I think they will few to no takers at that price. You can put a conversion together with other transmissions for half of that or even less if you source used items.

I am not a fan of hydraulic clutches based on experience with my daily drivers. I'll probably piss some people off. IMHO, Mechanical clutches typically give better pedal feel and can be repaired much faster than pretty much any hydraulic; especially if they have an internal slave such as those hydraulic throw out bearing set ups. Most mechanical set ups do not require removing the transmission/bell housing to replace worn or broken items.

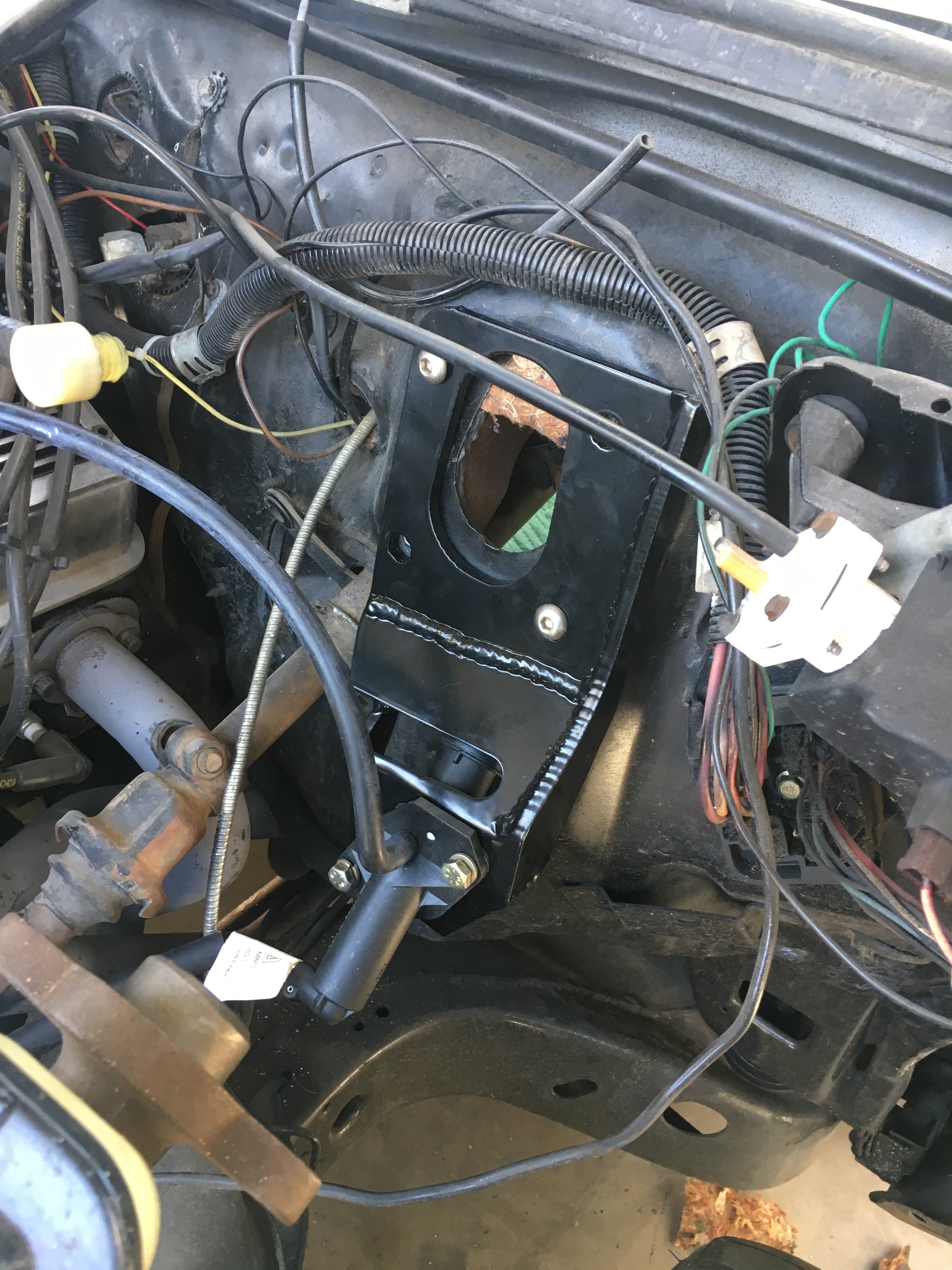

This is why I want to go with mechanical linkage.