I love this hobby.

It's not always (and shouldn't be) about dropping hundreds or thousands of dollars on the latest and greatest whizzy new part. Don't get me wrong, I will spend good money on good parts when it warrants, I've seldom been disappointed doing so, but sometimes using plain old creativity and a bit of imagination to find a way to complete a task or modify something can be so rewarding.

Case in point:

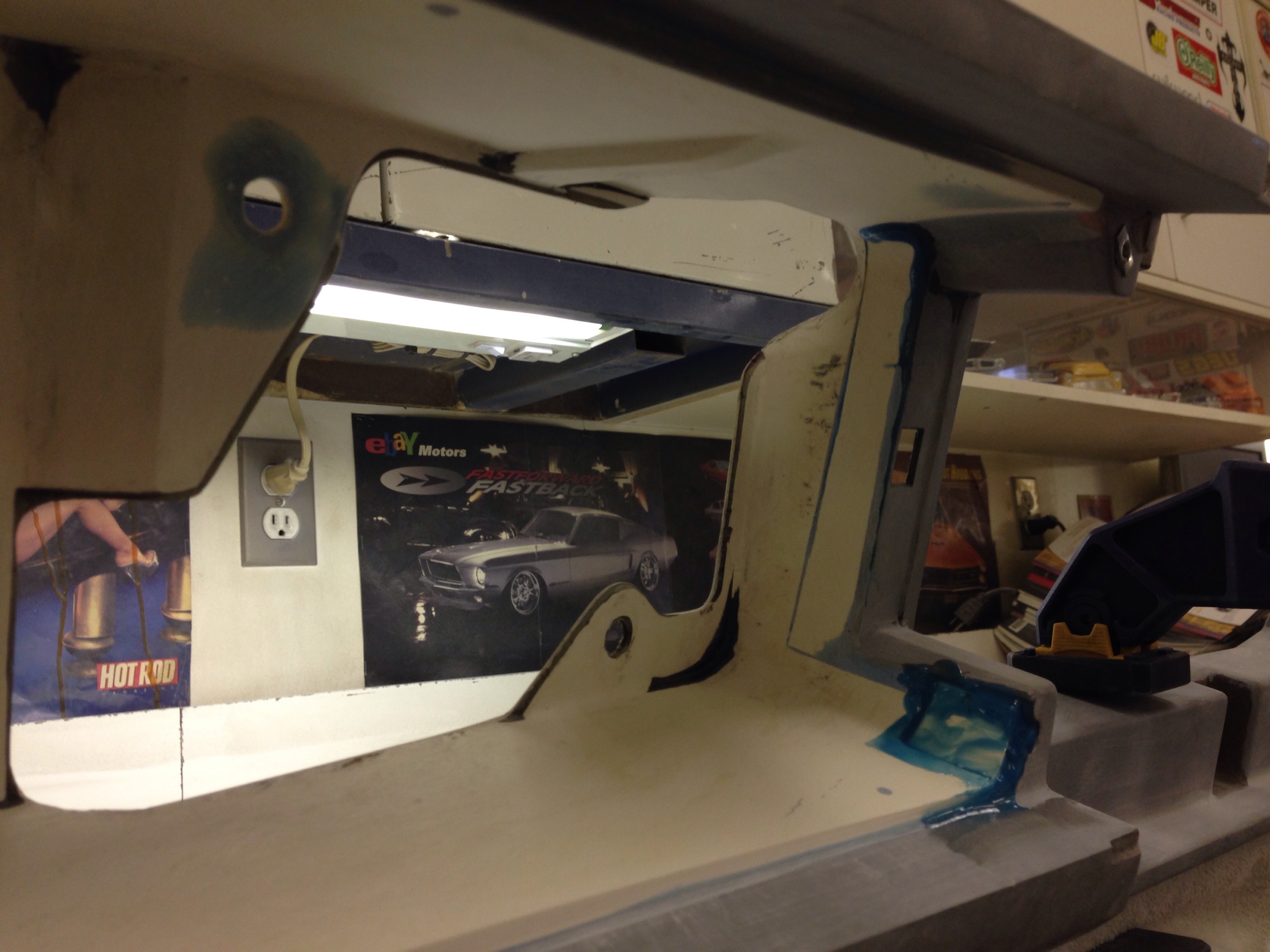

As most of you that have been following along on my journey recently know, I've been working on the header panel updating the look and function with a composite headlight conversion.

I've already covered trimming and placement of the Celebrity buckets into the Olds header and have been working feverishly (sometimes 14+ hours and 3am nights!) on sanding and blending all the seams to make it appear as if it was done from the factory. These many long hours spent doing this are probably to the point of excess as no one will likely notice it's not factory, but in a way, that's kinda the point.

😉

Anyways, things have been progressing slowly but surely and I'm very happy with the results so far. However...

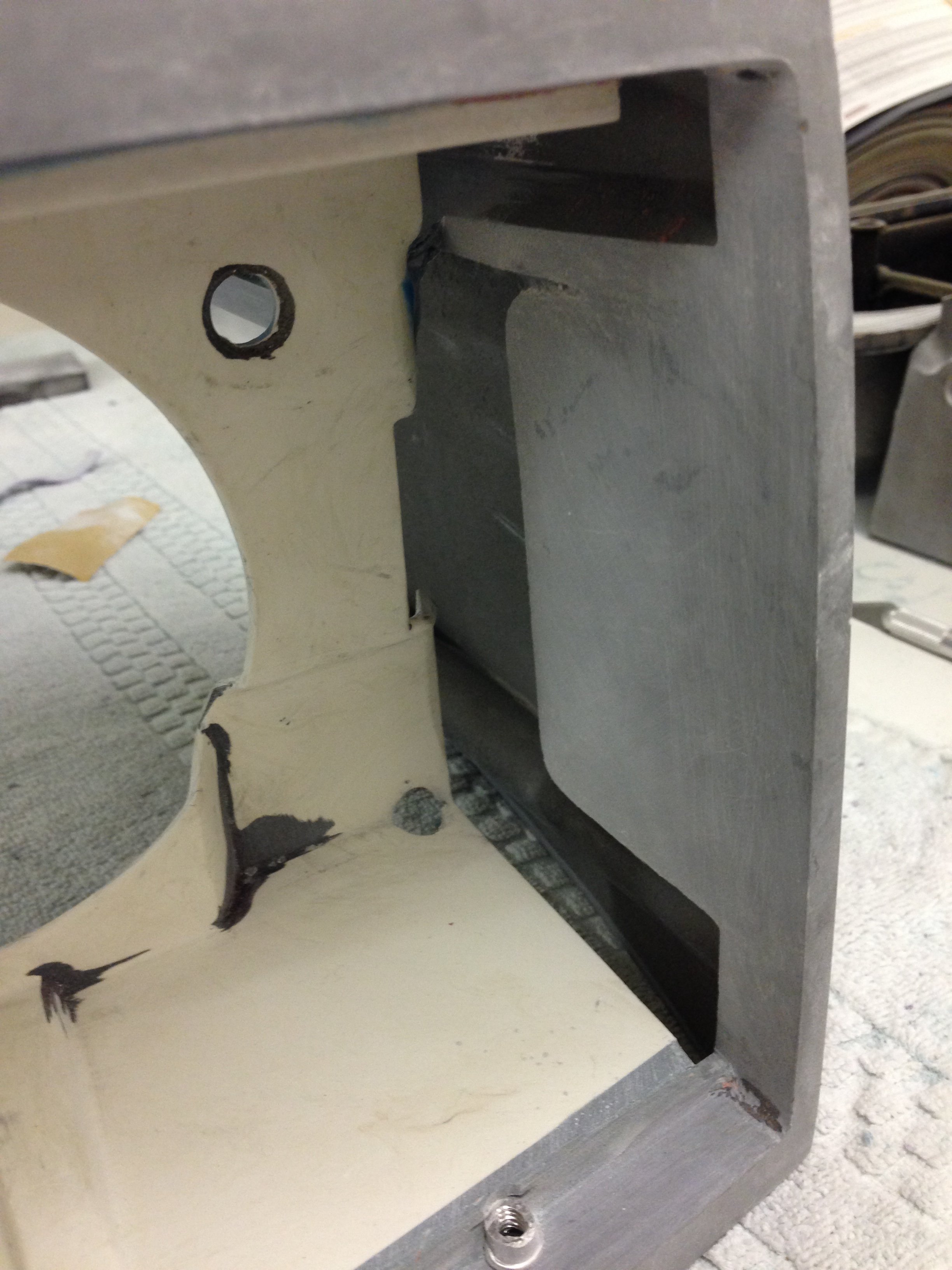

I was at a bit of a loss as how to finish off the outer edges of the bucket openings. This area on the Celebrity header originally adjoined the marker lights and had to be trimmed off to fit in the Olds header. This is what I was left with:

The problem was, I had no more flat SMC material left over from the trimming I had done in which to be able to use to fill in the gaps. I exhausted all the possible options I could think of open to me like seeing if I was able to buy some in bulk sheets (you can, but only in flexible sheets for bumper repairs), considered trying to fibreglass and resin it all up (not exactly a fun or easy option) and a few other less than desireable other ideas. This is where the creativity and resourcefulness? comes in.

I figured it was time for another trip to the autowreckers. This time I was on the hunt for a decklid spoiler from some sort of late 80's or early 90's GM car. Most of them during that period were still SMC before they switched to plastic. A spoiler would be perfect as it would be roughly the right size and flatness to allow me to cut the needed sections out of it.

🙂

I was rewarded today with finding one from a early 90's Pontiac Sunbird, and once again, it was back to cutting up a perfectly good part once I got back in the garage.

Lol

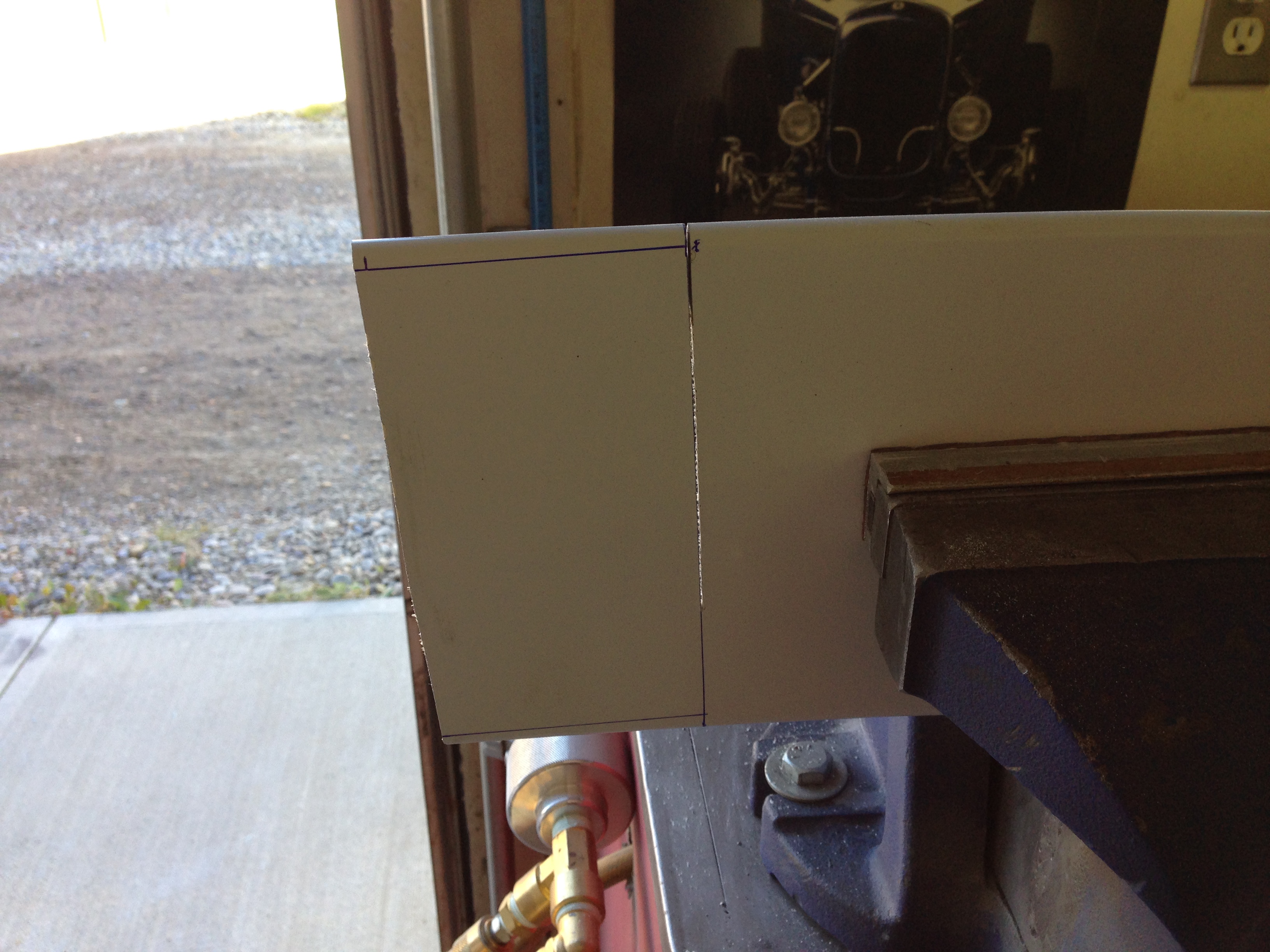

First, I cut the ends along with the stanchions off...

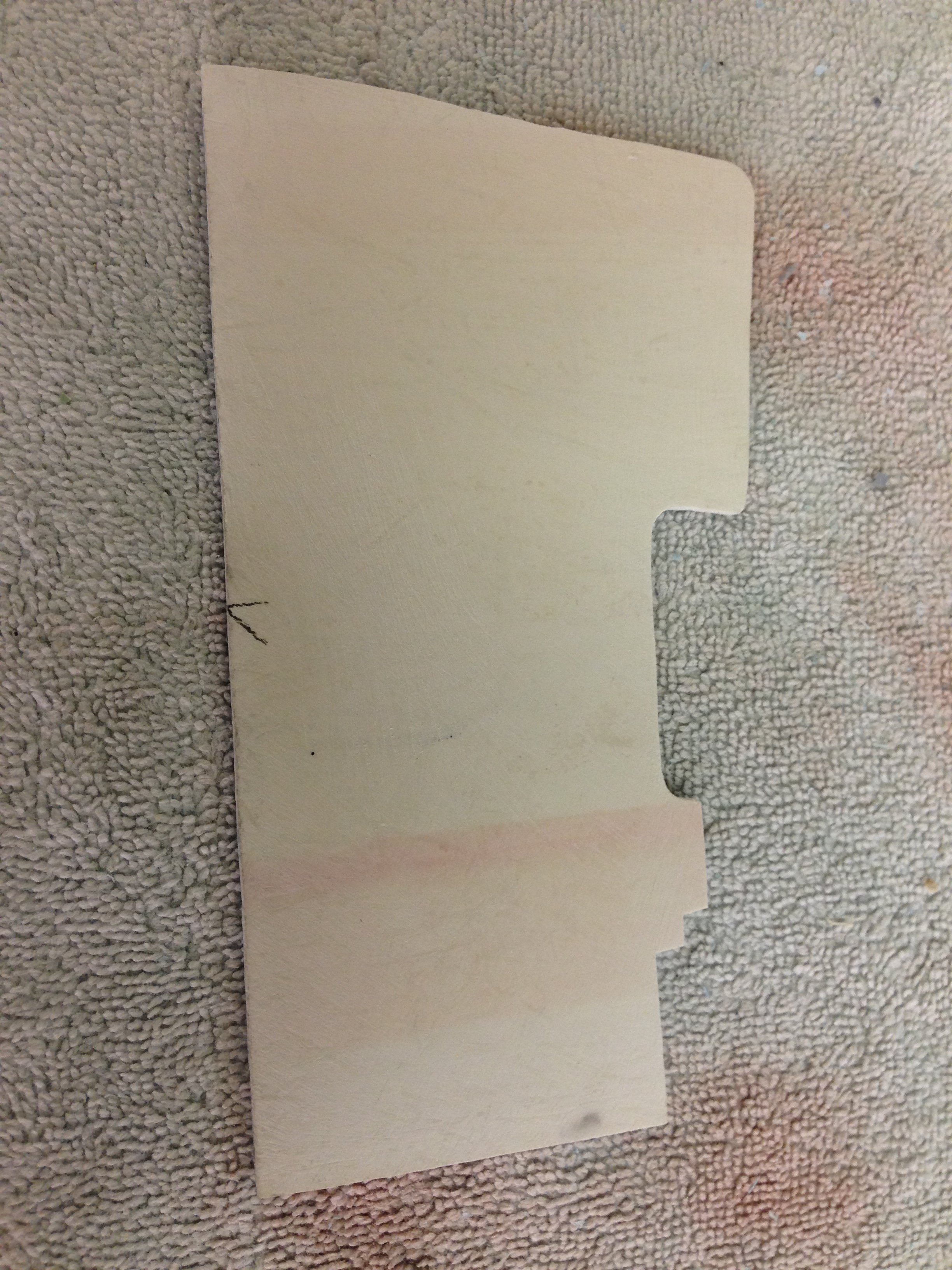

...then I measured and marked out a section of the flat "top" area I would need and cut that out.

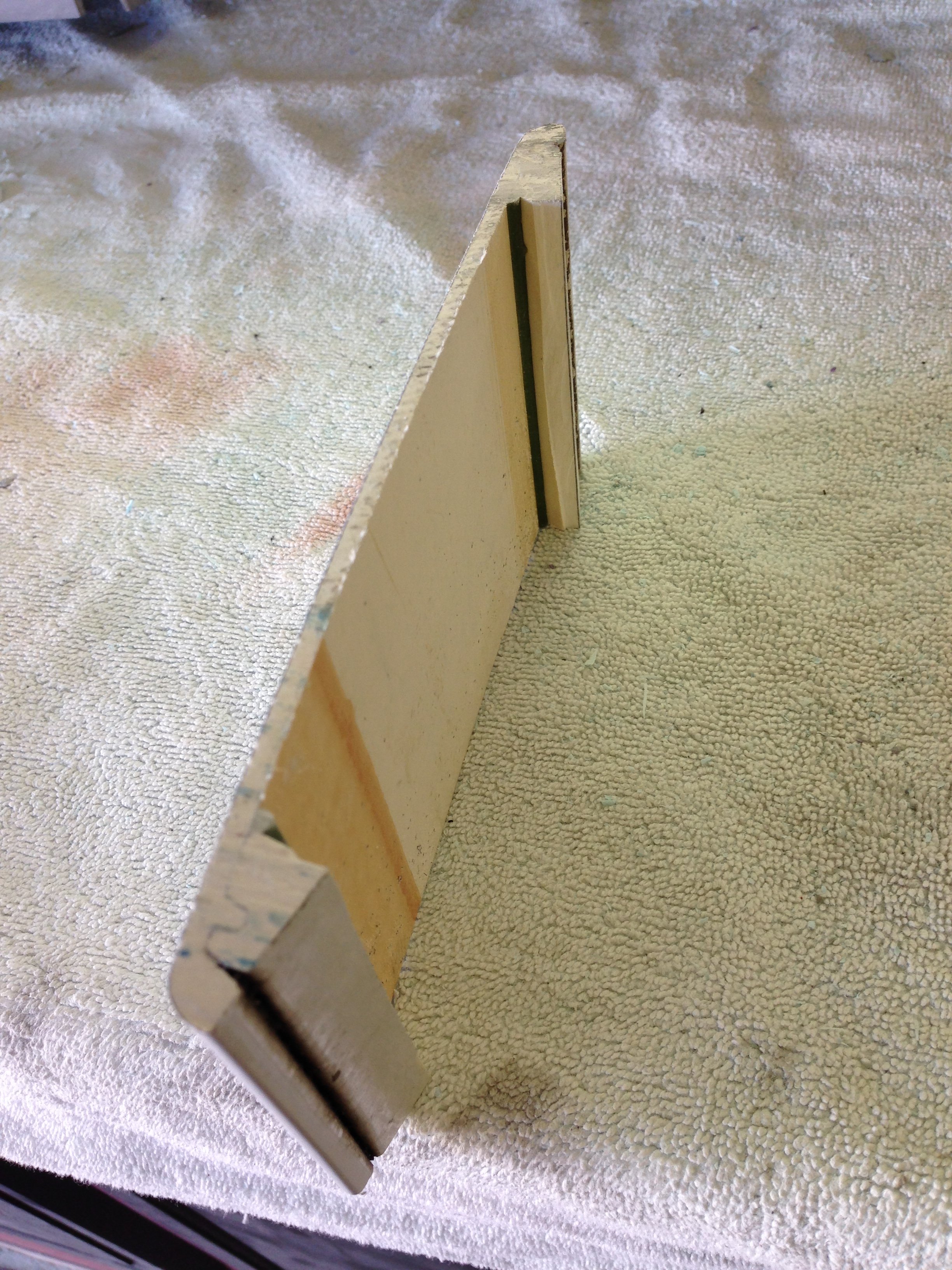

Once this was done, I separated the top from the bottom and cleaned and removed the adhesive holding the two halves together. A couple of carefully placed cuts did this with only a little bit left over to remove.

With that done, a light sanding with 120 grit on a block removed the last of the crud and residue.

A couple of test fits and a bit of trimming to size later, I had just what I needed to begin to fill in the gaps.

Happy with the fitment, it was time for Clecos to clamp and more 3M ridgid parts repair adhesive between the new part and the existing header to secure it in place permanently.

And that's pretty much where I'm currently at. I'm just waiting for the adhesive to finish curing, then I can remove the Clecos and begin to finish out the seams along the edges with a bit more 3M repair and a skim coat or two of "kitty hair" to finish it all off. Still left to be done is also adding back in the chrome trim bezel mounting holes as they had to be removed during the initial trimming of the header, but that should be fairly easy to do.

🙂

It's the little things like this and sometimes a bit of unconventional thinking that can make this such a fun and rewarding hobby.

Stay tuned as I should (hopefully) only be a coupl'a days away from getting this into primer and showing the finished product. Then it'll be onto the bezel modifications to make it all pop...

😀

Thanks for checking back on the progress!