Update time again on the old girl! Sorry in advance on the length of the next few posts...

🙁

I had the best of intentions to post this update shortly after covering the fabrication on the hood, but as luck would have it, life and work quickly got in the way, so here it is albeit a couple weeks late. Apologies for that too...

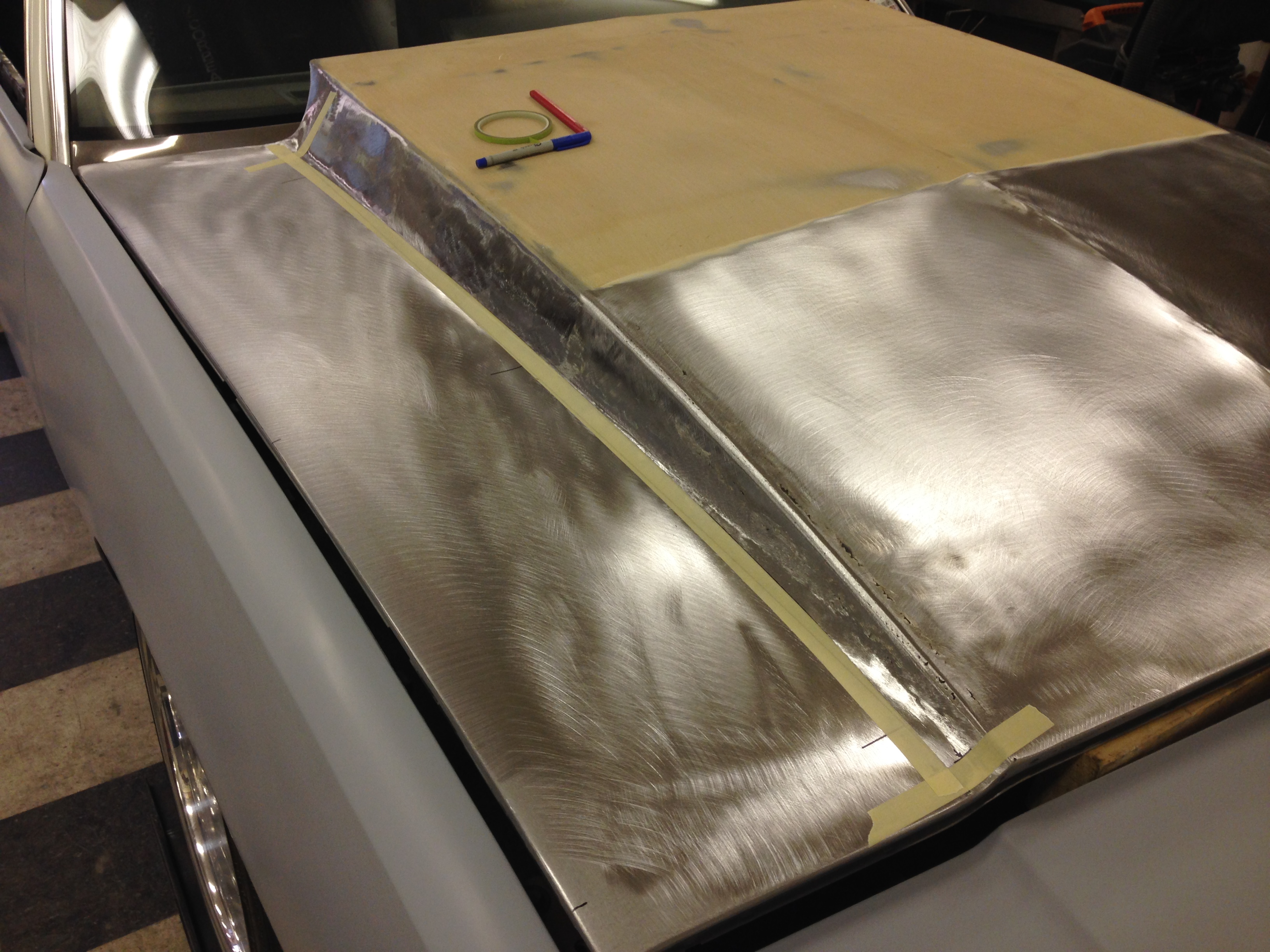

As I stated earlier, after the bulk of the fabrication was done on the hood, it got set aside for almost 3 years as the focus shifted to different areas of the car.

During that time, the hood found its way on and off the car several times for different reasons, giving me the opportunity to become more accustomed to seeing it as a "part of the car", rather than merely another "part" of the car.

Slowly during this time, I began to notice small things about the hood that just didn't seem right. It actually took me quite a while to hone in on what these things were, but finally one day this summer I was able to put my finger on what they were. This first instalment is going to cover what I found, and how I went about fixing them.

In my "lightbulb" moment when I finally figured out what wasn't quite right, I realized I actually had two separate issues that were going to require attention:

1) The first (and the most obvious to me) is perhaps the most critical part that makes the hood look like it belongs on the car.

The body lines that make up the raised center section have to "grow" out of where they start on the header panel.

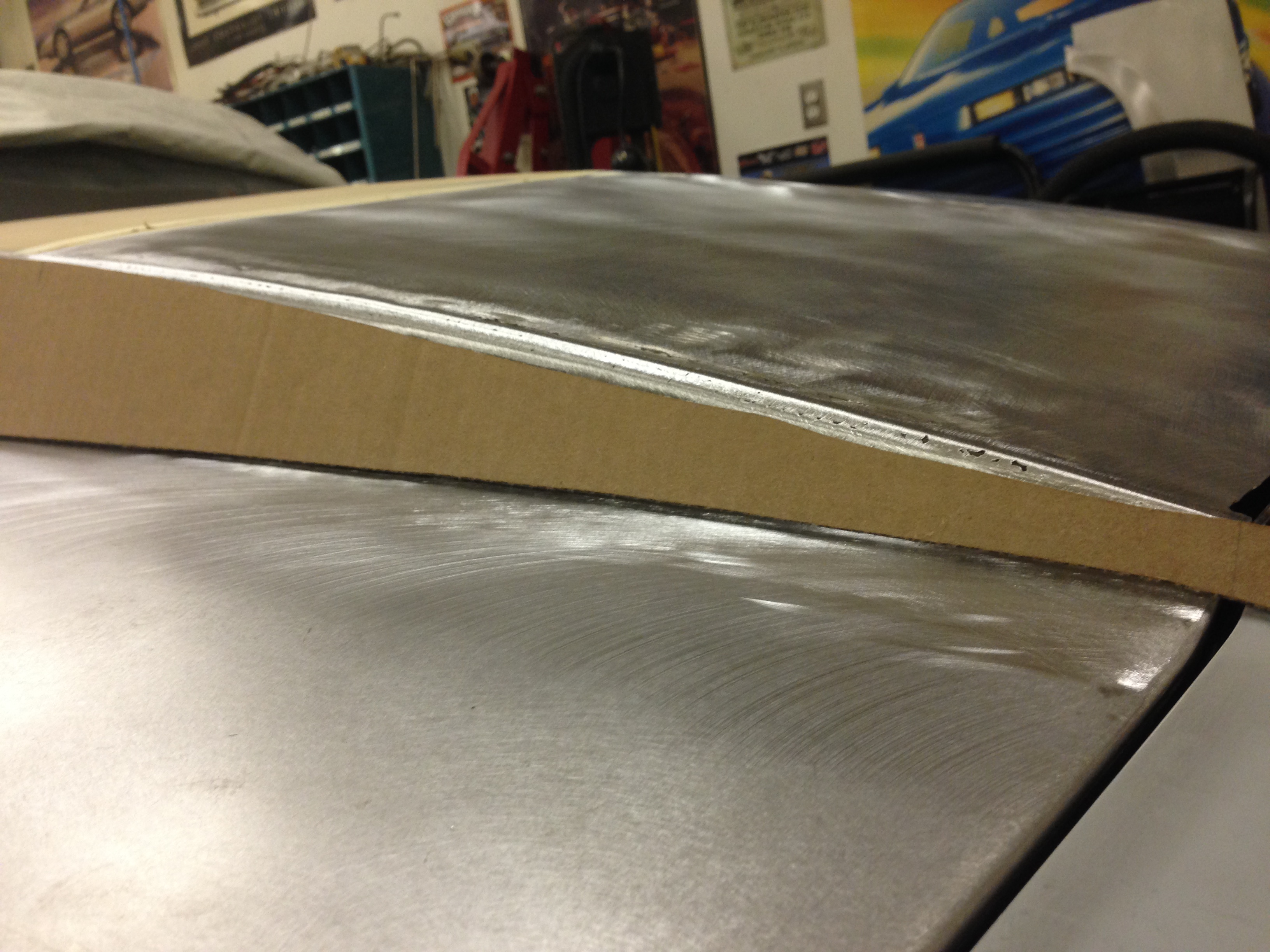

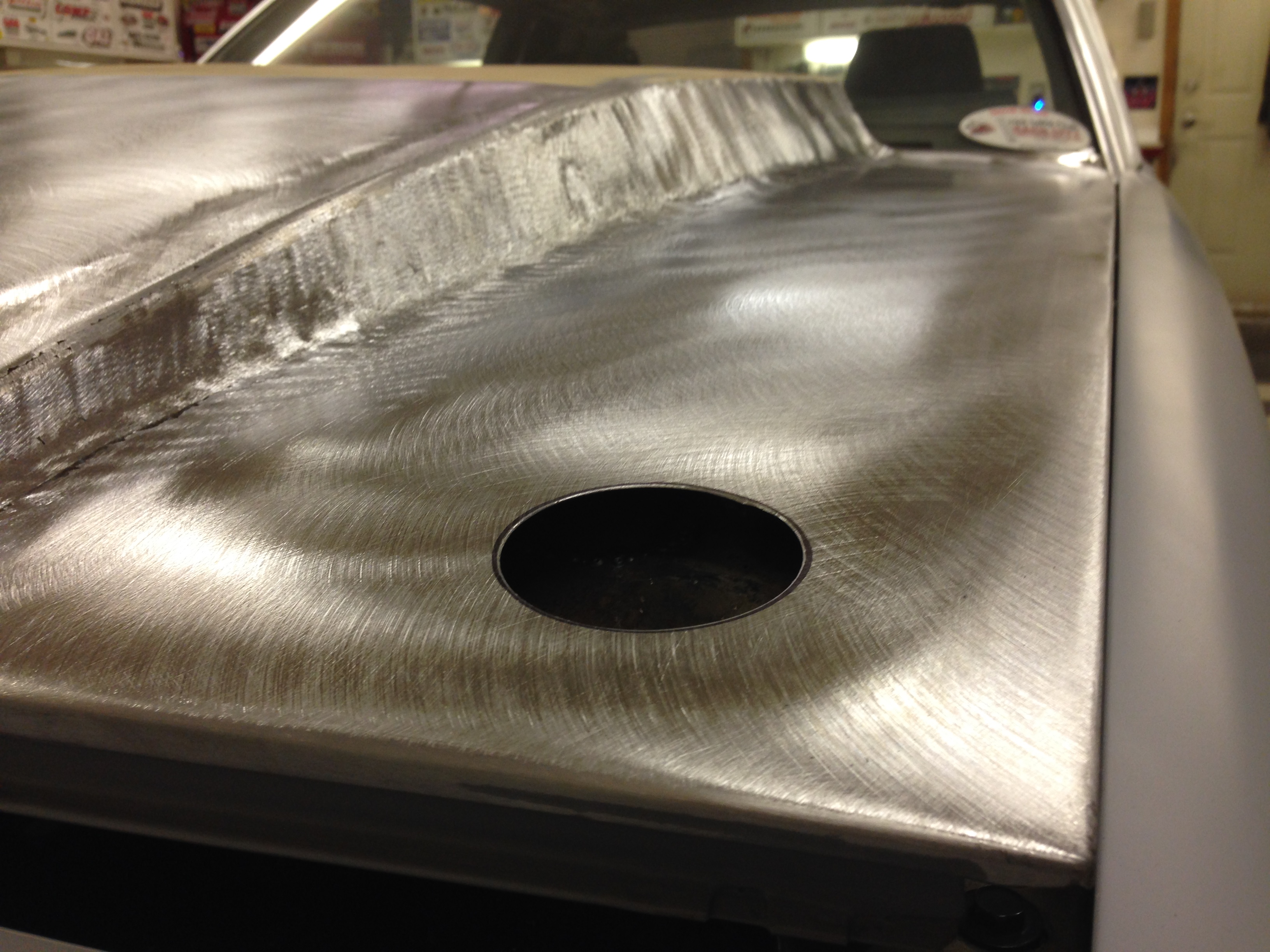

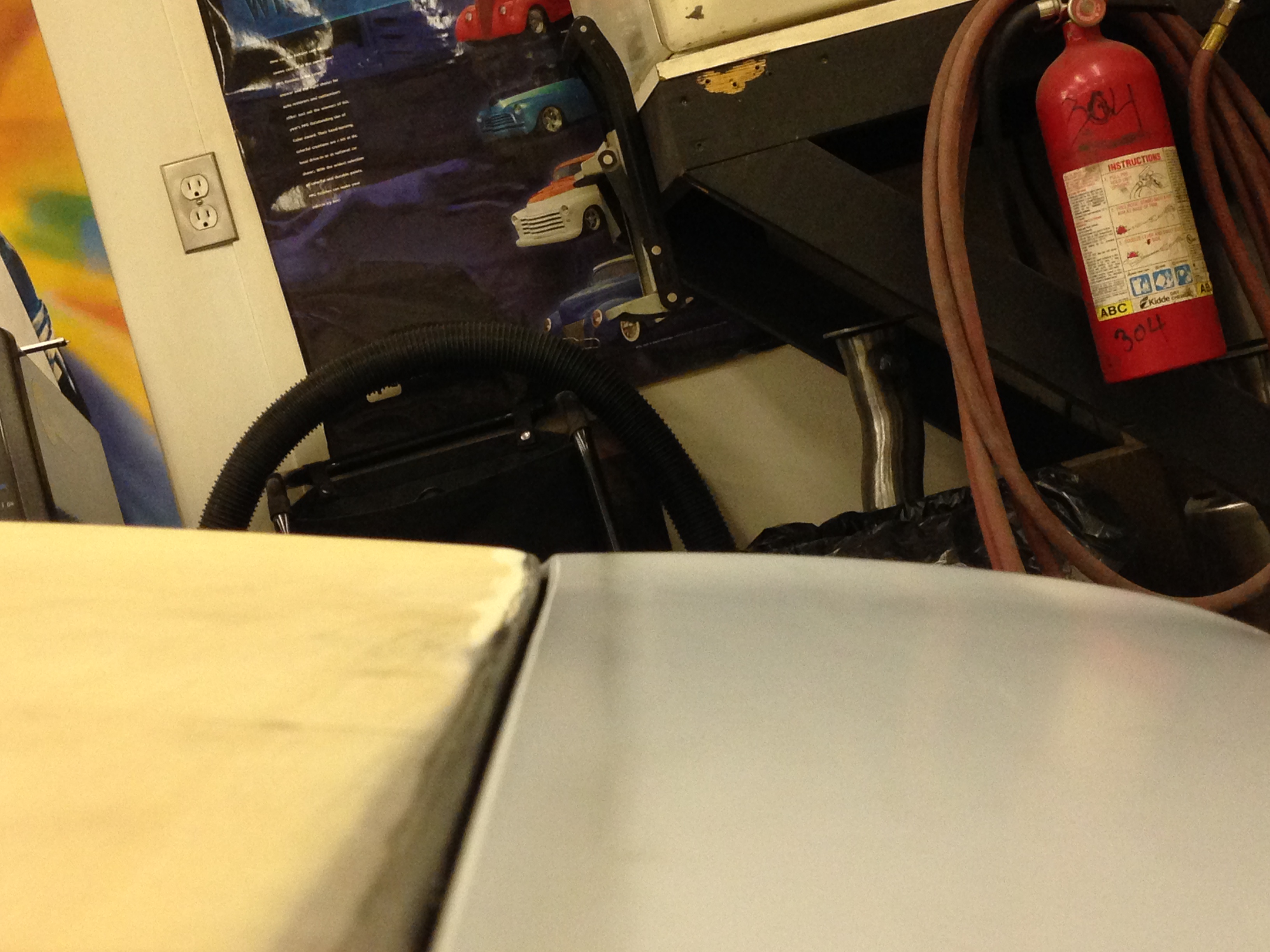

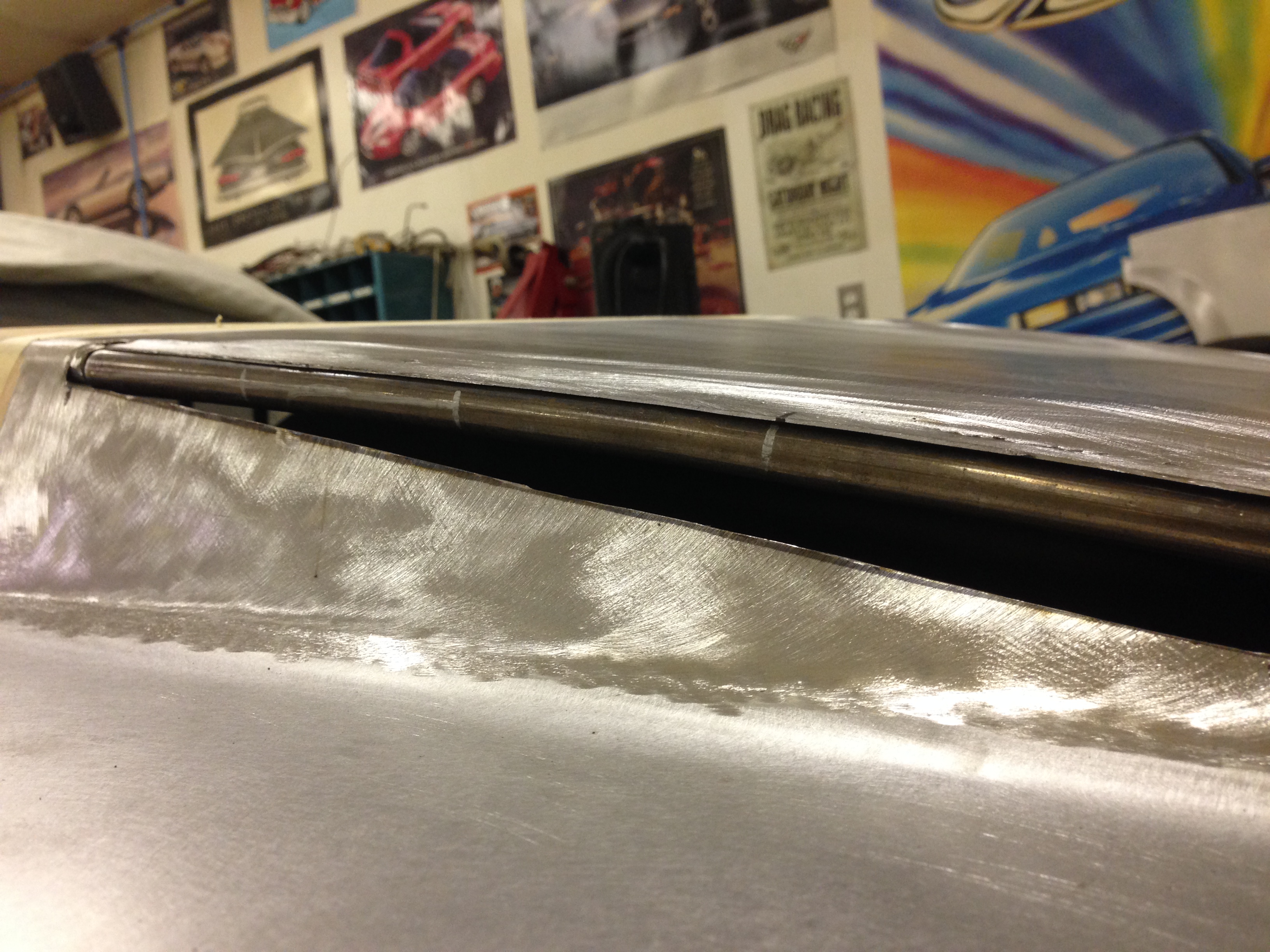

Eyeballing the lines of the header to the hood with a critical eye, I found the curvature to smoothly transition between the two wasn't right. I tried taking several pics to illustrate what I was seeing in person, but it was extremely hard to capture it with the camera.

This pic is about the best I could get, it's a closeup of the center body line across the hood and header. It drops at the edge of the hood and leaves a dip where it meets the header.

Not cool!

The decision (however painful) was made that I would have to go back in, cut out the hood skin and tube structure in these areas, bend up new tubing and redo them.

2) The second area that needed attention was a section on both sides where the "flat" areas transitioned into the raised sides of the cowl. I say "flat", but that was actually the problem. They were too flat. They should actually have a slight graceful curve to them.

When we stood up the sides of the original hood at the cut points, it's really hard to make a curved bend, so the bend points flattened out creating really low flat points.

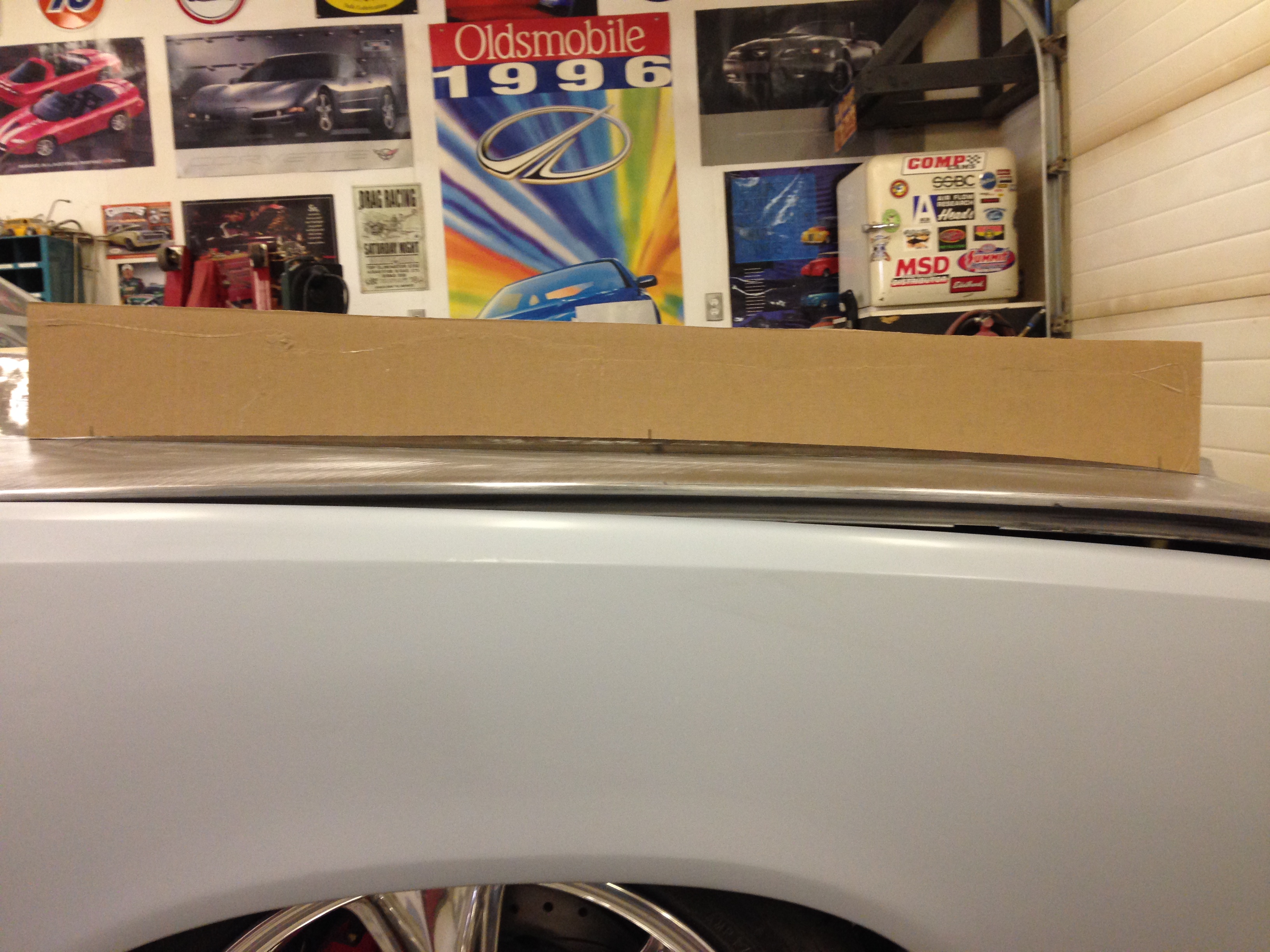

So, armed with a half assed plan to rectify the first issue, I drug home some cardboard from work, and made templates of the "proper" curvature I felt it needed to have and got down to business. Here is the template with the proper shape it SHOULD have.

Having this template to work towards was crucial, and by using the same one for both sides, it would ensure both sides would be symmetrical.

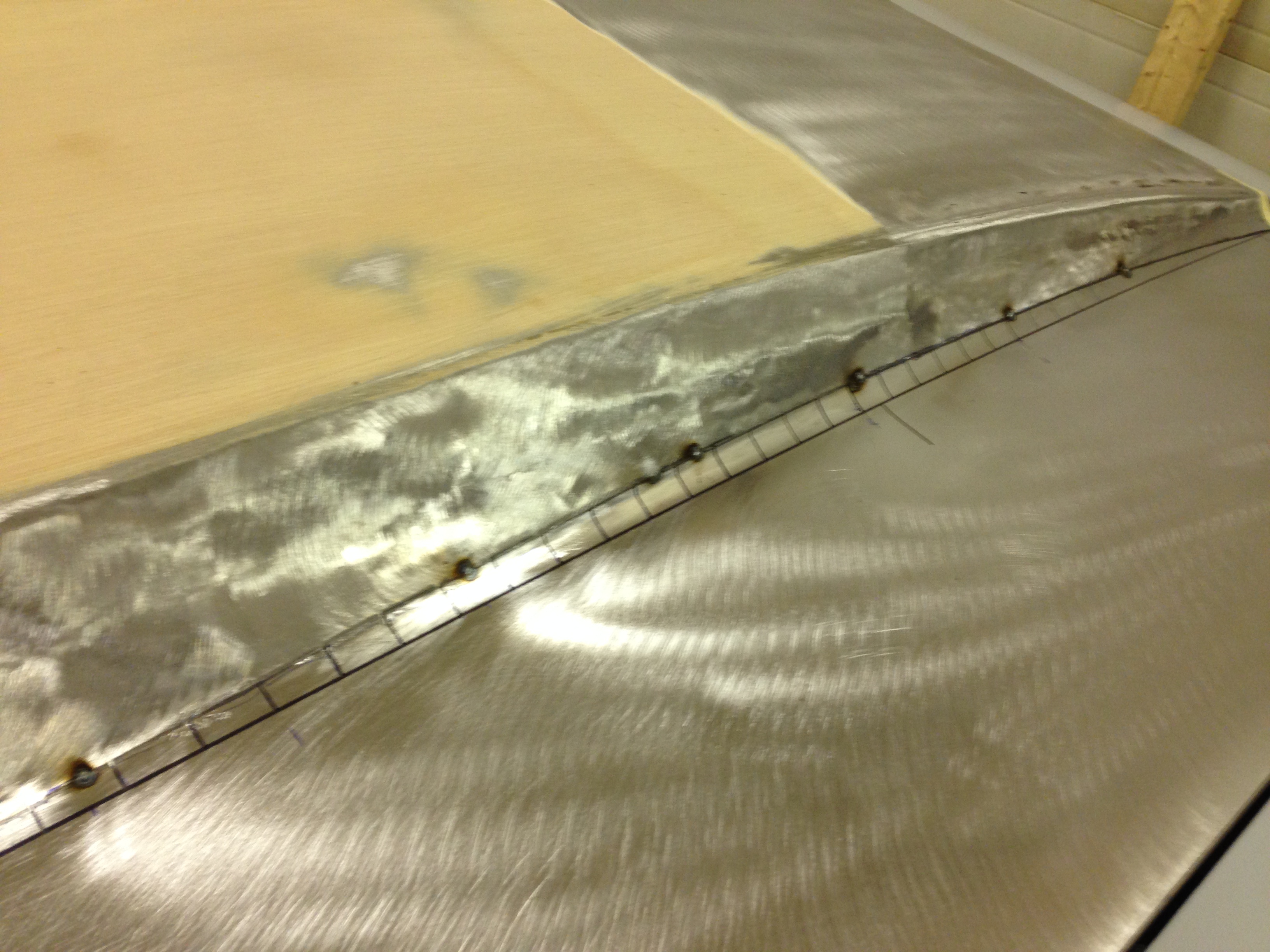

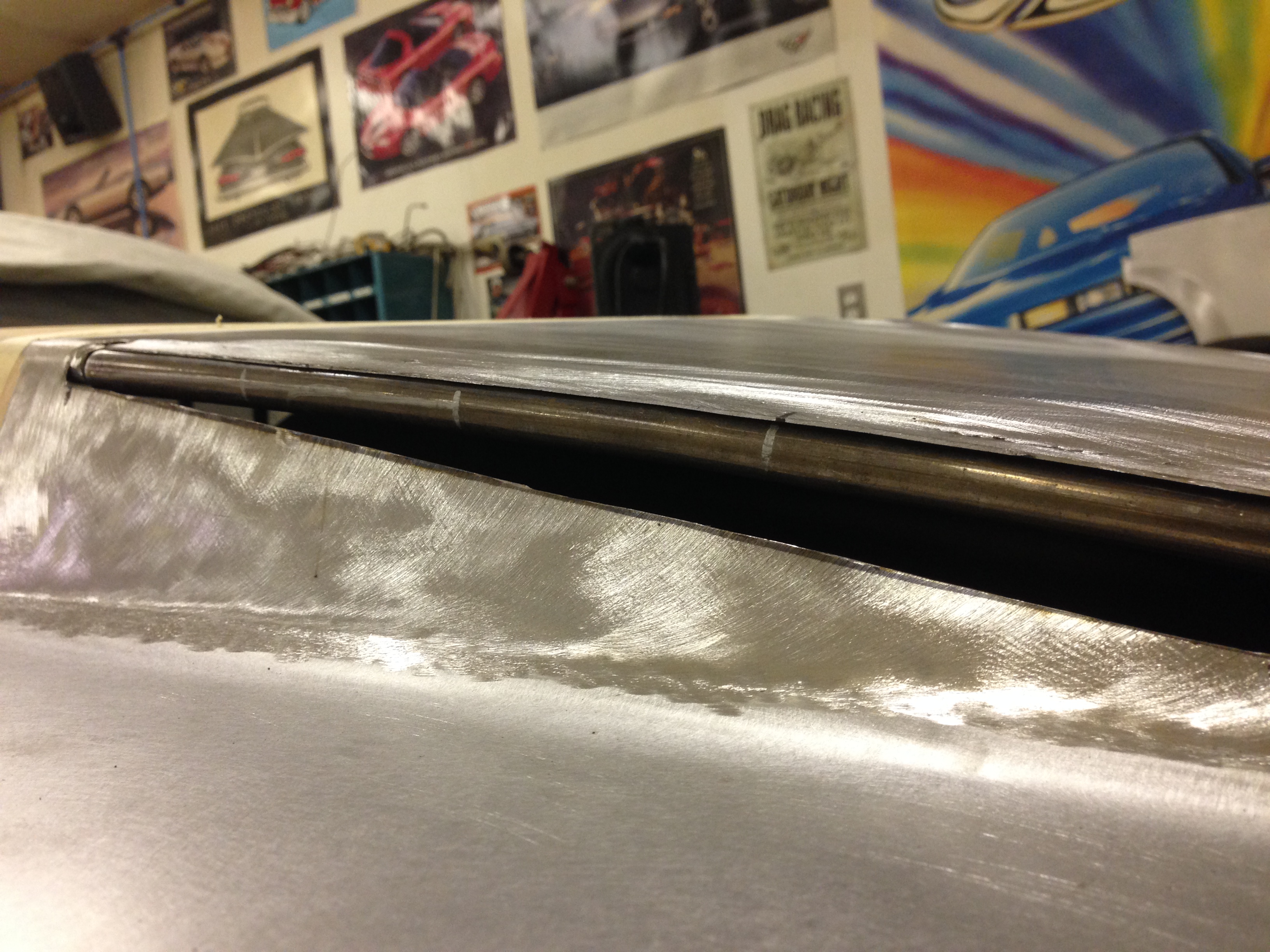

I ground off all the filler from the front half of the hood, and marked out the areas that would have to be cut out in Sharpie. Then, the surgery began. The hood skin, and the tubing below it were both cut out.

Using the template of the desired shape, I bent up two new tubes to match. In the next pic, you can see the tube matched up to the template. In the pic after that, you can see it matched up to a template I made of the original curvature it previously had. Big difference!

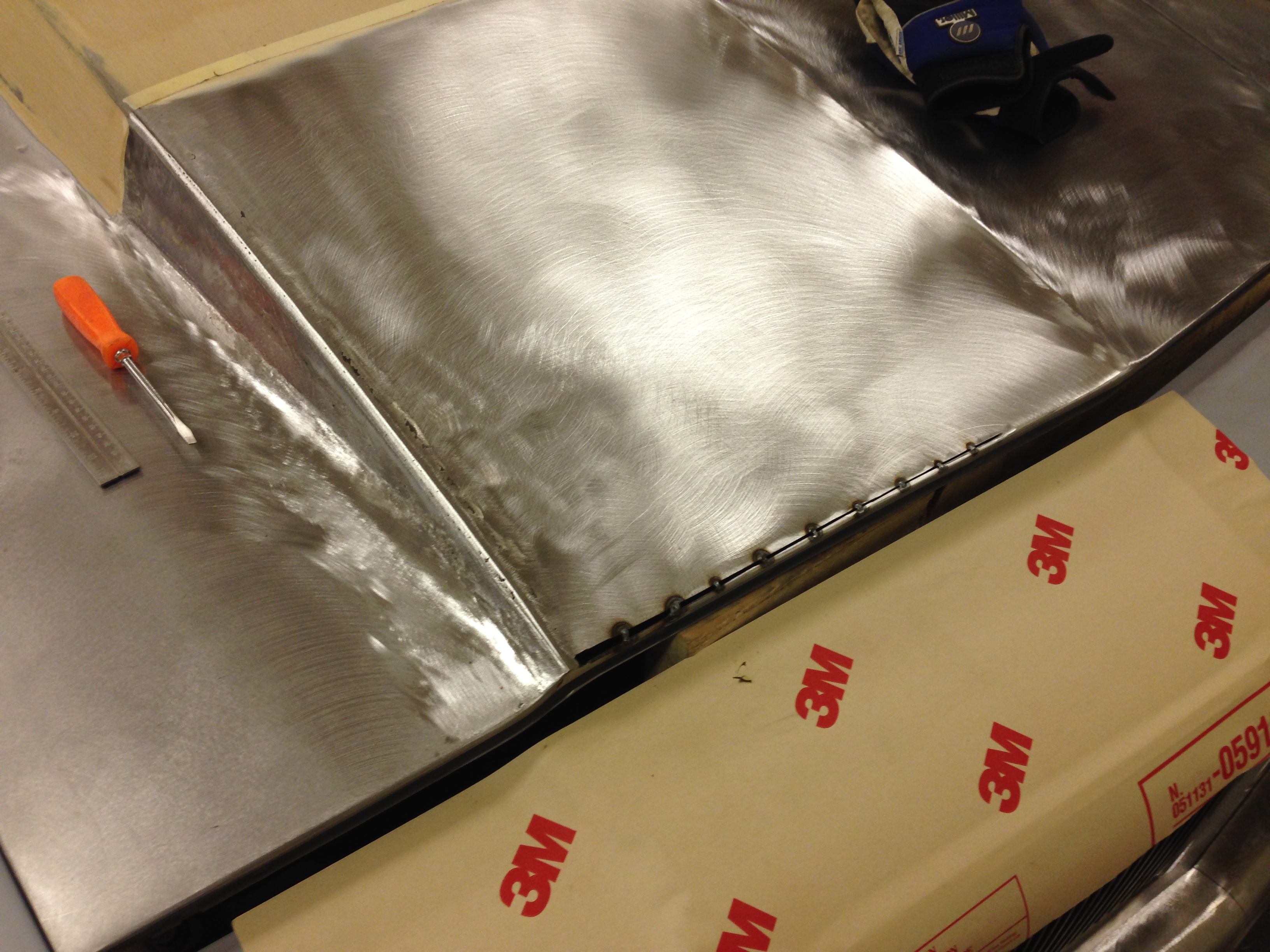

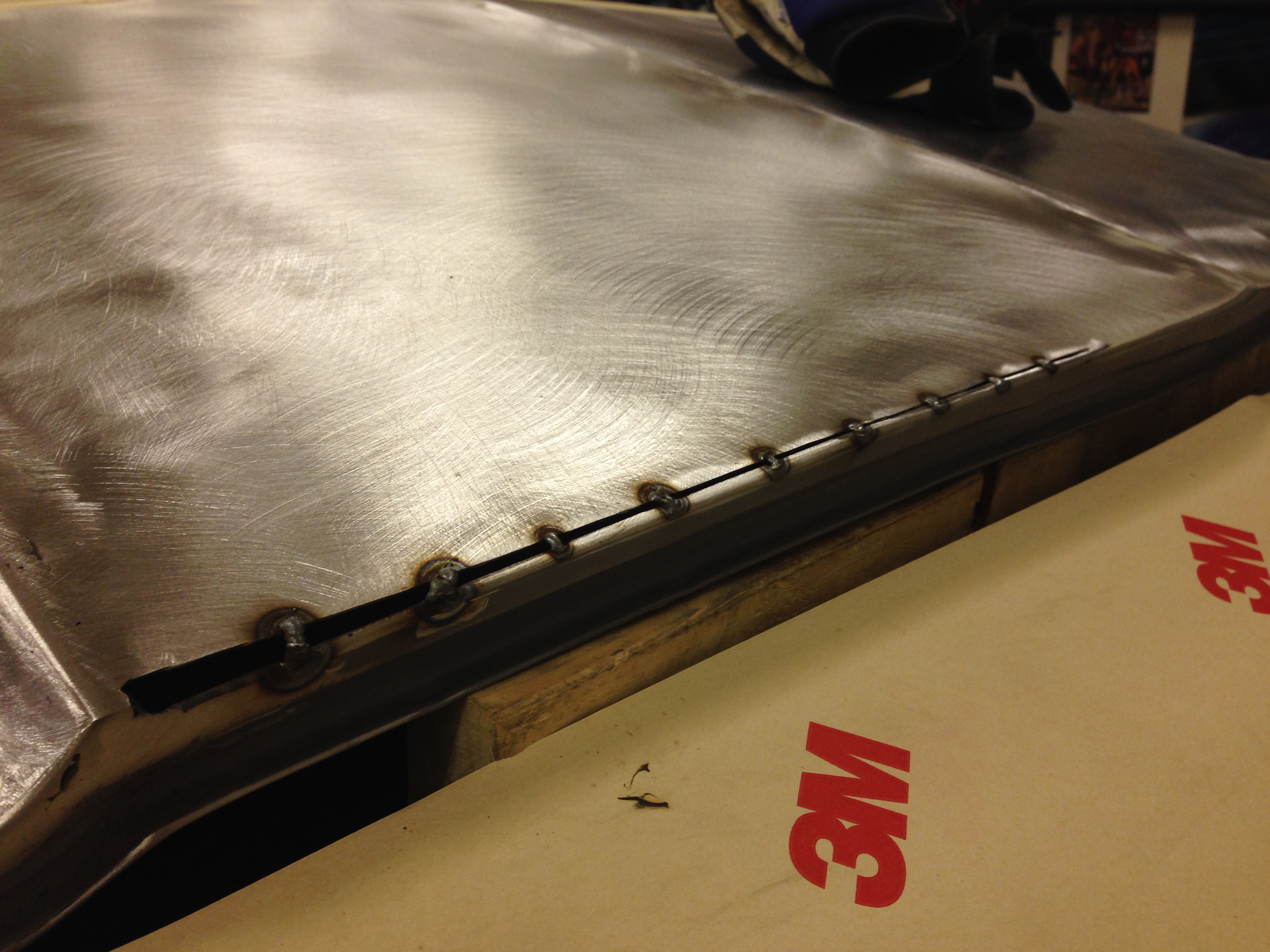

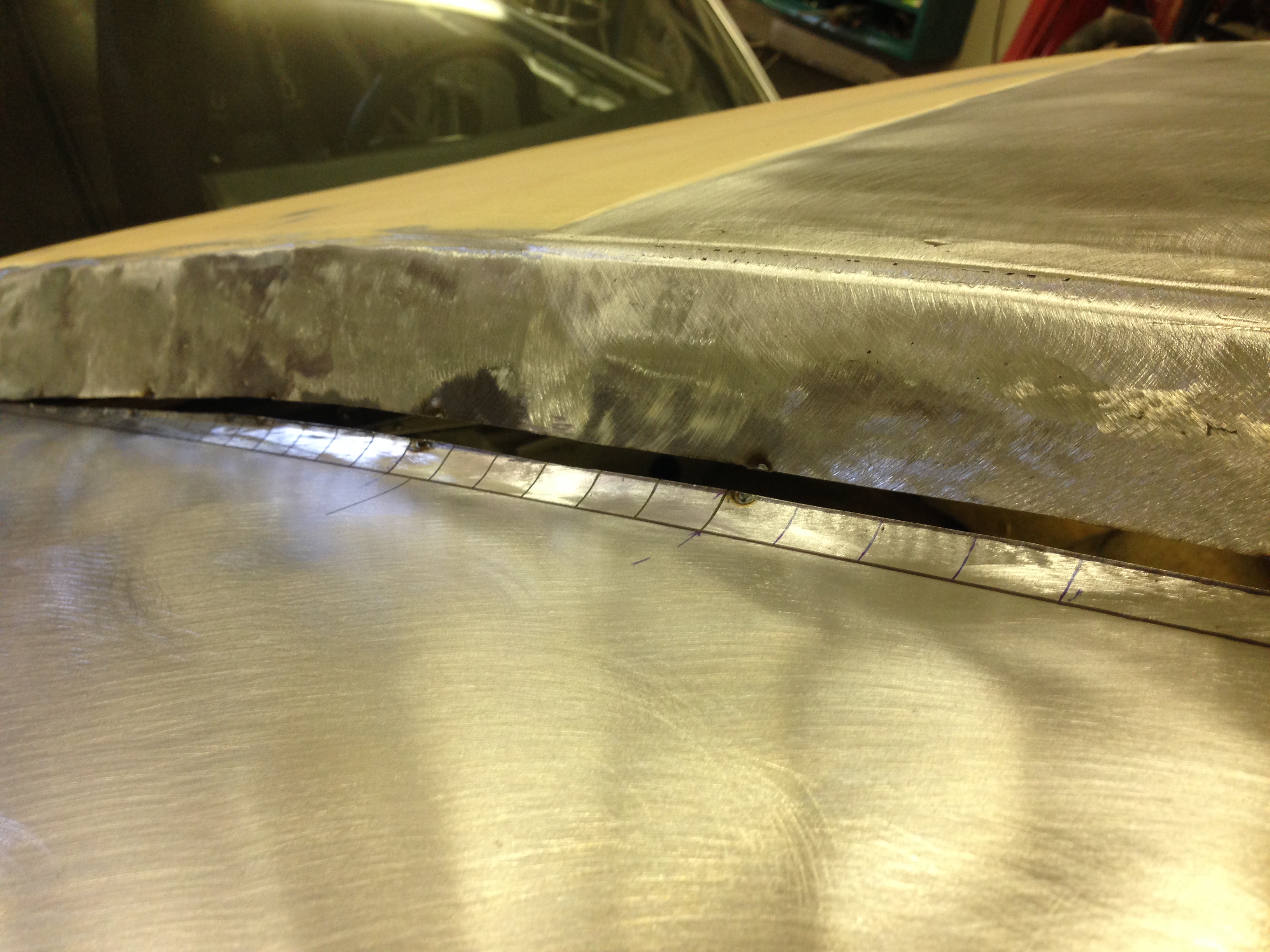

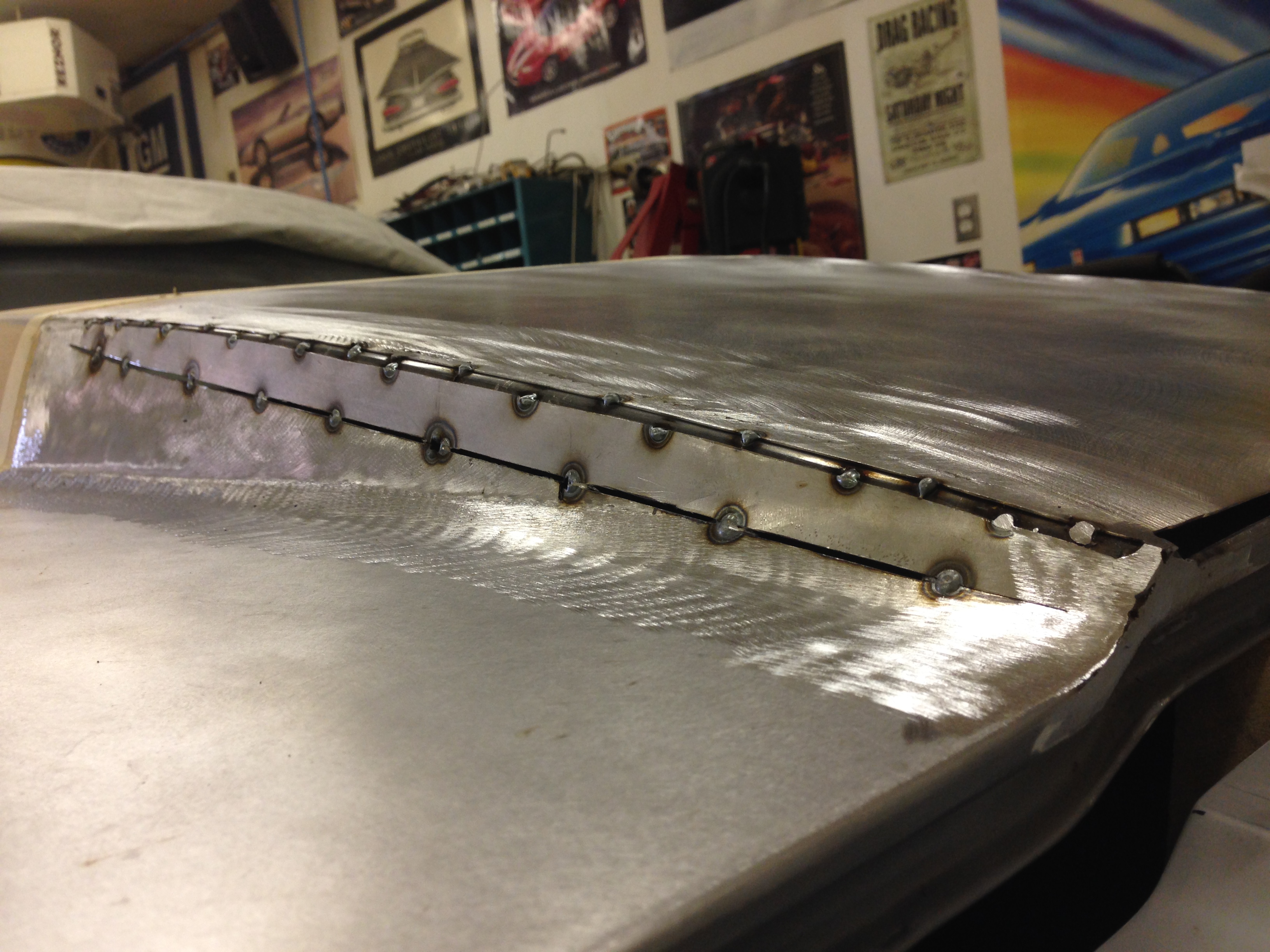

Before the new tubing could be welded in tho, the hood skin I cut out needed to be replaced.

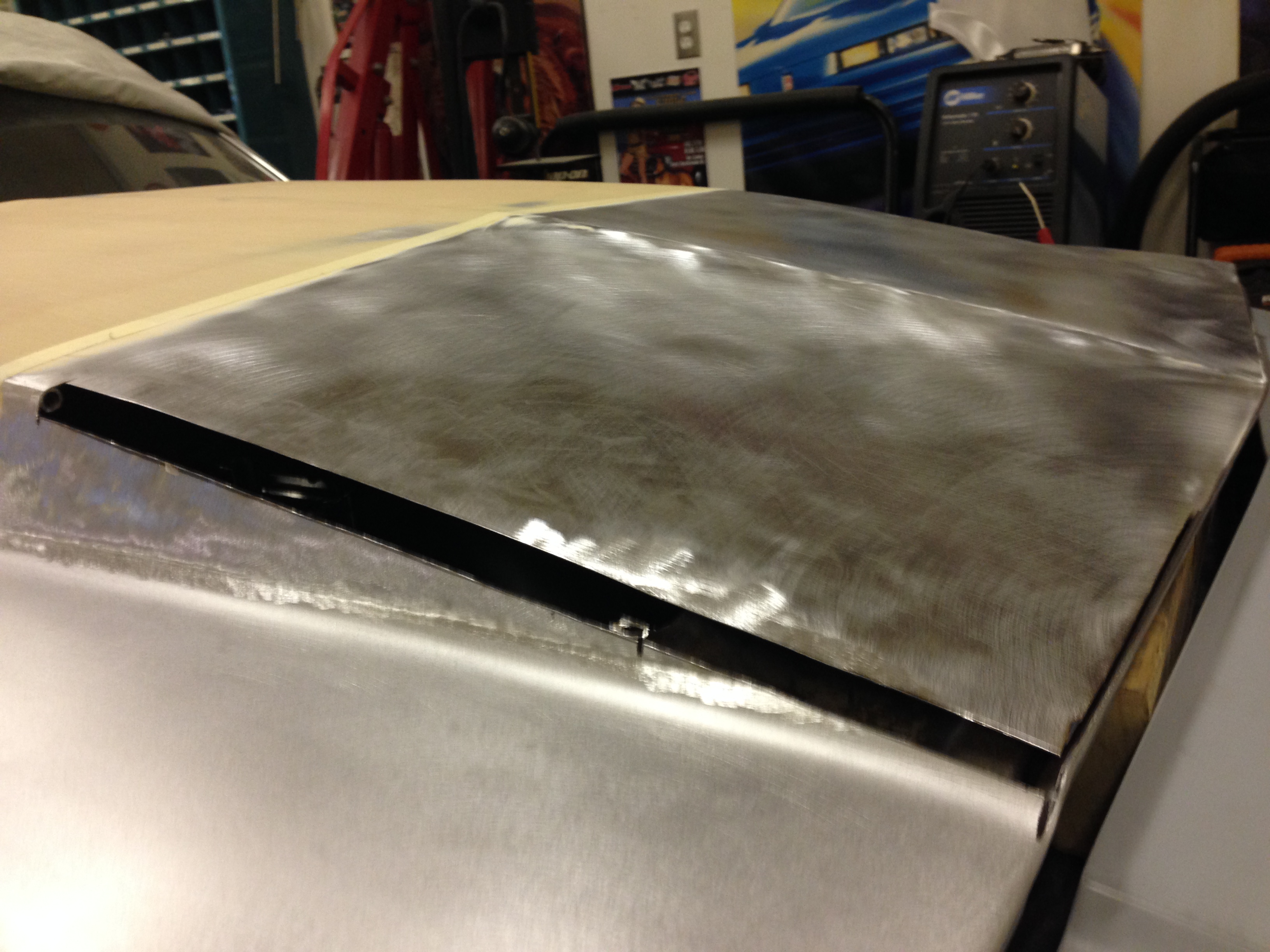

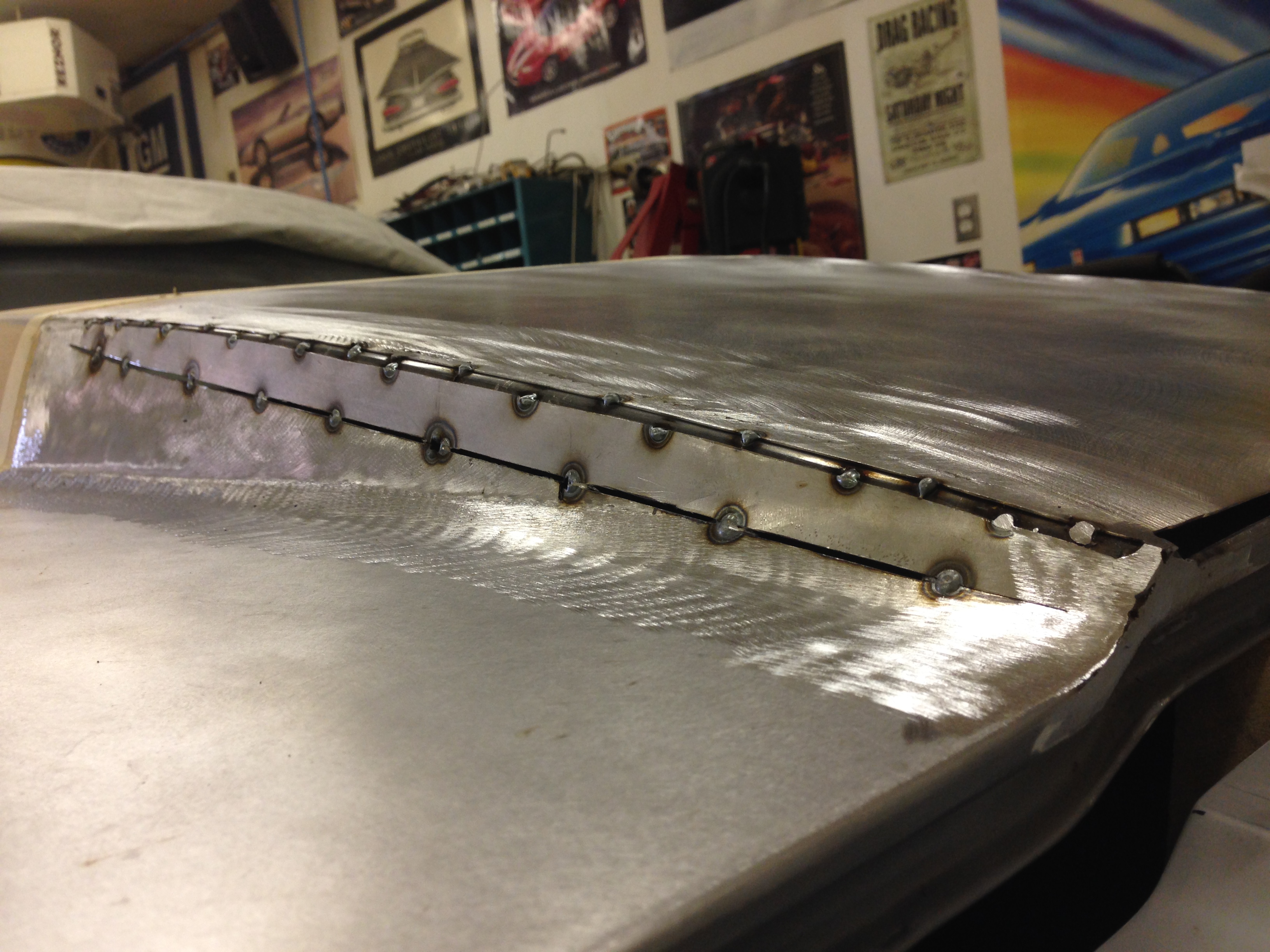

Welded in, and ground down:

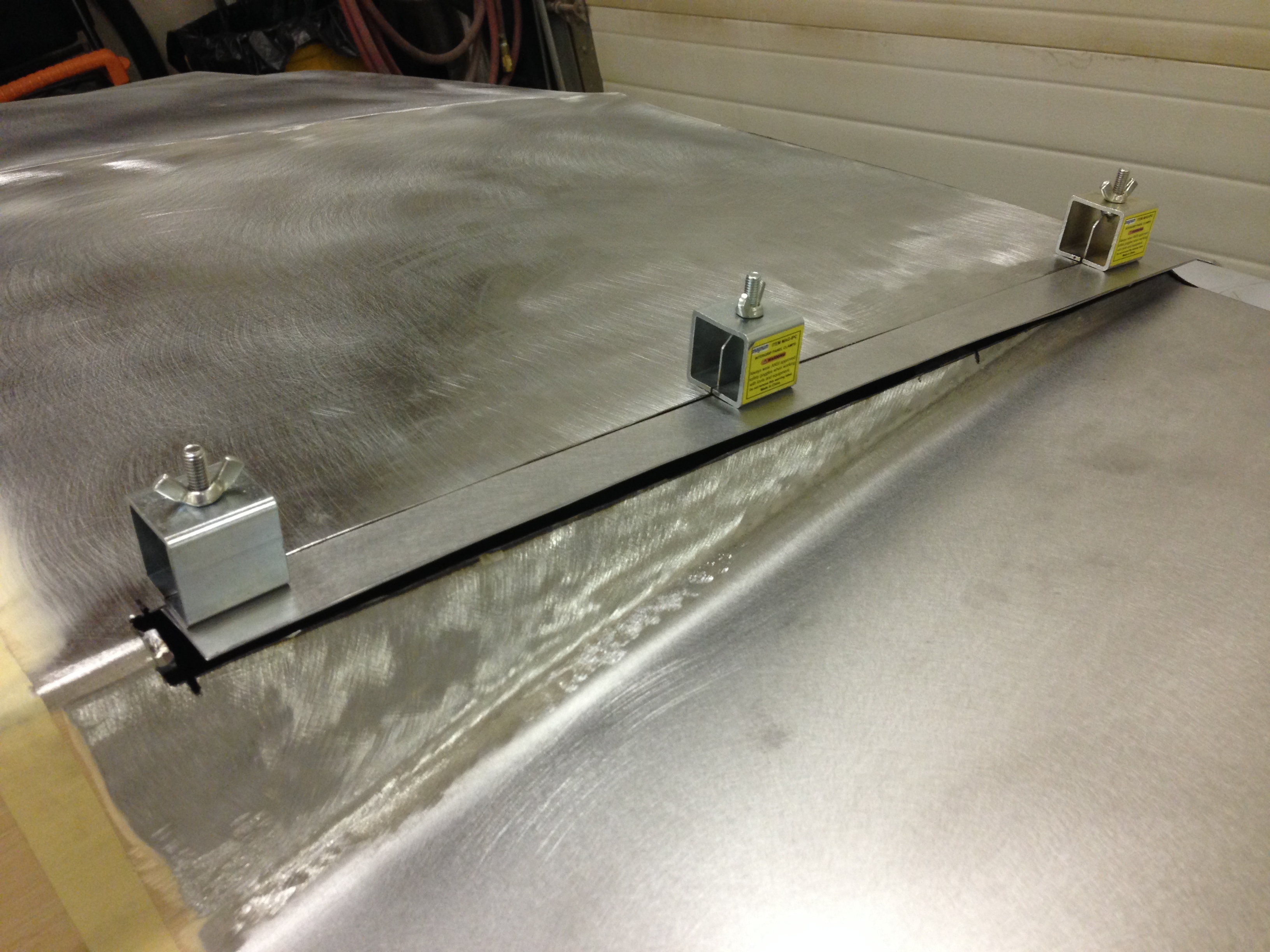

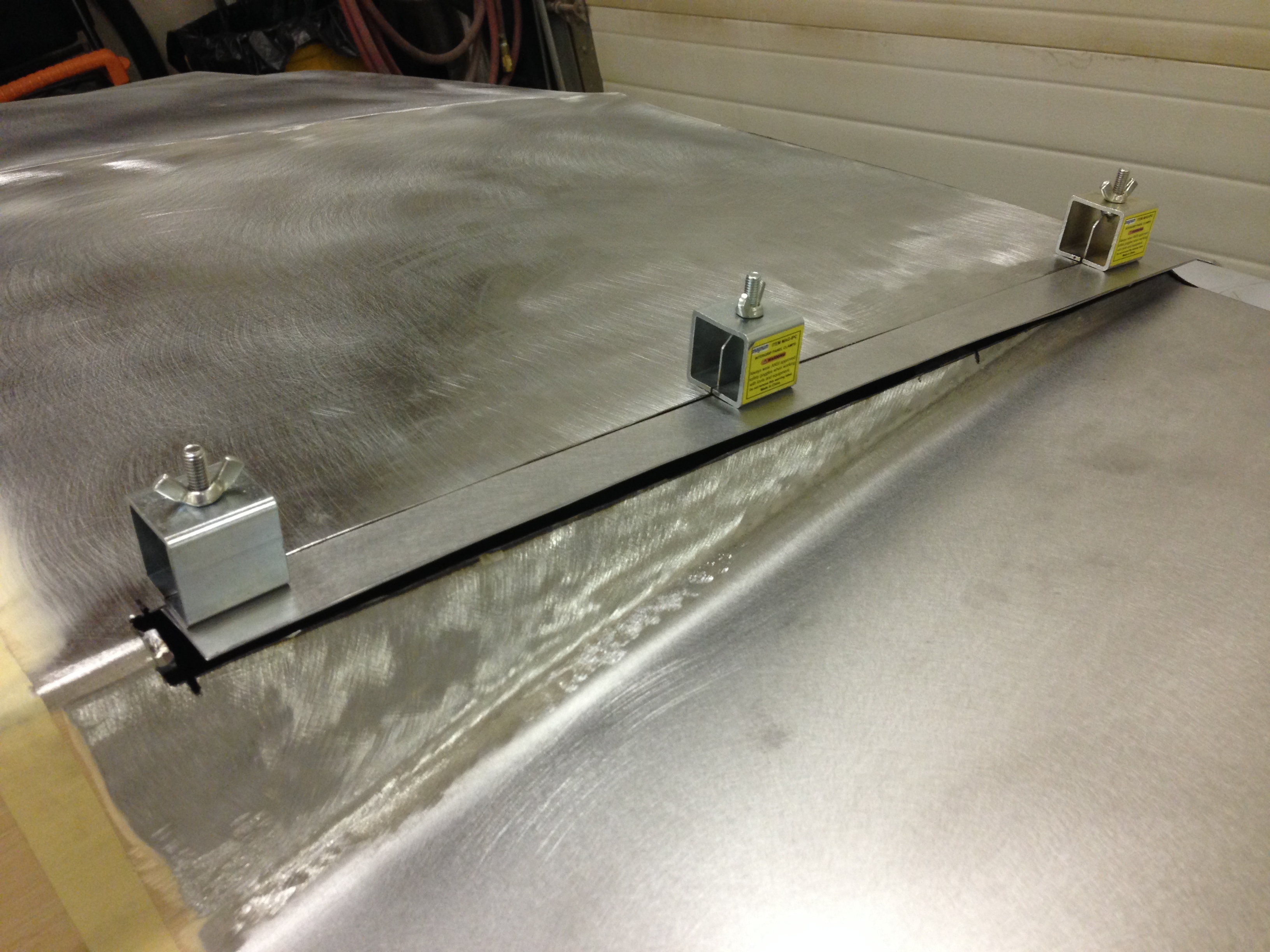

Then it was time to position and orient the new tube, and tack it in place. You may notice I had to make a relief cut across the front edge of the hood as well, this was necessary for the hood skin to move enough to accept the shape of the new tubing.

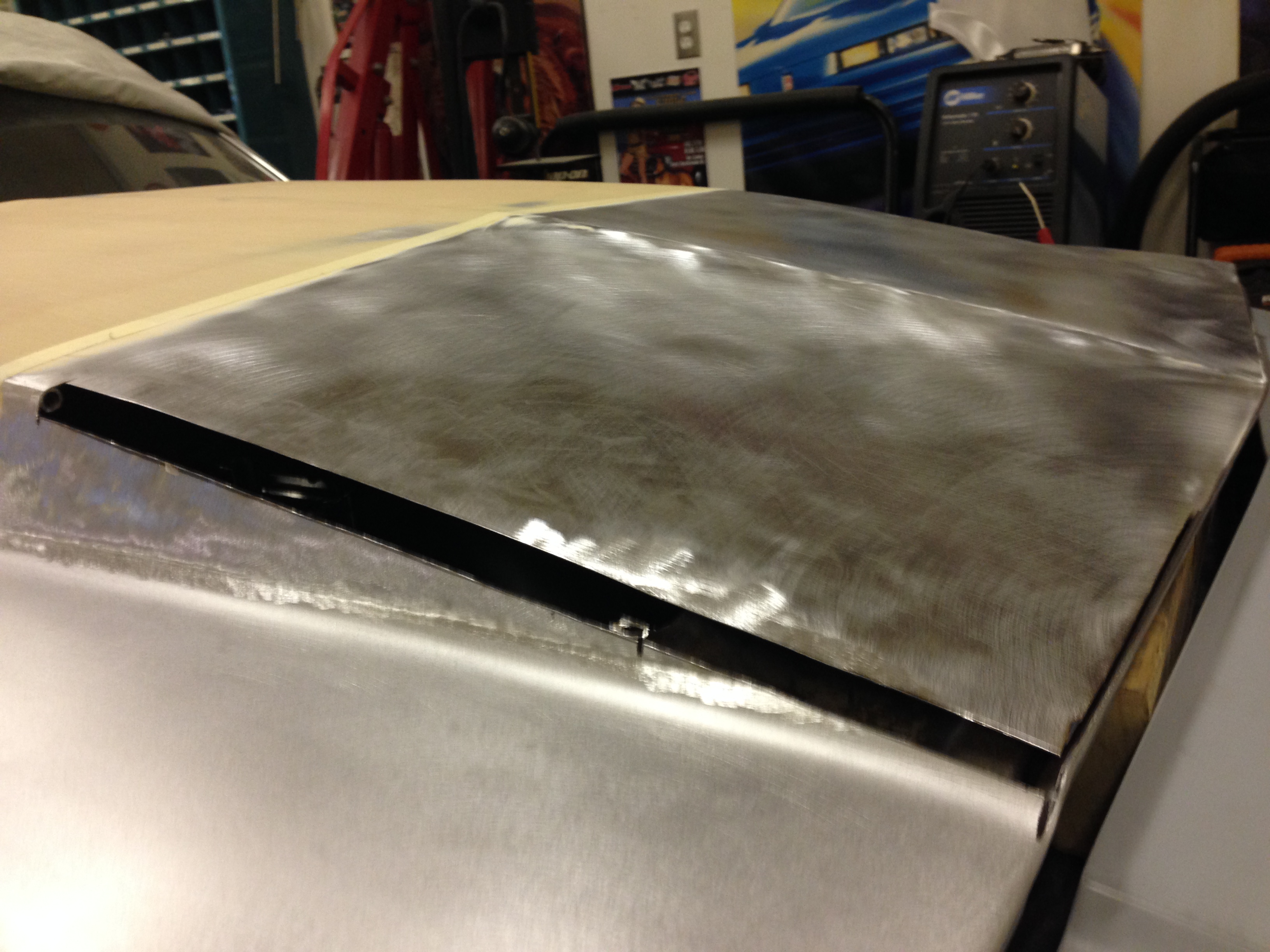

Next up was to cut and tack in a new piece of sheetmetal to replace the side that was trimmed out.

Continued >>>

🙁

I had the best of intentions to post this update shortly after covering the fabrication on the hood, but as luck would have it, life and work quickly got in the way, so here it is albeit a couple weeks late. Apologies for that too...

As I stated earlier, after the bulk of the fabrication was done on the hood, it got set aside for almost 3 years as the focus shifted to different areas of the car.

During that time, the hood found its way on and off the car several times for different reasons, giving me the opportunity to become more accustomed to seeing it as a "part of the car", rather than merely another "part" of the car.

Slowly during this time, I began to notice small things about the hood that just didn't seem right. It actually took me quite a while to hone in on what these things were, but finally one day this summer I was able to put my finger on what they were. This first instalment is going to cover what I found, and how I went about fixing them.

In my "lightbulb" moment when I finally figured out what wasn't quite right, I realized I actually had two separate issues that were going to require attention:

1) The first (and the most obvious to me) is perhaps the most critical part that makes the hood look like it belongs on the car.

The body lines that make up the raised center section have to "grow" out of where they start on the header panel.

Eyeballing the lines of the header to the hood with a critical eye, I found the curvature to smoothly transition between the two wasn't right. I tried taking several pics to illustrate what I was seeing in person, but it was extremely hard to capture it with the camera.

This pic is about the best I could get, it's a closeup of the center body line across the hood and header. It drops at the edge of the hood and leaves a dip where it meets the header.

Not cool!

The decision (however painful) was made that I would have to go back in, cut out the hood skin and tube structure in these areas, bend up new tubing and redo them.

2) The second area that needed attention was a section on both sides where the "flat" areas transitioned into the raised sides of the cowl. I say "flat", but that was actually the problem. They were too flat. They should actually have a slight graceful curve to them.

When we stood up the sides of the original hood at the cut points, it's really hard to make a curved bend, so the bend points flattened out creating really low flat points.

So, armed with a half assed plan to rectify the first issue, I drug home some cardboard from work, and made templates of the "proper" curvature I felt it needed to have and got down to business. Here is the template with the proper shape it SHOULD have.

Having this template to work towards was crucial, and by using the same one for both sides, it would ensure both sides would be symmetrical.

I ground off all the filler from the front half of the hood, and marked out the areas that would have to be cut out in Sharpie. Then, the surgery began. The hood skin, and the tubing below it were both cut out.

Using the template of the desired shape, I bent up two new tubes to match. In the next pic, you can see the tube matched up to the template. In the pic after that, you can see it matched up to a template I made of the original curvature it previously had. Big difference!

Before the new tubing could be welded in tho, the hood skin I cut out needed to be replaced.

Welded in, and ground down:

Then it was time to position and orient the new tube, and tack it in place. You may notice I had to make a relief cut across the front edge of the hood as well, this was necessary for the hood skin to move enough to accept the shape of the new tubing.

Next up was to cut and tack in a new piece of sheetmetal to replace the side that was trimmed out.

Continued >>>