Tried nailing down my speedo issue in the Camaro today. As soon as I move the thing buries itself. I swapped in my spare ECM/chip and suddenly the speedo was working. Put my chip BDZL with adapter in spare ECM and no go. Put just BDZL in spare ECM and good. Put spare chip BDLD in current ECM and good. Put BDZL in, no adapter, current ECM no good. Try spare chip with BDLD current ECM no good. WTF.

What did you do to your non-G body project today? [2020]

- Thread starter Bonnewagon

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Made some Brazilian Grilled Pineapple to go with the chicken. Our BBQ has an adult and a kid side.

EPIPHANY!!!

Back story to this is that I actually have two G Model vehicles. My newer? one is my project vehicle and the one about which I have periodically posted as I make progress or I fabricate or modify something that I think is worth mentioning. That, by name, is called Project Regress because for every step forward it seems like I take two steps back. (Check my threads and posts on other occasions to see what I mean)

My other G Body is actually my 1980 Chevrolet G-10 full size Sport Van. This is a combination vehicle for me as it has been my summer driver, hauler, camper, bar, mobile repair shop, as well as daily driver; but only in the summer. Winters it gets parked.

Over the years I have periodically visited it to update or upgrade various systems. One of the first things to go was the intake and carb in favor of an Edelbrock/Holley combination which worked okay but had its idiosyncracies. The Holley lovers society is probably going to dump on me for this but the Holley carb, for all its versatility and guts, is also a very finicky carb to keep in tune; particularly if where you live has actual seasons. The carb I started with was a 4150 with side floats, secondary jet plate, and a manual choke. What I ended up with was a 4150 with cathedral bowls and center floats, secondary metering block and jets and the second of two base plates because the first wore out. Only place in the world that that carb was happy was at Sturgis, S. Dakota. Here, on the northern lakes, it barfed and stalled and sneezed and wheezed and generally refused to cooperate when the weather was anything but 75 or hotter and no humidity!! In car, getting to a carb to tweak is as easy as popping the hood. In the van, the motor is buried half underneath the dash and you have to take things apart just to gain basic access.

Bottom line, I went EFI, specifically a FI Tech 400 hp unit. Nothing fancy.

Yes it did start and run right out of the box once I got all the subsystems sorted out. Tip: if you do use the vent system as the return, as the instructions suggested, don't leave the charcoal canister in the circuit. Gas all over the place and one very unhappy canister; it got exiled to the greenhouse to dry out for over a year-still there actually.

However, despite all the easiness, there was one thing that did not sit well with me. That was how stiff the throttle pedal was. Thought the issue was the throttle springs on the body itself and Fi Tech staff did suggest that one of them could be removed to soften the pressure.

Hadn't done anything about until this year when I finally decided that enough was too much and the pedal needed to be visited, along with I major periodic stumble that tweaking the IAC had not cured. Minus the original paperwork for the unit, which is somewhere hiding, I elected to surf some Y-T videos to see if they were on line. BIG SURPRISE!!

FI Tech units have idle stop screws!!! One for the throttle and one for the IAC setting. THIS I DID NOT KNOW and it was not mentioned as I recall in the original paperwork. So I went looking and there they were. Two unobtrusive little Philips headed screws tucked discretely under other things. Set the idle and visited the IAC, repeatedly. A lot better idle but higher than I wanted or had set for my default. Okay, back to video land. Turned out that when, along with setting the screws, I visited the A/F ratios to see if they could be tweaked, I had pushed them in the wrong direction. What I had done was to decrease the percentage of air per volume of fuel. = Way Rich. Okay, back to the tables and edit them to reverse the problem. Boy did that make a difference. Curb idle in park came down, idle screw became responsive, even the IAC settings started to come in.

Drove it today for a while, stop and go driving which is usually the hardest to map right and what a difference. Way more responsive to the pedal and the pedal an enormous amount of easier to push and feather.

Turns out that the front idle screw for the throttle must have been backed off completely as delivered from the factory. Remember that these units come in a box and apparently don't get physical tuning time before they are packaged. Build the body, load the software, and away it goes. The only thing with that front screw is that, being buried under the architecture of the throttle body as it is, you can't easily see when the screw tip first makes contact with the cam on the throttle lever. Not being out in the open like it is on a carb, Very hard to "feel" when the screw touches and is starting to move the lever.

So what will happen now is some daily driving to see how well all this works out in the commuter zone.

Oh, yeah, for anyone doing this type of tweak, Be Sure to Save Your Changes. Nothing you do will get remembered by the ECU unless you save it. Lot of sniveling attached to some of the videos by folks trying to make the change and it not taking effect. Gotta toggle that "Save to ECU icon or button or nothing will happen.

Nick

Back story to this is that I actually have two G Model vehicles. My newer? one is my project vehicle and the one about which I have periodically posted as I make progress or I fabricate or modify something that I think is worth mentioning. That, by name, is called Project Regress because for every step forward it seems like I take two steps back. (Check my threads and posts on other occasions to see what I mean)

My other G Body is actually my 1980 Chevrolet G-10 full size Sport Van. This is a combination vehicle for me as it has been my summer driver, hauler, camper, bar, mobile repair shop, as well as daily driver; but only in the summer. Winters it gets parked.

Over the years I have periodically visited it to update or upgrade various systems. One of the first things to go was the intake and carb in favor of an Edelbrock/Holley combination which worked okay but had its idiosyncracies. The Holley lovers society is probably going to dump on me for this but the Holley carb, for all its versatility and guts, is also a very finicky carb to keep in tune; particularly if where you live has actual seasons. The carb I started with was a 4150 with side floats, secondary jet plate, and a manual choke. What I ended up with was a 4150 with cathedral bowls and center floats, secondary metering block and jets and the second of two base plates because the first wore out. Only place in the world that that carb was happy was at Sturgis, S. Dakota. Here, on the northern lakes, it barfed and stalled and sneezed and wheezed and generally refused to cooperate when the weather was anything but 75 or hotter and no humidity!! In car, getting to a carb to tweak is as easy as popping the hood. In the van, the motor is buried half underneath the dash and you have to take things apart just to gain basic access.

Bottom line, I went EFI, specifically a FI Tech 400 hp unit. Nothing fancy.

Yes it did start and run right out of the box once I got all the subsystems sorted out. Tip: if you do use the vent system as the return, as the instructions suggested, don't leave the charcoal canister in the circuit. Gas all over the place and one very unhappy canister; it got exiled to the greenhouse to dry out for over a year-still there actually.

However, despite all the easiness, there was one thing that did not sit well with me. That was how stiff the throttle pedal was. Thought the issue was the throttle springs on the body itself and Fi Tech staff did suggest that one of them could be removed to soften the pressure.

Hadn't done anything about until this year when I finally decided that enough was too much and the pedal needed to be visited, along with I major periodic stumble that tweaking the IAC had not cured. Minus the original paperwork for the unit, which is somewhere hiding, I elected to surf some Y-T videos to see if they were on line. BIG SURPRISE!!

FI Tech units have idle stop screws!!! One for the throttle and one for the IAC setting. THIS I DID NOT KNOW and it was not mentioned as I recall in the original paperwork. So I went looking and there they were. Two unobtrusive little Philips headed screws tucked discretely under other things. Set the idle and visited the IAC, repeatedly. A lot better idle but higher than I wanted or had set for my default. Okay, back to video land. Turned out that when, along with setting the screws, I visited the A/F ratios to see if they could be tweaked, I had pushed them in the wrong direction. What I had done was to decrease the percentage of air per volume of fuel. = Way Rich. Okay, back to the tables and edit them to reverse the problem. Boy did that make a difference. Curb idle in park came down, idle screw became responsive, even the IAC settings started to come in.

Drove it today for a while, stop and go driving which is usually the hardest to map right and what a difference. Way more responsive to the pedal and the pedal an enormous amount of easier to push and feather.

Turns out that the front idle screw for the throttle must have been backed off completely as delivered from the factory. Remember that these units come in a box and apparently don't get physical tuning time before they are packaged. Build the body, load the software, and away it goes. The only thing with that front screw is that, being buried under the architecture of the throttle body as it is, you can't easily see when the screw tip first makes contact with the cam on the throttle lever. Not being out in the open like it is on a carb, Very hard to "feel" when the screw touches and is starting to move the lever.

So what will happen now is some daily driving to see how well all this works out in the commuter zone.

Oh, yeah, for anyone doing this type of tweak, Be Sure to Save Your Changes. Nothing you do will get remembered by the ECU unless you save it. Lot of sniveling attached to some of the videos by folks trying to make the change and it not taking effect. Gotta toggle that "Save to ECU icon or button or nothing will happen.

Nick

I went on a road trip today with my buddy Pat. 160 miles each way to my family's shop in PA he had to make the last payment on the restoration of his 87 square body and pack up the parts so I can finish the assembly and make the arrangements to have it shipped back to Jersey. Unfortunately I took a ton of video and don't know how to post it but the truck looks amazing!

Not bad at all for a truck that was a work truck in the northeast all it's life. Every thing is done even the frame is painted

Not bad at all for a truck that was a work truck in the northeast all it's life. Every thing is done even the frame is painted

Threw a new bar on my 272xp.

View attachment 149073

Chainsaws! I forget if I post whored mine or not. Had a fuel line deteriorate in the tank and cause a leak/no run condition. Fixed that, tightened the chain, and now I'm ready to chop up a shitload of deck boards into campfire wood. Got the saw from my dad when he died, didn't run but was damn clean and looked to be very low use.

Chainsaws! I forget if I post whored mine or not. Had a fuel line deteriorate in the tank and cause a leak/no run condition. Fixed that, tightened the chain, and now I'm ready to chop up a shitload of deck boards into campfire wood. Got the saw from my dad when he died, didn't run but was damn clean and looked to be very low use.

What kinda saw?

What kinda saw?

If I'm honest, it's a bit of a JV chainsaw, a Poulan Wild Thing. No chain brake, but more than enough for my needs. Beats the sh*t out of fetching campfire wood with a hatchet.

If I'm honest, it's a bit of a JV chainsaw, a Poulan Wild Thing. No chain brake, but more than enough for my needs. Beats the sh*t out of fetching campfire wood with a hatchet.

I've worked on a few of those. Neighbor has been heating his house for 15 years at least with one. They seem to last a long time for homeowner saws. I have two Poulans, old ones, 80s vintage. One is a 2800, 46cc, was $25 at a yard sale.

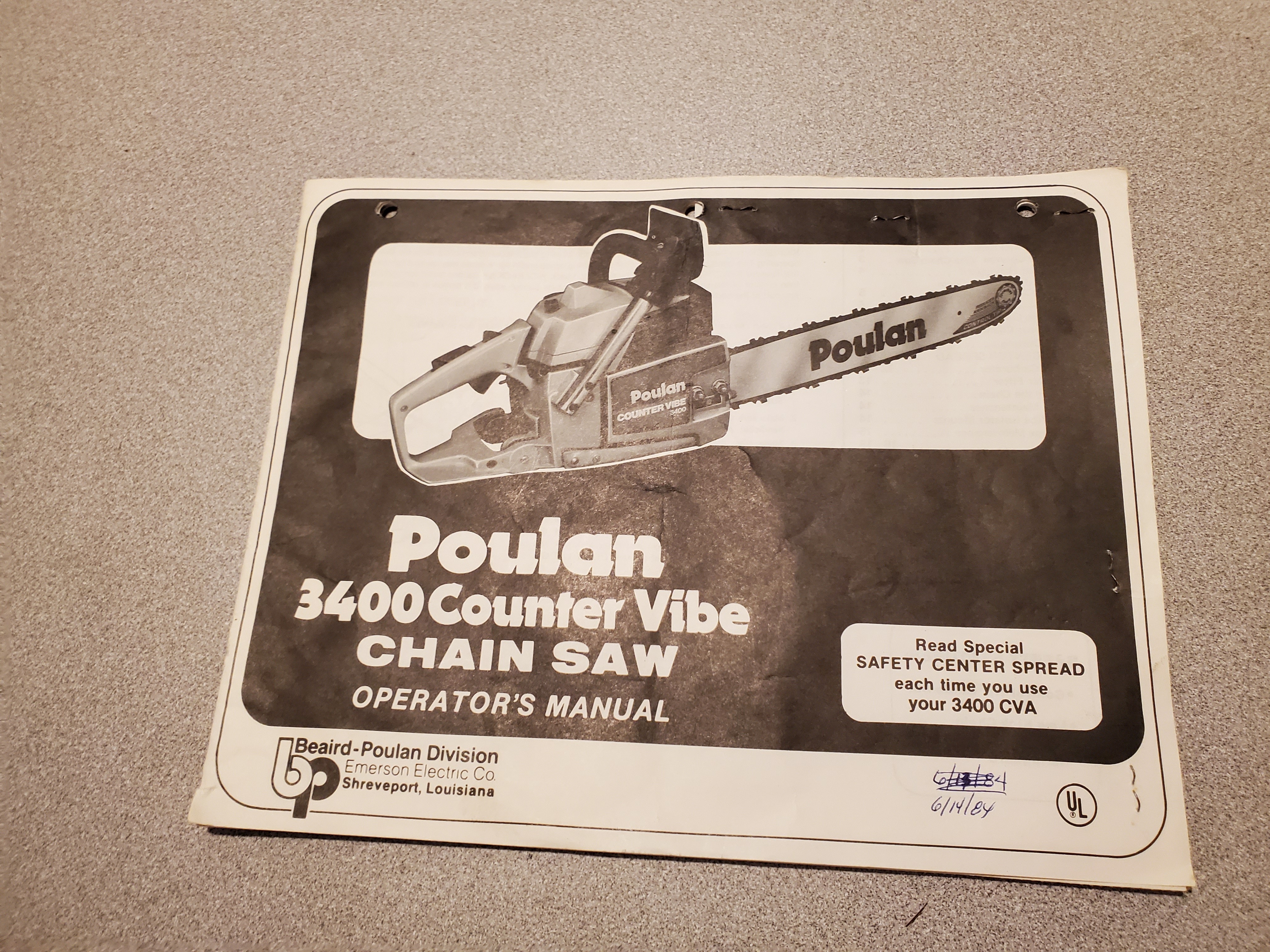

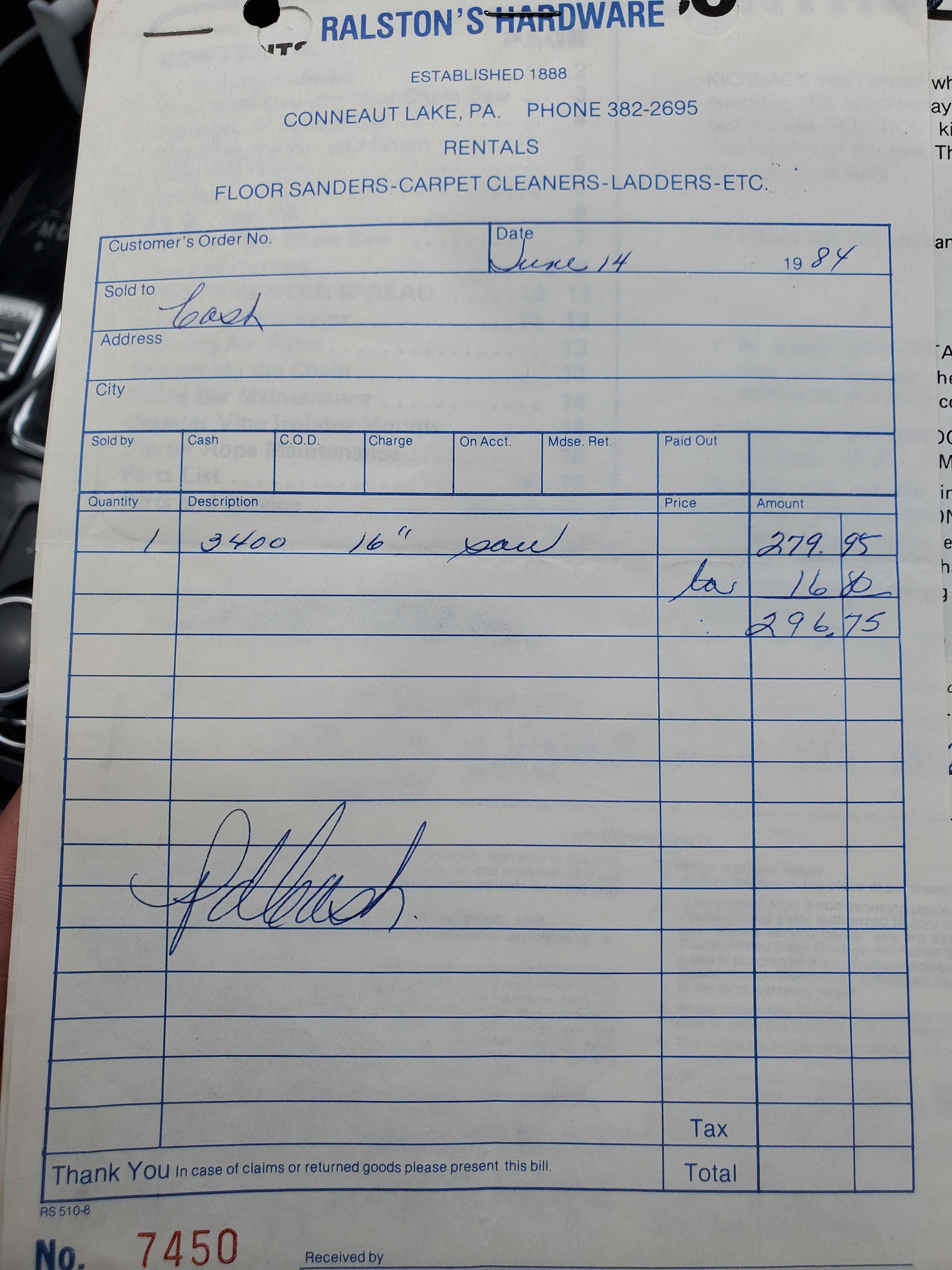

And the other is a 3400 Countervibe, 56cc. Was free on Facebook Marketplace. Came with original owner's manual and reciept from 1984. Neither one ran when I got them, now they both run and cut wood.

- Status

- Not open for further replies.

Similar threads

- Replies

- 394

- Views

- 20K

- Replies

- 107

- Views

- 5K

- Replies

- 267

- Views

- 13K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.