Many door lock or window switches will work that way too, so you could just find the ones you like, OEM or aftermarket and wire them up like a window motor.

So simple, one of those things that make you ask “why didn’t I think of that?” Thanks for that. I would assume you’d have to use the relays that the power windows use in conjunction with the switches as well though?

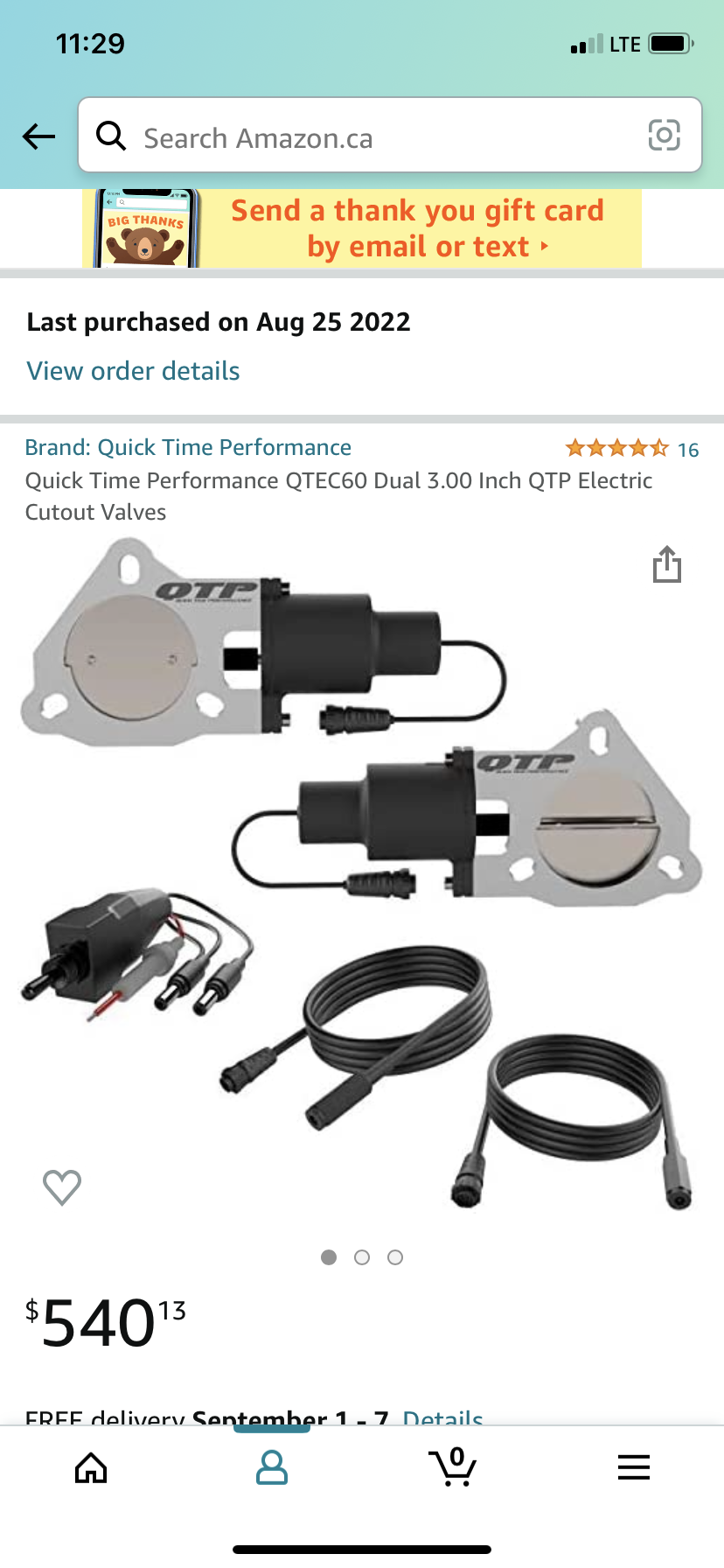

Do these cut out motors have end of line switching???

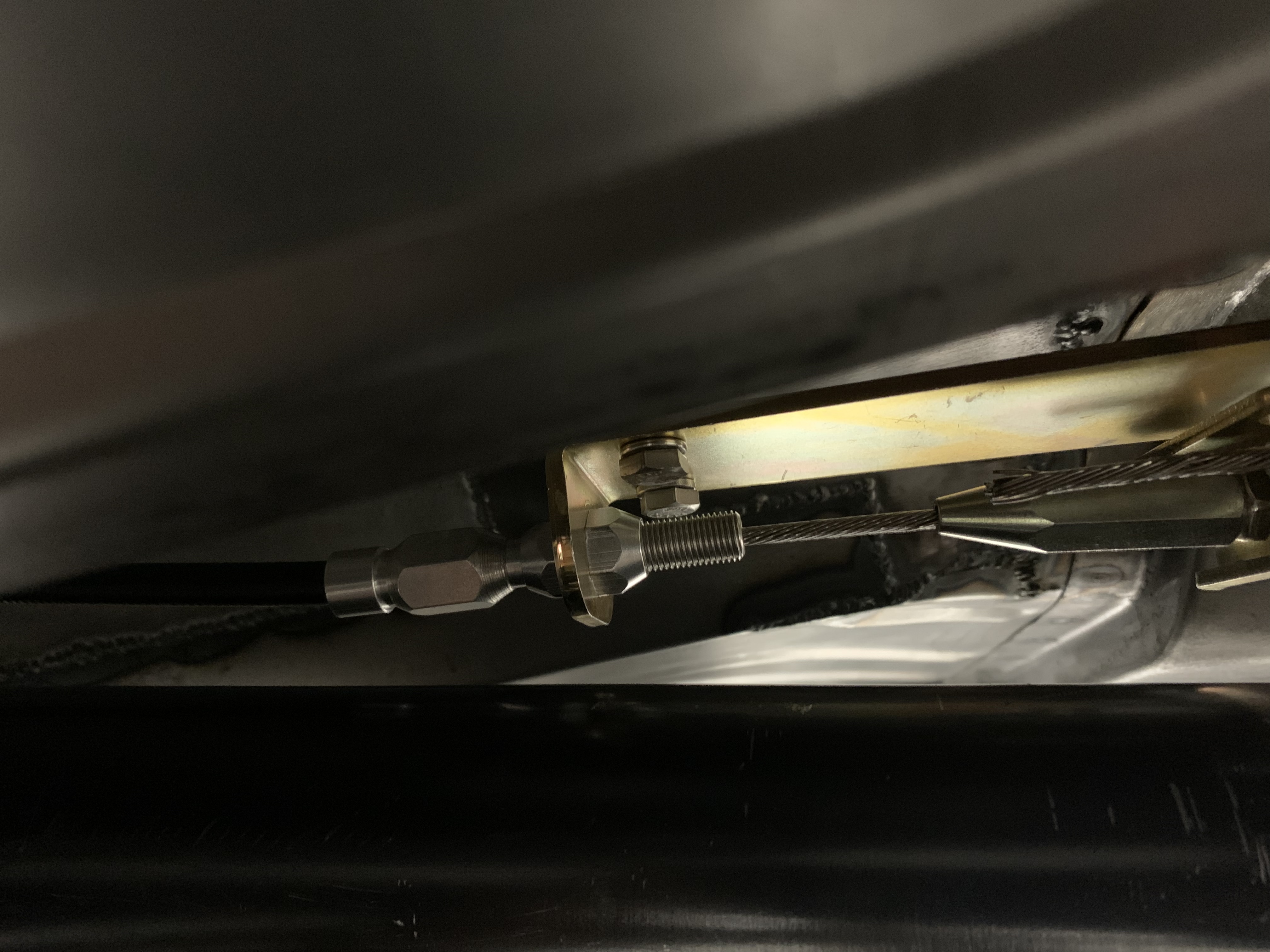

No they don’t Tony, if they did they’d just start to close again once they reached the end of the opening cycle. They also don’t have limit switches to kill the power to them at the end of a cycle, so it’s important not to have the switch held on for too long past fully open or closed.

Way more complicated than it needs to be.

You simply need two single pole relays, and a couple of diodes.

Hell for that matter, you could probably just use a power window switch. They operate the same exact way....

Appreciate the input Shawn. That’s what I was thinking too, seems like it’s all getting a lot more complicated than it really needs to be. I think part of it is going to depend on the type of switch that’s going to be used too.

i have the set up you posted,that switch isn't on/off/on,you can have it open a little or a lot.

Well damn. There ya go, so it looks like all this speculation has been for nothing when the switch they come with will already do what I want!

Thanks Chris.