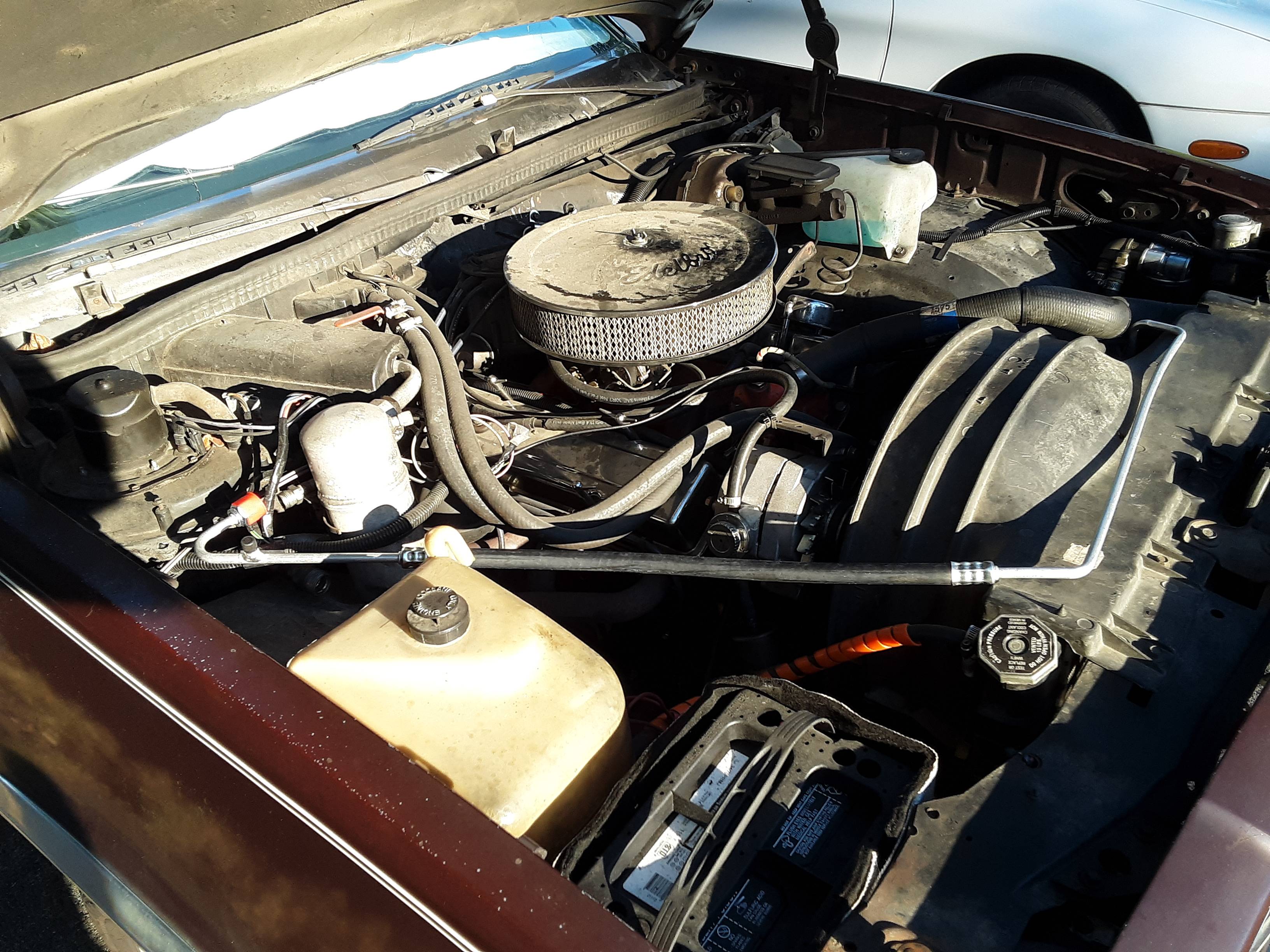

Well, it ended up being plan or ?? I dug that old mini-blaster out from its place on the bottom shelf on the rolling side table and tried to use fine blast sand to strip the rear end. The only that got blasted was my patience as it did exactly what caused me to dump it in the first place and clogged up, Did some hand stripping using a paint remover and a small hammer while the thunder roared and the rain came down. Then decided to tear down the blaster and see why it kept clogging up. Come to find out that the delivery port between the sand reservoir and the air passage was something on the order of 3/16ths or less in diameter so threw a 1/4 inch drill bit at it to see that would help matters............................and the bit broke.

Got the bit out and finished the oversizing, and put it mostly back together, still have to refit the nozzle. which now needs an oring to seal it. Plan Q is to hand strip all the undercoating that still is present, good stuff that 3M and then go sand for the rust and finish it off with either a wire wheel or an abrasive disk. The end game is to get it as clean and fresh as possible to avoid the return of rust and to give the paint a good surface to grab to.

Nick

Got the bit out and finished the oversizing, and put it mostly back together, still have to refit the nozzle. which now needs an oring to seal it. Plan Q is to hand strip all the undercoating that still is present, good stuff that 3M and then go sand for the rust and finish it off with either a wire wheel or an abrasive disk. The end game is to get it as clean and fresh as possible to avoid the return of rust and to give the paint a good surface to grab to.

Nick