Put in a little time and did some cleaning on 5.3. it came with iron exhaust manifolds that someone had hung with fresh new bolts so I pulled the one bank and applied a little never seize to the threads before returning them back into the holes. The heads are aluminum, the bolts are steel.; cheap insurance against galling a thread or seizing a bolt. Did some further scraping and wire brush work and rotated the water pump pulley a few times to keep it moving; it seems to want to lock up if I don't. Have to wonder if there is a build up of crud in the main gallery. New pump price is evil to brutal.

What did you do to your shop today?

- Thread starter RecklessRegal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Finally got started on the foundation this week. The building supplier was supposed to do the foundation, but apparently decided it just wasn't worth their time. After several weeks of bugging them about when they were going to get started and being constantly told, "just give me a couple days and I'll get back to you" they FINALLY sent a guy (Frank) out to check the property etc. and he tells me, "We can start in a bout 2 weeks, just have 2 other jobs in front of you". I though great, we're finally going to get started. After about a week and a half, I give Frank a call back just to verify if they have a firm start date yet. He proceeds to tell me that he couldn't come to an agreement on price with the building supplier, so he's off the job, but he is willing to contract directly with me. So I'm pissed. Nobody has contacted me to tell me anything. I call the building supplier, leave several messages with the Project Manager even the CEO. I send email. Zero response

At this point, I'd been trying to get quotes directly from several local companies but nearly every single one of them flakes out. So I decided screw it, give Frank a call back and tell him to write up the contract and he'll start in a couple weeks.

So finally, this week, Frank shows up on site as promised and finally starts work on my foundation.

Stripping the top soil for the build area

Starting to lay down the gravel base

Gravel base built up and starting to excavate the perimeter footings

Central part compacted

He's being very meticulous with measuring heights and everything. Still has to finish compacting the trenches for the footings and the tapered section. Needs to build the forms, and carve out the base for a couple lateral beams. Then I get to lay the insulation and pex for the radiant heat and then he can do the rebar. Then inspection and finally pouring concrete. Maybe by the end of next week

At this point, I'd been trying to get quotes directly from several local companies but nearly every single one of them flakes out. So I decided screw it, give Frank a call back and tell him to write up the contract and he'll start in a couple weeks.

So finally, this week, Frank shows up on site as promised and finally starts work on my foundation.

Stripping the top soil for the build area

Starting to lay down the gravel base

Gravel base built up and starting to excavate the perimeter footings

Central part compacted

He's being very meticulous with measuring heights and everything. Still has to finish compacting the trenches for the footings and the tapered section. Needs to build the forms, and carve out the base for a couple lateral beams. Then I get to lay the insulation and pex for the radiant heat and then he can do the rebar. Then inspection and finally pouring concrete. Maybe by the end of next week

Attachments

Like I noted in the doing to your G-Body forum, today was rotation day. For me that meant rolling the 10 bolt back behind the Monte and putting that project on hold.

Then it meant systematically putting the special services tools, pullers, drivers and impact units back into their boxes and trays, finding space for the floor jacks and lifts, moving everything around to where it wouldn't be in the way and then sweeping the floor multiple times.

It also meant being up on the short ladder for about 3 hours. Needed to shave the edges of the door skin on the man door access from the lawn/quarter deck so that I could install new gasketing. That door will shift once the frost starts up again so I may have to revisit that work but it is a start towards getting the shop to be air tight? for winter. Last year, despite the use of a high efficiency gas furnace, I got beaten like a cheap persian rug by my gas bills. I still have to bring in an overhead door tech to tweak the upper edge of the door where it hits the gasket. It seem that heat causes the door to bow and there is some kind of tension strap that has to be adjusted to eliminate that. HIIK.

So what I have is Bay One sitting empty and bare, for a day or so. What is coming in is my S-10; time for her to receive her annual dose of mechanical love and attention. The basic stuff, oil and filter, lube. Some major remedial work to the exhaust pipes and possibly the winter tires!

Don't laugh, up where I am it has been known to snow in the middle of July and enough on the ground that it could be measured. Rest of this week is supposed to be soggy to one degree or another which might postpone bringing it in as I hate rolling around on a soggy concrete floor and this one never did have a drain included in its design. Nowhere to drain the drain to.

Then it meant systematically putting the special services tools, pullers, drivers and impact units back into their boxes and trays, finding space for the floor jacks and lifts, moving everything around to where it wouldn't be in the way and then sweeping the floor multiple times.

It also meant being up on the short ladder for about 3 hours. Needed to shave the edges of the door skin on the man door access from the lawn/quarter deck so that I could install new gasketing. That door will shift once the frost starts up again so I may have to revisit that work but it is a start towards getting the shop to be air tight? for winter. Last year, despite the use of a high efficiency gas furnace, I got beaten like a cheap persian rug by my gas bills. I still have to bring in an overhead door tech to tweak the upper edge of the door where it hits the gasket. It seem that heat causes the door to bow and there is some kind of tension strap that has to be adjusted to eliminate that. HIIK.

So what I have is Bay One sitting empty and bare, for a day or so. What is coming in is my S-10; time for her to receive her annual dose of mechanical love and attention. The basic stuff, oil and filter, lube. Some major remedial work to the exhaust pipes and possibly the winter tires!

Don't laugh, up where I am it has been known to snow in the middle of July and enough on the ground that it could be measured. Rest of this week is supposed to be soggy to one degree or another which might postpone bringing it in as I hate rolling around on a soggy concrete floor and this one never did have a drain included in its design. Nowhere to drain the drain to.

Goot Evenick, and Velcominin to The InFamous Bay One of myth and legend. Currently it sits, quiet and peaceful, waiting for the next round of havoc and mayhem to commence. If this bay was to be given a Theme Song, it would most likley tend to be "Dirty Deeds done Dirt Cheap"! (or at least as reasonably as possible.) Today it was the site of a little tool time. I decided that my custom created transmission lift was a space hog and chose to remove the wide glide front axle/castors assembly; it being designed and fabricated to allow that to happen. I had kept the stock pins intact and just re-installed the original front iron wheels. I also removed the t-mission cradle and reset the palm back in place. Managed to locate the e-clips for the wheels but no joy on the palm. Another errand for the chase sheet.

Just a close up of the press and adjacent welding bench. Nothing fancy here. It is all sort of squashed into itself until I can shift the S-10 in and determine how much move around room is left over. This shot reminds me that I need to rotate the MIG to face towards the main door as that is the side that is likely to be having the exhaust connection problem that I have to remedy.

And my 85 SS, with all the stuff tucked back underneath it.

From left to right you see my m/c lift with three batteries sitting on its cradle. These batteries are more correctly ex Batteries; they have ceased to exist. What they are, are the 1000+ cranking amp items and they are heavy. That makes them great for use as dead weight to push things like floor panels down into their proper position so they can be marked. They are dry; the acid has been either wahed out by hose or leaked out from cracked cases.

Next is my low boy seat for snuggling up to body panels and staying comfortable, more or less.

Third are the post muffler tail pipes. They are nasty and do require some major love from a wire wheel and XLT stripping wheel. Purists will note they are not straight. Instead, in position, they dump just behins the rear wheel. I have already had to replace on rear frame horn because it rotted out due to interaction with the factory exhaust pipes. No desire to repeat the exercise. I wasn't set up to take pictures of how the work to replace that horn was done. Too much cutting and test fitting and tweaking to want to do it twice.

The tire is sitting in the wheel well but that is about all it is doing.

Finally, and barely visible, is the rear end, sitting in it transport cradle, just behind the car. Having it not installed is a pain but also a blessing because it lets me still get to the floor pan and touch it up, plus hang that frame brace off the shock towers and score new shocks (While you're there.........)

The driver's door off the 85. STill no new skin. Elsewhere there is a thread about issues that were had with Gbody Parts. The panel I have on order is supposed to be coming from Good Mark. TWO Years later...............(sounds of crickets)................................. Last heard from the distributor had supposedly been advised he had a shipment coming his way and that my panel was part of it................(more sounds of crickets)...........................My supplier is full continuous pester mode on this. I'm almost willing to bet it is stuck in customs quarantine in some obscure transit zone back of beyond just because.....

This is mostly a detail shot that shows the rot and damage. The inner skin has issues as well with a major repair/replace of sheet metal already done to it and more needed. The outer skin is terminal. The bottom edge/seam is weld that was never dressed out. That choice was due to discovering just how bad the panel had been dinged, and right where the anti-collsion re-inforcing panel sits internally. No chance of getting to the damage from the inside unless the skin is pealed off and that panel removed; at whic point, you are half way to installing a new panel anyway................now if only that panel would put in an appearance................................

Finally, a "Stuff" shot. Cherry Picker is in park mode. The tools in their cases on the pail are waiting on yet another furniture dolly to appear. Almost everything, one way or another, is on wheels in here. Didn't take that shot but even my heavy short timber blocks are stacked on a dolly. Much, much easier to move around or out of the way to access what's behind.

Tucked in at the back is my 5.3. It's engine harness is still back at the yard because the donor vehicle is a castle surrounded by a moat with more water to come. Told the yard guy today to let it sit until high tide recedes. Might be awhile.

Anyway, this has been a quck peek at my world, aka BAY ONE.

Nick

Finished up the forming, rebar, insulation and radiant tubing at the end of last week. Building inspector gave us the A-OK on Tuesday and have the pour booked for next week Tuesday. Will need to reposition some of the insulation just before the pour to try and minimize some of the gaps.

Think I'd want more and heavier bracing along that top edge and for the those ribs in the middle of the panels to prevent blowout. Concrete has a mind of its own when being poured and will try to seek out and exploit any weakness it can discover. Found that out when forming for a mezzanine landing and stairs a couple of years ago. If it can't escape it will do its best to bulge out the form

Nick

Nick

Yeah, the contractor should be here the day before the pour to fine tune the forms and set the anchor bolts etc. But part of the reason I contracted out all this part was so that I wasn't sitting there on the day of the pour with a couple grand worth of concrete sitting there with a blown out form. At least this way if it does happen, it's not my problemThink I'd want more and heavier bracing along that top edge and for the those ribs in the middle of the panels to prevent blowout. Concrete has a mind of its own when being poured and will try to seek out and exploit any weakness it can discover. Found that out when forming for a mezzanine landing and stairs a couple of years ago. If it can't escape it will do its best to bulge out the form

Nick

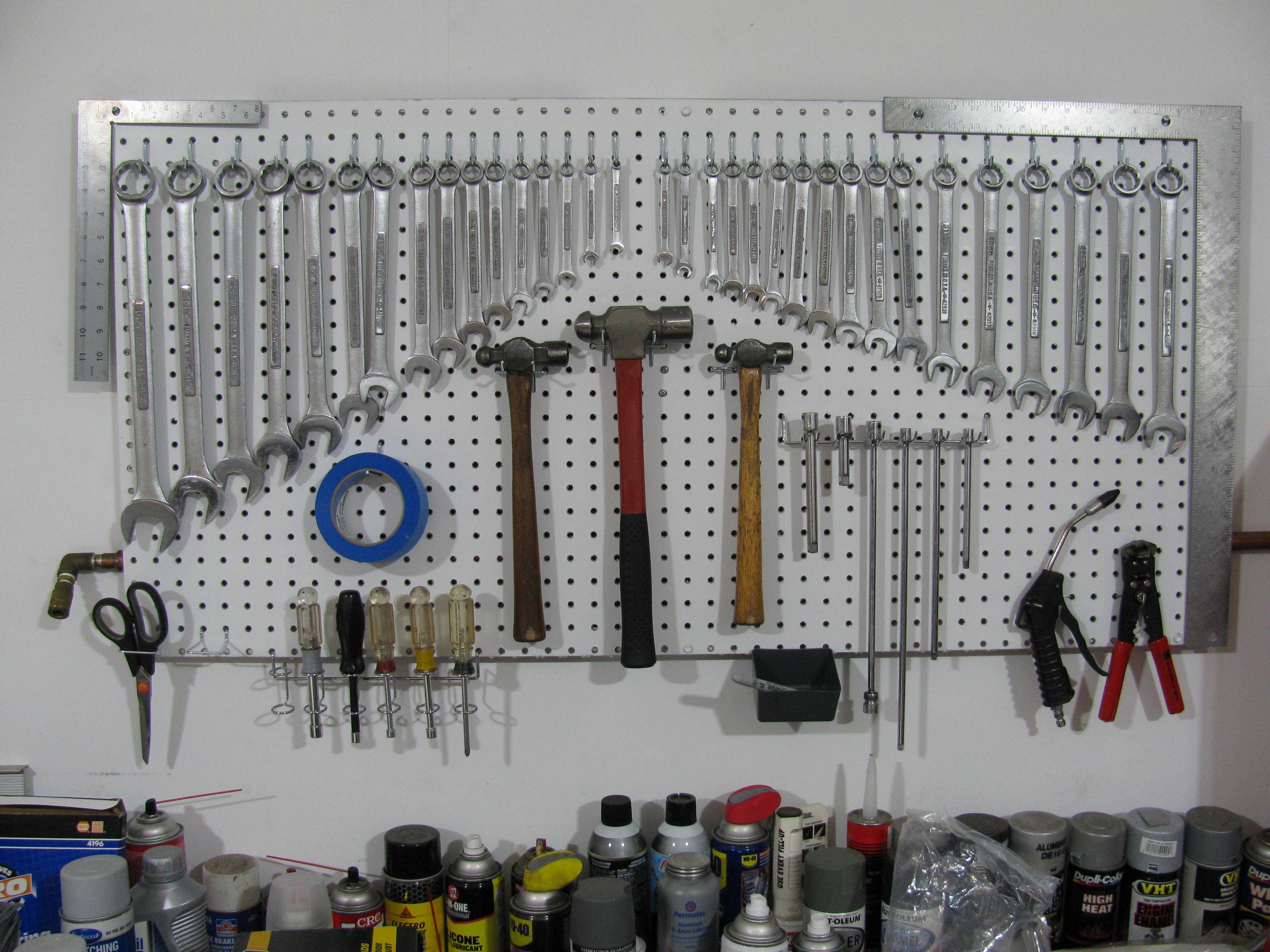

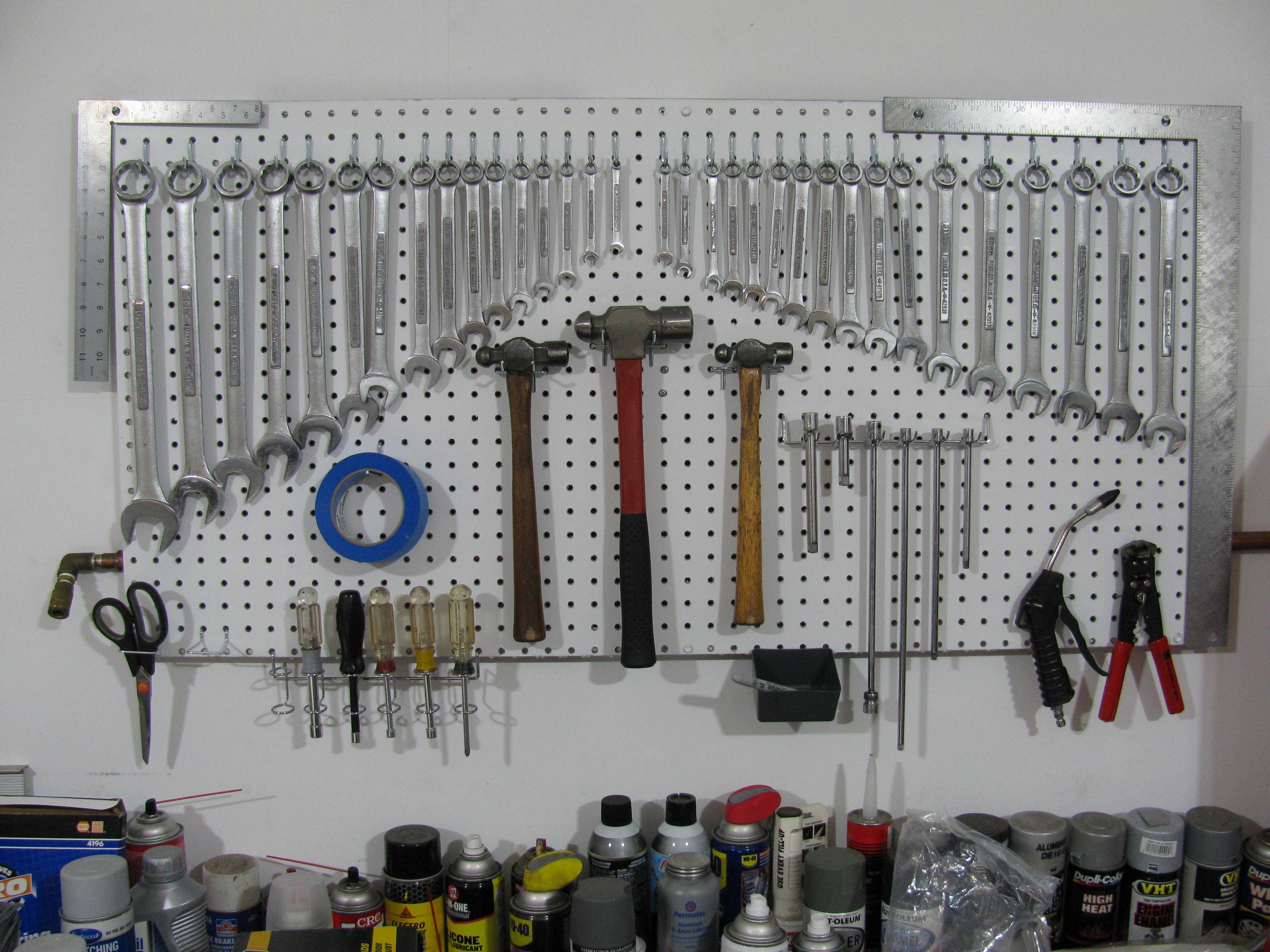

Put up a peg board to free up some tool box space.

Hutch

Hutch

Similar threads

- Replies

- 103

- Views

- 5K

- Replies

- 252

- Views

- 11K

- Replies

- 375

- Views

- 19K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.