My old one was about that age, and it did the water injection routine as well.It's a 20+ year old whirlpool lol

but thanks for the info

Nick

My old one was about that age, and it did the water injection routine as well.It's a 20+ year old whirlpool lol

but thanks for the info

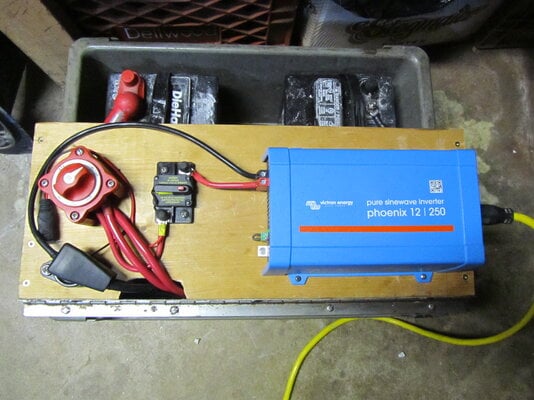

One of my endeavors was to rig up a battery back-up system for my boiler in case of a blackout. A while back I had power supply problems with the whole house blinking. A new meter box, supply line from the box to the light pole, and the box to my breaker panel, fixed that nicely. The meter box was 1950's vintage and way over due. That alerted me about power maybe going out in winter and staying warm. I researched and decided to take two of my 12 volt marine deep cycle batteries, hook them to an inverter, and power my gas boiler. I used a Kill-a-Watt meter to find that the boiler used about 20 watts to run. Steam is it's own motivator so no fans or pumps involved. Just a gas valve, thermostat, and control unit. I had scrounged an old Post Office flats tray made of real heavy plastic for the battery holder. An acid spill will not hurt it . Then I built a folding wood board on top to mount the inverter and control switches. I used a very good brand of pure sine wave inverter made by VICTRON. The smallest pure sine they made was 250 watts, way more than I needed. I made up some battery cables, used a marine grade multi-battery switch, and marine grade 25 amp manual reset breaker that can also be shut off manually. I even wired in a plug-in charging circuit so I can use my NOCO boat battery smart charger to keep the batteries topped off. For a final touch I added a couple of 12 volt LED boat lights to light up the area. No need to hold a flashlight in my mouth working around the boiler during a blackout. Future plans include looking for a nice solar panel for recharging the batteries during the day. The first test was a smashing success. I keep the house at 65° so I lowered it to 60° to see if it would work. And it did. I can switch between batteries, or use them both at once. I used the older, weaker battery first, to see if it would last. It ran a full boiler cycle and the fan in the inverter never even came on once. I also have the USB connector so I can plug a laptop in to the inverter and monitor/adjust the performance. I can test the battery discharge rate and boiler power usage in real time. So far so good. See pics. White stuff is baking soda from battery cleaning. Notice my boiler steam gauge is just above .5 pounds. This shot is at full pressure, after running for about 20 minutes. I run on ounces, not pounds. It is a quiet, economic steam system like you don't see anymore. Them old timers knew what worked. ------------------------------------------------------------------------------------------------------------------------------------------------------View attachment 233959View attachment 233960

Harbor freight has some pretty economical solar panels you could take a look at.One of my endeavors was to rig up a battery back-up system for my boiler in case of a blackout. A while back I had power supply problems with the whole house blinking. A new meter box, supply line from the box to the light pole, and the box to my breaker panel, fixed that nicely. The meter box was 1950's vintage and way over due. That alerted me about power maybe going out in winter and staying warm. I researched and decided to take two of my 12 volt marine deep cycle batteries, hook them to an inverter, and power my gas boiler. I used a Kill-a-Watt meter to find that the boiler used about 20 watts to run. Steam is it's own motivator so no fans or pumps involved. Just a gas valve, thermostat, and control unit. I had scrounged an old Post Office flats tray made of real heavy plastic for the battery holder. An acid spill will not hurt it . Then I built a folding wood board on top to mount the inverter and control switches. I used a very good brand of pure sine wave inverter made by VICTRON. The smallest pure sine they made was 250 watts, way more than I needed. I made up some battery cables, used a marine grade multi-battery switch, and marine grade 25 amp manual reset breaker that can also be shut off manually. I even wired in a plug-in charging circuit so I can use my NOCO boat battery smart charger to keep the batteries topped off. For a final touch I added a couple of 12 volt LED boat lights to light up the area. No need to hold a flashlight in my mouth working around the boiler during a blackout. Future plans include looking for a nice solar panel for recharging the batteries during the day. The first test was a smashing success. I keep the house at 65° so I lowered it to 60° to see if it would work. And it did. I can switch between batteries, or use them both at once. I used the older, weaker battery first, to see if it would last. It ran a full boiler cycle and the fan in the inverter never even came on once. I also have the USB connector so I can plug a laptop in to the inverter and monitor/adjust the performance. I can test the battery discharge rate and boiler power usage in real time. So far so good. See pics. White stuff is baking soda from battery cleaning. Notice my boiler steam gauge is just above .5 pounds. This shot is at full pressure, after running for about 20 minutes. I run on ounces, not pounds. It is a quiet, economic steam system like you don't see anymore. Them old timers knew what worked. ------------------------------------------------------------------------------------------------------------------------------------------------------View attachment 233959View attachment 233960

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.