I been working on a rear end swap for a while now (mostly bc I was so disorganized from the start). Anyway I’m at a point where I want to change the the pinion seal but I really don’t want to mess with replacing the crush sleeve bc I over torqued it.

Searching for specs I found this which says with a used bearing it should be 6-7 inch-lbs which sounds low imo. https://www.drivetrainspecialists.com/setup-specs

I’ve also seen where it should be 20-25 , right now mine is reading about 5-6 this is a 10 bolt 7.5 3:73 posi rear end I’m working with.

Here’s a few pictures of what I’ve done so far.

Clean up and painted underneath.

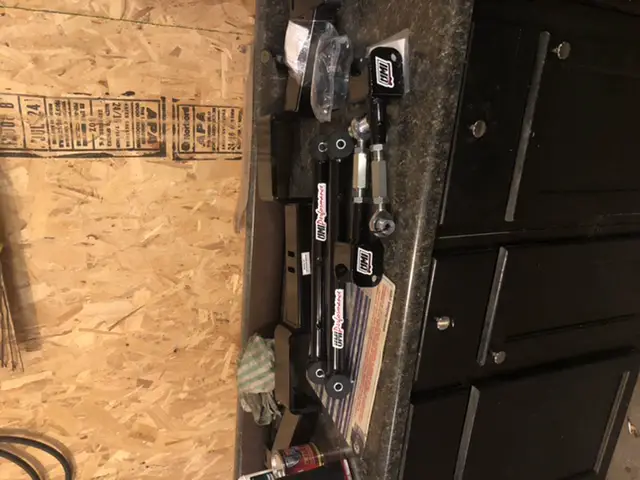

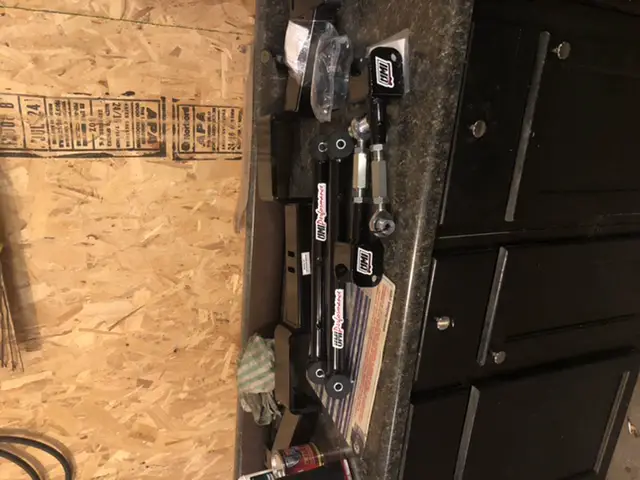

Bought some cool parts

Replaced bushing, backing plates & axle seals

Still waiting on a new diff cover& KYB Gas adjust shocks. Any help would be appreciated.

Searching for specs I found this which says with a used bearing it should be 6-7 inch-lbs which sounds low imo. https://www.drivetrainspecialists.com/setup-specs

I’ve also seen where it should be 20-25 , right now mine is reading about 5-6 this is a 10 bolt 7.5 3:73 posi rear end I’m working with.

Here’s a few pictures of what I’ve done so far.

Clean up and painted underneath.

Bought some cool parts

Replaced bushing, backing plates & axle seals

Still waiting on a new diff cover& KYB Gas adjust shocks. Any help would be appreciated.

Last edited: