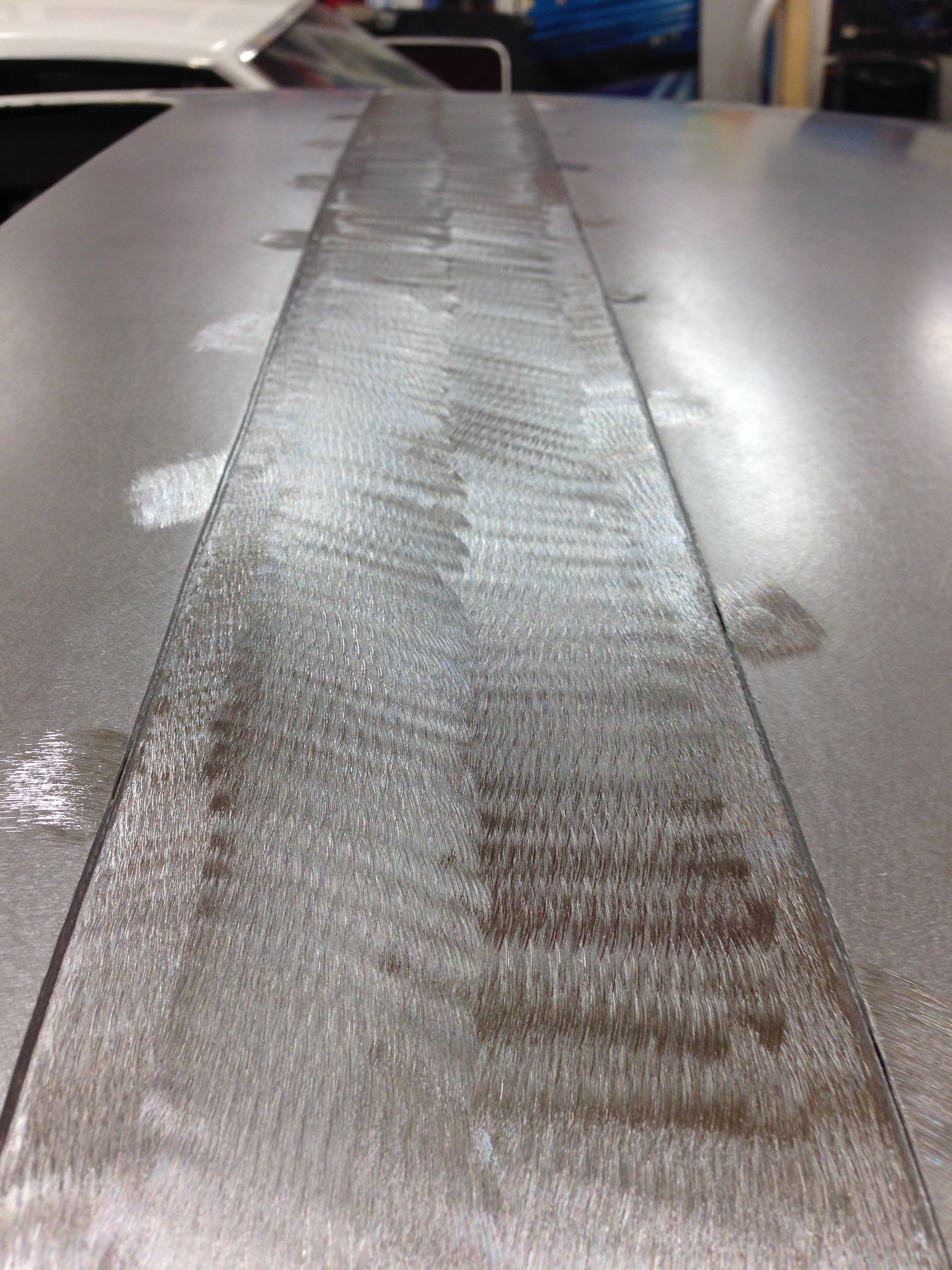

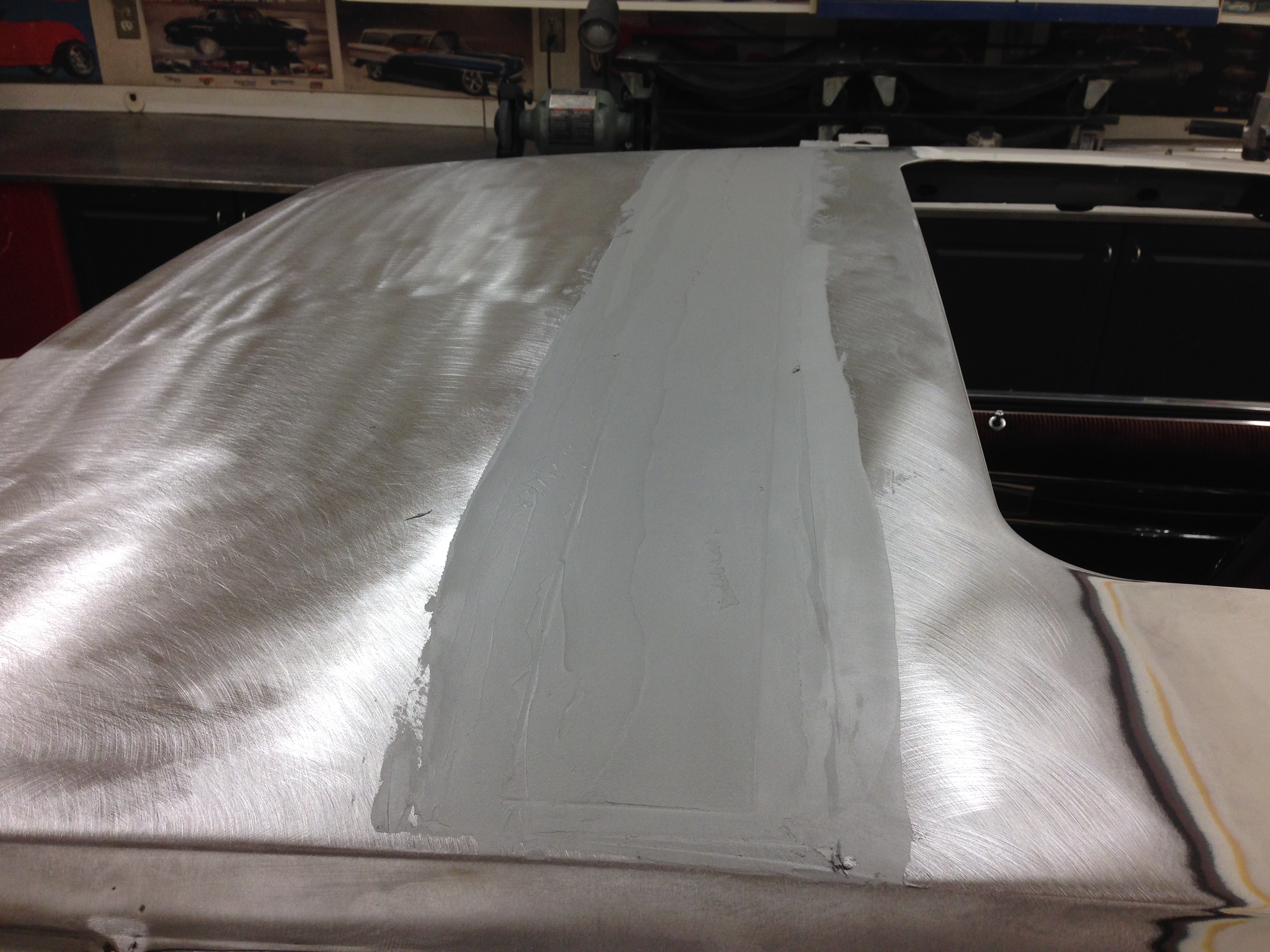

Very nice a detailed repair Donavan, as usual. I'm glad to see someone doing detailed write ups using the panel bond.

Sent from my Z981 using Tapatalk

Thanks Jim.

Yeah, you don't see a lot of people documenting using the panel bond, but it's pretty easy really. Which probably explains why.

In the limited number of times I've used it, it's always worked well. I really think this is the best way to repair this particular area.

Nice to see you on here a little more regularly again, and the wagon is looking amazing my friend! Great job. Can't wait to see you be able to start enjoying it!

Thanks for the bodywork tip! I think I have most of that stuff at home already.

No problem Mike. You're quite welcome.

Like I said before, I'll document that process too when I get there, so if you have any questions then, don't hesitate to ask.

Amazing work, does make me thankful that my Olds has no rust. Wish I was this good at repairs!

Thanks for the compliment!

Those of you that have cars that are rust free are lucky - and probably shrinking!

I wouldn't hesitate to guess there are probably more G's out there with rust issues in one form or another than not.

That's one of the reasons I'm going thru the effort to document these repairs on here. If it can help even one or two people with fixing theirs, I feel like I've given back to the G body community that's helped me out so much.

Thanks very much for commenting on the car and progress.

It's much appreciated!

Donovan