awww man, they're not full-size riding toys? I thought they were until I saw the desk drawer and the scale of them came into focusTo preface this post, way back when my kids were young I took up building wooden toys for them. Toy cars, tractors, a train, cab over flat bed truck with a race car on the deck and even a Peterbilt for my dad to put behind his bar in the basement pool hall.

I have been away from the little hobby for a while now but had this idea for a pair of team Zamboni's for a few years. I started these back in October, one for my daughter, a Bruins fan like me and another for my Godson / Nephew who is an Islander fan. They came out pretty well.

View attachment 232724View attachment 232727

What did you do to your non-G body project today? [2023]

- Thread starter Wraith

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I built some toy boxes when my kids were small and on Christmas morning they each had more fun climbing into those things than all the presents we wrapped for them. lolawww man, they're not full-size riding toys? I thought they were until I saw the desk drawer and the scale of them came into focus

Picked up the plow from my old place (dad is living there until the landlord sells the property in april), and after finding the pins, i drove home at night with no plow lights.

On the bright side, I only got pulled over once because the truck now has no taillights at all. yay.

On the bright side, I only got pulled over once because the truck now has no taillights at all. yay.

After dealing with USPS shipping hell for two weeks, I finally got my wheel bearings in and was able to resume my 4 wheeler project.

I got my old bearings pounded out and the bores cleaned for the new ones to go in. Unsurprisingly the new ones slid in a lot easier than the old ones came out.

New ball joints were installed on the remaining side, and new nuts were bought for all four of the ball joints. I still need to overhaul the brakes, but those adjusters are frozen solid and while they look like garbage they do still work. There is a disc brake conversion kit for these on eBay that I will probably purchase that will get rid of the whole drum assembly and give me all fresh parts. That can happen after the Christmas season quits sucking all the money out of my wallet.

I then reinstalled the CV shafts and got everything back together.

I took it out for a test drive and was quite happy with the results. No more creaky, squeaky noises and I was able to get it up to 45 without eminent fear of death. It is still a little flighty on deceleration, but with the new ball joints I'm sure it needs the toe-in adjusted.

I'm calling it complete until spring, anyways.

Also, got the good news that the youngest daughter is pregnant so I guess I'm going to be a grandpa. Talk about a good Christmas present.

I got my old bearings pounded out and the bores cleaned for the new ones to go in. Unsurprisingly the new ones slid in a lot easier than the old ones came out.

New ball joints were installed on the remaining side, and new nuts were bought for all four of the ball joints. I still need to overhaul the brakes, but those adjusters are frozen solid and while they look like garbage they do still work. There is a disc brake conversion kit for these on eBay that I will probably purchase that will get rid of the whole drum assembly and give me all fresh parts. That can happen after the Christmas season quits sucking all the money out of my wallet.

I then reinstalled the CV shafts and got everything back together.

I took it out for a test drive and was quite happy with the results. No more creaky, squeaky noises and I was able to get it up to 45 without eminent fear of death. It is still a little flighty on deceleration, but with the new ball joints I'm sure it needs the toe-in adjusted.

I'm calling it complete until spring, anyways.

Also, got the good news that the youngest daughter is pregnant so I guess I'm going to be a grandpa. Talk about a good Christmas present.

So back a number of pages ago I posted a pic or two of some work I was doing on a vintage Indian fender to return it back to the stock length and curve.

So what you see here is the finished overall new length, plus the initial curve that I cut and shaped for the front leading edge. I think I mentioned that the material used for this was not new metal. The top surface was harvested from a cab panel that had been removed from my S-10 as part of the repairs done to the passenger side back cab corner. The edges on it were rotten but the central surface was still in decent shape, plus which it measured out for thickness at .05 which was only a thou under the .06 that the recipient fender was made from. Close enough to do business, sez I.

The side panel blanks that I fabricated came from the remanents of the S-10 front bumper that found had self destructed/committed suicide during the spring. After poking through the scraps I managed to come up with a length from which I could cut two sections which I could then shape to match the curve of the side edges on the top face. Only concern was that I had to get them right the first time as I had only the one strip from which to salvage them; nothing else was left. The results, I suppose, speak for themselves.

And a couple of close up shots of the new leading edge. This may not be its final shape as, as you can see, there is a marker line laid out on the side wall that rises at an angle to intersect with the front edge about half way up the existing curve. The point of this is to thin out the edge and make it less blunt and blocky looking. The current shape is a mirror image of the trailing edge at the bottom of the fender. it became the edge from which i could create a cardboard template to use to create the new edge at the front. Easy peasy way to create either a starting point from which to move forward, or to leave as is. Why as is?

Simply because all this is getting done without the benefit of pictures or drawings of what that fender actually looks like. They are not exactly plentiful on the ground and the ones I have come across have mostly lost that same fender tip/section at one point or another in the past. Any damage inflicted on the fender tip usually got repaired by amputating the crumpled metal and taking a file to the new edge to make it look presentable. These were war era parts and no priority existed for the factory to fabricate or supply parts to the civilian market. The military got it all.

Anyway, some progress. Still have to do some metal working on the surfaces and finish dressing the welds on the inner seams. I have to be careful; i blew up another Dremel 3000 the day before Christmas Eve, and that makes two of them that have died for my art. Seems the culprit might be the field winding leads where they get set into the towers that accept the brush housing. Those wires are finer than cat hair and vibration can break them. Not worth buying new fields as a whole motor is only a bit over a C-note. Going to try the 4000 series motor this time as it is heavier at 1.6 volts to what the 3000 was rated at and doesn't come with all the extra garbage that the 4300 seems doomed to wear. (Personally I don't need cute little lights that can't be removed because the switch is a permanent part of the shell/housing)

If tomorrow is half decent, I will wend my way back to the shop and do a little more metal work, and possibly decide whether "to clip, or not to clip" Questions, questions, always the questions.

Oh yeah, for the G-Body men, that A pillar dissection is on hold until my Steck panel separating tool comes in. i did get the plug welds cut away, and blew up about every plug weld cutter that I had doing it; GM did not shirk when it came to jamming plug welds in tight and nasty locations. So there is that, plus the portable vise needs some dental work done to its track cleats to build them up.

I go back in for the balance of the week post New Years and after that remains to be seem; no shift notice posted yet. The weather seems inclined to be cooperative so......................

Nick

So what you see here is the finished overall new length, plus the initial curve that I cut and shaped for the front leading edge. I think I mentioned that the material used for this was not new metal. The top surface was harvested from a cab panel that had been removed from my S-10 as part of the repairs done to the passenger side back cab corner. The edges on it were rotten but the central surface was still in decent shape, plus which it measured out for thickness at .05 which was only a thou under the .06 that the recipient fender was made from. Close enough to do business, sez I.

The side panel blanks that I fabricated came from the remanents of the S-10 front bumper that found had self destructed/committed suicide during the spring. After poking through the scraps I managed to come up with a length from which I could cut two sections which I could then shape to match the curve of the side edges on the top face. Only concern was that I had to get them right the first time as I had only the one strip from which to salvage them; nothing else was left. The results, I suppose, speak for themselves.

And a couple of close up shots of the new leading edge. This may not be its final shape as, as you can see, there is a marker line laid out on the side wall that rises at an angle to intersect with the front edge about half way up the existing curve. The point of this is to thin out the edge and make it less blunt and blocky looking. The current shape is a mirror image of the trailing edge at the bottom of the fender. it became the edge from which i could create a cardboard template to use to create the new edge at the front. Easy peasy way to create either a starting point from which to move forward, or to leave as is. Why as is?

Simply because all this is getting done without the benefit of pictures or drawings of what that fender actually looks like. They are not exactly plentiful on the ground and the ones I have come across have mostly lost that same fender tip/section at one point or another in the past. Any damage inflicted on the fender tip usually got repaired by amputating the crumpled metal and taking a file to the new edge to make it look presentable. These were war era parts and no priority existed for the factory to fabricate or supply parts to the civilian market. The military got it all.

Anyway, some progress. Still have to do some metal working on the surfaces and finish dressing the welds on the inner seams. I have to be careful; i blew up another Dremel 3000 the day before Christmas Eve, and that makes two of them that have died for my art. Seems the culprit might be the field winding leads where they get set into the towers that accept the brush housing. Those wires are finer than cat hair and vibration can break them. Not worth buying new fields as a whole motor is only a bit over a C-note. Going to try the 4000 series motor this time as it is heavier at 1.6 volts to what the 3000 was rated at and doesn't come with all the extra garbage that the 4300 seems doomed to wear. (Personally I don't need cute little lights that can't be removed because the switch is a permanent part of the shell/housing)

If tomorrow is half decent, I will wend my way back to the shop and do a little more metal work, and possibly decide whether "to clip, or not to clip" Questions, questions, always the questions.

Oh yeah, for the G-Body men, that A pillar dissection is on hold until my Steck panel separating tool comes in. i did get the plug welds cut away, and blew up about every plug weld cutter that I had doing it; GM did not shirk when it came to jamming plug welds in tight and nasty locations. So there is that, plus the portable vise needs some dental work done to its track cleats to build them up.

I go back in for the balance of the week post New Years and after that remains to be seem; no shift notice posted yet. The weather seems inclined to be cooperative so......................

Nick

Last edited:

Cut off old Y pipe and drilled and tapped manifolds for new studs, old ones were basically non existent. Holes are mostly centered. New y pipe will be purchased soon, as long as the snow is away I have the Regal to drive.

And the decision is to, for now, leave the front edge more or less like it is. The less is that the curve is going to get a slightly slower shallower shape or radius to it. I still have my curves forms from my drafting kit so will be checking them out for a shape that I like. Then the lower edge will get finished and it will all receive a coat of primer and then skim coat of mud to bring all the surfaces into alignment. I could spend a month with a body hammer and dolly on this and still not be happy with what I have in the end so better to set a done by point and move on.

HAPPY NEW YEAR!!!!

Nick

HAPPY NEW YEAR!!!!

Nick

I went over to Dad's on Wednesday to see if I could help him with his 2006 Sierra. It has the 5.3 and has a pretty bad oil leak. The oil cooler line block off plate got the blame. He replaced the gasket on the stock plate but the leak got worse. He's also replaced the oil pressure sender. I spent about an hour cleaning up the oil pan, oil filter, starter, etc. Then I replaced the oil cooler block off plate with one from ICT Billet that uses a rubber o-ring instead of the paper gasket....

I also re-torqued the oil pan, but it may need a gasket. The passenger valve cover is leaking down on the starter. I'll likely do the valve cover gaskets Sunday and then take it from there.

I also re-torqued the oil pan, but it may need a gasket. The passenger valve cover is leaking down on the starter. I'll likely do the valve cover gaskets Sunday and then take it from there.

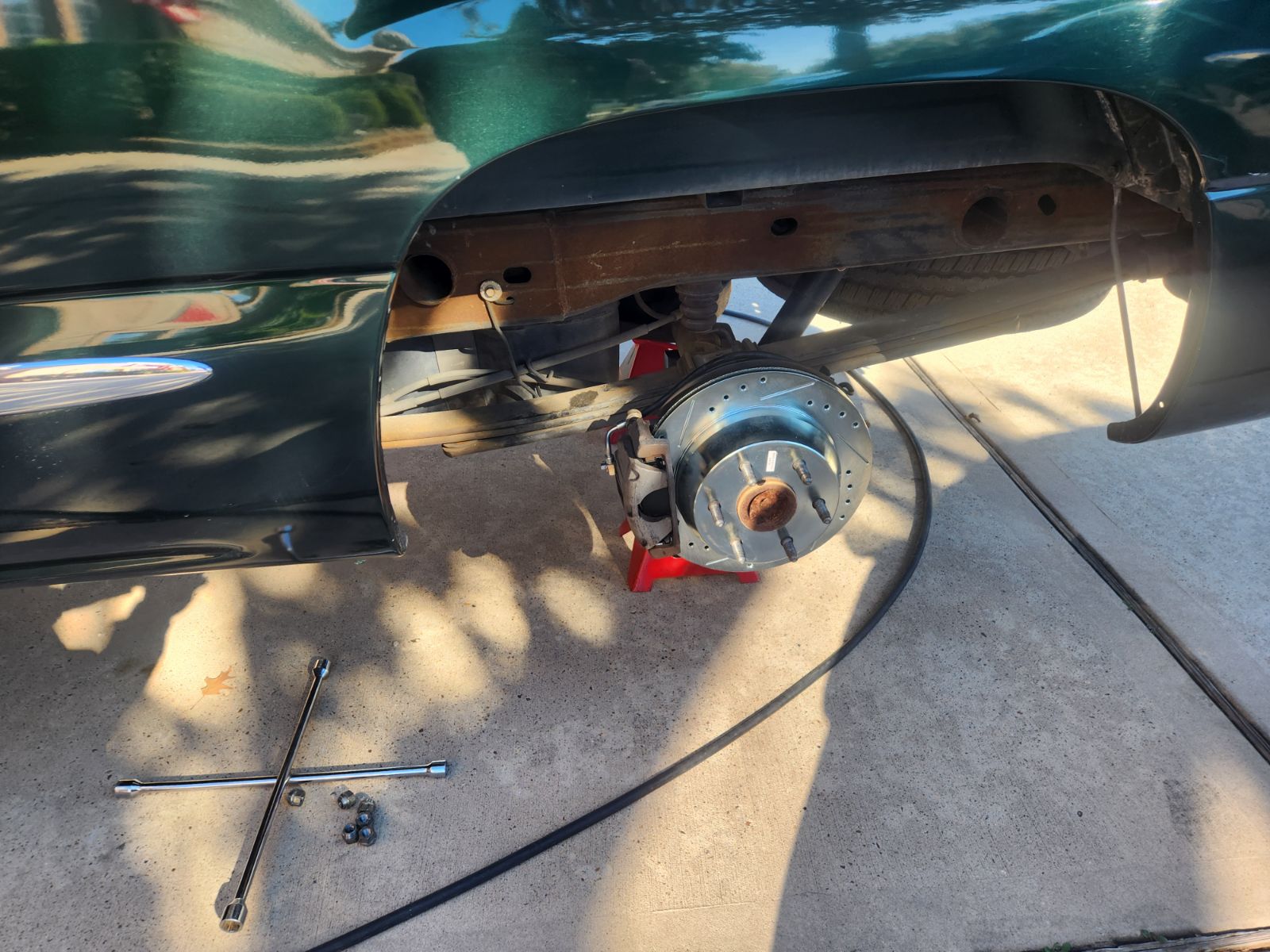

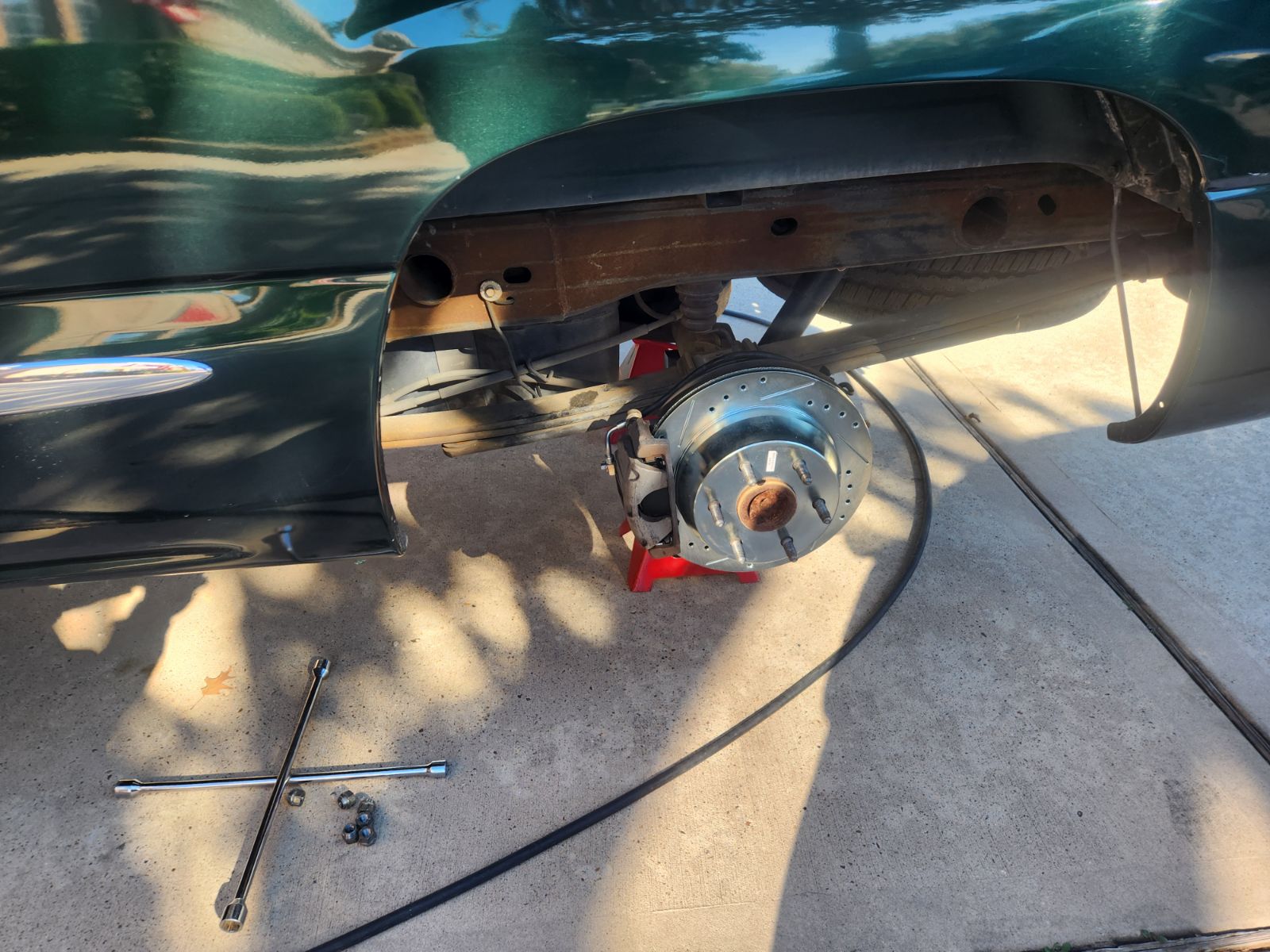

Sean and I did a rear brake job on his 2002 Sierra yesterday. We did rotors, pads and brake hoses on both sides. The rotors and pads are Power Stop. We've had good luck with their stuff. The hoses are Genuine GM and I couldn't be happier with them. We ended up replacing the passenger caliper. The piston didn't act right when I went to push it back in. I eventually got pushed back in but it took more effort than it should. We want this brake job to last a long time so I sent Sean up to Napa after a rebuilt caliper. I spent a fair amount of time and put a lot of detail into adjusting the parking brake shoes. We didn't replace them, as there was nothing wrong with them but they were adjusted too loose. Before this brake job, you had to push the pedal all the way to the floor to hold the vehicle. Now the pedal won't go to the floor but I'm pretty certain the shoes aren't dragging. It all turned out good. We just did the fronts so it's all new all the way around now. The truck's brakes are the best they've been in a long time.....

Similar threads

- Replies

- 345

- Views

- 18K

- Replies

- 100

- Views

- 4K

- Replies

- 244

- Views

- 11K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.