Donovan, I really like the idea of painting the B pillar black. A very slick and steathly body mod. When you're done with both of your cutlasses I will be sending my 78 cutlass to you .LOL. As always great work!

Thanks Mike. Glad you like the mod I have planned for it.

I just think it frames the window openings nicely that way, and looks clean. I have to remind myself sometimes that the factory '78-80 hardtop Cutlasses didn't actually come that way, I've been looking at The Juggernaut this way so long!

Lol

Makes you wonder why GM didn't do it...??

😕

Thanks for the compliments my friend!

Donovan,

You're almost too generous with your answers and advice. Don't hesitate to let us know when we get to be tiresome. Here's my new contribution.

What is it about All Metal that you like for this use at this point in the process?

BTW, I employed a similar flanged-and-epoxied approach to bodywork some 20 years ago, without the welding, substituting pop rivets, with success beyond any reasonable hope, on a 65 VW microbus. My epoxy of choice was PC-7, which I still consider a miracle adhesive, but I haven't tested my luck on any comparable project since then. I may have some hard copy evidence of my experiment but with any luck I won't be able to find anything incriminating. 🙂

Best - Gary

No worries Gary, it's not tiresome at all. I'm always happy to address and answer everyone's questions.

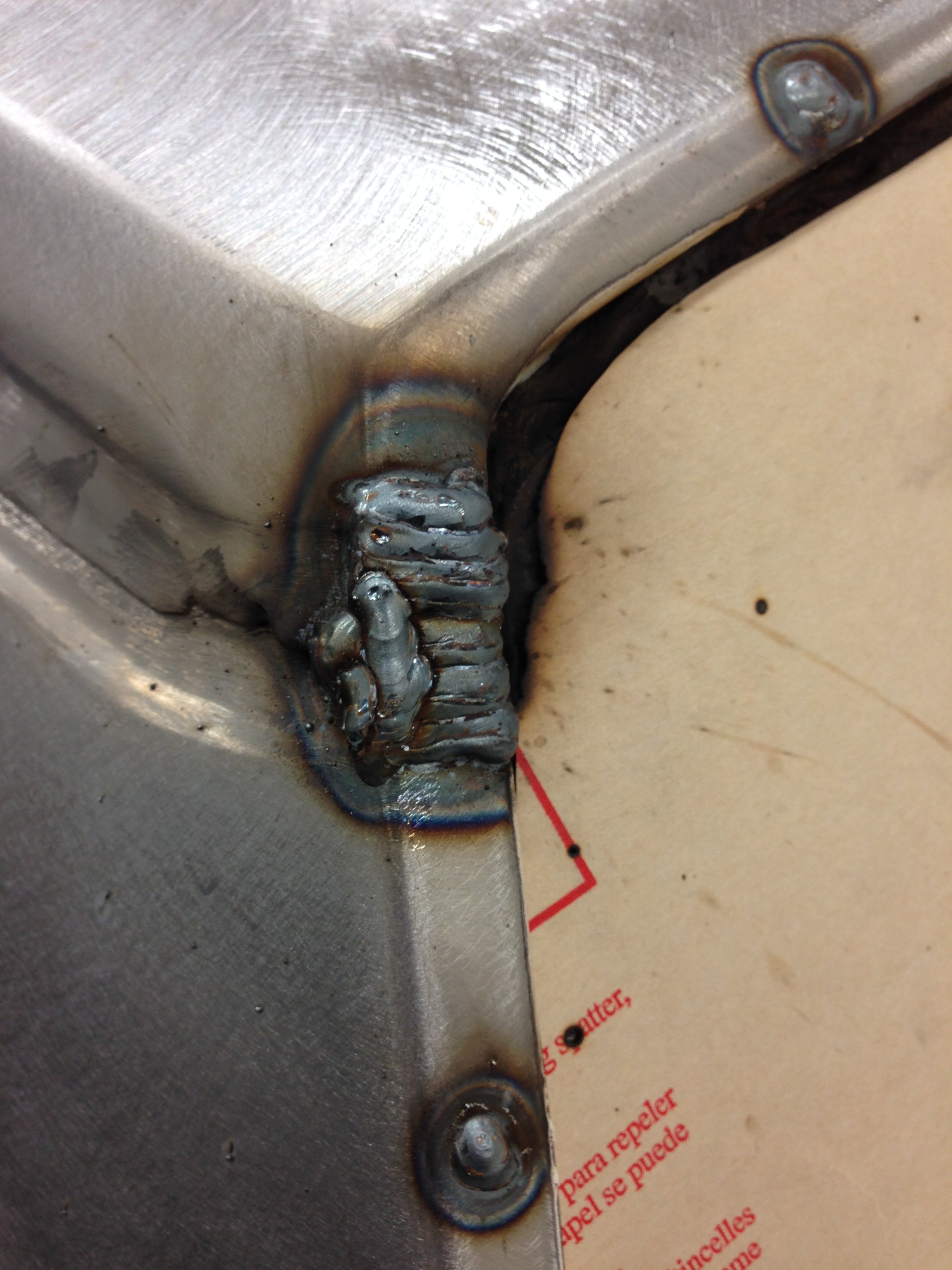

My answer to your question about the All Metal is pretty simple really.

I like the strength that it will add to the repair, and its ease of sanding. The repair is what I would consider to be just a little low to fill over with only conventional body filler, but not really deep enough to require short or long strand fibreglass filler. So the All Metal seemed to be a nice alternative that will still provide excellent results.

Thanks for relating your previous experiences with epoxying in panels on your Vee-Dub. Appreciate it!

Hi D,

As always, I'm totally impressed with your work. I know I must sound like a broken record, but I'm astonished with your level of craftsmanship and work ethic...I enjoy seeing your work in progress. Thank you again for showing us how it's done and being an all out great guy to boot.

Thank you very much Jack!

You're too kind as always sir.

😳

It's my pleasure to share the journey. I just hope everyone finds it enjoyable as well.

Your comments are very flattering, I'm honoured to be held in such regard in your eyes. Thank you.

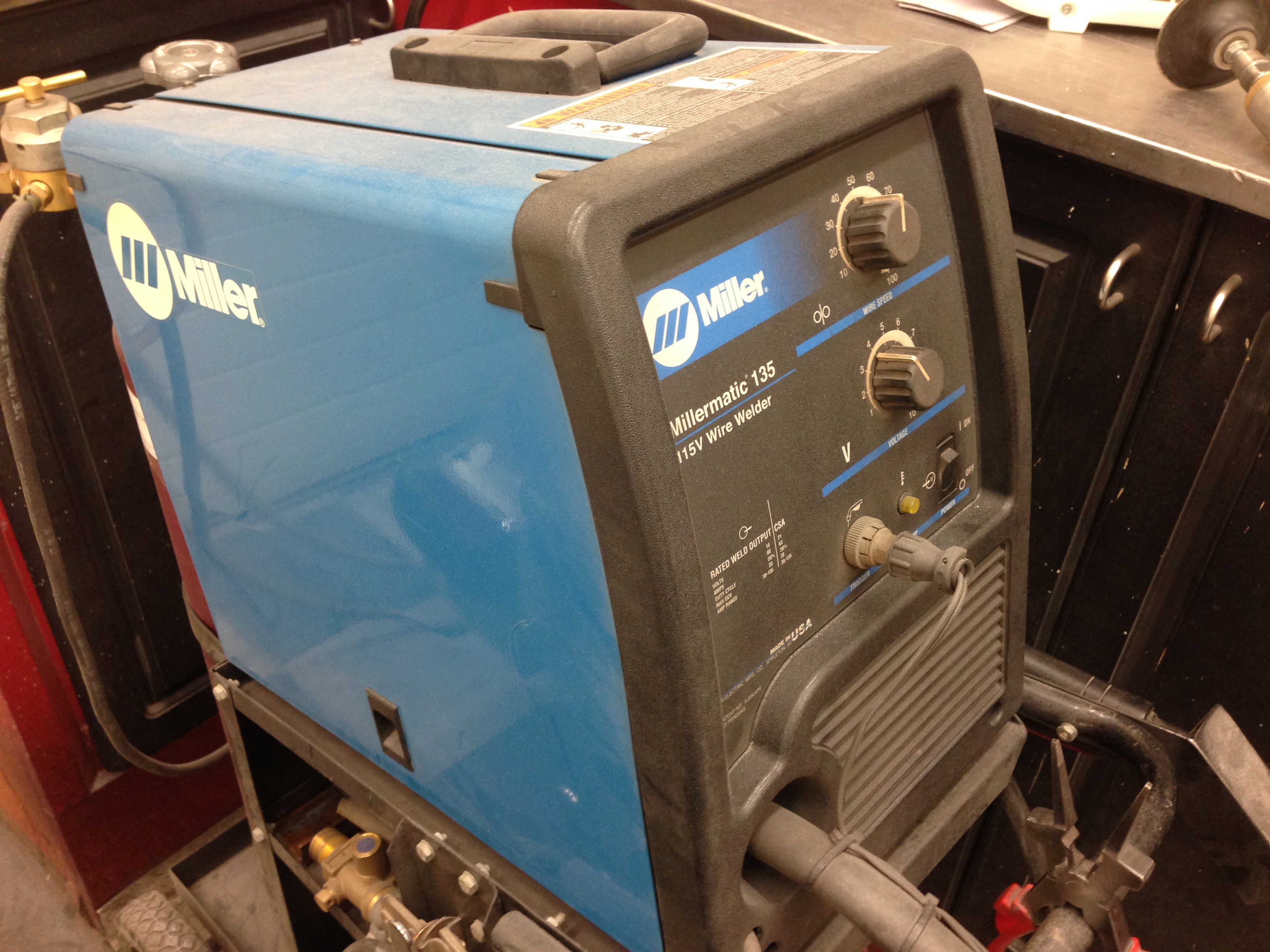

The craftsmanship you speak of wasn't always there. It's slowly evolving and being refined over the years. I started out like everyone else, not even knowing which end of the welder to hold so to speak!

Lol

Every time I delve into something new, or something I've done a million times before, I always try and improve upon it, and "do it better this time".

As far as the work ethic is concerned, I'm not scared of hard work, or getting my hands dirty. But then again, I don't really consider this work. Quite the opposite actually. It's my release, my sanctuary, my place to go and do my thing, and leave the stresses of the world outside and the day behind me.

Besides, what else am I gonna do with my time? Binge watch seasons of Dancing With The Stars?

Thanks to everyone again, for all the comments and support.

D.

Last edited:

!!!

!!!