On another note I didn't check yesterday because my friends minivan radiator hose found jesus and he didn't know what year it was so we spent too long finding the right hose! I plan to do oil change on the same van tonight and make him help me with the fender bolt.

87 Monte Carlo LS

- Thread starter Montepit87

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Im not knowledgeable enough to tell you what you should not or should run on those heads, but take Rabbit’s advice on the camels. They will need inspected at the least so you can have a plan forward.I want a street/ strip car and the 1.94s and 1.50s are both stock to the motor but they've been replaced as far as I know.

Here’s a little flow info on 461X heads:

461X Heads flow results - CorvetteForum - Chevrolet Corvette Forum Discussion

C1 & C2 Corvettes - 461X Heads flow results - Found some interesting flow bench numbers from factory 461X heads 1.94 intake but with larger exhaust valves @ 1.60, and basic pocket porting. 461X fuelie heads 1.94 / 1.60 flow @ 28 of water mild porting taken from Stan Weiss. Int lift....Flow...

www.corvetteforum.com

Runner volume chart for vintage SBC heads? Old Chevy High article? - The BangShift.com Forums

The strip had a nice race/show. Western Fuel Altered's Nitro cars / Alky cars plus a nice sized show. The pics are not great due to the suns position and my

bangshift.com

If you’re planning on sticking with the press in studs and stamped rockers, your cam options will be kind of limited so you’re not pulling the studs out.

And if you’re hunting for more info, this is absolutely the place to go:

I am unaware if it has press or screw in studs but I will check tonight when I have the time. I want to shoot for 350 or 400 horsepower. Thanks man.Im not knowledgeable enough to tell you what you should not or should run on those heads, but take Rabbit’s advice on the camels. They will need inspected at the least so you can have a plan forward.

Here’s a little flow info on 461X heads:

And some other info on camels as a whole:461X Heads flow results - CorvetteForum - Chevrolet Corvette Forum Discussion

C1 & C2 Corvettes - 461X Heads flow results - Found some interesting flow bench numbers from factory 461X heads 1.94 intake but with larger exhaust valves @ 1.60, and basic pocket porting. 461X fuelie heads 1.94 / 1.60 flow @ 28 of water mild porting taken from Stan Weiss. Int lift....Flow...www.corvetteforum.com

Runner volume chart for vintage SBC heads? Old Chevy High article? - The BangShift.com Forums

The strip had a nice race/show. Western Fuel Altered's Nitro cars / Alky cars plus a nice sized show. The pics are not great due to the suns position and mybangshift.com

If you’re planning on sticking with the press in studs and stamped rockers, your cam options will be kind of limited so you’re not pulling the studs out.

And if you’re hunting for more info, this is absolutely the place to go:

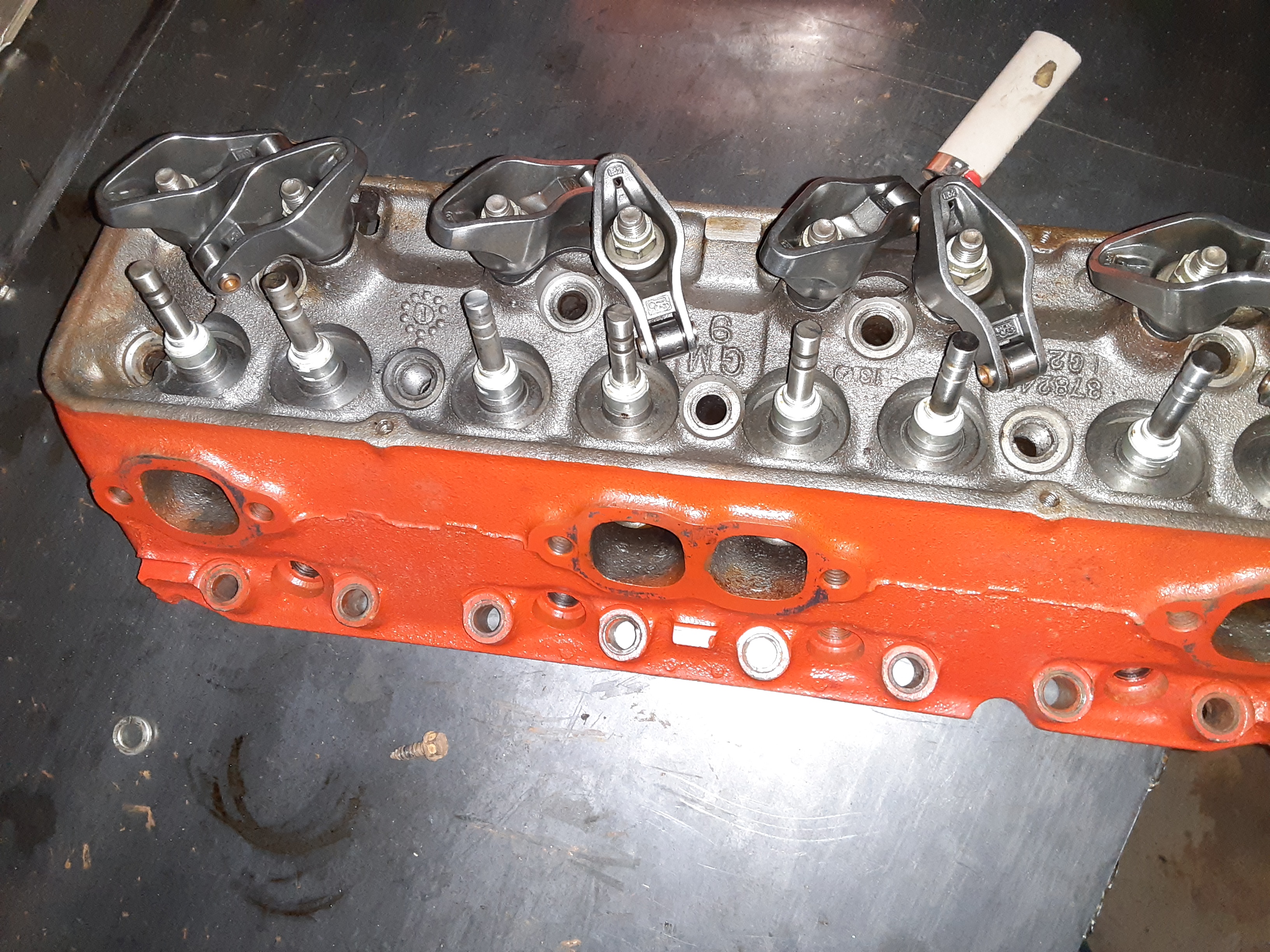

The heads are the 468 or something like that castings from the 64 to 66ish on the 327 small blocks. They had a 3 angle valve job new seals and the heads were decked. It came with some roller rockers of the 1.52 comp cams ratio and some pushrod guide plates that go on the studs.

If you’ve got guide plates, you’ve got screw in studs. Snap a picture of them when you get a chance, 468 doesn’t ring a bellThe heads are the 468 or something like that castings from the 64 to 66ish on the 327 small blocks. They had a 3 angle valve job new seals and the heads were decked. It came with some roller rockers of the 1.52 comp cams ratio and some pushrod guide plates that go on the studs.

I dont quite remember but I will when I get the chanceIf you’ve got guide plates, you’ve got screw in studs. Snap a picture of them when you get a chance, 468 doesn’t ring a bell

Just found your post and read it over. Your HP goal should be pretty easy to reach. As far as your crank a cast will do just fine at that HP, to find what you have get the casting number from it and check. As far as dual plane intakes the performer RPM was the best I used for HP and higher rpms. I hope those double hump heads have the holes for mounting your accessories. I see your block is a drivers side dip stick so you have a 2 piece rear main non roller. Put pen to paper and decide if you what to spend the money to go roller. It would have been a lot easier to pull the front end off as a clip - around 12 bolts. When you chose you cam make sure it complements the rest of your drive train and buy the springs for that cam. Make sure they get installed at the proper height and that your valve train geometry is right.

Last edited:

I wouldnt have the room for that. Also I wish I wouldve known and researched instead of working on it after a long day. But it wouldnt have worked out anyway due to the bolt that is still holding me back. I tried pulling and that didn't work none. I want a manual swap but I also dont want to be replacing my rearend too soon yet. Thanks for the tip on the intake.Just found your post and read it over. Your HP goal should be pretty easy to reach. As far as your crank a cast will do just fine at that HP, to find what you have get the casting number from it and check. As far as dual plane intakes the performer RPM was the best I used for HP and higher rpms. I hope those double hump heads have the holes for mounting your accessories. I see your block is a drivers side dip stick so you have a 2 piece rear main non roller. Put pen to paper and decide if you what to spend the money to go roller. It would have been a lot easier to pull the front end off as a clip - around 12 bolts. When you chose you cam make sure it complements the rest of your drive train and buy the springs for that cam. Make sure they get installed at the proper height and that your valve train geometry is right.

View attachment 159003

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 183

- Replies

- 0

- Views

- 91

- Replies

- 10

- Views

- 691

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.