Ok. That was my problem. I set timer to 15 minutes and never checked actual flash of primer. Still learning. Appreciate all the help for sure 👍I'd stick w/the medium @that temp but that's just me,again theres a lot of variables with these types things so whatever works better with xyz product/conditions.if it's flashed off inside the coat window I'm not watching the clock for the next coat.

84' Cutlass pro touring build

- Thread starter Tony1968

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

something to remember,the reducer provides the transportation for the product.if it's not moving how you like it,it's a usually a viscosity issue.

Wow, need to sticky the last couple of pages of priming knowledge lol.

My experience with 2k is not precise. - if it goes in badly, then I bust out the 120 grit and knock it all off and start over.

I’ve always used the budget stuff and had decent results with plenty of wet sanding.

Good luck and so glad it’s coming along Tony - keep at it!!

My experience with 2k is not precise. - if it goes in badly, then I bust out the 120 grit and knock it all off and start over.

I’ve always used the budget stuff and had decent results with plenty of wet sanding.

Good luck and so glad it’s coming along Tony - keep at it!!

Definitely an issue. After I cleared gun when it started sputtering, it was much better plus I added more reducer.something to remember,the reducer provides the transportation for the product.if it's not moving how you like it,it's a usually a viscosity issue.

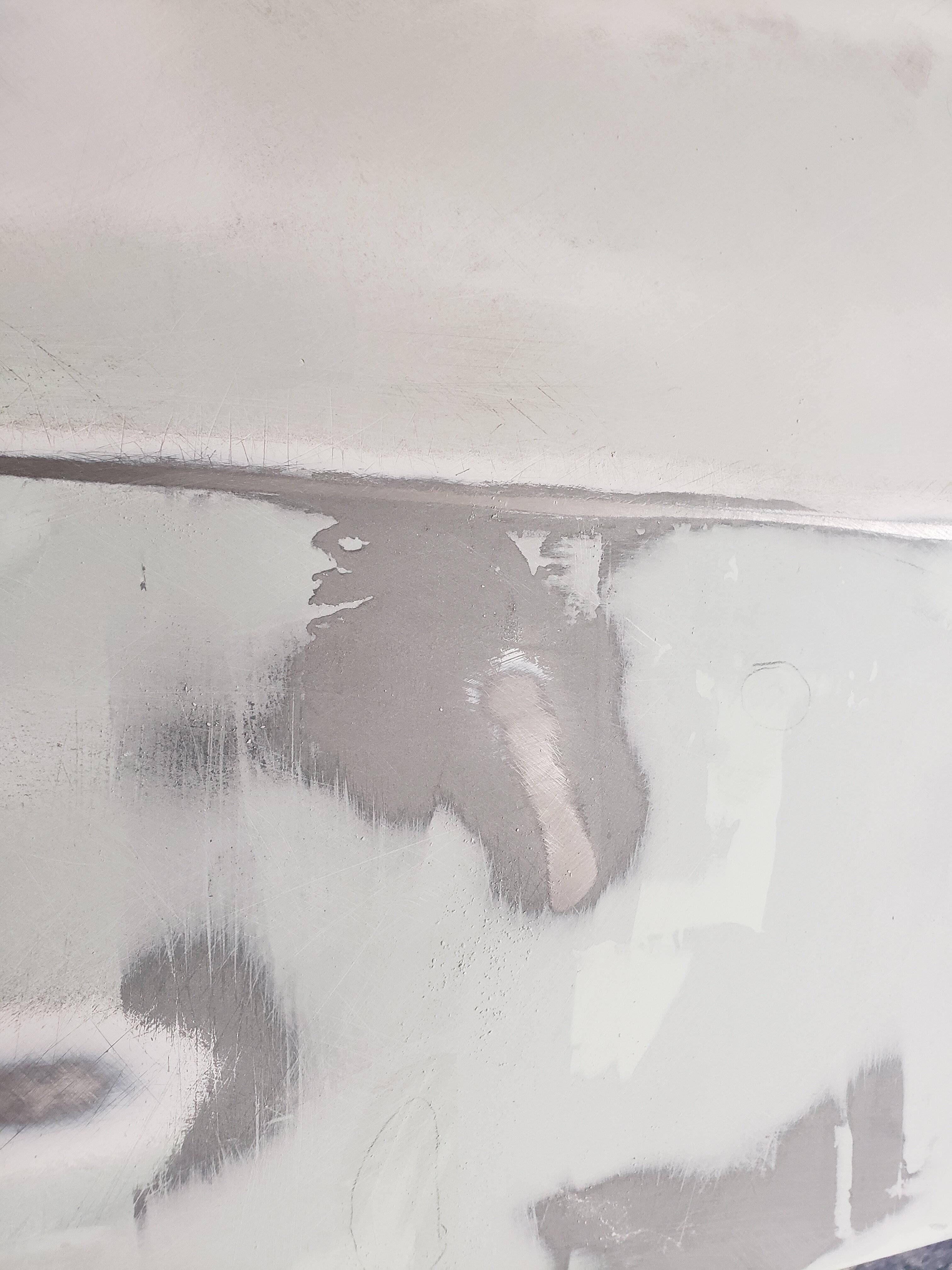

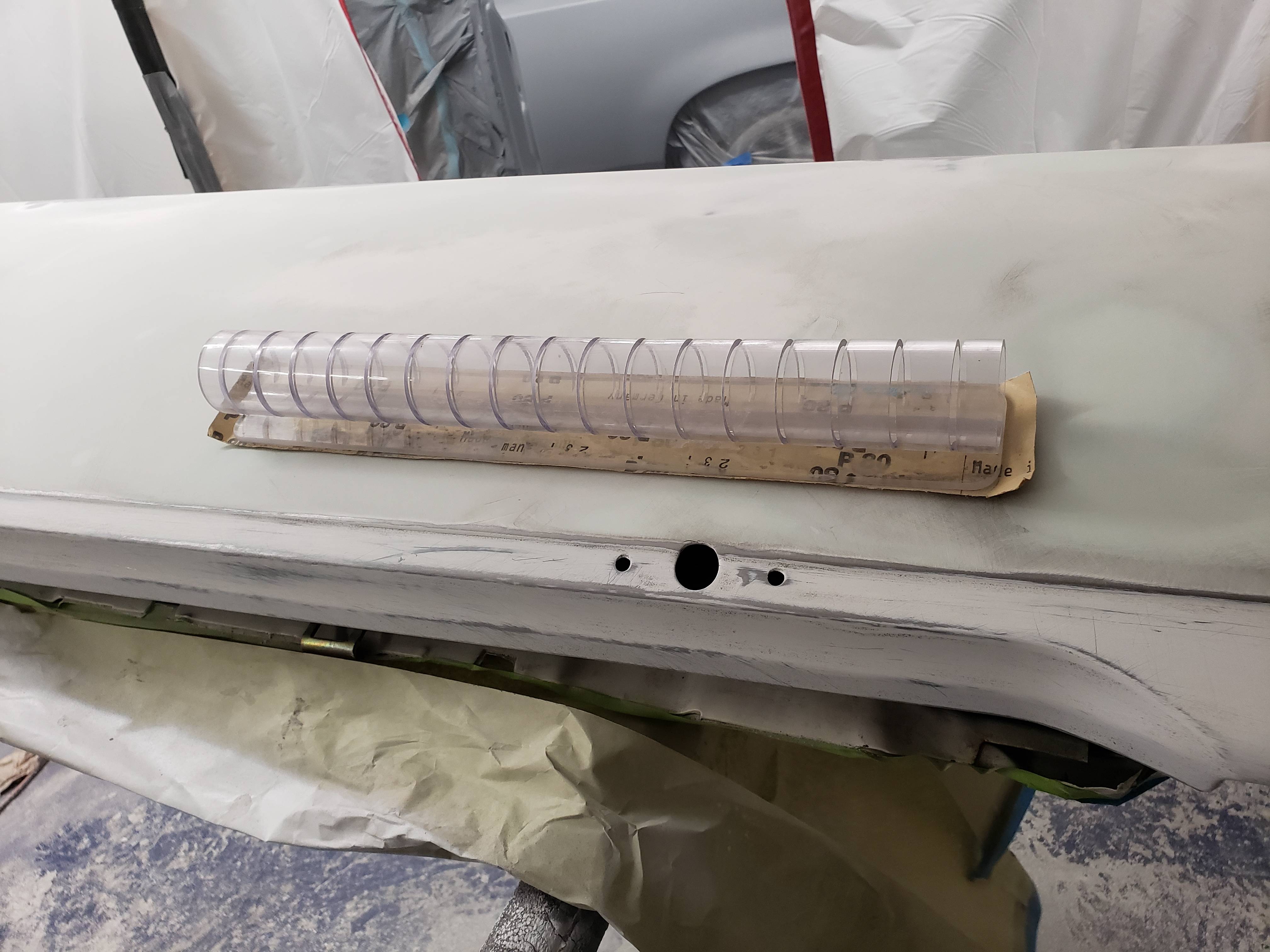

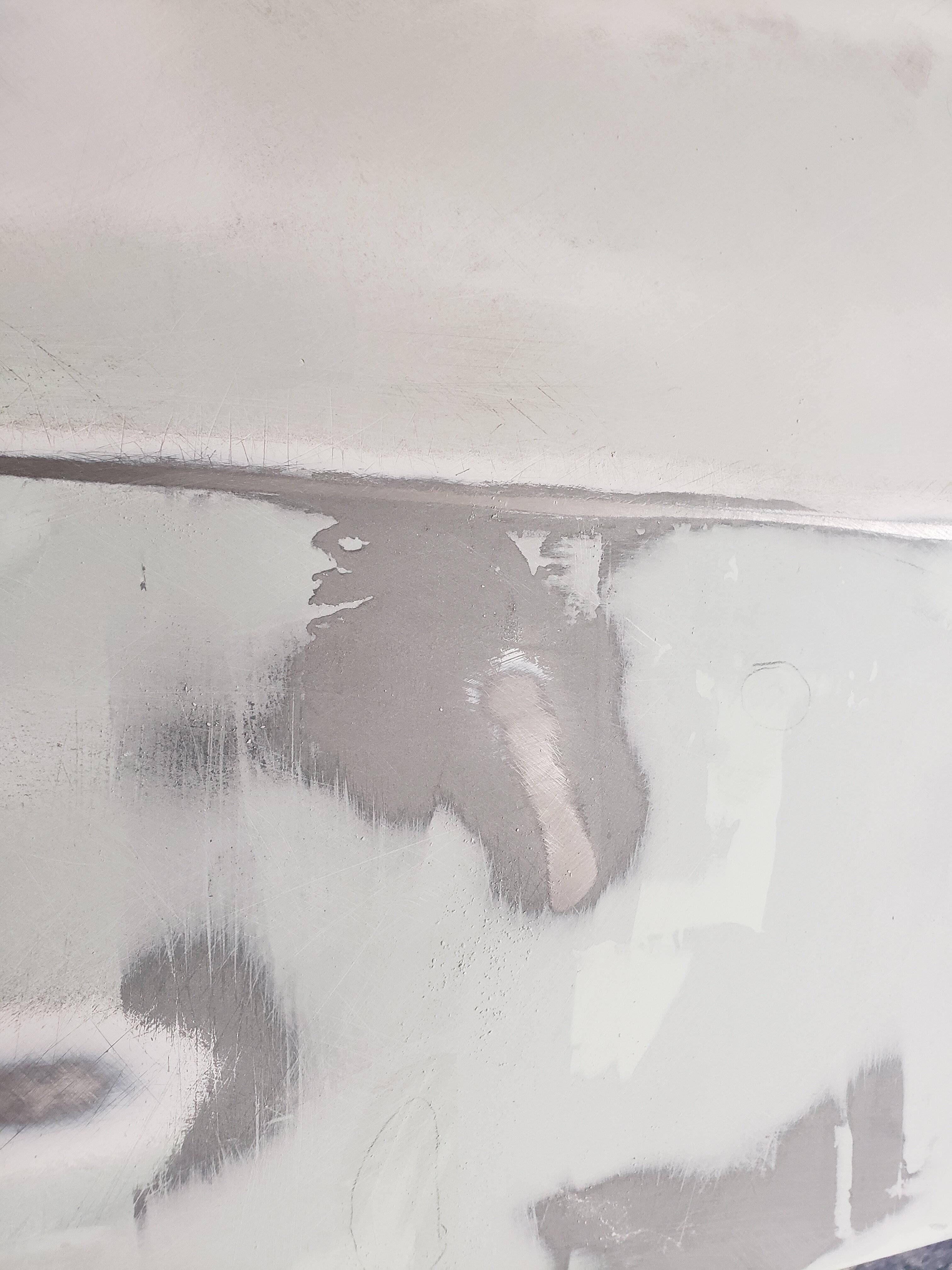

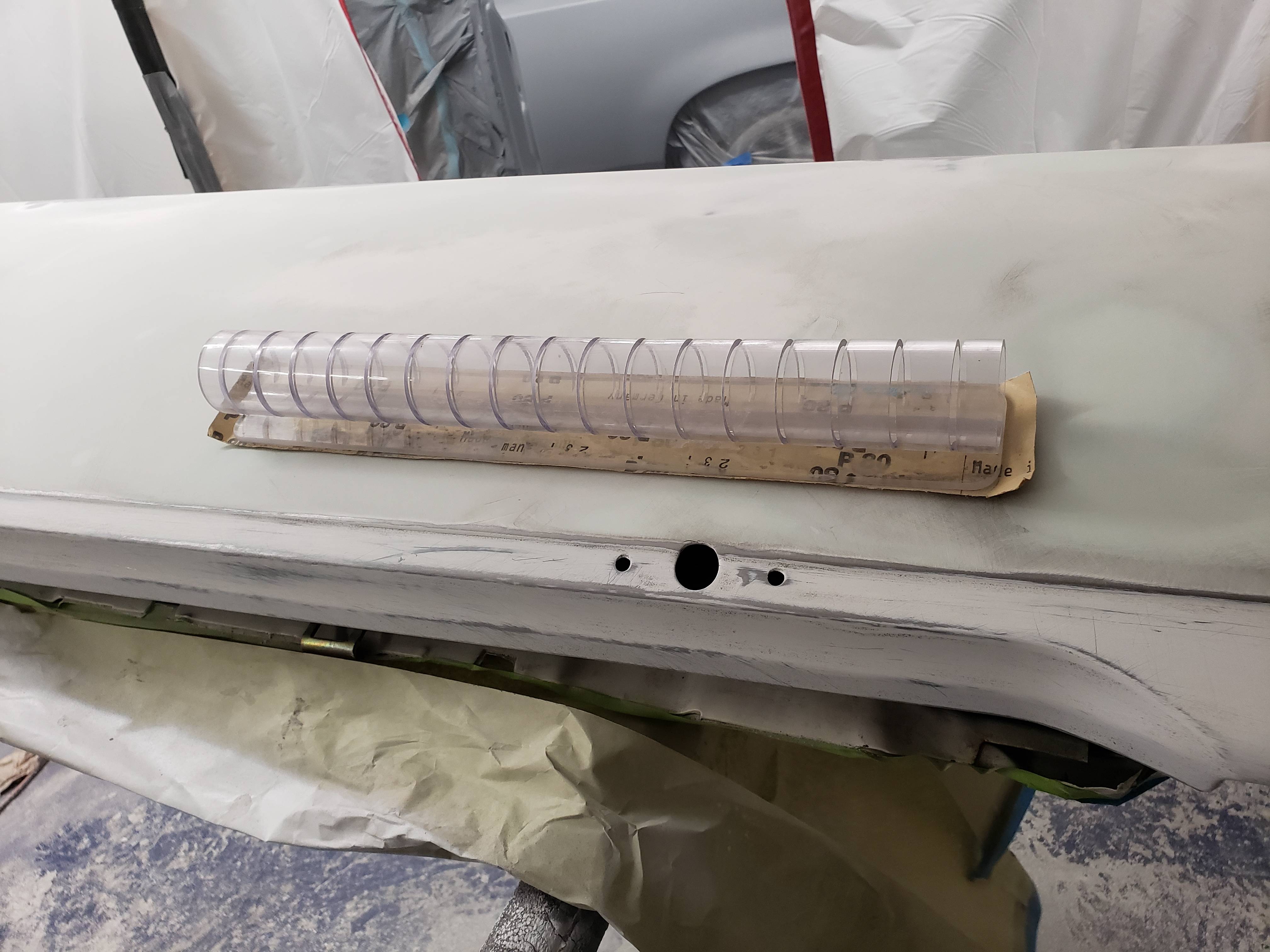

Monday, after getting some dings metal worked, I put driver side door in epoxy primer. 24hrs later i did some wet sanding with guide coat. Amazing the amount of dings and divots that I really couldn't tell were there prior. It was going to be easier to Rage ultra over entire door. First time I've really done that much fill at one time (in sections) Blocked well. Used powdered guide coat for first time also. Found small lows that were easily filled with finishing glaze. So here i am. I will be able to epoxy then hi build tomorrow as today it's only 50 degrees. This depends on answers i get for this question. Look at the strip of bare metal near center of door. At very bottom of it i feel an ever so slight bump. I have ran my gloved hands over the door all week. Everything is very very smooth and flat. Before I try to tap it flat (?) What say you guys? I can just get my hand inside with a dolly but I'm worried I might make a mistake. Honestly it is so light and barely 'feel able' that I think hi build may take care of it.

Looking good!

If you can feel it, you need to hammer and dolly it out. As I always tell Mike, bodywork is done by feel, not by sight. I’m a little concerned about the wet sanding you mentioned, I’ve never wet sanded epoxy before filler. Wet sanding won’t give you enough “tooth” for mechanical adhesion for filler to stick to, it needs an 80 grit scratch minimum. I’ve never seen wet sandpaper in that coarse of grit.

If you can feel it, you need to hammer and dolly it out. As I always tell Mike, bodywork is done by feel, not by sight. I’m a little concerned about the wet sanding you mentioned, I’ve never wet sanded epoxy before filler. Wet sanding won’t give you enough “tooth” for mechanical adhesion for filler to stick to, it needs an 80 grit scratch minimum. I’ve never seen wet sandpaper in that coarse of grit.

I was concerned about that also. Here's what I did. Epoxy I used said to wet sand after 24 hours or dry after 3 days. I didn't want to wait. I had 150 grit wet that I went over epoxy just to give me an idea with guide coat. Once lows were found I used 80 to clean out paint in lows and went over entire door with 80 dry which was fun due to the gummy nature of un cured epoxy. Just need to clean paper. A lot. Then I used filler. Hope that makes senseLooking good!

If you can feel it, you need to hammer and dolly it out. As I always tell Mike, bodywork is done by feel, not by sight. I’m a little concerned about the wet sanding you mentioned, I’ve never wet sanded epoxy before filler. Wet sanding won’t give you enough “tooth” for mechanical adhesion for filler to stick to, it needs an 80 grit scratch minimum. I’ve never seen wet sandpaper in that coarse of grit.

Once filler set up i took ridges down with grater and then 40 grit on linear block. Then 80 and any lows were filled with 3M ultra glaze

@this stage don't worry about making a mistake,this is the time to sheer have @ it.

call me old fashion(I'm not scared)but even with adhesion promoters on the market and the paint company's pushing their direct to un scuffed ecoat in certain areas I'll still error closer to the side of caution and trust mechanical adhesion. I worked with a guy that used to wet sand epoxy with wax and grease remover to stop the clogging if he missed the window.he was nuts @every turn that guy.

call me old fashion(I'm not scared)but even with adhesion promoters on the market and the paint company's pushing their direct to un scuffed ecoat in certain areas I'll still error closer to the side of caution and trust mechanical adhesion. I worked with a guy that used to wet sand epoxy with wax and grease remover to stop the clogging if he missed the window.he was nuts @every turn that guy.

I make mistakes, no doubt. But I'm pretty sure I've got not only chemical but mechanical adhesion also. 4 to 5 day adhesion with this epoxy.@this stage don't worry about making a mistake,this is the time to sheer have @ it.

call me old fashion(I'm not scared)but even with adhesion promoters on the market and the paint company's pushing their direct to un scuffed ecoat in certain areas I'll still error closer to the side of caution and trust mechanical adhesion. I worked with a guy that used to wet sand epoxy with wax and grease remover to stop the clogging if he missed the window.he was nuts @every turn that guy.

From what I've learned lately and what kinda concerns me is that 2k primer surfacer can take a month or more to offgas and shrink. If you stack too much on. I didn't know that.

Similar threads

- Replies

- 1

- Views

- 90

- Replies

- 4

- Views

- 345

- Replies

- 0

- Views

- 88

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.