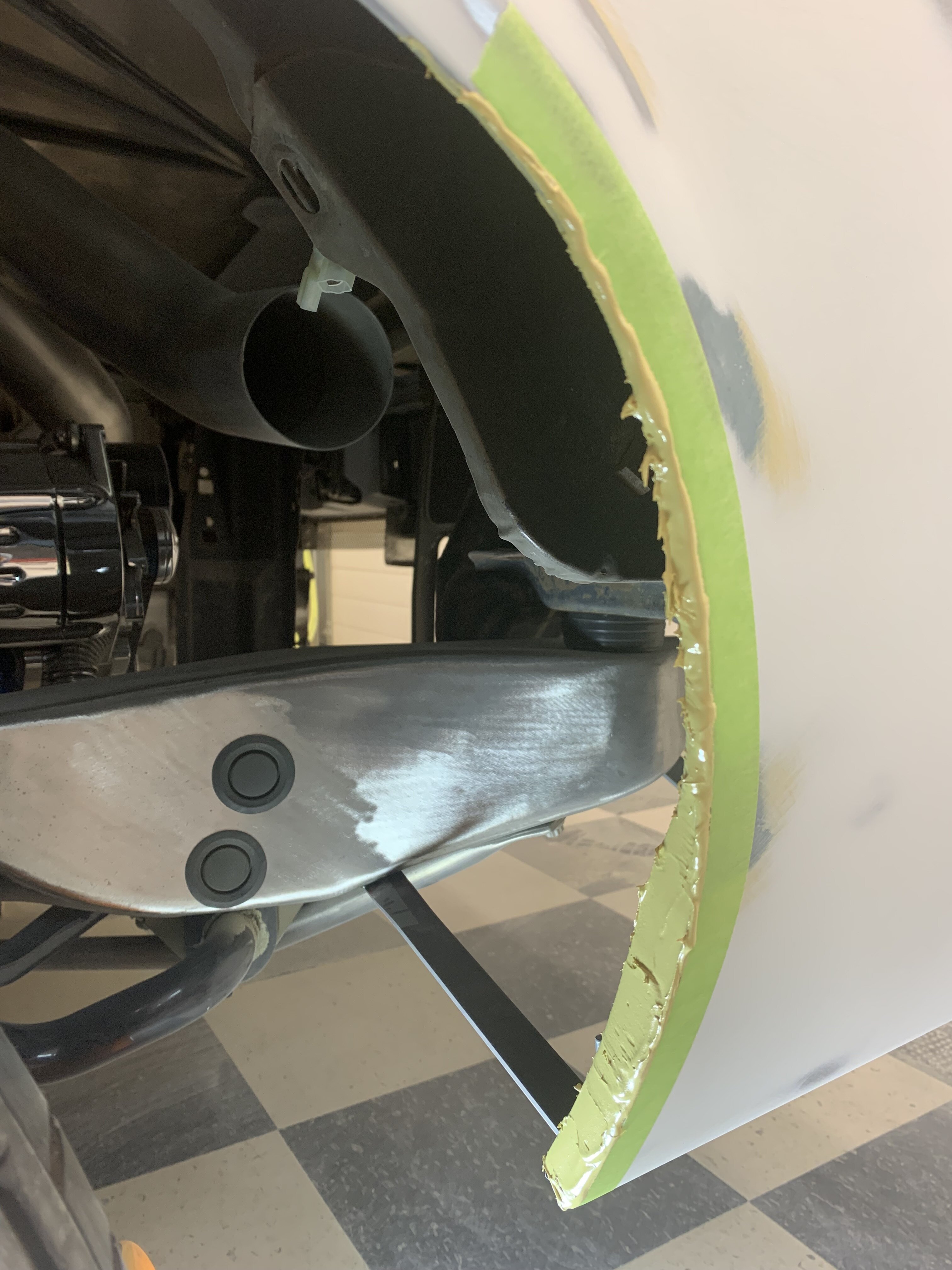

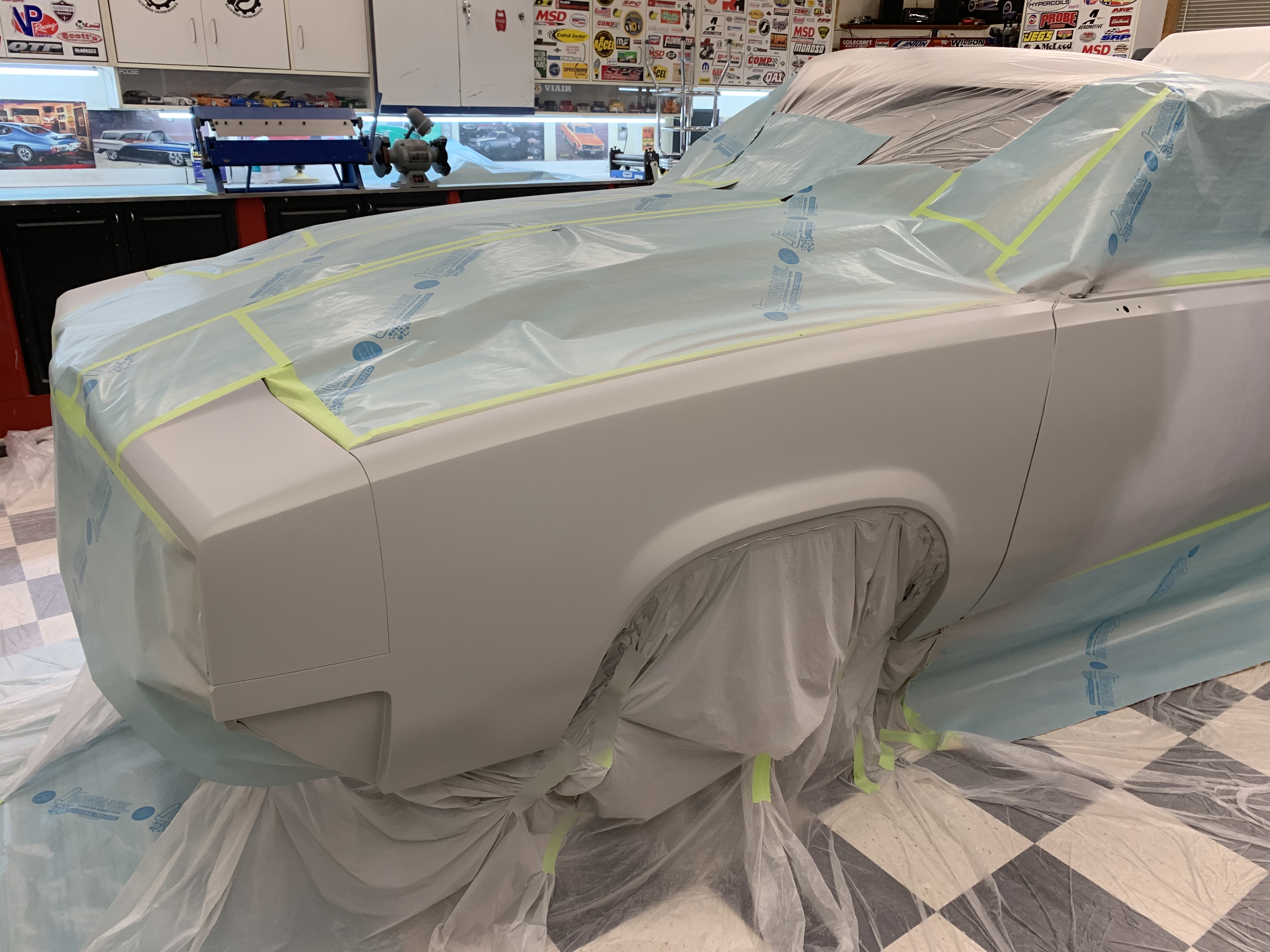

Well, it took an additional day due to the complexity and completion of the masking and plastic process, but tonight I finally got to spraying.

This is the end result after 2 coats of epoxy primer and 2 coats of poly spray filler:

View attachment 235077

View attachment 235078

View attachment 235079

View attachment 235080

View attachment 235081

That’s a lot of work to this point for Malibu flares on Cutlass fenders. But well worth it IMO, I think they not only look like they belong there, but also like it came that way which was the point.

And the additional work to eliminate the dive between panels? This is what it’s looking like so far:

View attachment 235083

View attachment 235082

As I said before, this isn’t the end of the process, but it is the beginning of the end. Next step is to block out the surfaces in 120 grit and see how it comes out. If everything blocks out ok, then we’re laughing and can finish it off with another round of blocking in 220, and then 2 coats of regular high build primer surfacer.

If not, then it’s back to 2 more coats of spray filler and repeat the blocking process. Either way, I’m going to attempt to leave the car masked up for the time being to try and save some time and effort.

The end is in sight though!