Rktpwrd might have some insight on tightening up those mirrors. I think he did on Oldscool.

84' Cutlass pro touring build

- Thread starter Tony1968

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rktpwrd might have some insight on tightening up those mirrors. I think he did on Oldscool.

I did tighten up Olds Cools mirrors, but it was in the cable adjustment, and they are the bullet style. Apples and oranges unfortunately. There probably is a way to tighten them up, but it likely is going to require removing the glass sections. I think there is a screw in behind there that governs how tight they can be.

Personally speaking, I don’t feel that style of mirror suits the direction that Tony is going with his car. I would put out a want-ad on the forum here for some bullet style ones, but again, that’s just me.

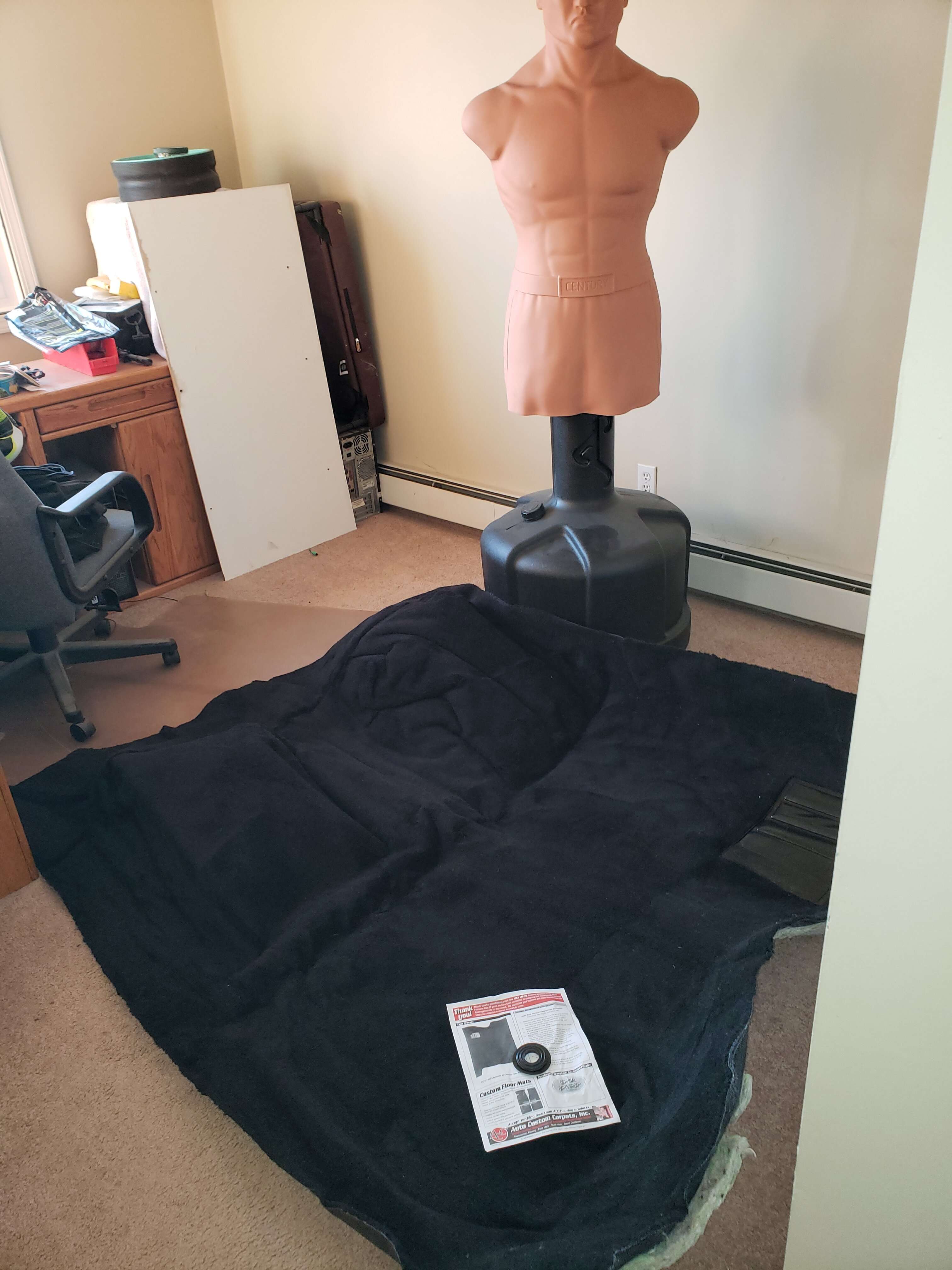

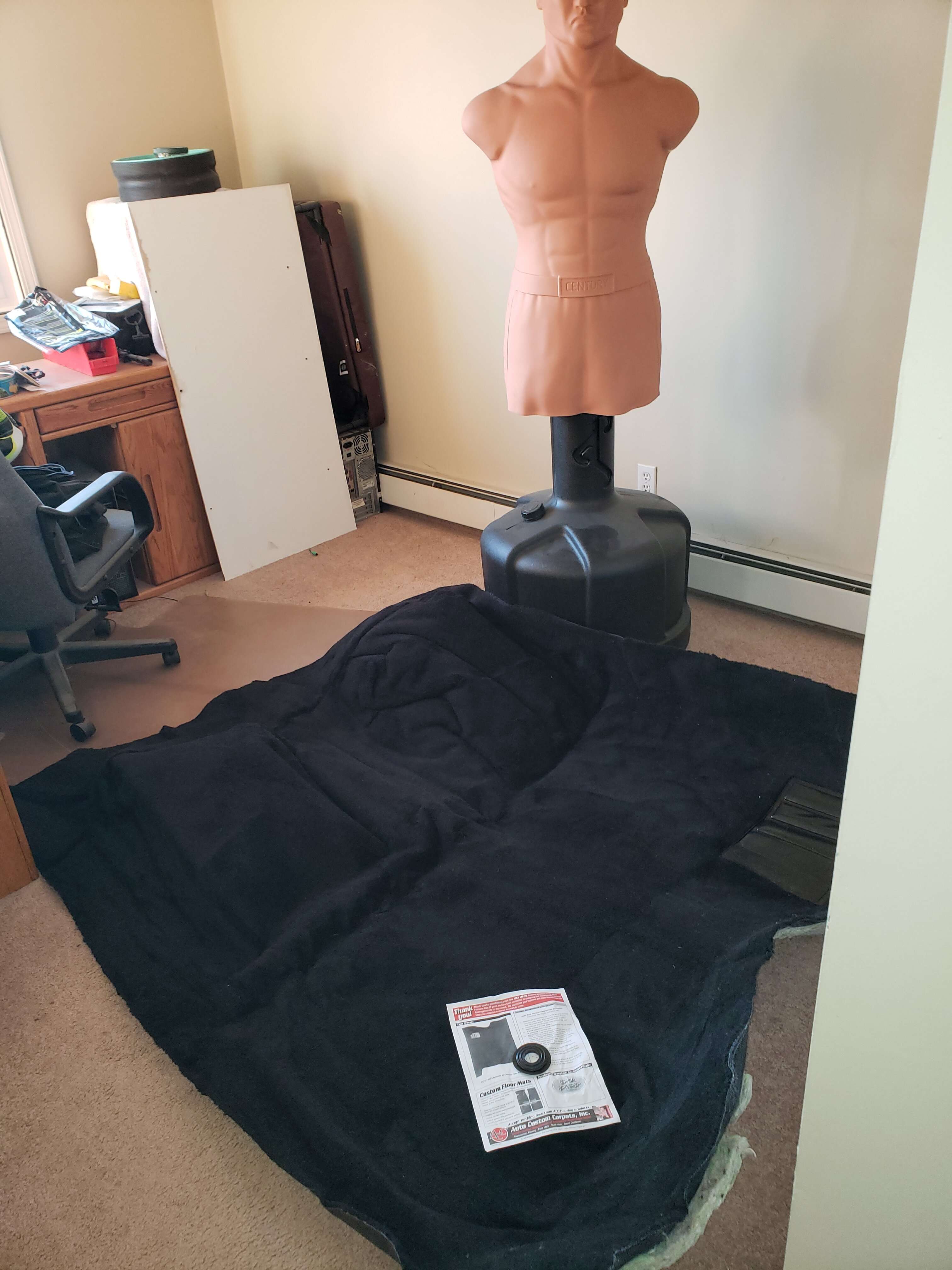

Picked up an impact driver and was able to remove door latch. Cleaned and checked it out only to reinstall and same problems. Bit the bullet and bought new latches for both side and new drivers side handle. Passenger is on backorder until May. Also some interior bling. Couldn't pass it up for under a hundo plus adapter for another 50. Have a few more wires to run and need to weld in inner seat mounts before carpet goes in.

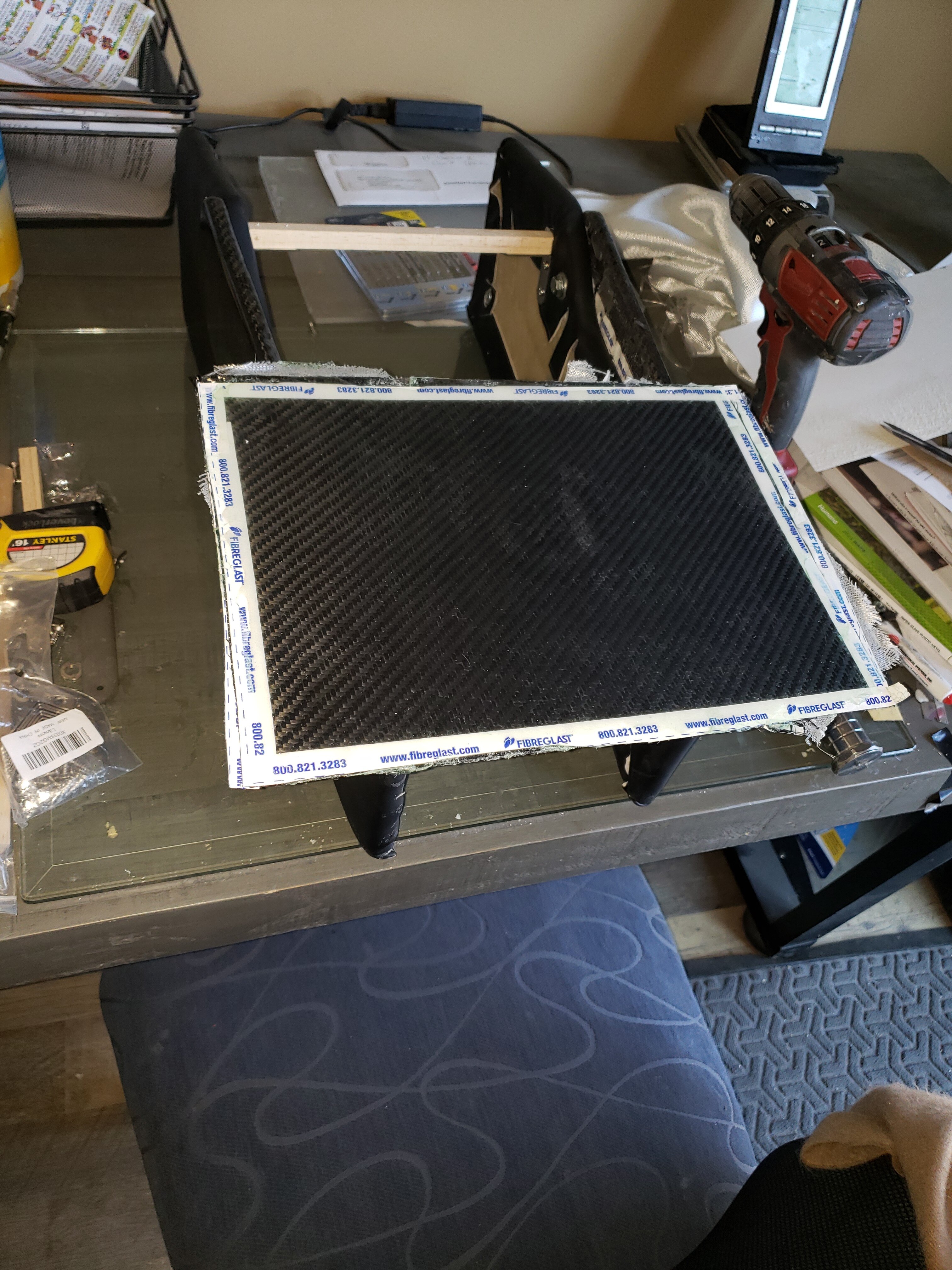

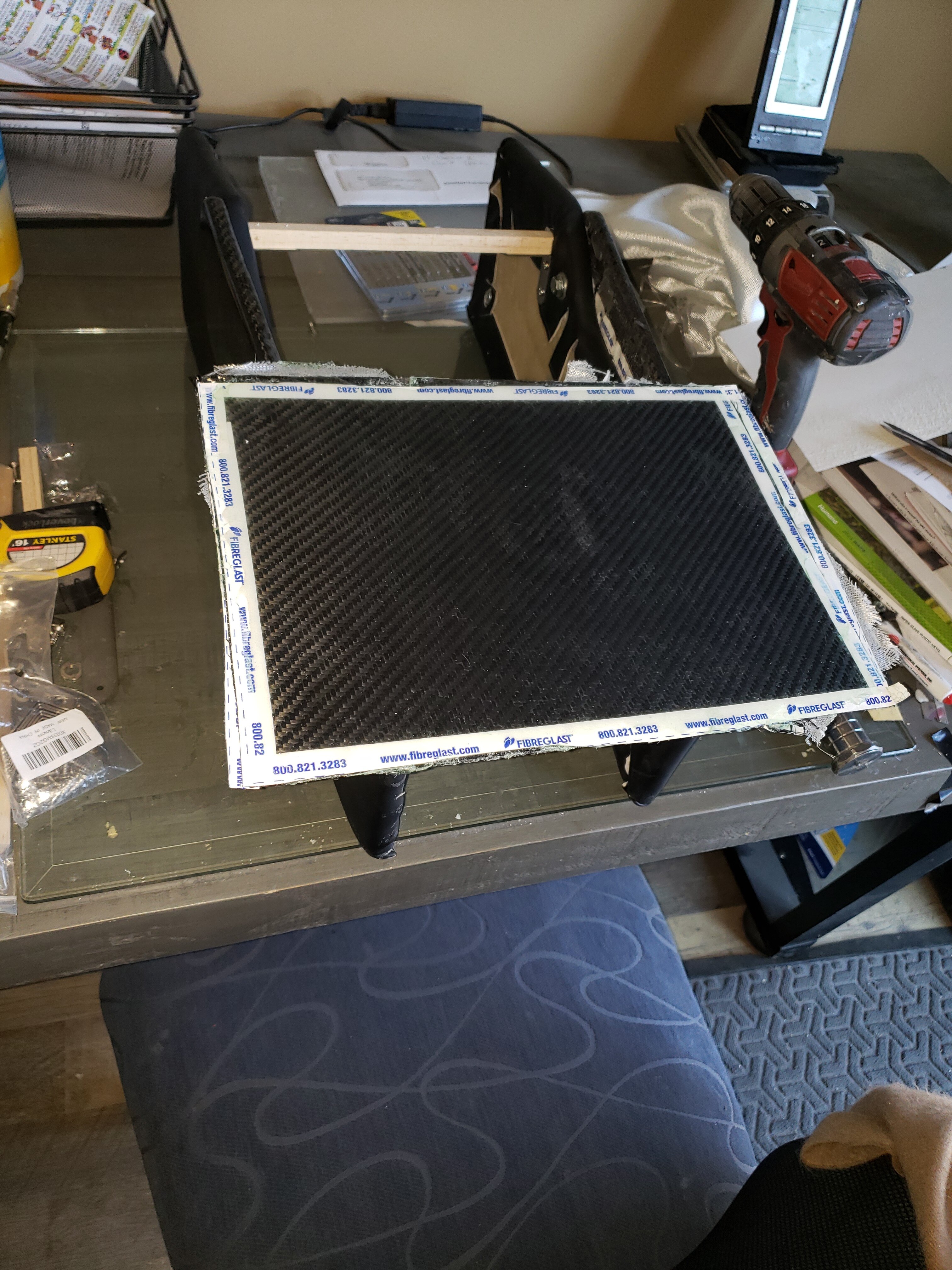

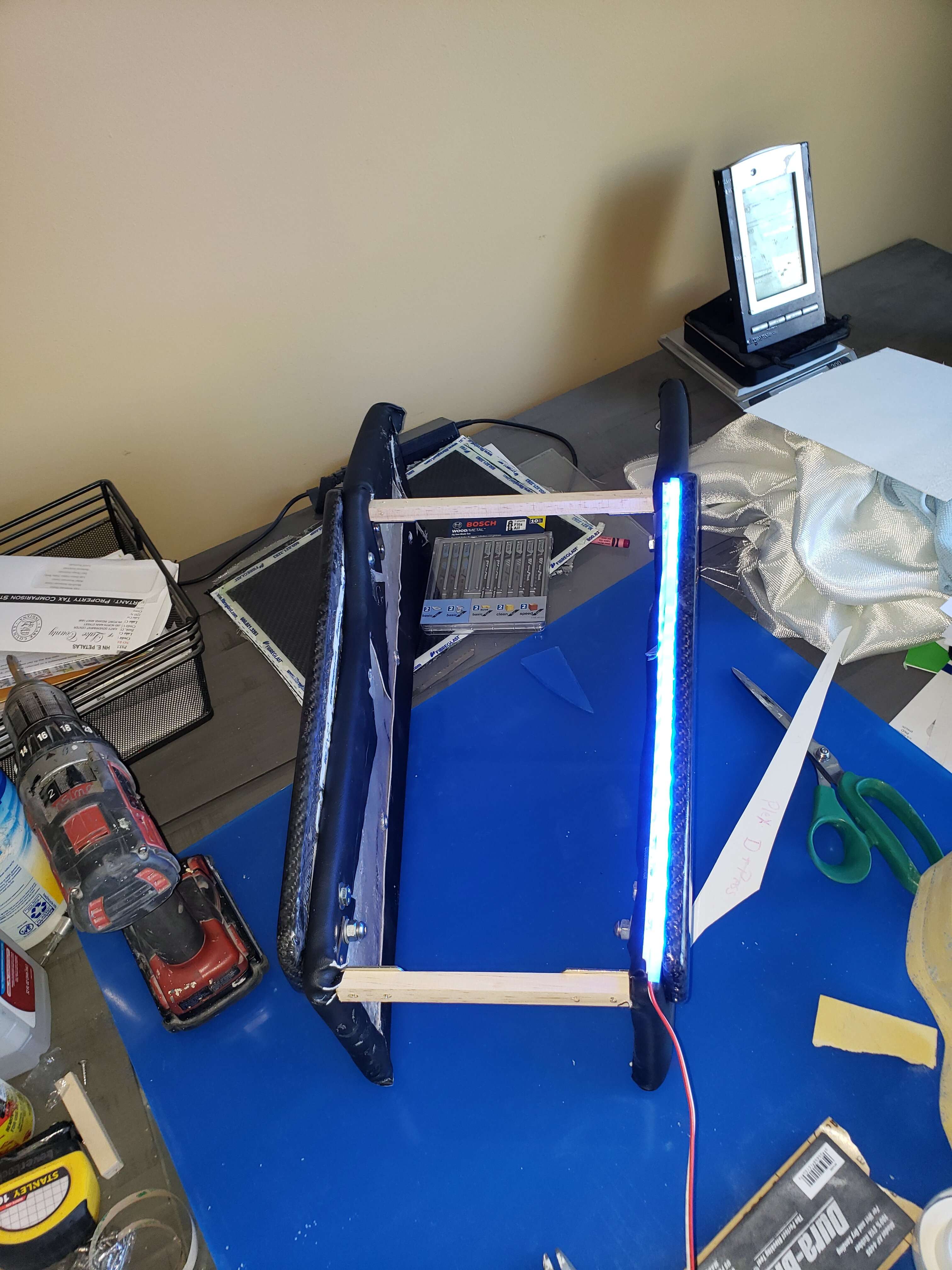

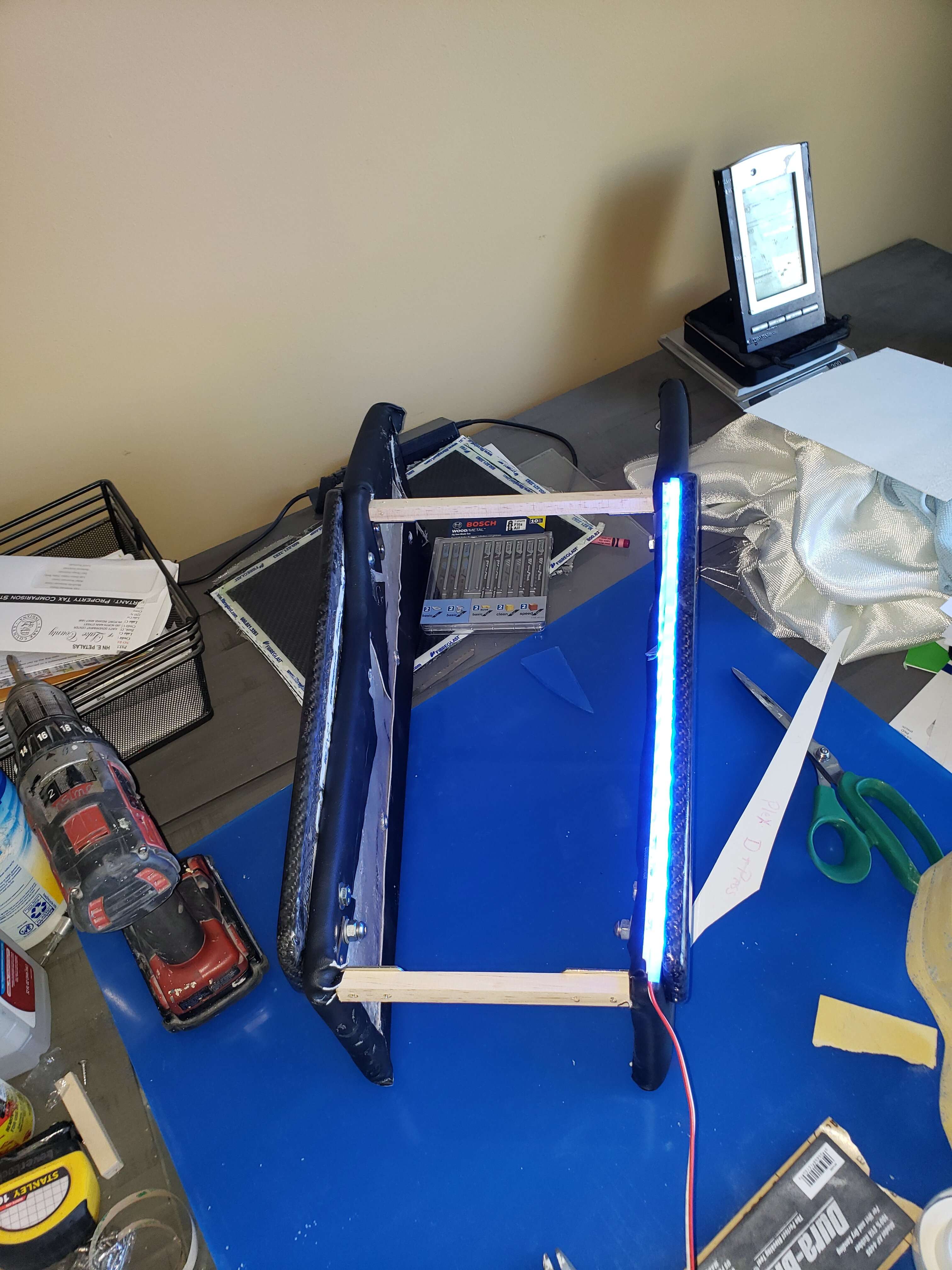

It's been awhile since I've posted. I have been working on the Cutlass on and off so let me add what I've done. Ran rear speaker wiring, 3rd brake light mounted and wire towards front, rear camera wiring ran. Finished rear insulation. And began making a center console from scratch. I went with a totally new concept and I've been wanting to try this for a long time. Using things from the aerospace industry (marine also) . 3/8" foam structural board and carbon fiber along with fiberglass sheets. All put together with epoxy resin. Covered in a high quality vinyl. Big learning curve. Still have to add rear portion of console. I didn't want to make one huge part so splitting it in two seems easier.

I want a good sized console and I want it to be special. Making it out of plywood or mdf would have been easier but much heavier. And cheaper. I have so much time invested in this process already but it's fulfilling to me. I'm also running the harness and Holley ecu through the console and will be mounted inside console lid. Haven't seen that done yet either.

I want a good sized console and I want it to be special. Making it out of plywood or mdf would have been easier but much heavier. And cheaper. I have so much time invested in this process already but it's fulfilling to me. I'm also running the harness and Holley ecu through the console and will be mounted inside console lid. Haven't seen that done yet either.

Here is first piece of 2x2 twill carbon fiber i made. Flat plate that will surround the double din radio. Obviously need to finish trimming. There are 3 layers of fiber each being .012" thick. Very thin yet the strength is amazing. Using carbon fiber is a lot like bodywork honestly. Once laminated you need to sand and layer more resin to get it as flat as possible then lay on clear for UV resistance. I have many more plans for the car using it.

Good to see the progress. Console is looking awesome!

Very cool!Here is first piece of 2x2 twill carbon fiber i made. Flat plate that will surround the double din radio. Obviously need to finish trimming. There are 3 layers of fiber each being .012" thick. Very thin yet the strength is amazing. Using carbon fiber is a lot like bodywork honestly. Once laminated you need to sand and layer more resin to get it as flat as possible then lay on clear for UV resistance. I have many more plans for the car using it. View attachment 218913View attachment 218914

Polished acrylic over led. Just a mock up

Similar threads

- Replies

- 0

- Views

- 54

- Replies

- 4

- Views

- 147

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.