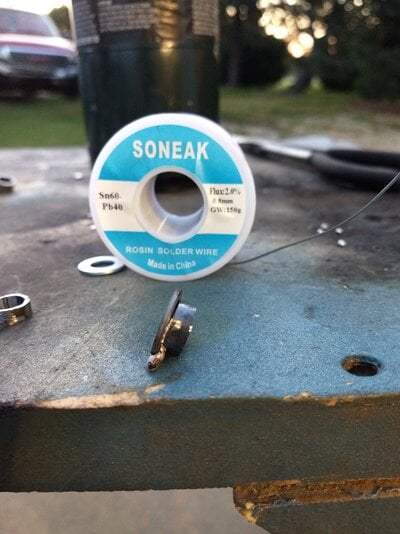

After tacking the pieces together I opted to solder them to make things nice and solid, but this can be tricky since the shields are coated in zinc. The absolute best way to get the solder to stick is to remove the zinc coating where possible and use a zinc chloride flux to make it flow. In leu of this you can utilize hydrochloric/ muriatic acid and that reacts with the zinc to make the chloride. This can be important in some applications because the antimony (lead substitute) in the solder combines with the zinc and makes a somewhat brittle intermetallic compound, but it's really only an issue when flexed and doesn't concern me and the big flat areas I was joining today so I didn't bother. I performed a durability test of dropping the soldered shield to the concrete from a height of 3 or 4 feet and it passed- nothing rattled, nothing broke.

Don't breathe in any of the fumes while welding or soldering something with zinc on it- it won't kill you but it's nasty and not exactly healthy.

I used some rosin core solder and a propane torch to accomplish my goal, had to add a hole to the '98-'05 Blazer pieces for one of the 3 mounting bolts, and that bolt will also require a spacer. A battery operated cut off wheel was used to make a couple pieces of sleeve to be combined with a washer on each end to achieve a total thickness equal to 5 washers. I held the sleeve with some hose pliers while I cut.

I then cleaned the burrs from the little sleeves using the side of the cutoff wheel as a grinder and tried to solder 2 washers to each.

And failed miserably. So I switched gears and mixed up a little JB Weld to hold things together. I grabbed an old bolt, wrapped the threads in Teflon tape to prevent sticking, and screwed a nut up against the washer/sleeve combo to hold things in place. Even with the tape I needed to use a deep well socket and hammer to dislodge the spacer I'd made from the bolt.

The end result is 2 little spacers that are just about even.

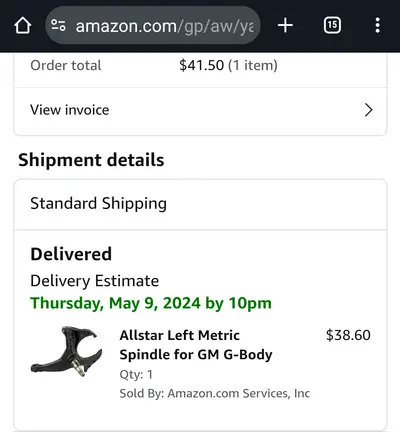

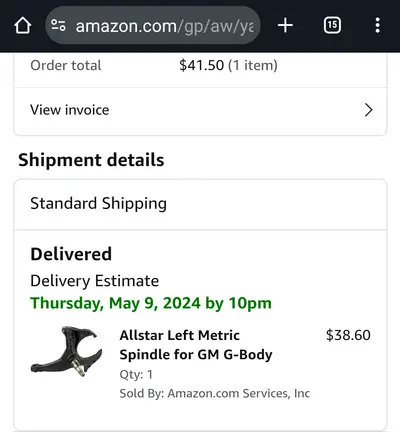

Being a car guy means I can't install tubular control arms and replace my booster/ master without also upgrading the brakes, but that's not so simple with a '78 model. New drilled and slotted rotors require new spindles with the appropriate sized bearings, so I chose spindles from All Star since I've had good luck with their parts and these are forged steel where others are cast iron. The right side is part # ALL56319 and set me back $135 on Amazon but the left (ALL56318) was available for just $40, "used".

A pair of 4739 seals and some Set 6 (A6) alongside Set 3 (A3) bearings will keep the new TRQ drilled and slotted rotors (BRA74842) spinning. The factory replacement spindles require a 3/4 - 20 castle nut, 1/8" x 1.5" cotter pin, and funky washer to keep it all together, Dorman part numbers 615-065 (nut), 44503 (pin), and 618005 (washer). You can also buy these as Dorman kit 304993 for $7 - $10.

After tacking the pieces together I opted to solder them to make things nice and solid, but this can be tricky since the shields are coated in zinc. The absolute best way to get the solder to stick is to remove the zinc coating where possible and use a zinc chloride flux to make it flow. In leu of this you can utilize hydrochloric/ muriatic acid and that reacts with the zinc to make the chloride. This can be important in some applications because the antimony (lead substitute) in the solder combines with the zinc and makes a somewhat brittle intermetallic compound, but it's really only an issue when flexed and doesn't concern me and the big flat areas I was joining today so I didn't bother. I performed a durability test of dropping the soldered shield to the concrete from a height of 3 or 4 feet and it passed- nothing rattled, nothing broke.

Don't breathe in any of the fumes while welding or soldering something with zinc on it- it won't kill you but it's nasty and not exactly healthy.

I used some rosin core solder and a propane torch to accomplish my goal, had to add a hole to the '98-'05 Blazer pieces for one of the 3 mounting bolts, and that bolt will also require a spacer. A battery operated cut off wheel was used to make a couple pieces of sleeve to be combined with a washer on each end to achieve a total thickness equal to 5 washers. I held the sleeve with some hose pliers while I cut.

I then cleaned the burrs from the little sleeves using the side of the cutoff wheel as a grinder and tried to solder 2 washers to each.

And failed miserably. So I switched gears and mixed up a little JB Weld to hold things together. I grabbed an old bolt, wrapped the threads in Teflon tape to prevent sticking, and screwed a nut up against the washer/sleeve combo to hold things in place. Even with the tape I needed to use a deep well socket and hammer to dislodge the spacer I'd made from the bolt.

The end result is 2 little spacers that are just about even.

Being a car guy means I can't install tubular control arms and replace my booster/ master without also upgrading the brakes, but that's not so simple with a '78 model. New drilled and slotted rotors require new spindles with the appropriate sized bearings, so I chose spindles from All Star since I've had good luck with their parts and these are forged steel where others are cast iron. The right side is part # ALL56319 and set me back $135 on Amazon but the left (ALL56318) was available for just $40, "used".

A pair of 4739 seals and some Set 6 (A6) alongside Set 3 (A3) bearings will keep the new TRQ drilled and slotted rotors (BRA74842) spinning. The factory replacement spindles require a 3/4 - 20 castle nut, 1/8" x 1.5" cotter pin, and funky washer to keep it all together, Dorman part numbers 615-065 (nut), 44503 (pin), and 618005 (washer). You can also buy these as Dorman kit 304993 for $7 - $10.