Re: My t56 and ford 8.8 swap!

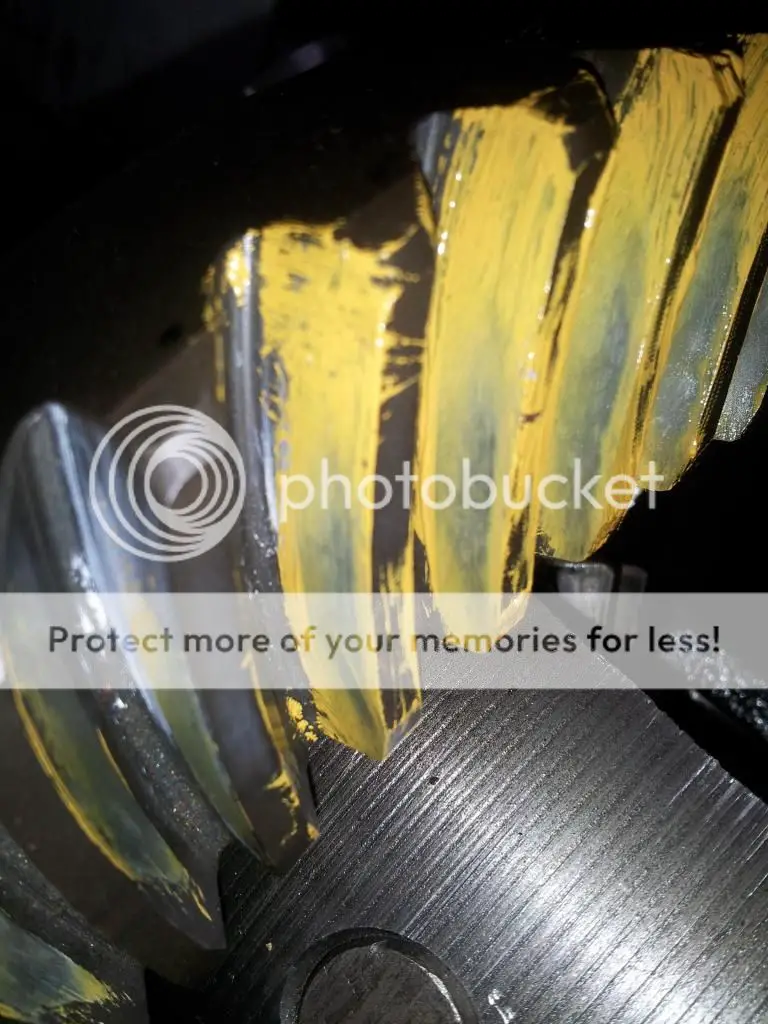

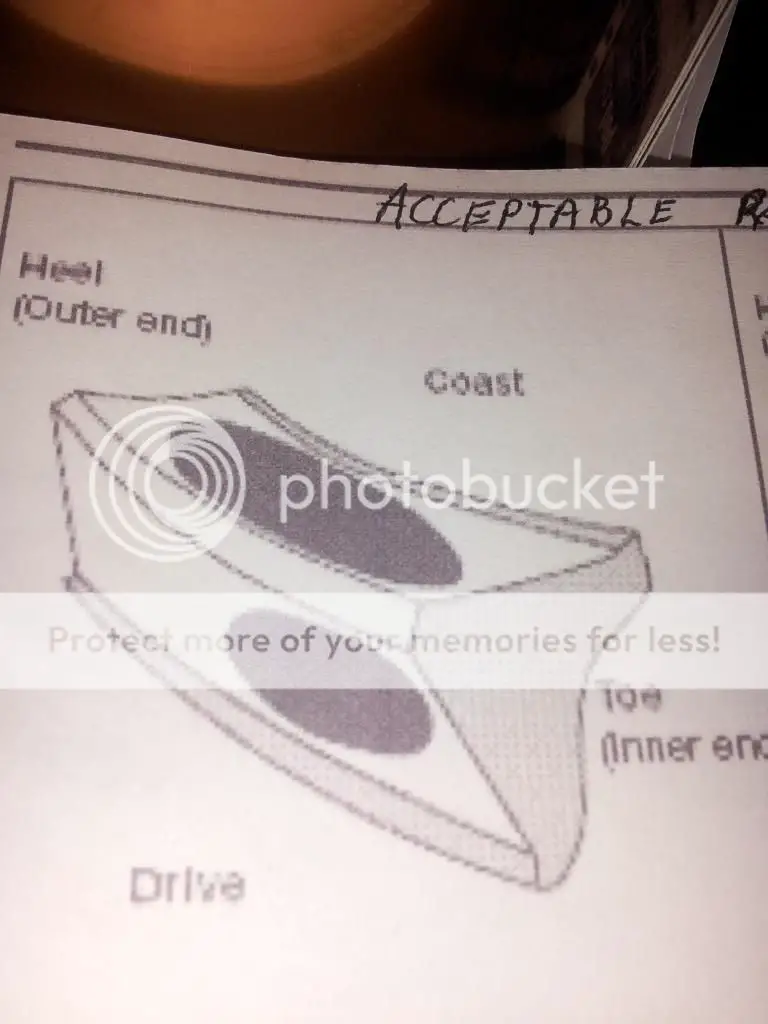

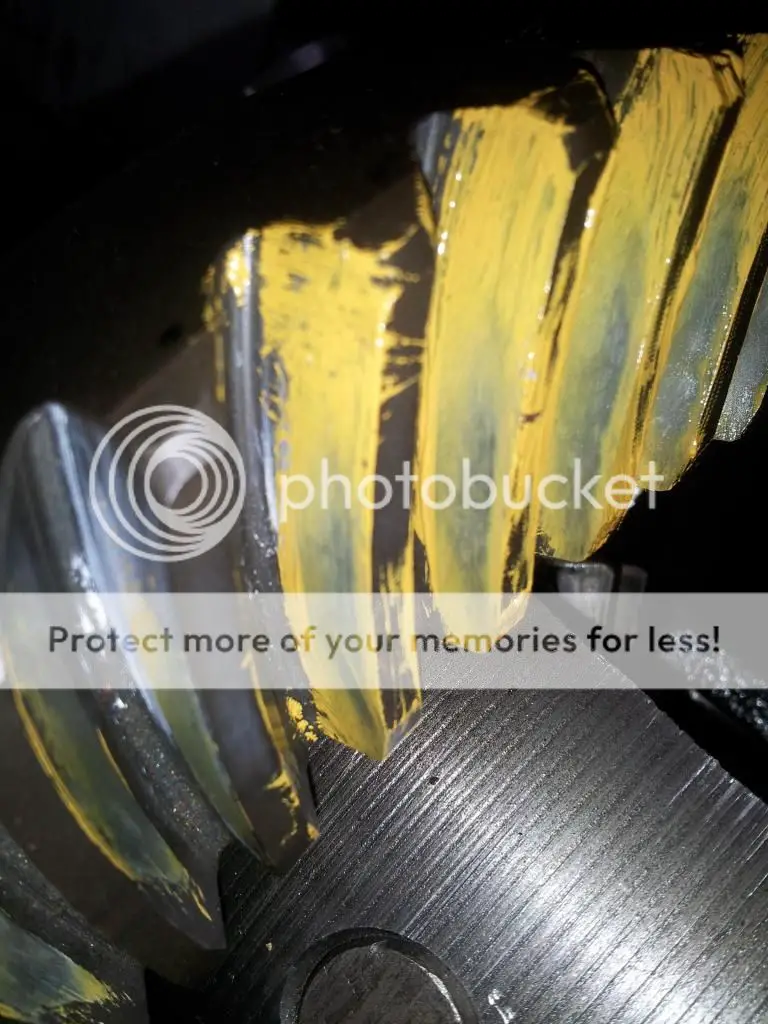

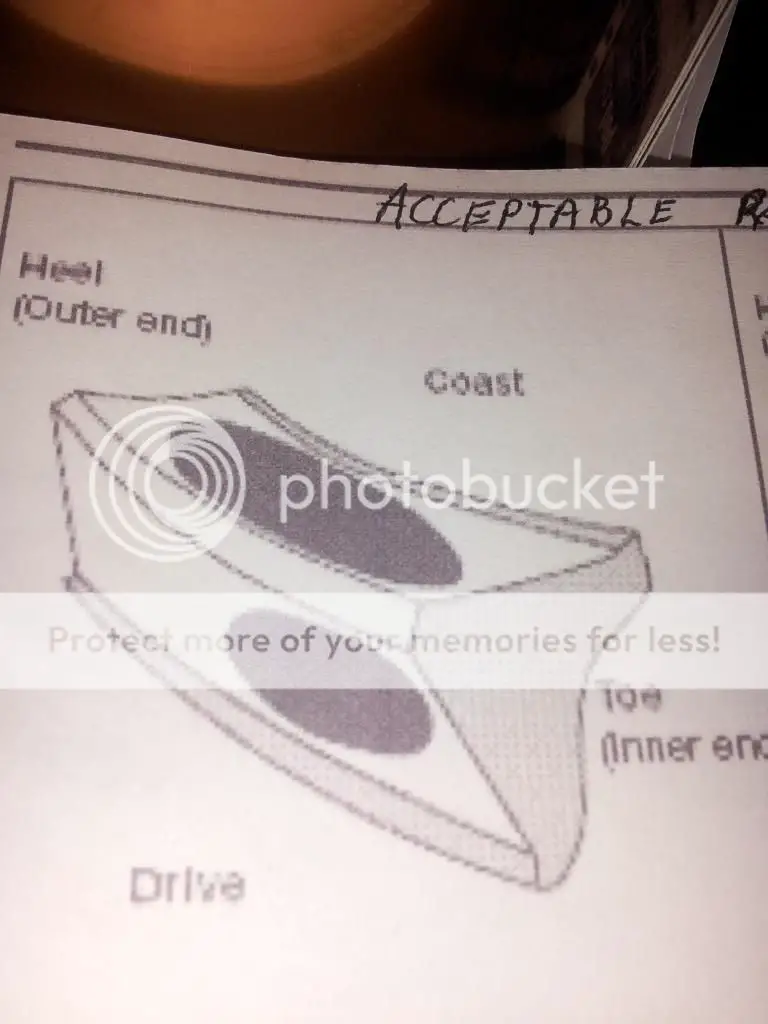

Well I got some work done on the 8.8. Double checked the gear pattern, got it cleaned up and primed, and bought the rubber lines for it and the conversion u joint. The local napa had books and someone who knew how to use them. He looked up the u joints for the 2 cars and then went into a conversion joint catalog, found one joint with both joints in one and I got what I needed, a #355 moog u joint fits the stock 87 cutlass shaft and the 90's mustang flange piece according to the book.

Gotta get some maintenance work done on the wagon, then I'll swap them for working garage and storage garage, get some paint on this thing and make some lines, then put it in maybe. Just up in the air though, I picked up a set of mopar steelies with the 5x4.5 pattern, but I'm thinking of picking up this:

http://www.rottenleonard.com/Menu.html

and redrilling it for the gm pattern, I'm just unsure if the stock wheels will fit with the backspacing and the wider rear... I'd rather have the same bolt pattern all the way around.

Well I got some work done on the 8.8. Double checked the gear pattern, got it cleaned up and primed, and bought the rubber lines for it and the conversion u joint. The local napa had books and someone who knew how to use them. He looked up the u joints for the 2 cars and then went into a conversion joint catalog, found one joint with both joints in one and I got what I needed, a #355 moog u joint fits the stock 87 cutlass shaft and the 90's mustang flange piece according to the book.

Gotta get some maintenance work done on the wagon, then I'll swap them for working garage and storage garage, get some paint on this thing and make some lines, then put it in maybe. Just up in the air though, I picked up a set of mopar steelies with the 5x4.5 pattern, but I'm thinking of picking up this:

http://www.rottenleonard.com/Menu.html

and redrilling it for the gm pattern, I'm just unsure if the stock wheels will fit with the backspacing and the wider rear... I'd rather have the same bolt pattern all the way around.