So Thursday and Friday turned out to be call in days, meaning that by the time the shift was over I was beat and bent beyond having any energy or desire to head to the shop and turn wrenches. They were also day one and day two after my second Covid shot and it was hard to tell if my body was just feeling its normal self after a day dealing with the city or if if was feeling the side effects of the second shot.

An--ny way, I did manage to drag my bones into the shop and proceeded to drop the 700's pan and pull the nitrile-rubber pan gasket that I had put in originally. it just plain squirmed around too much and didn't want to stay between the gasket faces under any kind of torque on the fasteners. There was actually enough room between the crossmember and the pan that I could get a 1/4 drive socket and swivel in there and access the bolts along that pan face so that made the whole snatch routine a lot simpler. This time around i went with a common cork gasket and made sure to thoroughly saturate it with Permatex Spray A Gasket. Took the set up time to reclean the pan's gasket rails and belly and throw a coat of S-A-G at it too. Added the gasket to the pan and slid the whole thing back under the van and up into position on the T-body's pan rails. This time I just used my 1/4 inch ratchet and 13mm socket to run the bolts back down. There is no listed torque for the pan rail bolts in the manual so it was just a case of repeated passes with the ratchet and socket until i was happy with the resistance i got. Yeah, yeah, totally unscientific but it was a lemons and lemonade kind of day so i went with it.

Today being Sunday, I returned back into the shop and revisited the pan bolts one more time. Got about a 1/4 turn more out of all the them which put me in a happy place so I quit right then and there and added the ATF. The stick says full plus but this is a t-mission that was emptied of all fluid and allowed to drain over a prolonged amount of time (Months) The cooler lines were also emptied and the cooler is not an in the radiator unit but a free standing external version that holds more than usual so I am not worried at this point. I can't get an accurate reading on the stick until I fire off the engine and the t-mission gets to circulate its oil again.

Last I looked the floor under the van was dry. (That fresh new concrete clean surface look went away about five years ago; i go for swept free of debris and go with that.)

Took a few minutes to pay some axe file love to my pair of hedge clippers and get its edges clean and edgie. (Snigger) Not planning to use it on the hedge; that is pure labor and left to my electric hedge whacker. Just some routine maintenance intended to prolong the life of a valuable tool.

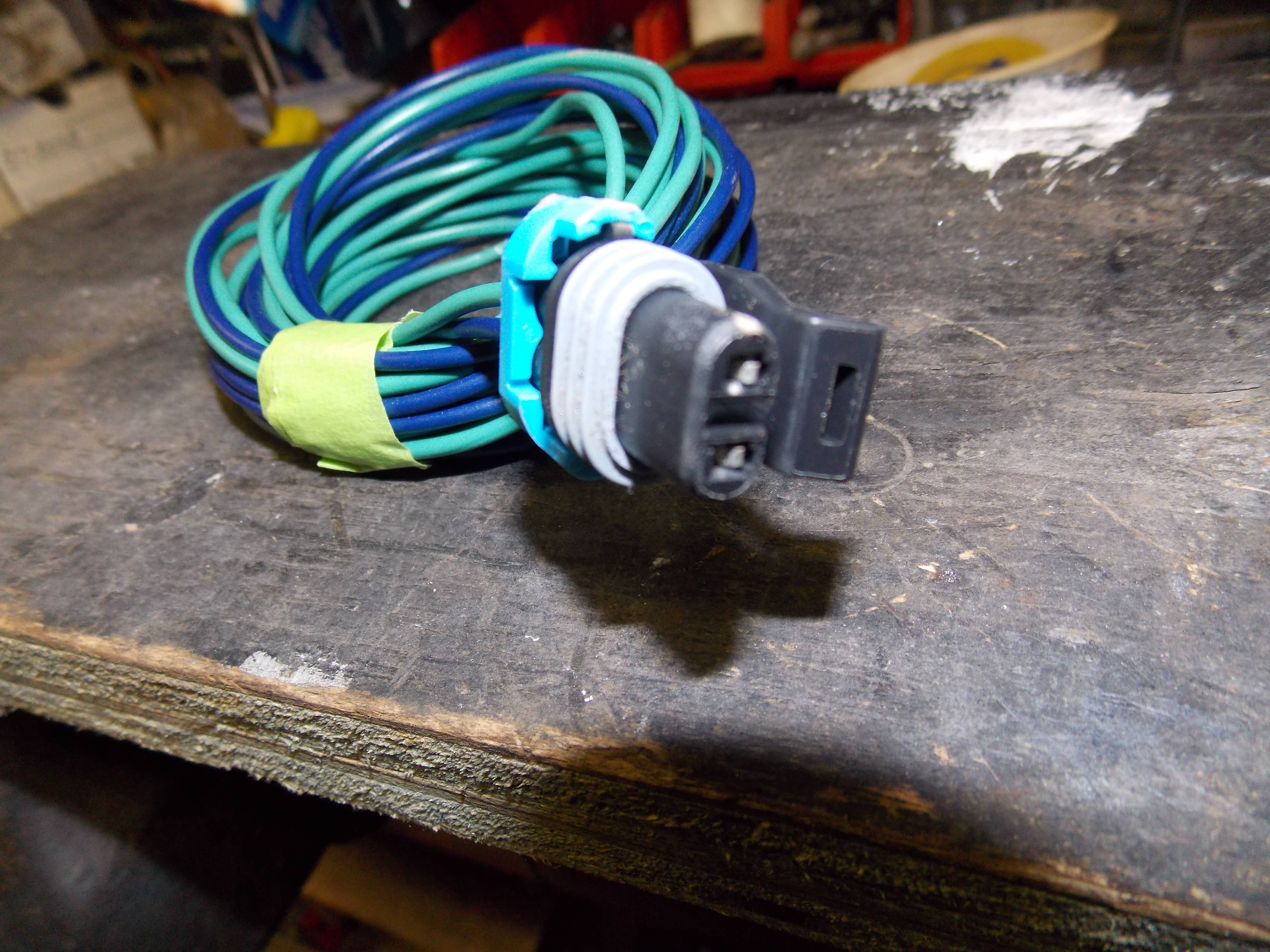

Left to do are the exhaust pipes and the VOES electrical/vacuum circuit. For some reason, 3/16ths id heavy wall vacuum hose has become unavailable around here. I can get all the windshield wiper hose that I could ever want but not the heavy wall stuff and I do not want the hose to collapse. Apart from that I still have yet to get out to an old yard whose owner thinks he has a couple of hulks old enough that they might have the rest of the electrical side of the system. Gotta get this done so I can drop the rear end out of the Monte and clean the whole thing up. After that It is on to the S-10 and back to creating a true dual pipe system for it. Oh yeah, and work.

Nick

An--ny way, I did manage to drag my bones into the shop and proceeded to drop the 700's pan and pull the nitrile-rubber pan gasket that I had put in originally. it just plain squirmed around too much and didn't want to stay between the gasket faces under any kind of torque on the fasteners. There was actually enough room between the crossmember and the pan that I could get a 1/4 drive socket and swivel in there and access the bolts along that pan face so that made the whole snatch routine a lot simpler. This time around i went with a common cork gasket and made sure to thoroughly saturate it with Permatex Spray A Gasket. Took the set up time to reclean the pan's gasket rails and belly and throw a coat of S-A-G at it too. Added the gasket to the pan and slid the whole thing back under the van and up into position on the T-body's pan rails. This time I just used my 1/4 inch ratchet and 13mm socket to run the bolts back down. There is no listed torque for the pan rail bolts in the manual so it was just a case of repeated passes with the ratchet and socket until i was happy with the resistance i got. Yeah, yeah, totally unscientific but it was a lemons and lemonade kind of day so i went with it.

Today being Sunday, I returned back into the shop and revisited the pan bolts one more time. Got about a 1/4 turn more out of all the them which put me in a happy place so I quit right then and there and added the ATF. The stick says full plus but this is a t-mission that was emptied of all fluid and allowed to drain over a prolonged amount of time (Months) The cooler lines were also emptied and the cooler is not an in the radiator unit but a free standing external version that holds more than usual so I am not worried at this point. I can't get an accurate reading on the stick until I fire off the engine and the t-mission gets to circulate its oil again.

Last I looked the floor under the van was dry. (That fresh new concrete clean surface look went away about five years ago; i go for swept free of debris and go with that.)

Took a few minutes to pay some axe file love to my pair of hedge clippers and get its edges clean and edgie. (Snigger) Not planning to use it on the hedge; that is pure labor and left to my electric hedge whacker. Just some routine maintenance intended to prolong the life of a valuable tool.

Left to do are the exhaust pipes and the VOES electrical/vacuum circuit. For some reason, 3/16ths id heavy wall vacuum hose has become unavailable around here. I can get all the windshield wiper hose that I could ever want but not the heavy wall stuff and I do not want the hose to collapse. Apart from that I still have yet to get out to an old yard whose owner thinks he has a couple of hulks old enough that they might have the rest of the electrical side of the system. Gotta get this done so I can drop the rear end out of the Monte and clean the whole thing up. After that It is on to the S-10 and back to creating a true dual pipe system for it. Oh yeah, and work.

Nick