My son has decided that he's looking for some more power, 650-700 whp, that can be daily driven implying reliable. We tossed around the idea of grabbing an SHP block and forged crank for his 327 and cranking the boost up to low to mid 20's, or grabbing a junkyard 6.0/4L80, but both lead to a unreliable program in our opinions. After talking to our engine/machine shop guy my kid decided to build a different motor and leave his current motor as is and put it into another project (which I'm a fan of) because a bolt in 500 HP 327 is a neat setup.

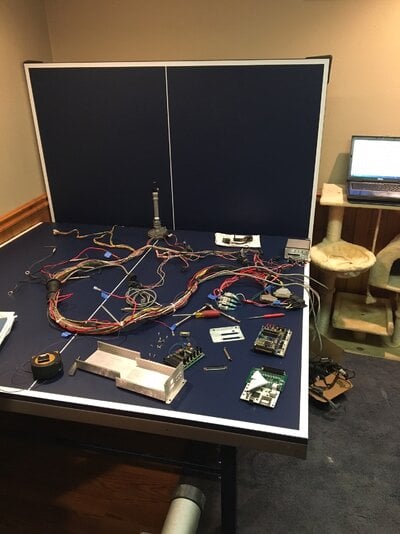

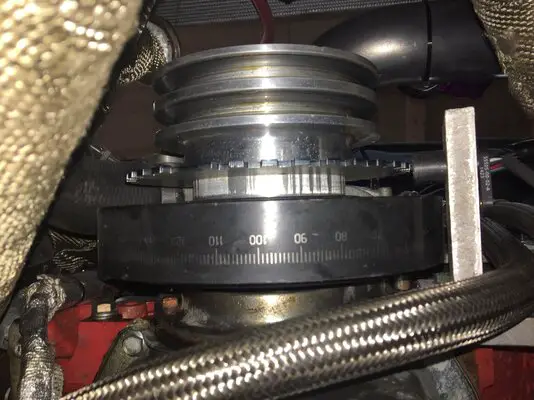

He just ordered a World Products LS hybrid block and rotating assembly combination consisting of a Scat crank and rods, SRP pistons, and Erson hydro roller. We're going to use a set of 317 truck heads and a T6 S475 turbo. We are estimating that we ought to be 650 whp with 10-12psi. This our first 'real' high HP, garage build that doesn't consist of scrounging every component possible and pushing every component to the edge of failure, which is where we are at presently with a stock 2 bolt block and cast crank.

We are working on 'packaging' the setup under the hood with rear exhaust, flipped truck headers and using an air cleaner. I know that many turbo builds seem to treat the air filter as an optional component, but I don't agree with that, especially considering it's a fresh motor. I've never understood making the effort to build a street car that is a screamer only to wipe out the cylinders via no air filter - maybe I'm just too anal retentive about it 🙂. But it definitely adds to the packaging issue as the T6 might be LARGE.

We still need to find another converter, but presently still are shopping for one.

He just ordered a World Products LS hybrid block and rotating assembly combination consisting of a Scat crank and rods, SRP pistons, and Erson hydro roller. We're going to use a set of 317 truck heads and a T6 S475 turbo. We are estimating that we ought to be 650 whp with 10-12psi. This our first 'real' high HP, garage build that doesn't consist of scrounging every component possible and pushing every component to the edge of failure, which is where we are at presently with a stock 2 bolt block and cast crank.

We are working on 'packaging' the setup under the hood with rear exhaust, flipped truck headers and using an air cleaner. I know that many turbo builds seem to treat the air filter as an optional component, but I don't agree with that, especially considering it's a fresh motor. I've never understood making the effort to build a street car that is a screamer only to wipe out the cylinders via no air filter - maybe I'm just too anal retentive about it 🙂. But it definitely adds to the packaging issue as the T6 might be LARGE.

We still need to find another converter, but presently still are shopping for one.