Awe geeze. You know you're somebody when your name becomes a verb.

What did you do to your non-G body project today? [2020]

- Thread starter Bonnewagon

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

True, I do have a welder

Vee it out, grind it flat and fishplate it.

Anyone order bubblegum?

I did manage to get the two halves realigned before I put those globs down, now I have to grind and prep a plate for tomorrow.

I did manage to get the two halves realigned before I put those globs down, now I have to grind and prep a plate for tomorrow.

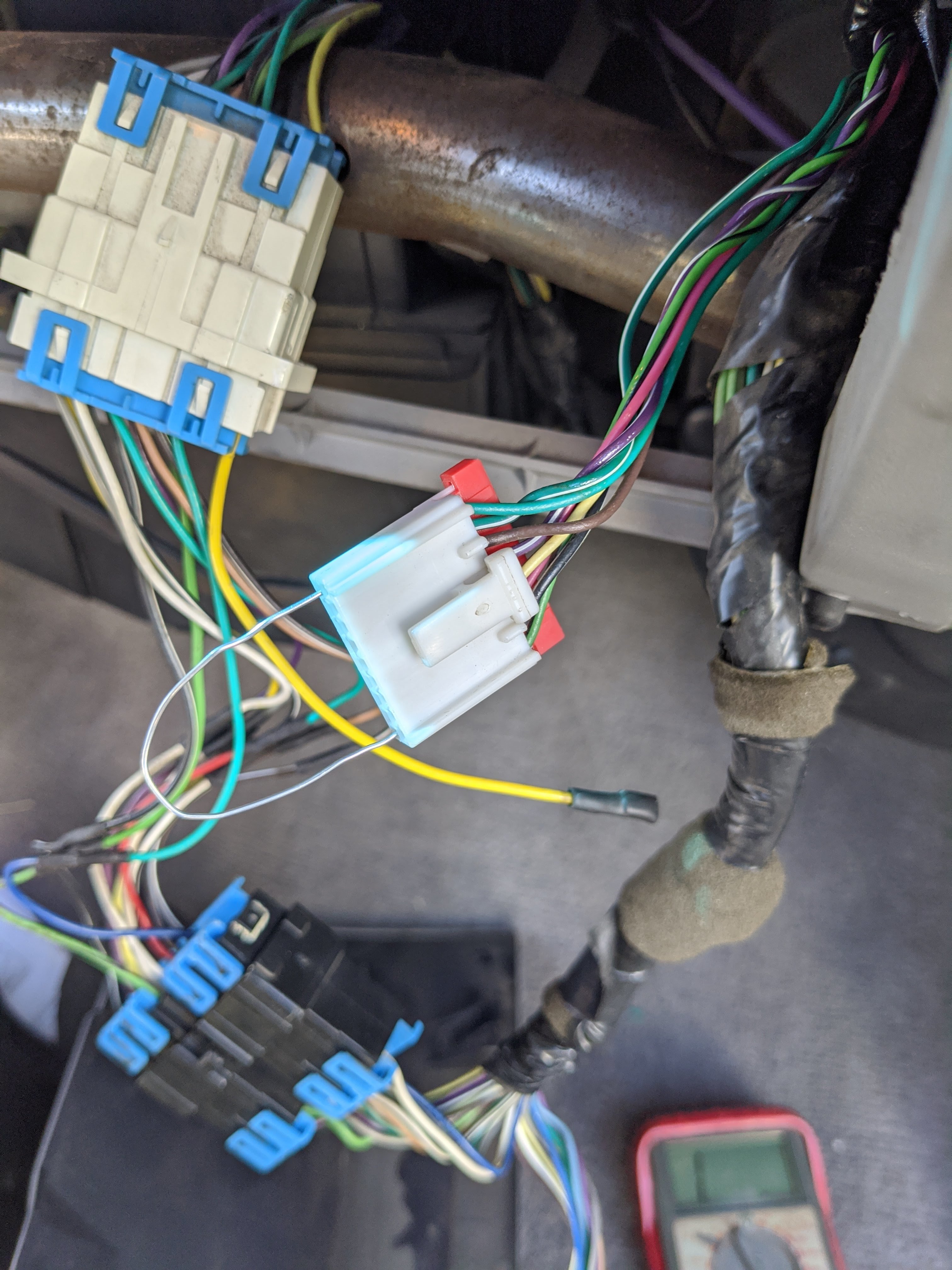

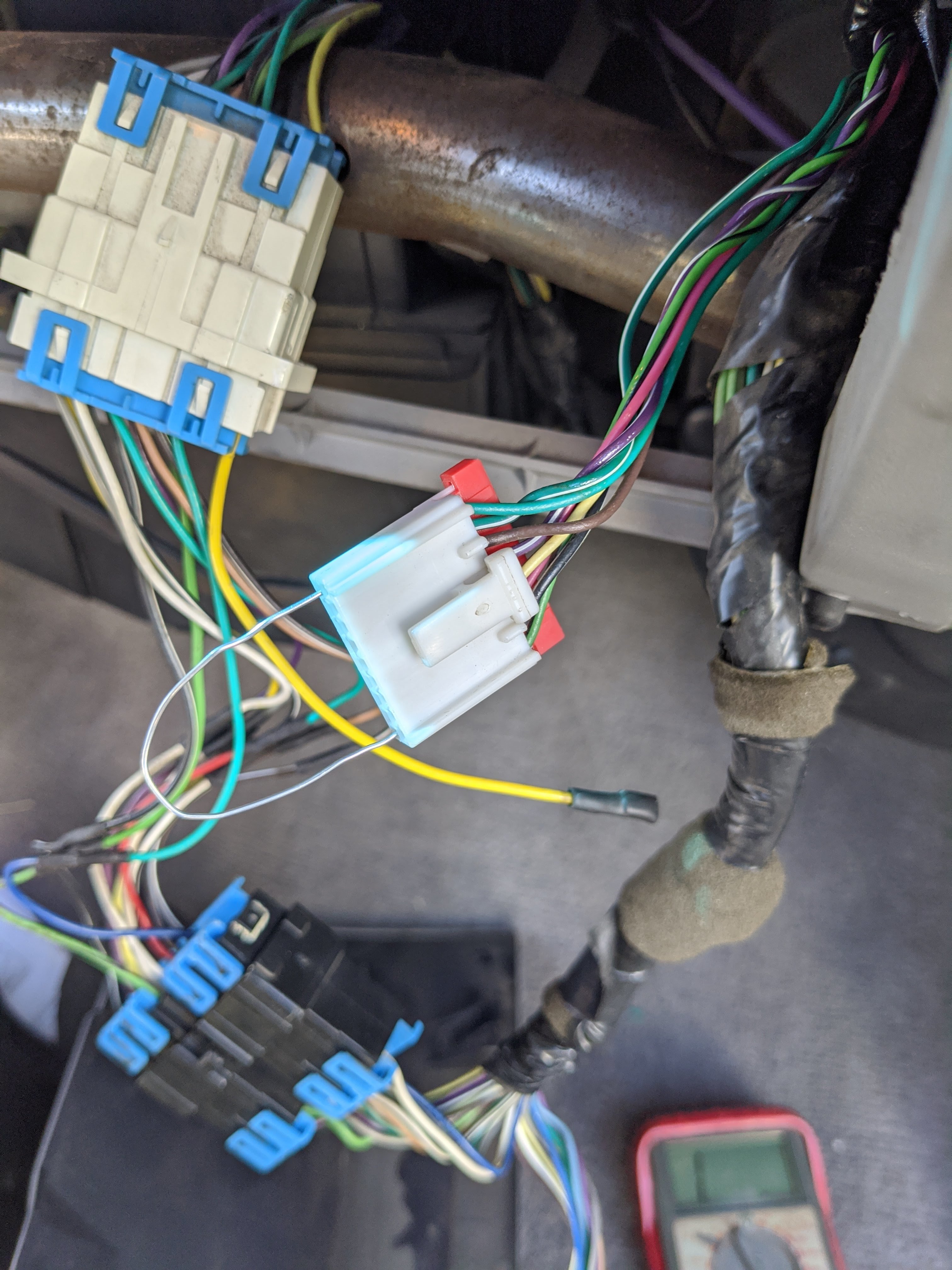

Got the speedo working on my flipper dually, had to jump the speedo buffer plug as the gas PCM buffers the signal itself. The truck started as a diesel roller when I got it. What you don't see is the hours wasted by a bad pinout and misinformation sending me down a rabbit hole of epic proportions for such a small job.

Of course the next step is to add a splice. There's a 2nd signal there for the radio, but I need to check and see if the EBCM is getting its signal too.

Of course the next step is to add a splice. There's a 2nd signal there for the radio, but I need to check and see if the EBCM is getting its signal too.

Employed my garage monkey. Building those skills that most every other person in her generation will lack. Mechanically inclined and fit as f*ck.

As my boy Robert Frank would say: Swole is the goal. Size is the prize. It's gains o'clock MFer... LET'S GO!

As my boy Robert Frank would say: Swole is the goal. Size is the prize. It's gains o'clock MFer... LET'S GO!

Those crack halves had to have been grinding against each other for a while to get the amount of edge rounding and deformity that the picture showed. Fish plating the frame is a great idea. If you can get good access to the inside of the frame in that area, create a second fish plate and plug or rose weld it into position to sandwich the damaged and repaired area from both sides. Would also give some thought to boxing the frame in that spot to minimize any torque or twist that the frame might be experiencing. How is your other side frame rail in that area or location?

Oh, yeah, non G Work. Got the second layer of aluminum metal dust laced filler sanded down and threw a top coat layer of Bondo at it. Shaved and sanded that down today using muscle memory and an open tooth body file and a sanding block and identified a few spots that displeased me. Threw a second thin topcoat of Bondo at them. Most of that coat will disappear due to still more block sanding. The plan is to have the panel smoothed and shaped to the point where I can throw a coat of primer at it and then a spritz of black check coat so that I can sand some more and make sure it is flat and curved where it has to be flat and curved. Yeah, yeah, air and power are faster but it is also easier to go too far and remove too much; meaning more has to be added to fix it. If the weather sucks, which it is supposed to, then it will be a slither and slide job under the truck to grab one of the exhaust pipes and deliver it to the welding bench for cleaning and inspection. S-10's don't normally come with true duals; mine did when I bought it but what was a beautiful idea turned out to be a lousy creation. The split head pipes were pure custom fabrication and I have had to revisit that work and do a lot of rehab to it do get them to work right. Along the way I added flanges to them using 3/16ths flat plate with matching plates attached to the cats only with a shoulder included to get them to index into each other. The flanges allow me to remove the cats if I have to take down the whole system for one reason or another. Basically it is now modular. The crippled exhaust section is the one that crosses from the drivers over to the passenger's side. Necessary due to the gas tank being in the road of having it make a straight shot to the rear. Total lack of open territory necessary to do it the easy way.

Nick

Nick

- Status

- Not open for further replies.

Similar threads

- Replies

- 378

- Views

- 19K

- Replies

- 104

- Views

- 5K

- Replies

- 253

- Views

- 11K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.