Its been in the upper 20F's outside and with the snow and salt crap they threw on the roads Sunday I haven't had motivation to get the 2+2 out for a drive. I need to get insurance on it anyways. I need to get the flex fuel PCM swapped in and a tune made, but its junk outside to do that so the car is just sitting.

Been doing model building instead. Wrapped up these pair of combines for customers.

One is about an '83 model and the other is like a '77 model.

View attachment 142465

View attachment 142466

And a pair of tractors. One forklift and one highway ditch mower. I checked my orders list and I have like 40 more orders for different variations of these damn things, lol.

View attachment 142468

And I fiddled with CAD last week to build some more attachments.

My 3D printing contract company is on Long Island and they have gotten SLOW but are still miraculously running their equipment. I was expecting to run out of raw stock but I keep ordering parts and they keep showing up on my door.

View attachment 142469

And college stuff. Getting dangerous! Learning Computational Fluid Dynamics software. Modeled an air filter last week. I should be able to flow model intake elbows and plumbing stuff with what I am learning.

View attachment 142470

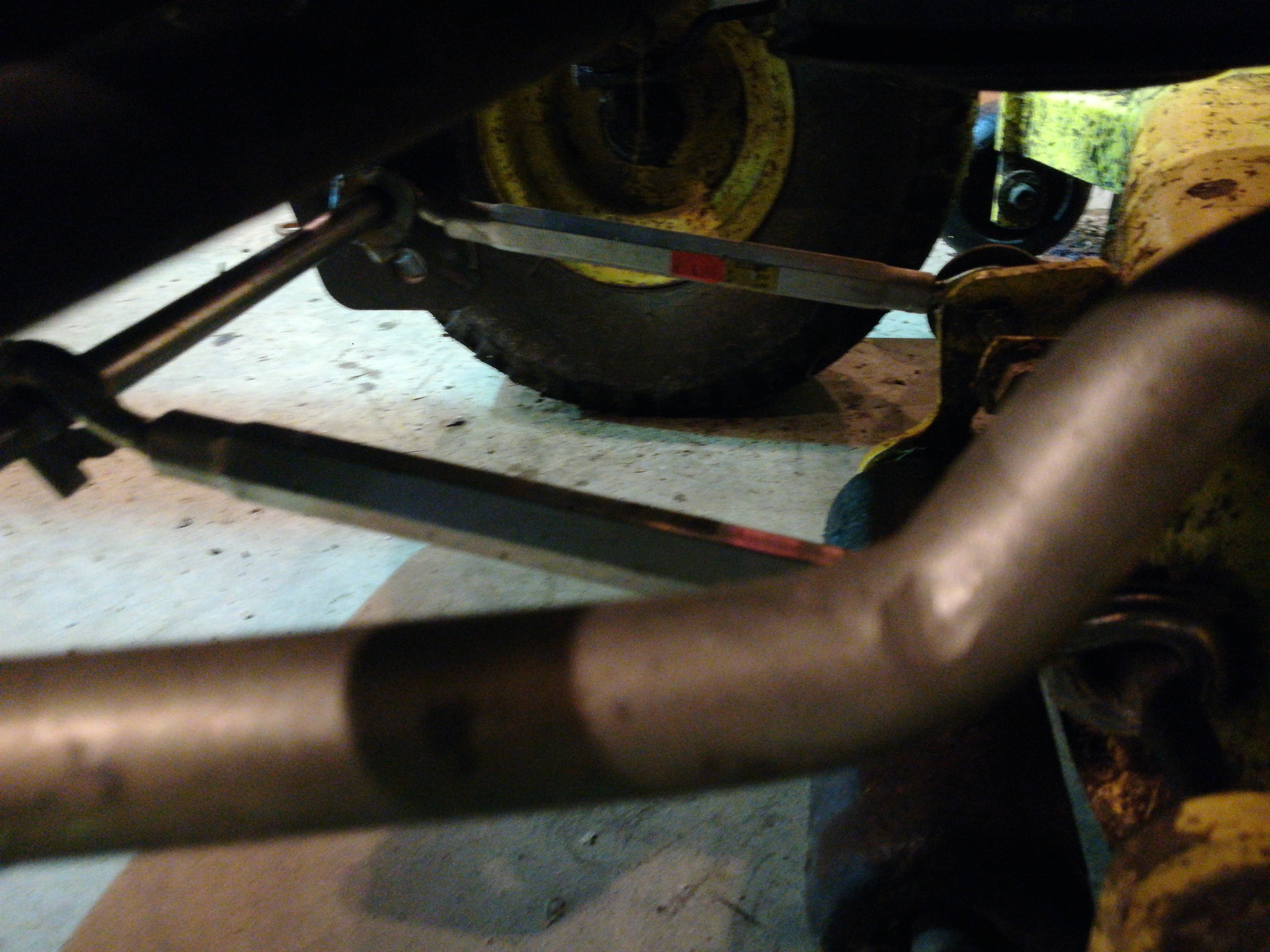

My stretch goal this summer is to design an intake manifold for my long term ~400 inch turbo olds DX motor. I already have a holley street dominator single plane I was going to to just weld injector bungs into, but since I learned how to run the waterjet at campus, I might as well cut some intake flanges and fab an intake similar to those new BTR equalizer LS intakes. I have an aluminum hood for my '81 cutlass that I want to put on and I don't think I can clear the hood with a single plane carb manifold and an elbow.

Those models are awesome looking!!