Another copy/paste from my LS1Tech thread.

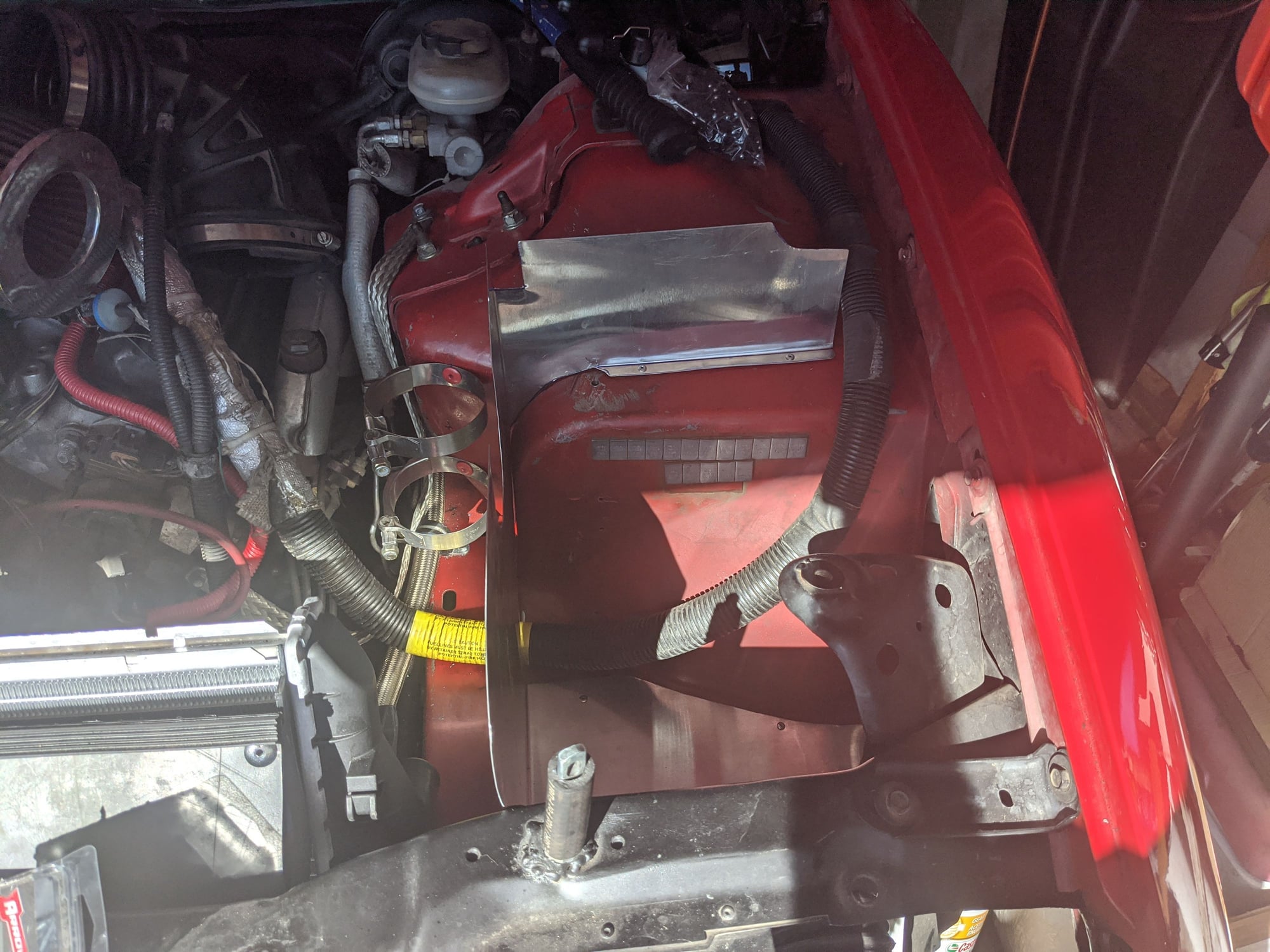

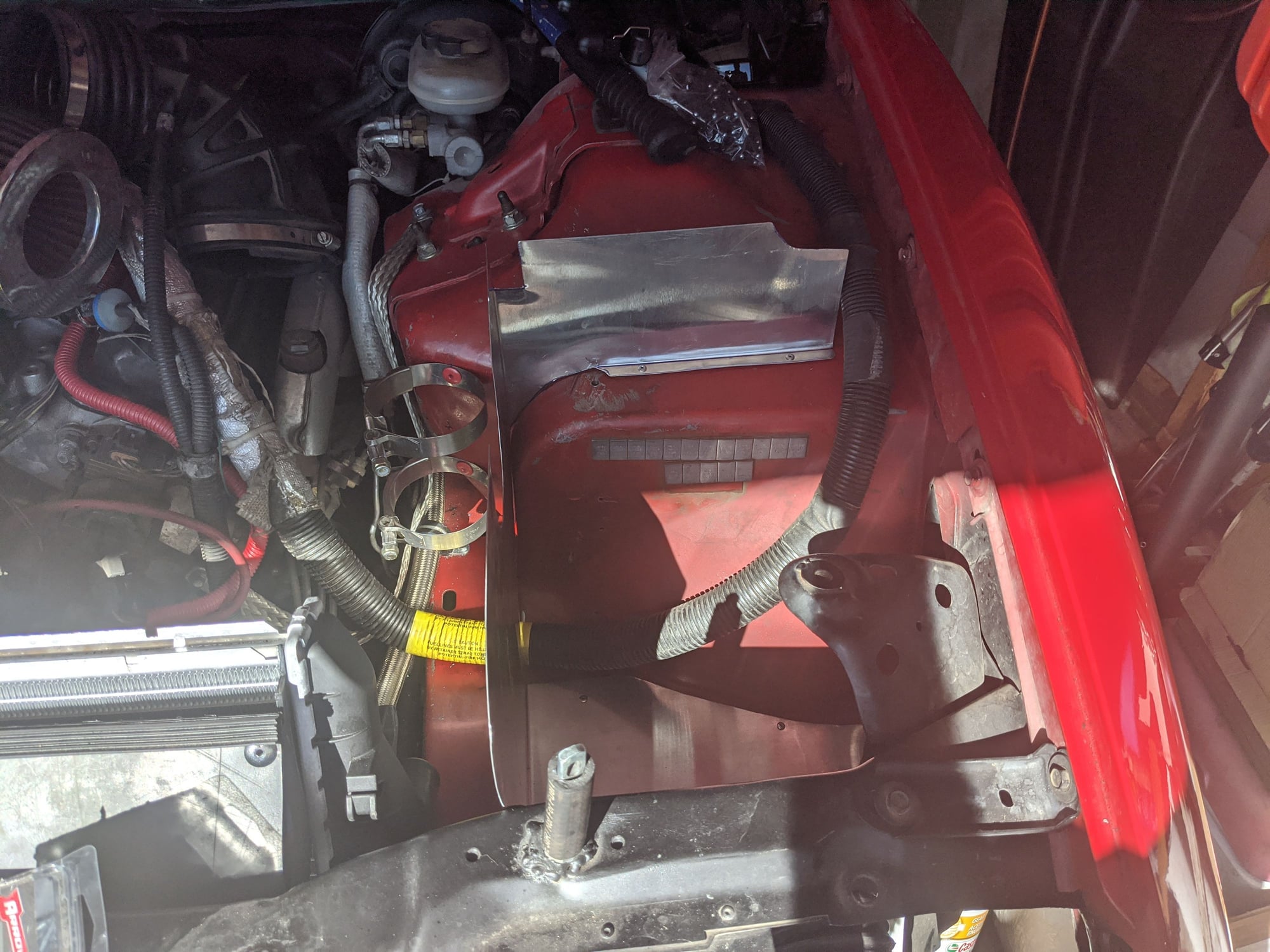

1step closer. Here's a couple crappy pics of the shroud all nailed down with the hose feeding it from the foglight hole. Blame the sun.

You can see my super simple catch can mount in the second pic as the 2 lone riveted t bolt clamps. Incorporating the can with the shroud was going to present some unanticipated and very unique challenges. This was the easy effective way out. Next up I had to cut the original mount off of the can. I got this can for free off of my local Dyno shop last fall as the mount had broken. I chopped it off, smoothed it out, and will slather some silicone onto the case where it separated.

The next problem is that measley 3/8' NPT entry bung. Seems like a bit of a restriction compared to my proof of concept 5/8" hose into a bigass Coors can.

I had this 3/4' bit which was around .010" under the recommended drill size for a 1/2" NPT tap.

1step closer. Here's a couple crappy pics of the shroud all nailed down with the hose feeding it from the foglight hole. Blame the sun.

You can see my super simple catch can mount in the second pic as the 2 lone riveted t bolt clamps. Incorporating the can with the shroud was going to present some unanticipated and very unique challenges. This was the easy effective way out. Next up I had to cut the original mount off of the can. I got this can for free off of my local Dyno shop last fall as the mount had broken. I chopped it off, smoothed it out, and will slather some silicone onto the case where it separated.

The next problem is that measley 3/8' NPT entry bung. Seems like a bit of a restriction compared to my proof of concept 5/8" hose into a bigass Coors can.

I had this 3/4' bit which was around .010" under the recommended drill size for a 1/2" NPT tap.