They are actually not called "star" washers, just don't remember the technical name. I'll dig into it get you actual name. They are placed on the stud after the drum is on. They keep the drum from falling off as the car goes down assembly line.

They are stampings made from very thin spring steel, and it could be they rusted away and just left like a ghost image in the rusty metal where they used to be.

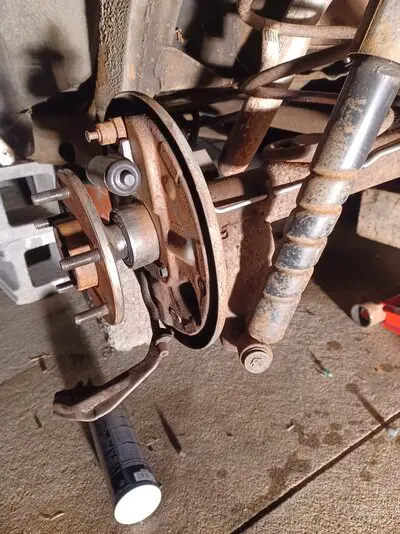

This one....

And this one....

Also note threads on this stud need chased or stud replaced. The threads look fairly damaged and can cause lug nut to cross thread. If you don't have the proper die to recut the threads, you can use the nut, but put on by hand (1/2 inch drive) not impact. Or you can end up on side of road with a nut that won't come off.

Note I used word "can" meaning "possibility"..., future tense. You also need to inspect threads on the 5 nuts, you don't want to put the nut with gummed up threads on another stud, or now you have two studs with damaged threads.

But you got the drums off and that's good. The best is Jack up rear of car from center section and put Jack stands under axle..., one per side. Put up high enough so that you have enough room to work.

When ever you do brakes pull drums both sides and do all the replacement parts one side at a time. This way you have the other side to look at in case you forget how it goes back together. This is also another method for you to QC your work, and make sure it is back together correctly.

Just remember it's basically like a mirror image. And the star adjusters are particular to a specific side. Get those reversed and they will not work.