BUILD THREAD A Teenager and His Malibu Wagon.

- Thread starter BlairC_789

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Good idea. I’ve got a small list written down on my phone. I’ll maybe put a post together tonight when I get home for work. Or tomorrow since I’m going to be working on pulling the 305 out of the wagon tonightPost a needs list in the Wanted/For Sale section and the collective will try to help you out.

I really enjoy what you are doing with the car so far. I have good and bad news for you. Good news: you are definitely one of us! Bad news: you are definitely one of us!

Oh lord! 😆I really enjoy what you are doing with the car so far. I have good and bad news for you. Good news: you are definitely one of us! Bad news: you are definitely one of us!

Todays update is "The Good, the Bad and the Ugly"

I was wanting to do an LS swap in the wagon but just don't have the time right now.

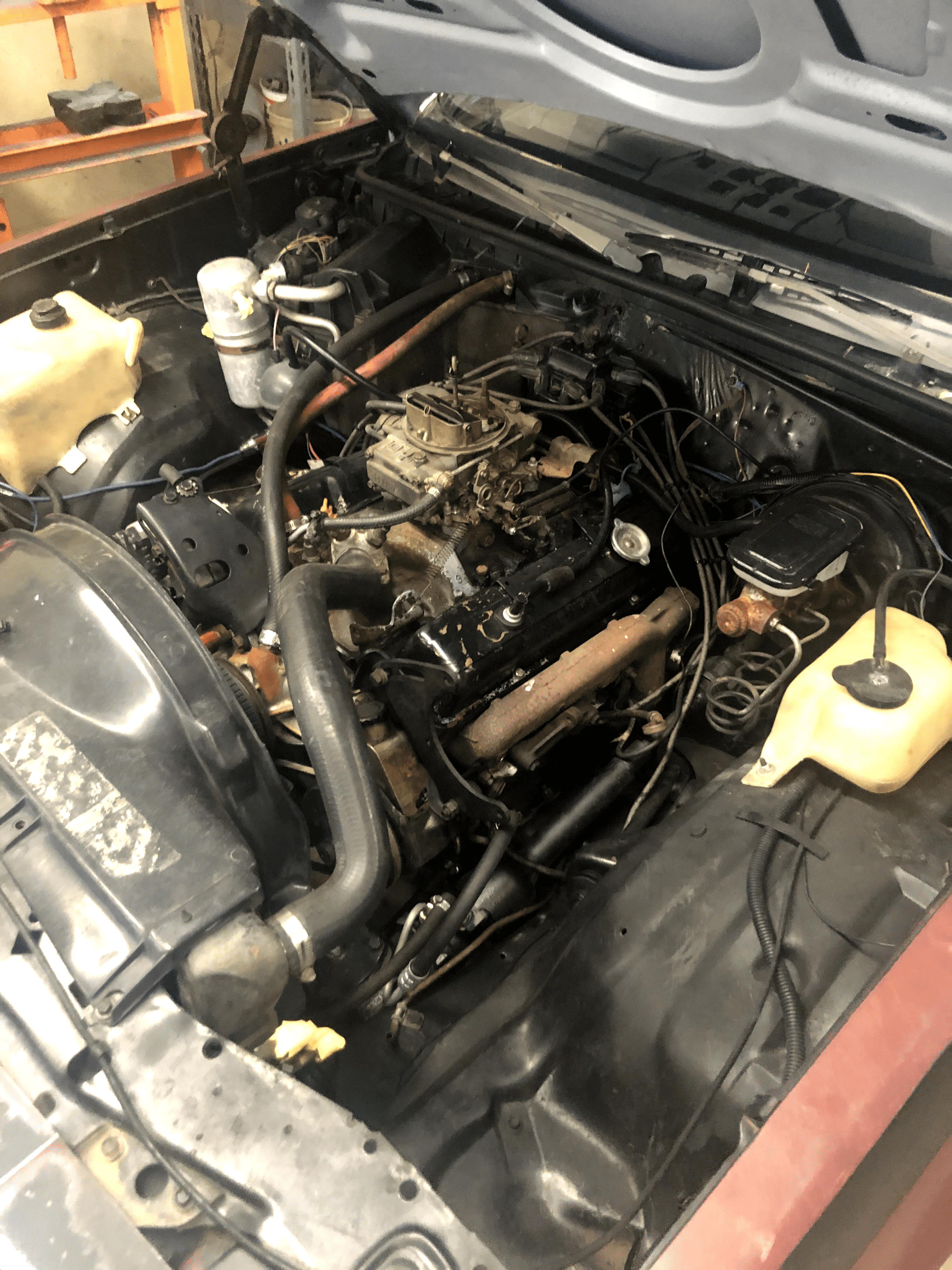

The 305 I had expected to last maybe 3-4 months before blowing up had now lasted 2 years of just so much abuse (overheated a couple time, foot to the floor all the time, old used motor oil since it burned through so much. I have much more respect for 305's after actually having a car with one it it because it was damn reliable and had enough power to pull the wagon on 11.00 flat run after run in the 1/8mile. That was until it ate a cam lobe completely off, so my brother had the great idea of sticking a nut under the rocker arm to keep the valve open to prevent fuel buildup. So we did that and I continued to drive it 3000 miles more! Never did give me any problems on all those miles except for the sound of an obvious miss. Bravo 305, I never did end up killing it before pulling the motor out.

6 months ago

So I decided on just going for a mild built 350. Found a vortec 350 motor from a guy on Facebook market place who owned a junkyard, got it home and pulled the pan and it was just filled with massive shavings. Pulled the bearings and they were completely wore out and I decided not to look any further since the junkyard had a warranty on the motor. I knew I could do a bearing kit but didn't feel like finding our later that metal came from something else other than the bearings.

Just a little adventure on getting another engine, feel free to skip this next part

5 months ago

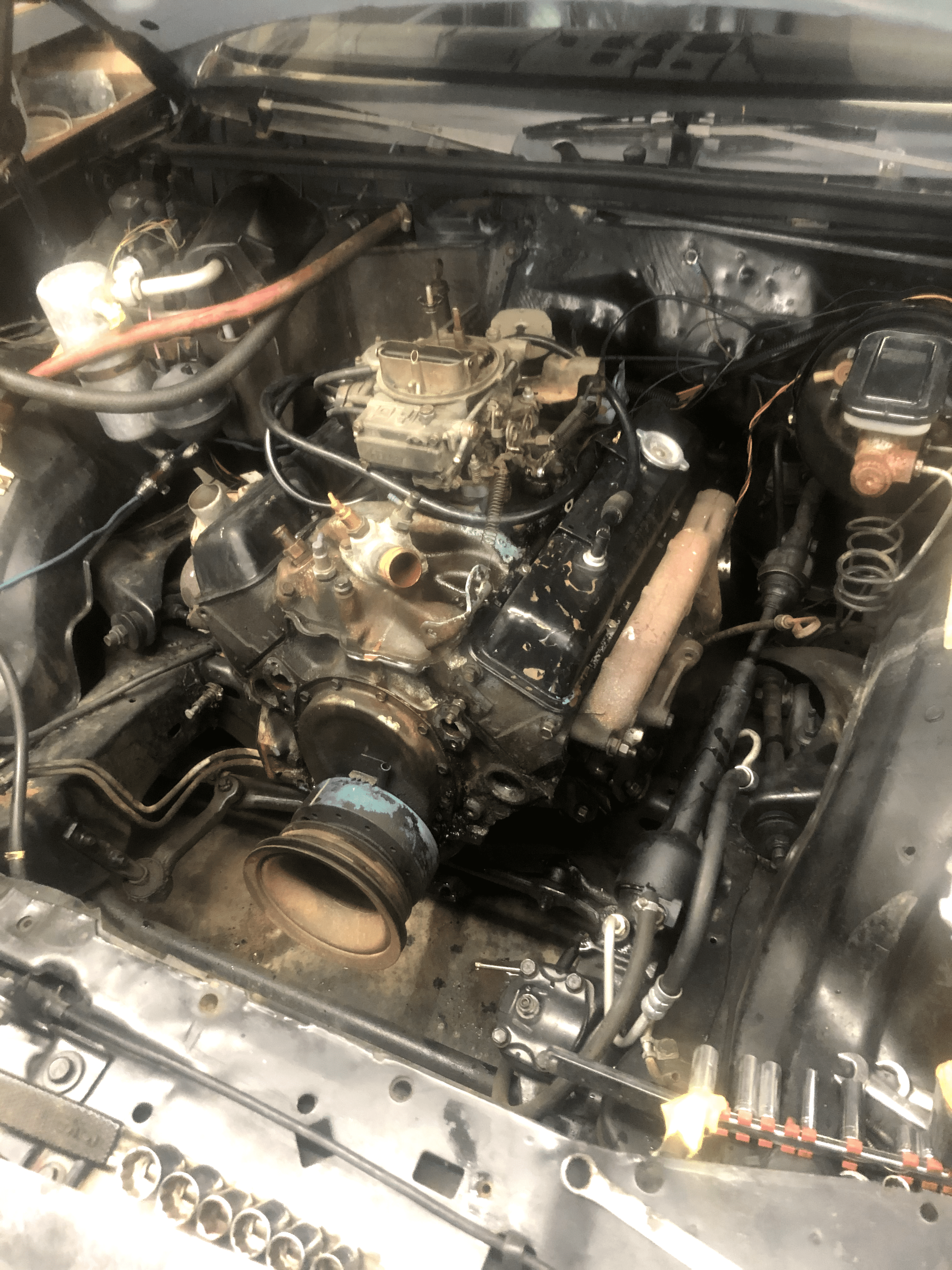

Looked around on Facebook market place a bit more and found a great deal. $300 supposed running. Got there and talked to the guy for a while, the motor had some longtube headers, holley contender allum intake, nice ACCEL distributor, all the accessories including serpentine setup. Pulled the valve covers and got met with some milkshake (great drove 90 minutes for this). Told him ill give him $200 since he said it was running, expected a $250 counter offer but he actually took the $200! There was 3 amish people there hanging out with this guy so all 5 of us loaded it into my Ranger. Set the motor down on a tire, put 3 ratchet straps on. Talked for a long while with everyone and the Amish were quite interested in what the motor was going into, and also my schooling since it was related to National parks. Really nice folks. Hit the road back home around 10:00pm.

On the trip back I was taking turns slow on the back roads and just before getting on the high way I hear a bang after going around a turn. I look behind me and see the motor has fallen over. I pull into this parking lot right under the one and only dimly light light posts and find our one of my ratchet straps broke (my fault I didnt put them in a good spot so it was top heavy still). I decide I have to get this motor set back up since its in a position to roll around in my bed now. So now Im left with my phone on 4% and I cant charge it while the trucks not running because my battery was trash, a barley working light post for my illumination, and a motor that is now leaking this milkshake of coolant, oil, and (maybe) motor honey all over the bed of my truck and soon to be leaking all over the parking lot. Thinking to myself there's no way for my 150lb self is going to move this 600lb block of metal back onto the tire. So i get to work strategically moving and using the ratchet straps around to slowly crank it back up and into position. I finally manage to get it back up and strap it down extra good (this timing using all my straps). Finally got back in my truck and made it the rest of the way home with no troubles a little after midnight.

Further engine inspection

Pulling the pan off it revealed the motor to be a 4 bolt main (010 block) , a welcoming sight. the bearings were fine, but 2 of the cylinders on one side were filled with coolant, and had scorched the walls a bit. From what I can tell is they rebuilt this motor and didn't know what they were doing and started it up and then the head gasket didnt seal and it spewed coolant into the cylinder and that resulted in the milkshake. This assumption was made because during the tear down lots of the bolts weren't torqued (some where barley hand tight, others had to uses the impact to get off), and just tons of mismatched bolts.

After doing some more inspecting the head on the side of the coolant leak had cracked in-between the 2 exhaust valves. Cant catch a break. 😢

I was still able to sell the set of heads for $100 since they are apparently good for circle track racing (forgot the casting number) to a local guy I know. Then found a set of aluminum '113' heads (on Facebook of course) with screw in studs for just $300. Got some vortec valve covers from the junkyard to match.

Engine building

Took the engine and crank to Allison's Machine Shop in Asheboro, NC. They do really good work, my family has taken lots of things there to get machined. The block got bored out .30 over because of the scorched walls, and the crank got polished. and they had the entire engine block cleaned.

I've painted the engine block ford blue upon its return from the machine shop. Don't judge my decision on the color I just though it would be funny in some type of weird way.

No clue why the Holley contender intake was painted, and so terribly at that so I had my brother take it to his work and media blasted using glass beads. Polished the text/logos smooth and then applied a thin coat of high temp clear to make cleaning dirt off easier in the future.

Decided to do a retro fit hydraulic roller cam set up. Went with "Comp Cams 12-422-8 Xtreme Energy", and it was hard to find retro fit hydraulic lifters in stock anywhere, but I finally found some after calling different retailers.

ARP bolt fastener kit, full gasket kit, Speed Pro Hypereutectic pistons, msd cut to fit plug wire set, some very nice 304 stainless shorty headers from a guy at work, B&M 20404 torque converter (2400 stall) from Facebook, and some other odds and ends.

I've got everything put together and just waiting on pulling the 305 to transfer things over to the new motor like brackets and accessories and other odds and ends.

I was wanting to do an LS swap in the wagon but just don't have the time right now.

The 305 I had expected to last maybe 3-4 months before blowing up had now lasted 2 years of just so much abuse (overheated a couple time, foot to the floor all the time, old used motor oil since it burned through so much. I have much more respect for 305's after actually having a car with one it it because it was damn reliable and had enough power to pull the wagon on 11.00 flat run after run in the 1/8mile. That was until it ate a cam lobe completely off, so my brother had the great idea of sticking a nut under the rocker arm to keep the valve open to prevent fuel buildup. So we did that and I continued to drive it 3000 miles more! Never did give me any problems on all those miles except for the sound of an obvious miss. Bravo 305, I never did end up killing it before pulling the motor out.

6 months ago

So I decided on just going for a mild built 350. Found a vortec 350 motor from a guy on Facebook market place who owned a junkyard, got it home and pulled the pan and it was just filled with massive shavings. Pulled the bearings and they were completely wore out and I decided not to look any further since the junkyard had a warranty on the motor. I knew I could do a bearing kit but didn't feel like finding our later that metal came from something else other than the bearings.

Just a little adventure on getting another engine, feel free to skip this next part

5 months ago

Looked around on Facebook market place a bit more and found a great deal. $300 supposed running. Got there and talked to the guy for a while, the motor had some longtube headers, holley contender allum intake, nice ACCEL distributor, all the accessories including serpentine setup. Pulled the valve covers and got met with some milkshake (great drove 90 minutes for this). Told him ill give him $200 since he said it was running, expected a $250 counter offer but he actually took the $200! There was 3 amish people there hanging out with this guy so all 5 of us loaded it into my Ranger. Set the motor down on a tire, put 3 ratchet straps on. Talked for a long while with everyone and the Amish were quite interested in what the motor was going into, and also my schooling since it was related to National parks. Really nice folks. Hit the road back home around 10:00pm.

On the trip back I was taking turns slow on the back roads and just before getting on the high way I hear a bang after going around a turn. I look behind me and see the motor has fallen over. I pull into this parking lot right under the one and only dimly light light posts and find our one of my ratchet straps broke (my fault I didnt put them in a good spot so it was top heavy still). I decide I have to get this motor set back up since its in a position to roll around in my bed now. So now Im left with my phone on 4% and I cant charge it while the trucks not running because my battery was trash, a barley working light post for my illumination, and a motor that is now leaking this milkshake of coolant, oil, and (maybe) motor honey all over the bed of my truck and soon to be leaking all over the parking lot. Thinking to myself there's no way for my 150lb self is going to move this 600lb block of metal back onto the tire. So i get to work strategically moving and using the ratchet straps around to slowly crank it back up and into position. I finally manage to get it back up and strap it down extra good (this timing using all my straps). Finally got back in my truck and made it the rest of the way home with no troubles a little after midnight.

Further engine inspection

Pulling the pan off it revealed the motor to be a 4 bolt main (010 block) , a welcoming sight. the bearings were fine, but 2 of the cylinders on one side were filled with coolant, and had scorched the walls a bit. From what I can tell is they rebuilt this motor and didn't know what they were doing and started it up and then the head gasket didnt seal and it spewed coolant into the cylinder and that resulted in the milkshake. This assumption was made because during the tear down lots of the bolts weren't torqued (some where barley hand tight, others had to uses the impact to get off), and just tons of mismatched bolts.

After doing some more inspecting the head on the side of the coolant leak had cracked in-between the 2 exhaust valves. Cant catch a break. 😢

I was still able to sell the set of heads for $100 since they are apparently good for circle track racing (forgot the casting number) to a local guy I know. Then found a set of aluminum '113' heads (on Facebook of course) with screw in studs for just $300. Got some vortec valve covers from the junkyard to match.

Engine building

Took the engine and crank to Allison's Machine Shop in Asheboro, NC. They do really good work, my family has taken lots of things there to get machined. The block got bored out .30 over because of the scorched walls, and the crank got polished. and they had the entire engine block cleaned.

I've painted the engine block ford blue upon its return from the machine shop. Don't judge my decision on the color I just though it would be funny in some type of weird way.

No clue why the Holley contender intake was painted, and so terribly at that so I had my brother take it to his work and media blasted using glass beads. Polished the text/logos smooth and then applied a thin coat of high temp clear to make cleaning dirt off easier in the future.

Decided to do a retro fit hydraulic roller cam set up. Went with "Comp Cams 12-422-8 Xtreme Energy", and it was hard to find retro fit hydraulic lifters in stock anywhere, but I finally found some after calling different retailers.

ARP bolt fastener kit, full gasket kit, Speed Pro Hypereutectic pistons, msd cut to fit plug wire set, some very nice 304 stainless shorty headers from a guy at work, B&M 20404 torque converter (2400 stall) from Facebook, and some other odds and ends.

I've got everything put together and just waiting on pulling the 305 to transfer things over to the new motor like brackets and accessories and other odds and ends.

Attachments

Engine swap time!

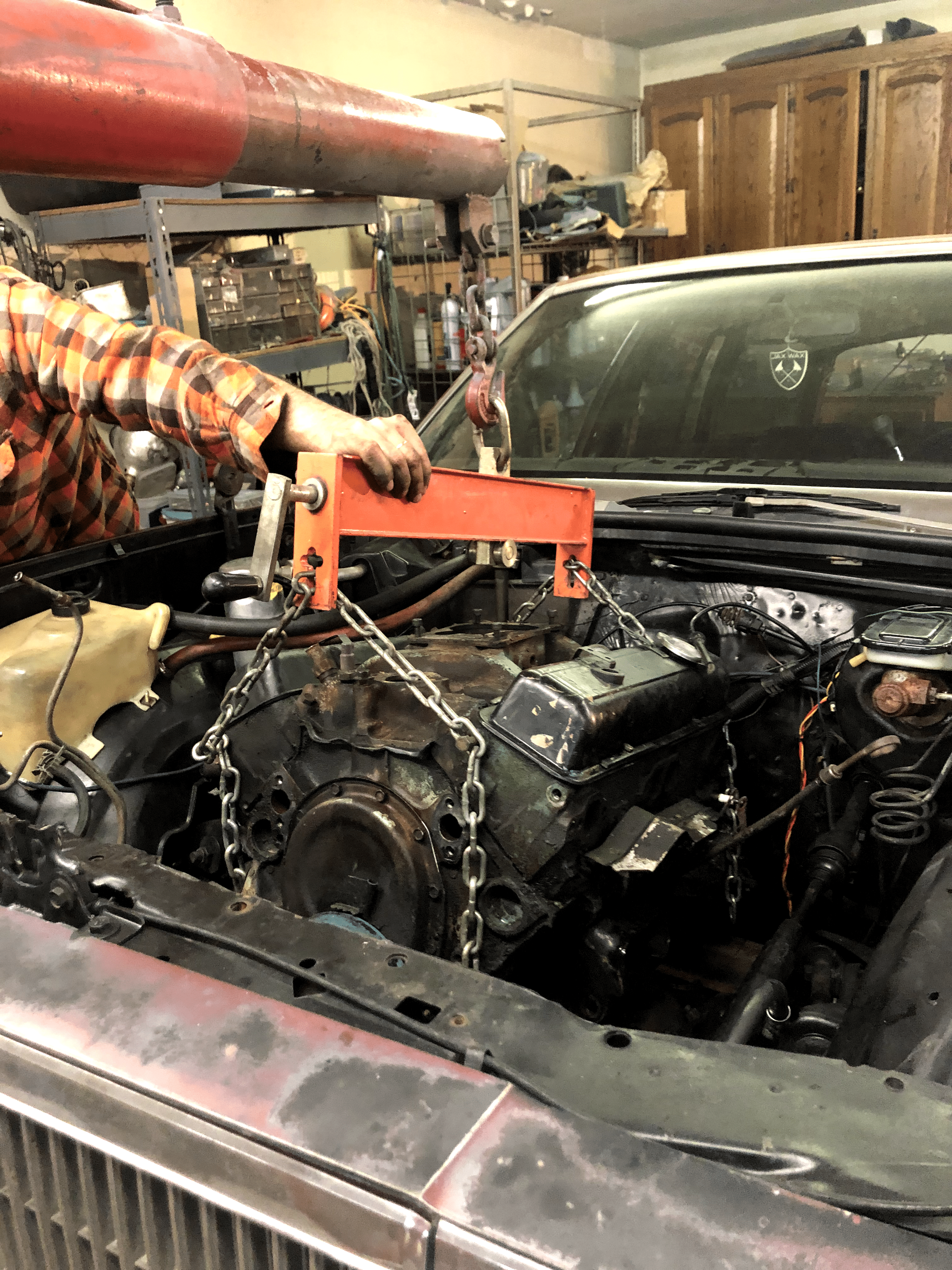

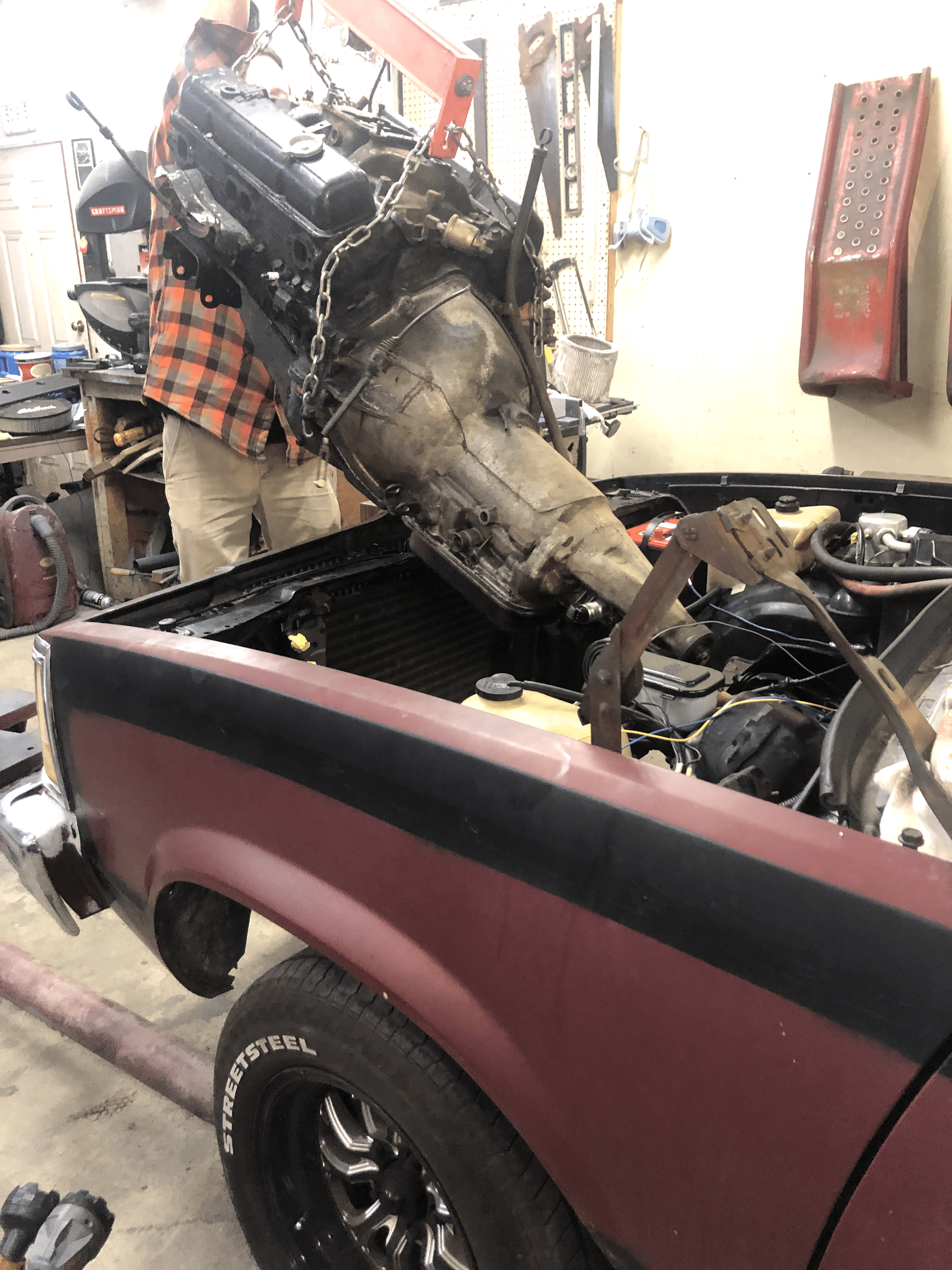

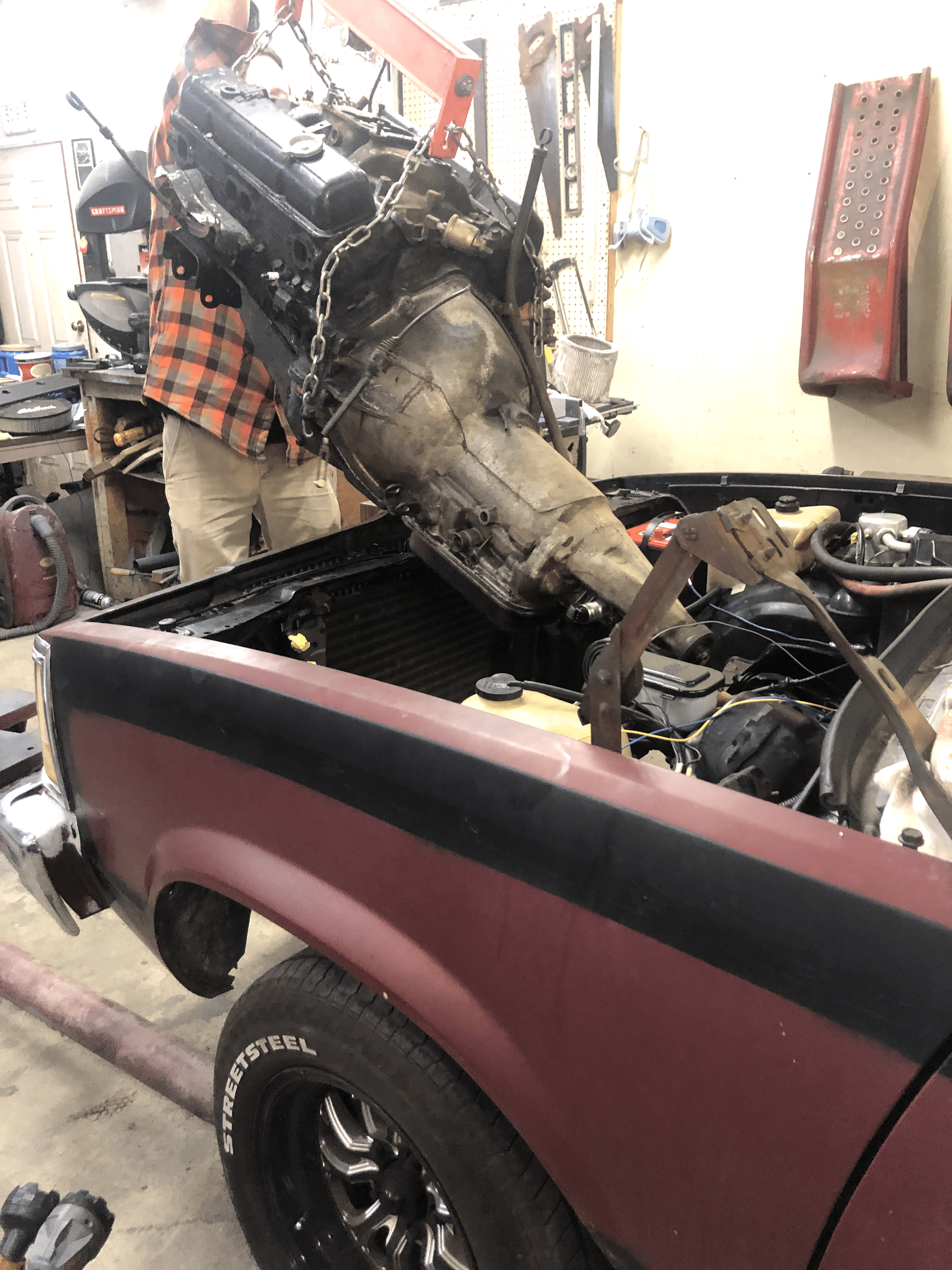

Over the past week I've started to take the 305 out.

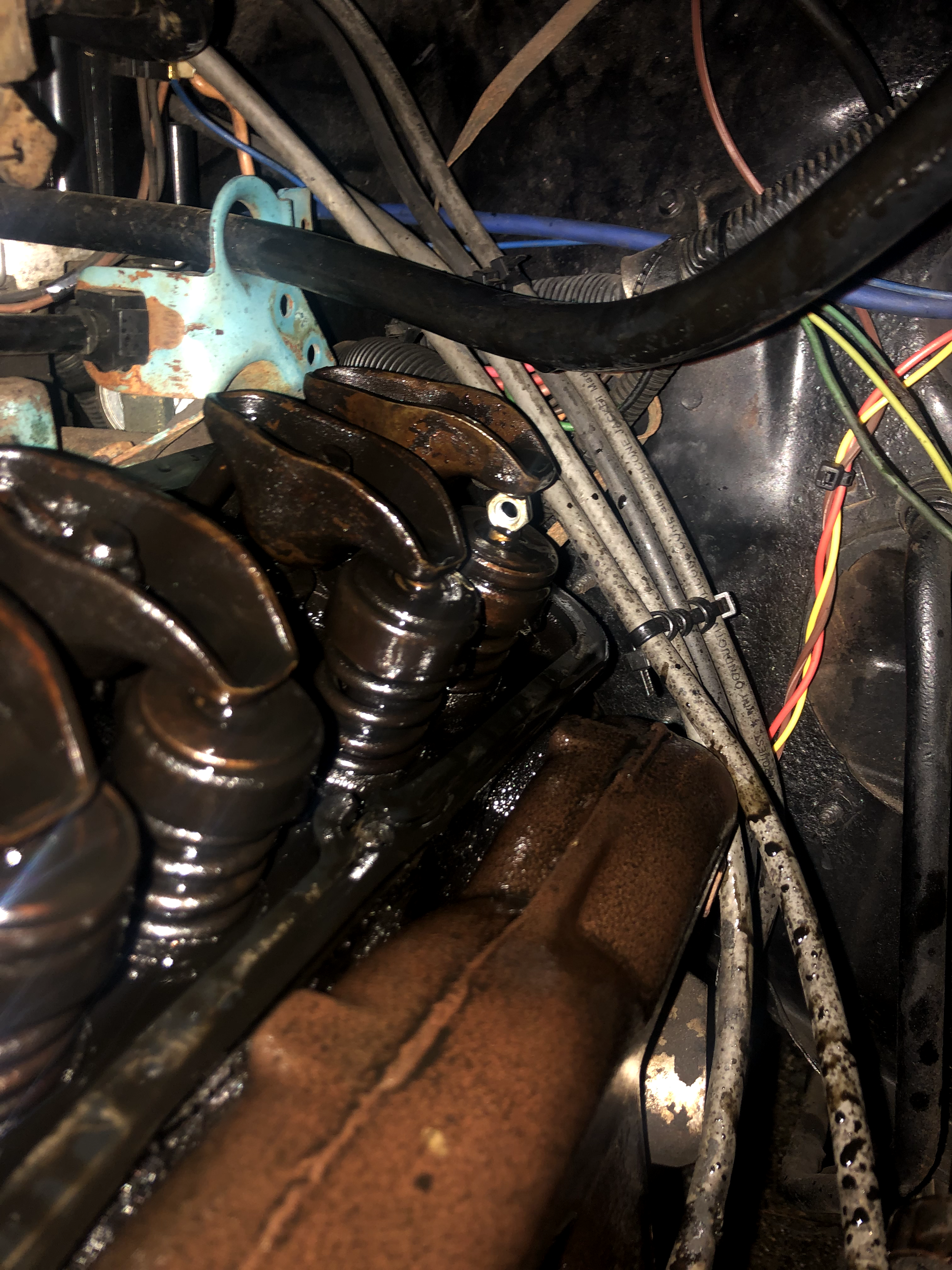

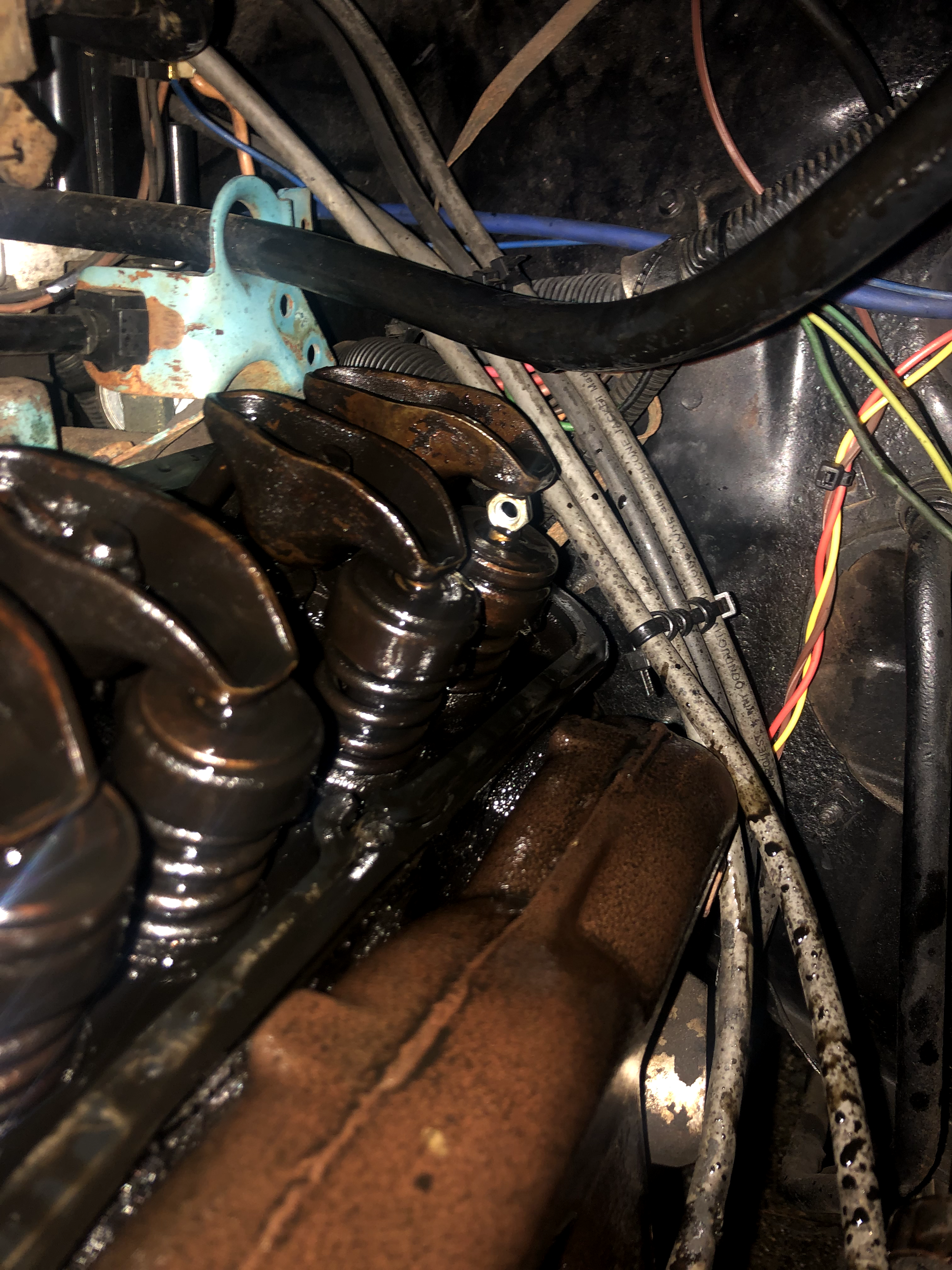

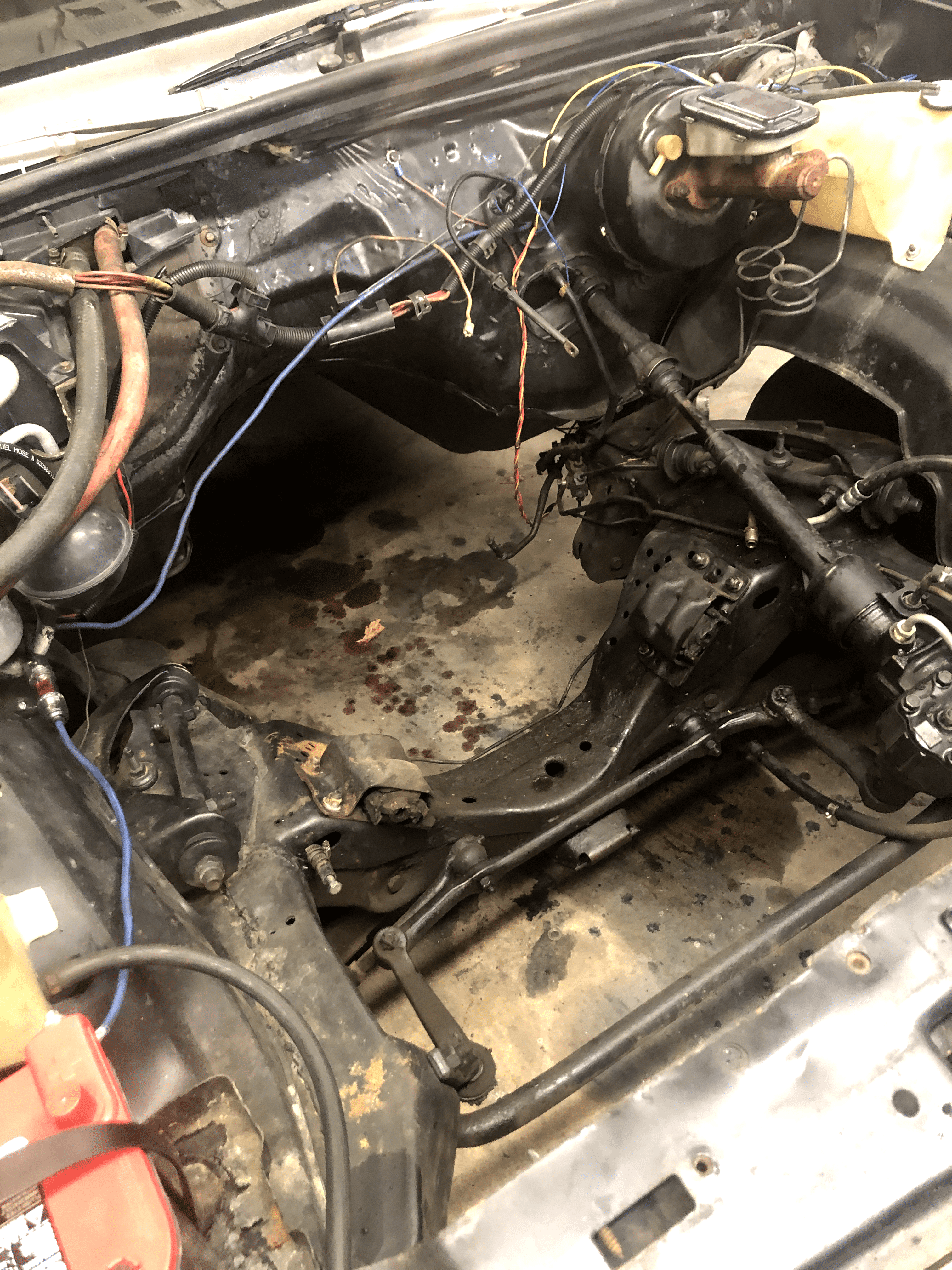

This started with deleting wires in the engine bay/under dash, consisting of mostly of old cruise control, quadrajunk wiring, and old sending unit wiring (thank you to 'Ribbedroof' for the help on that)

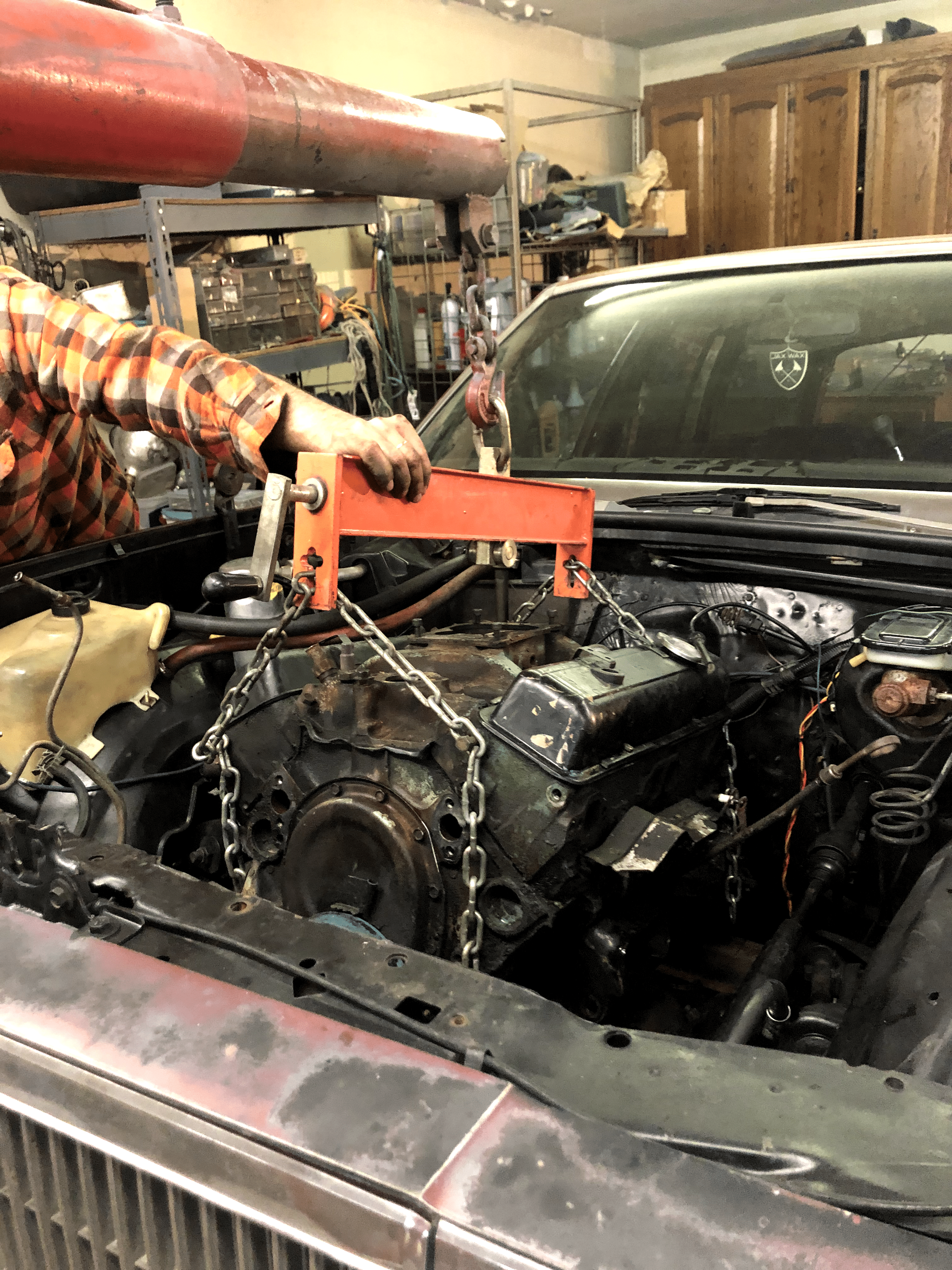

Woke up early one morning a pulled all the accessories, radiator, brackets and what not, and pulled the drive shaft. Drained fluids including the transmission since I would be changing torque converter along with new seals and filter. Went to work and upon getting back home that night had my dads help pulling the motor out within 30 minutes or so then went to bed.

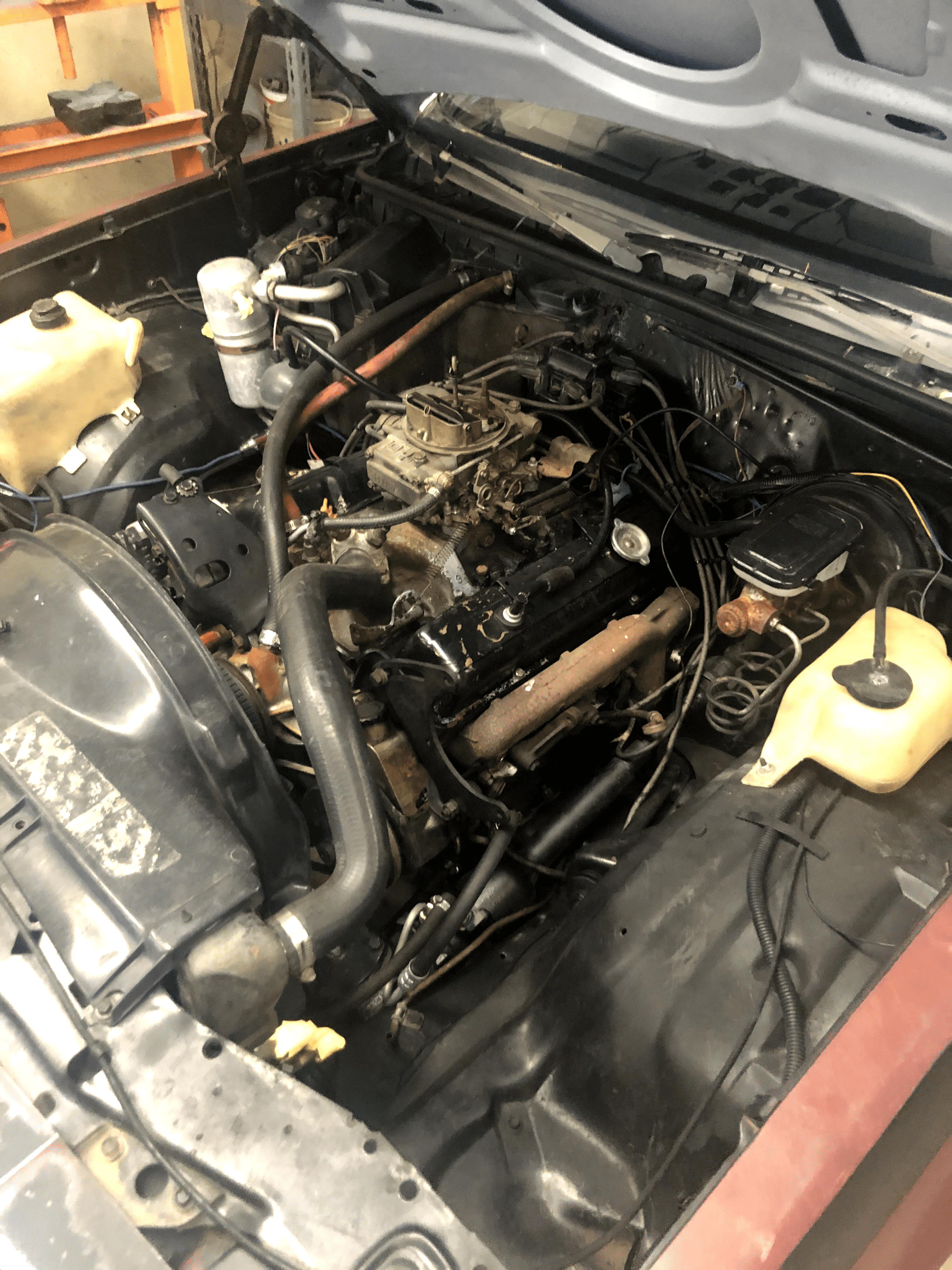

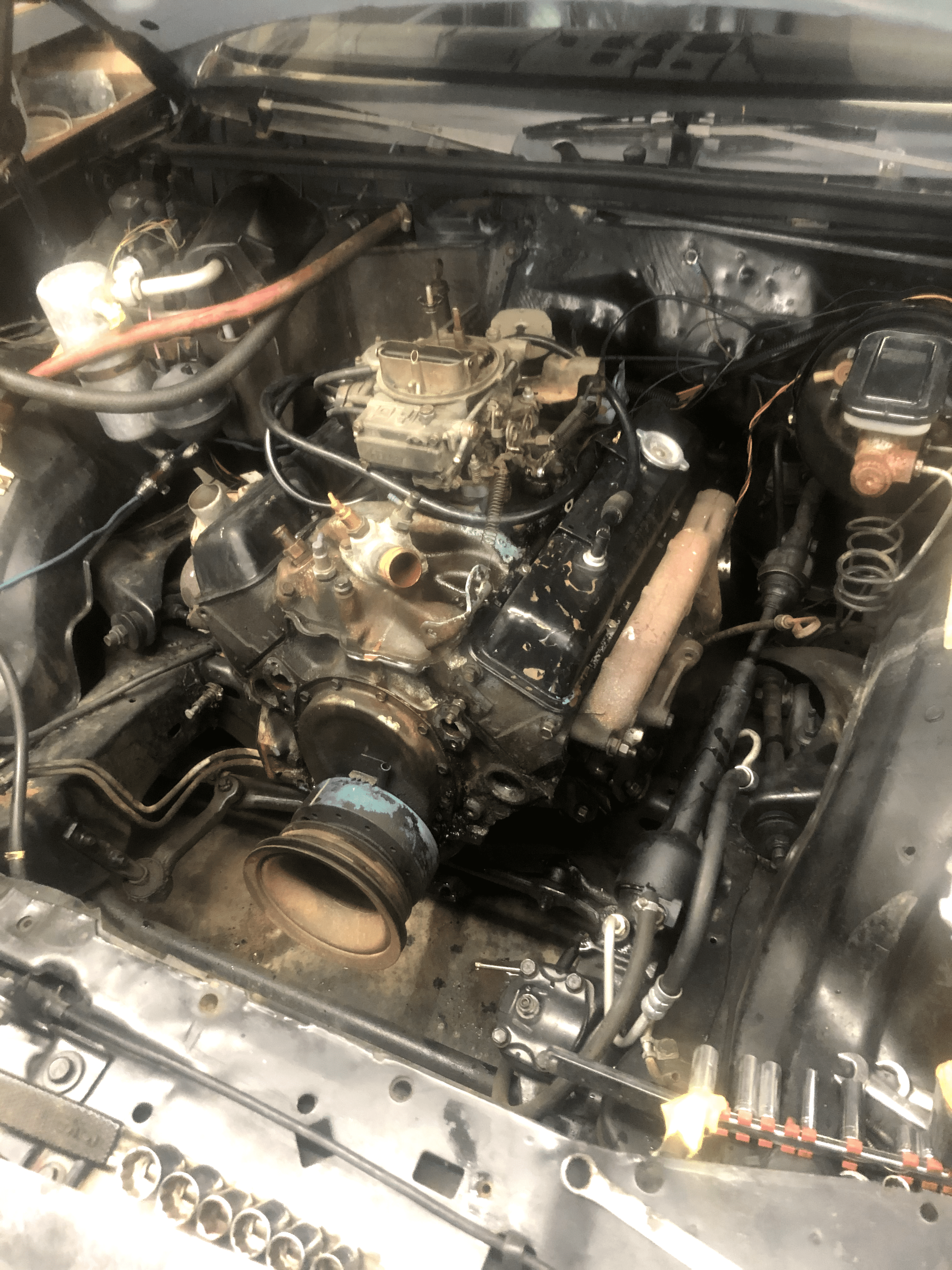

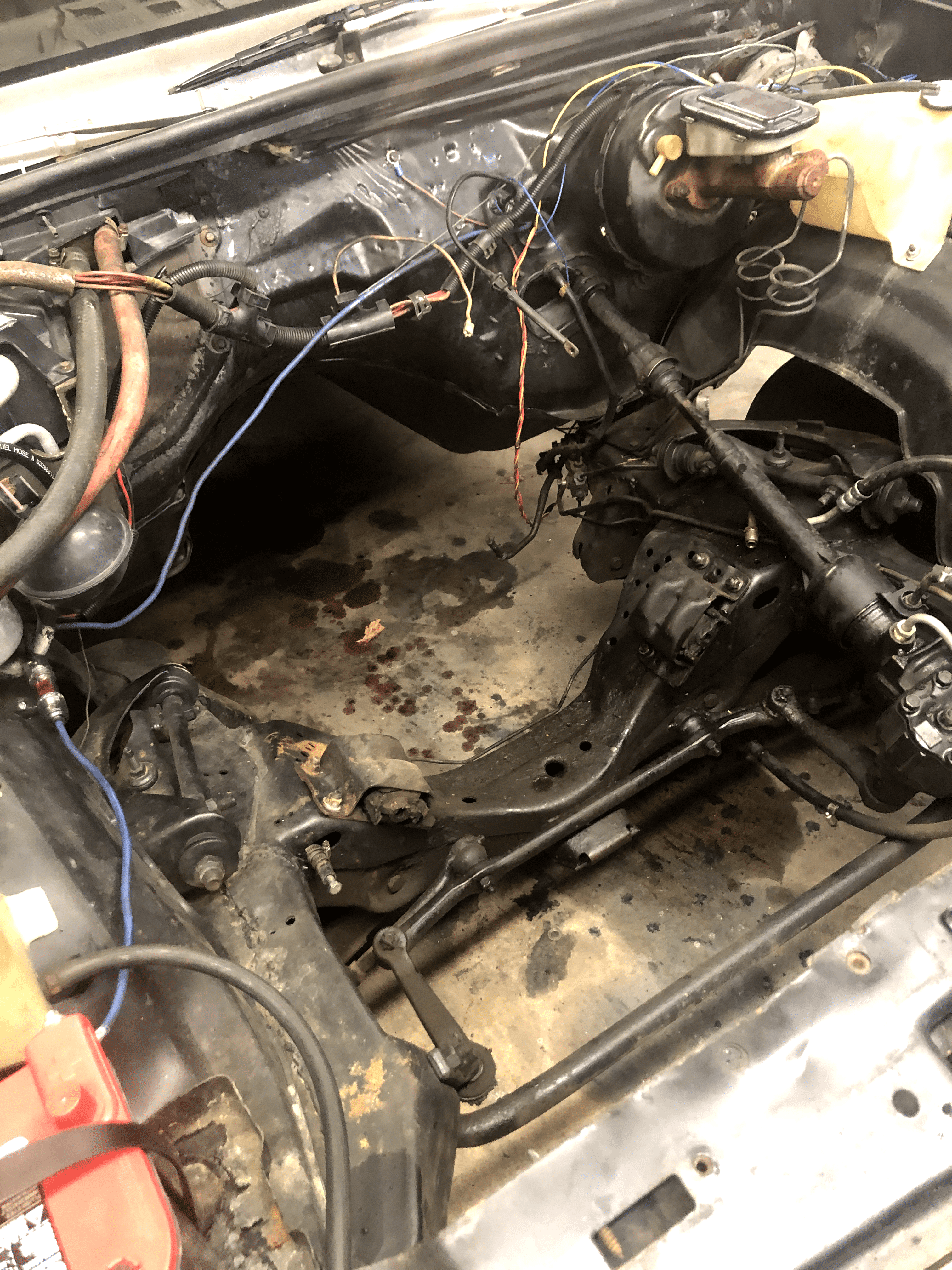

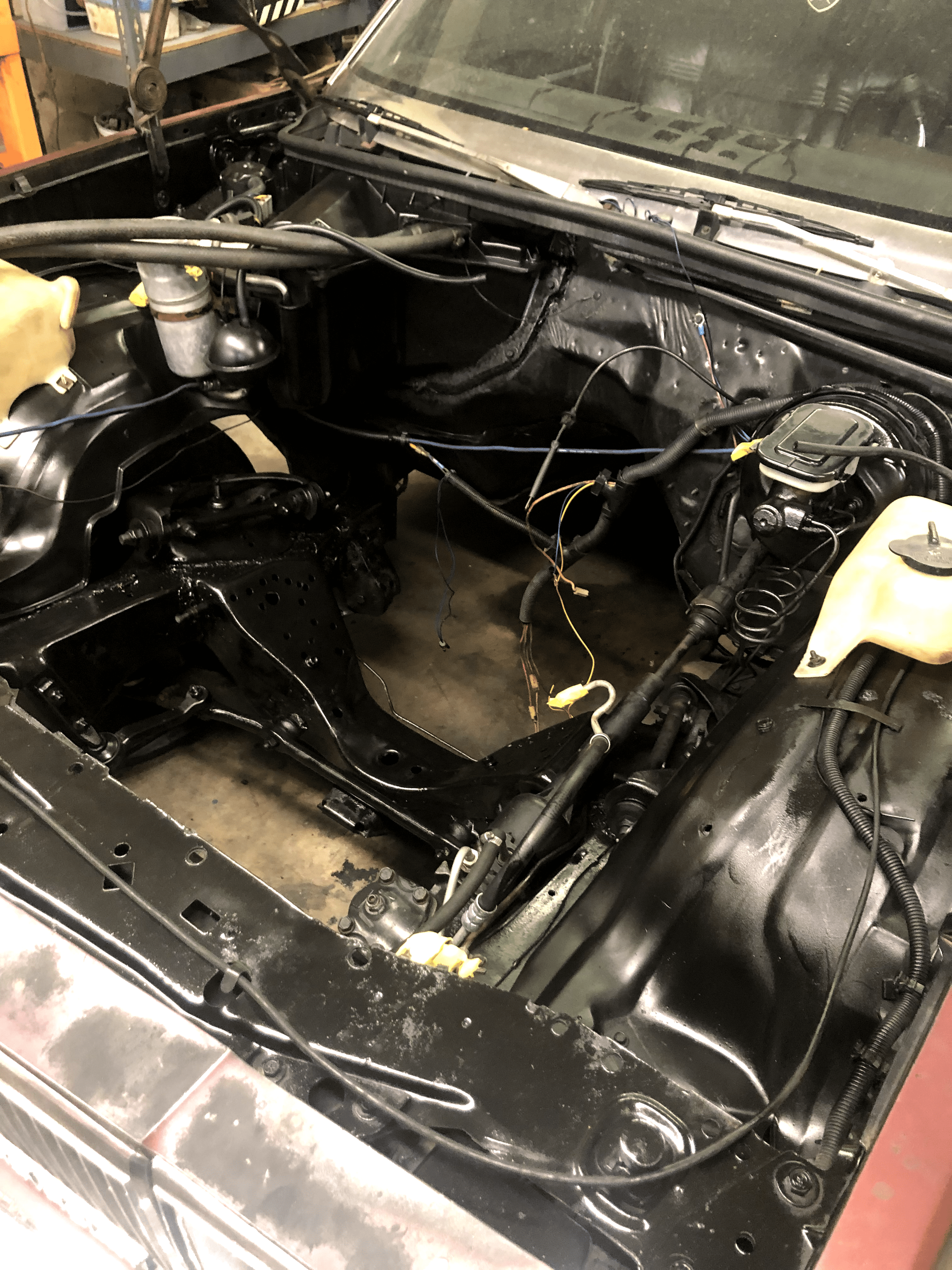

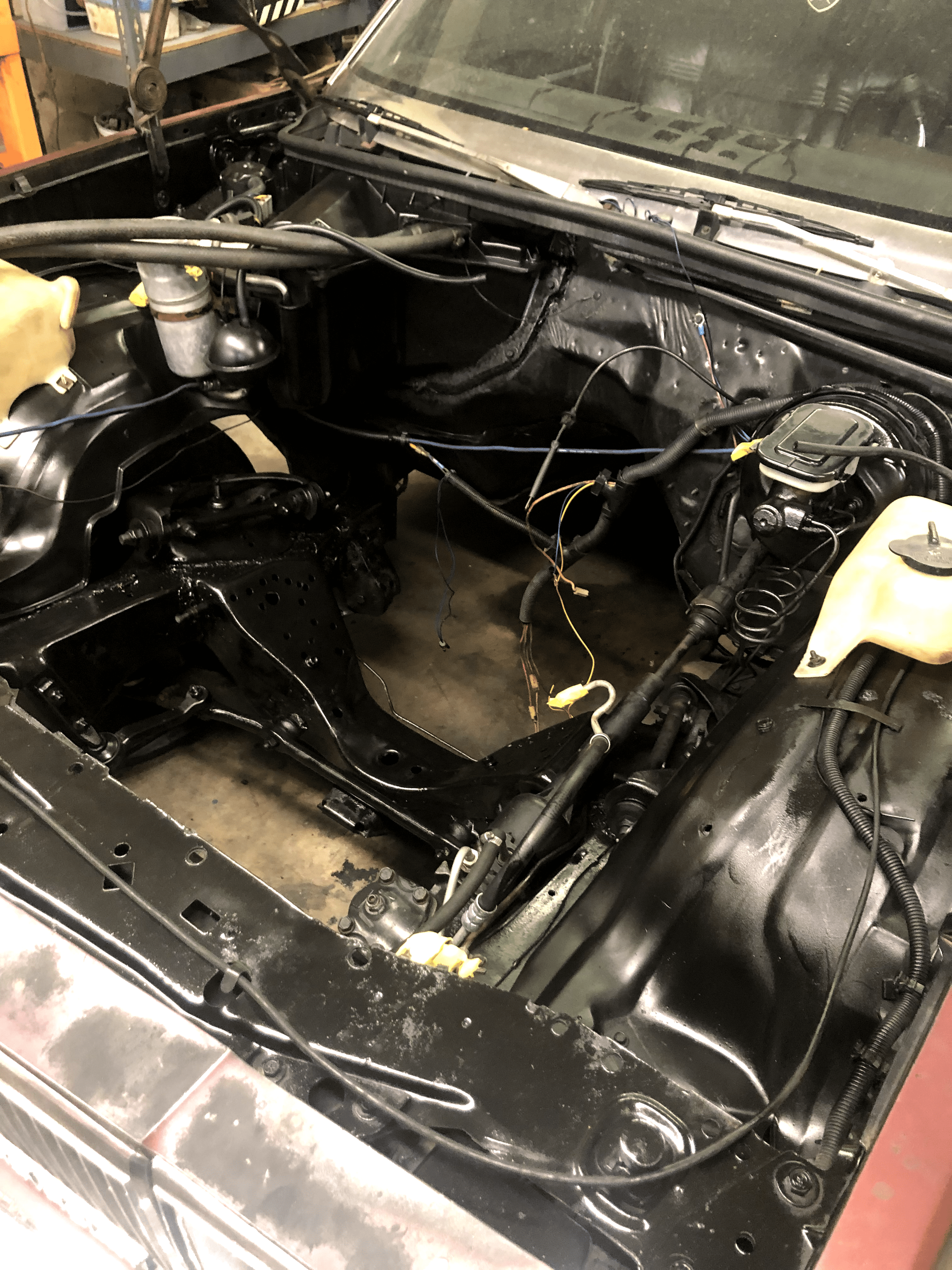

Couldn't do much for 2 days for my brother was painting his car in the garage so I had to wait, but soon as he was done and cleaned up I jumped back on it. Going in and using oven clean and degreaser on everything in that engine bay. That 305 leaked so much so everything was covered. Using the pressure washer and scrub brush I got everything cleaned and paint stripped down on the frame. Resealed the entire AC/Heater box since I found a water leak in one spot, used VHT plastic paint on the box, and inner fenders. Then applied black paint to the frame and suspension, and painted the engine accessories. Once finished I climbed into the engine bay and finished up the wiring. This involved running the new sending unit wires for the Intellitronix gauge cluster and looming up everything, and of course new engine mounts (those were a pain).

Back up to speed now (everything will be talking about things I'm currently doing instead of the past)

Today I separated the 305 from the turbo 350 in order to put on the main seals and torque converter. The front shaft seal I had gotten didnt fit so I assumed I bought the wrong one. I attempted to test for the torque converter on and well..... it doesn't fit either! disaster. I do some research on what's going on and it turns out its not a Turbo 350 but a THM-200. Im not familiar with Chevy's so before I didn't even know that the thm-200 existed let alone the tell tale signs of the "metric hydramatic" stampings on the pan. When I bought the car it had 3 speeds and the pan shape was the same as a turbo 350 so I just assumed it was one. Oh well.

I've decided just to put the 355 in the wagon with the THM-200 and its stock converter. The only problem is I don't know how drivable it'll be since the cam that is in the 355 is decently sized (although summit lists it as "largest with stock converter"), but we will see with time. This isn't that big of a problem since I am planning on doing a swap to a 200r4 anyway, just a little upsetting that I wont have a stall converter to use for now.

So if anyone has a 200r4 for sale near central NC let me know

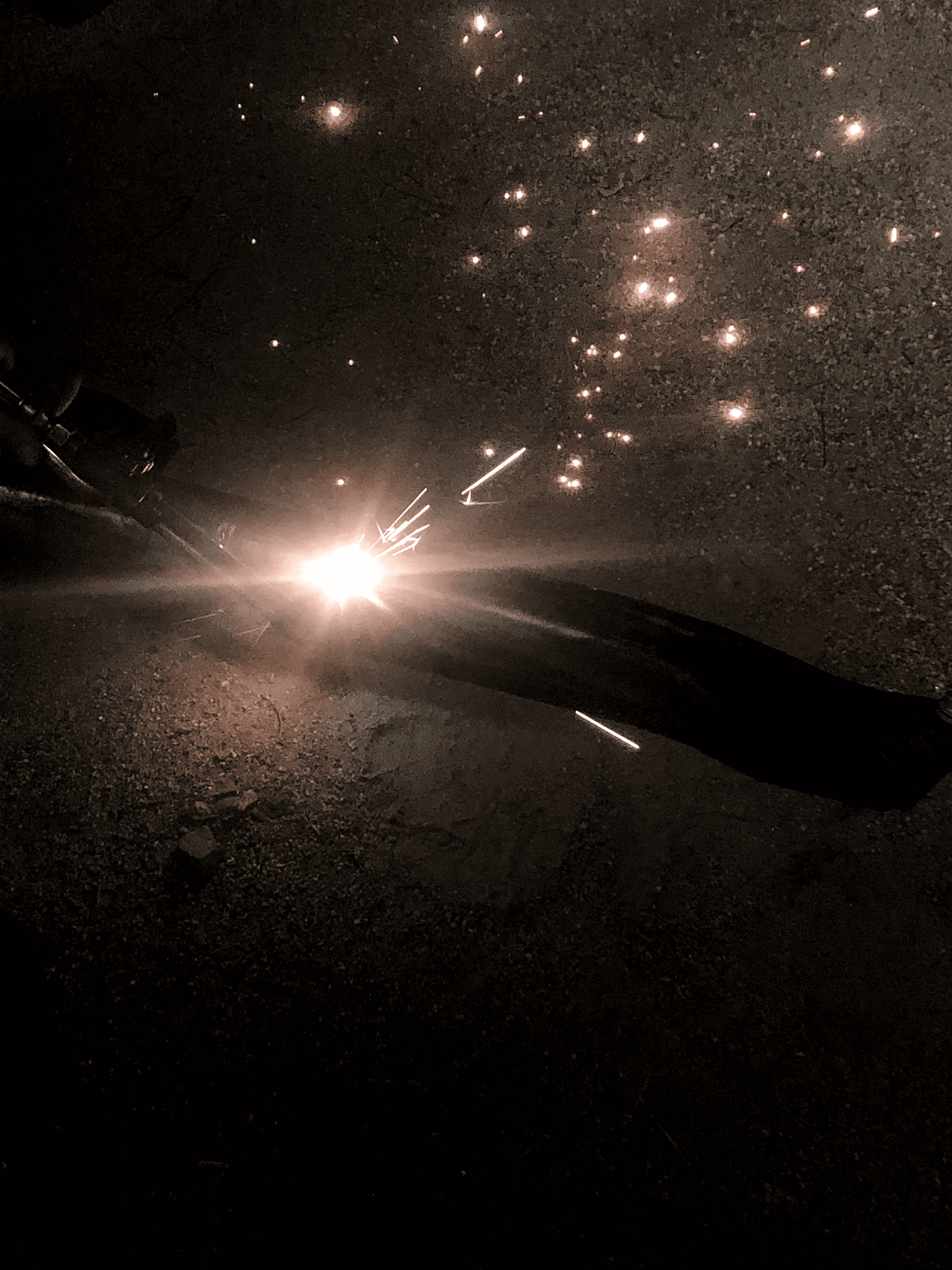

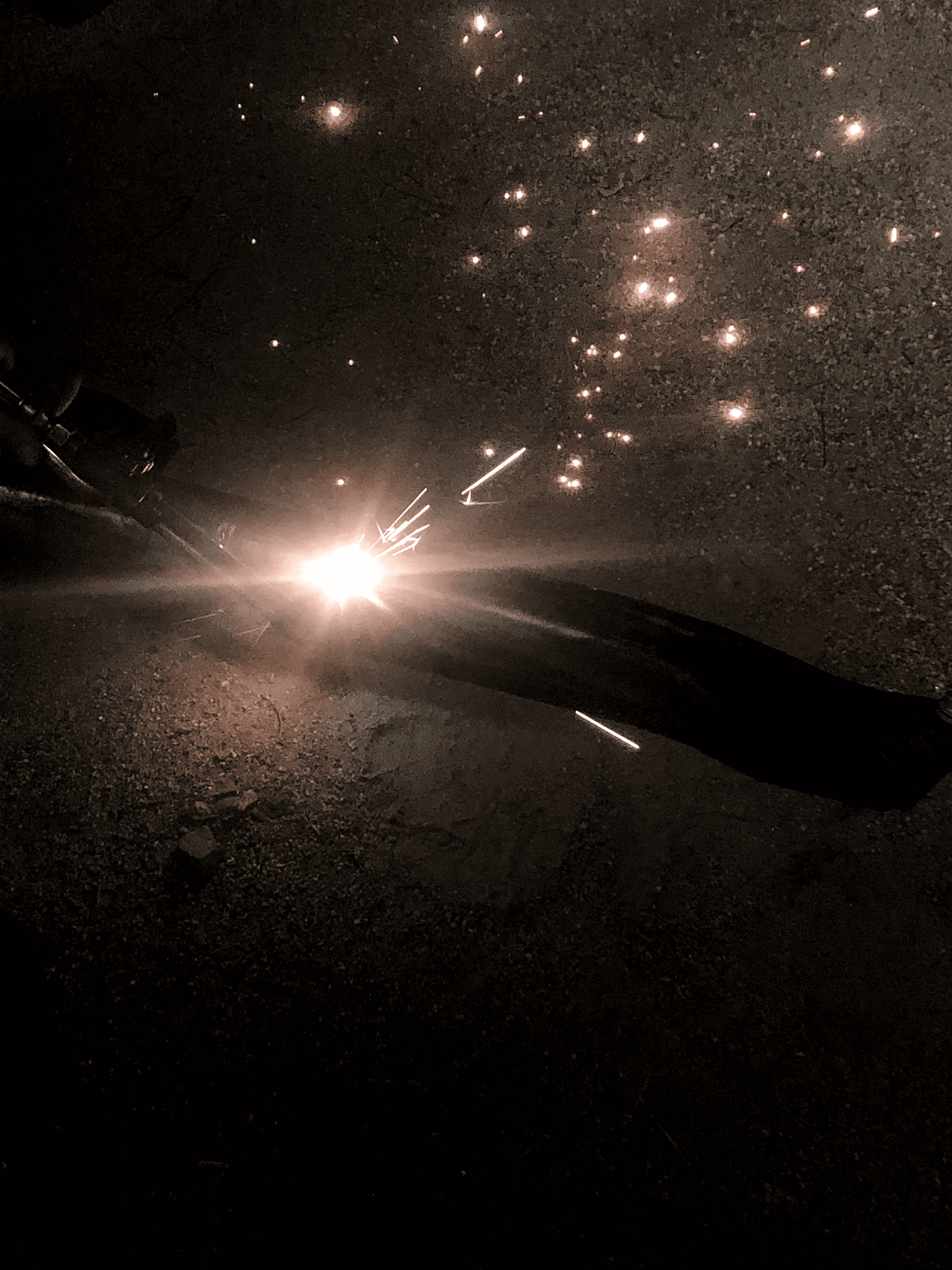

Today I also pulled the transmission crossmember out in order to modify it for dual exhaust. put some oven clean on it and cleaned it off because it was quite nasty. Then pulled out the oxygen acetylene torch and cut an arch out of it. Tomorrow ill be welding in a piece of half round pipe that has 1/4 thick walls for structural support. The plan is to have the motor and everything put in back into the car before Monday, but I've got exams this week so we will see how that goes

Over the past week I've started to take the 305 out.

This started with deleting wires in the engine bay/under dash, consisting of mostly of old cruise control, quadrajunk wiring, and old sending unit wiring (thank you to 'Ribbedroof' for the help on that)

Woke up early one morning a pulled all the accessories, radiator, brackets and what not, and pulled the drive shaft. Drained fluids including the transmission since I would be changing torque converter along with new seals and filter. Went to work and upon getting back home that night had my dads help pulling the motor out within 30 minutes or so then went to bed.

Couldn't do much for 2 days for my brother was painting his car in the garage so I had to wait, but soon as he was done and cleaned up I jumped back on it. Going in and using oven clean and degreaser on everything in that engine bay. That 305 leaked so much so everything was covered. Using the pressure washer and scrub brush I got everything cleaned and paint stripped down on the frame. Resealed the entire AC/Heater box since I found a water leak in one spot, used VHT plastic paint on the box, and inner fenders. Then applied black paint to the frame and suspension, and painted the engine accessories. Once finished I climbed into the engine bay and finished up the wiring. This involved running the new sending unit wires for the Intellitronix gauge cluster and looming up everything, and of course new engine mounts (those were a pain).

Back up to speed now (everything will be talking about things I'm currently doing instead of the past)

Today I separated the 305 from the turbo 350 in order to put on the main seals and torque converter. The front shaft seal I had gotten didnt fit so I assumed I bought the wrong one. I attempted to test for the torque converter on and well..... it doesn't fit either! disaster. I do some research on what's going on and it turns out its not a Turbo 350 but a THM-200. Im not familiar with Chevy's so before I didn't even know that the thm-200 existed let alone the tell tale signs of the "metric hydramatic" stampings on the pan. When I bought the car it had 3 speeds and the pan shape was the same as a turbo 350 so I just assumed it was one. Oh well.

I've decided just to put the 355 in the wagon with the THM-200 and its stock converter. The only problem is I don't know how drivable it'll be since the cam that is in the 355 is decently sized (although summit lists it as "largest with stock converter"), but we will see with time. This isn't that big of a problem since I am planning on doing a swap to a 200r4 anyway, just a little upsetting that I wont have a stall converter to use for now.

So if anyone has a 200r4 for sale near central NC let me know

Today I also pulled the transmission crossmember out in order to modify it for dual exhaust. put some oven clean on it and cleaned it off because it was quite nasty. Then pulled out the oxygen acetylene torch and cut an arch out of it. Tomorrow ill be welding in a piece of half round pipe that has 1/4 thick walls for structural support. The plan is to have the motor and everything put in back into the car before Monday, but I've got exams this week so we will see how that goes

Last edited:

So yesterday I found a bit of extra time after work and managed to get the motor off the engine stand and back onto the motor. Dropped in the distributor since I believe I can put the motor in with it already in but worst case I can pull it back out.

I also finished welding up the crossmember. Its Kind of like the corvette stingray crossmember where the exhaust goes through the crossmember. Gave a quick spray with some black spraypaint to finish it off. Ignore the bubbly looking welds wanted to stick weld it to make sure I penetrated all the way through the metal and lets just say I'm still learning 🤣

Hopefully tomorrow Ill have the time to drop the motor in and start trying to get the headers to fit.

I also finished welding up the crossmember. Its Kind of like the corvette stingray crossmember where the exhaust goes through the crossmember. Gave a quick spray with some black spraypaint to finish it off. Ignore the bubbly looking welds wanted to stick weld it to make sure I penetrated all the way through the metal and lets just say I'm still learning 🤣

Hopefully tomorrow Ill have the time to drop the motor in and start trying to get the headers to fit.

Been quite busy recently with work and then my mowing business (thanks rain) and helping parents out by staining their entire house in the hot NC weather. Its been past due for an update on the wagon but the goods news is I'm on the home stretch for the engine swap!

Motor Going In

Dropping the motor in was a piece of cake only took maybe 30 minutes. Everything went smoothly then I started to bolt things onto the motor to get it ready.

Tried to fit in both sets of headers I had on hand but sadly neither of them fit. The shorties were not even close, but the long tubes most likely would've fit if I did a little bit of modification on them but decided to go buy new ones that would bolt on to save a little time and effort (foreshadowing: It did not). Got the modified crossmember bolted back up.

Went on Hedman Headers website since I've heard about how they always fit quite easily. Input all the car information like having a 5.7, column shift, automatic, power steering, AC, angled spark plugs, etc. Had a selection of 6 different but only really had an option of 3 because I can only afford a set of steel ones instead of stainless. Decided on "Hedman Hedders 68620". They arrived and the passenger side fit perfectly, plenty of clearance on the HVAC box and starter (did add a bit of heat reflection stuff on the starter wires just in

case).

case).

The driver side was another story. It was a pain in the you know what to get it down into position. Had to take a hammer to a tube to help clear the steering rag joint. Then once installed I noticed how one of the tubes was maybe a centimeter from the engine mount, so I took it back out and cut that tube off and rewelded it back further. Upon installing again noticed how close it was to the brake lines and proportioning valve and didn't want to risk any boiling brake fluid. Ontop of that the header flange was veryyy close to the transmission dust cover and to make matters worse the shift linkage hit the collector and prevented me from having 1st gear. Decided this would be fine just to do a test startup of the engine before taking the driver header out and completely redoing it.

The driver side was another story. It was a pain in the you know what to get it down into position. Had to take a hammer to a tube to help clear the steering rag joint. Then once installed I noticed how one of the tubes was maybe a centimeter from the engine mount, so I took it back out and cut that tube off and rewelded it back further. Upon installing again noticed how close it was to the brake lines and proportioning valve and didn't want to risk any boiling brake fluid. Ontop of that the header flange was veryyy close to the transmission dust cover and to make matters worse the shift linkage hit the collector and prevented me from having 1st gear. Decided this would be fine just to do a test startup of the engine before taking the driver header out and completely redoing it.

First Start Up

With a splash of gas down the carb and one crank of the key the motor roared to life. It ran great except for a slight surging idle which a stuck carb float valve was found to be the culprit and possibly a small vacuum leak on a line that got a hose clamp put on.

Oil pressure was perfect but problems arose when the temp rose quickly up to 180, then 190, then 200. The 180 thermostat wasnt opening so I replaced it with a new one to no avail. So I then realized it was the temp sender being heat soaked by the headers (I placed it on the rear passenger side port). Pulled the sender out and put a plug in and when I started to remove the plug from the intake it stripped out. So I drained the coolant put a cloth in the intake through the water neck hole to catch metal shavings as I drilled it out. I drilled out with a 1/2" drill bit then started hitting the outer edge of the plug with a punch & hammer until it caved in on itself. Then ran a tap down the hole to make sure the threads were still okay. While I was at that point I also removed the heater hose fitting. It was a straight fitting so It kinked the hose a bit so I removed it and put a 45 degree fitting in its place. After putting everything back together with the temp sender now in the intake everything ran much better keeping around 175-180.

First Drive

Went to the gas station and filled er' up and on the way back the temp was still going up to around 190-195 which shouldn't be happening on this cool 70 degree day. Running too hot even for being a new motor running with tight clearances that need to break in. Stopped by a friends house to let it cool off before making it the rest of the way home.

The old radiator has a little bit of mineral build up in it so I wasn't to surprised at needed to get a new one. The clutch in the clutch fan also appears to be about worn out so to get rid of the problem I went ahead and ordered a 3 core aluminum radiator with dual electric fans.

Current & Next Tasks

Motor Going In

Dropping the motor in was a piece of cake only took maybe 30 minutes. Everything went smoothly then I started to bolt things onto the motor to get it ready.

Tried to fit in both sets of headers I had on hand but sadly neither of them fit. The shorties were not even close, but the long tubes most likely would've fit if I did a little bit of modification on them but decided to go buy new ones that would bolt on to save a little time and effort (foreshadowing: It did not). Got the modified crossmember bolted back up.

Went on Hedman Headers website since I've heard about how they always fit quite easily. Input all the car information like having a 5.7, column shift, automatic, power steering, AC, angled spark plugs, etc. Had a selection of 6 different but only really had an option of 3 because I can only afford a set of steel ones instead of stainless. Decided on "Hedman Hedders 68620". They arrived and the passenger side fit perfectly, plenty of clearance on the HVAC box and starter (did add a bit of heat reflection stuff on the starter wires just in

First Start Up

With a splash of gas down the carb and one crank of the key the motor roared to life. It ran great except for a slight surging idle which a stuck carb float valve was found to be the culprit and possibly a small vacuum leak on a line that got a hose clamp put on.

Oil pressure was perfect but problems arose when the temp rose quickly up to 180, then 190, then 200. The 180 thermostat wasnt opening so I replaced it with a new one to no avail. So I then realized it was the temp sender being heat soaked by the headers (I placed it on the rear passenger side port). Pulled the sender out and put a plug in and when I started to remove the plug from the intake it stripped out. So I drained the coolant put a cloth in the intake through the water neck hole to catch metal shavings as I drilled it out. I drilled out with a 1/2" drill bit then started hitting the outer edge of the plug with a punch & hammer until it caved in on itself. Then ran a tap down the hole to make sure the threads were still okay. While I was at that point I also removed the heater hose fitting. It was a straight fitting so It kinked the hose a bit so I removed it and put a 45 degree fitting in its place. After putting everything back together with the temp sender now in the intake everything ran much better keeping around 175-180.

First Drive

Went to the gas station and filled er' up and on the way back the temp was still going up to around 190-195 which shouldn't be happening on this cool 70 degree day. Running too hot even for being a new motor running with tight clearances that need to break in. Stopped by a friends house to let it cool off before making it the rest of the way home.

The old radiator has a little bit of mineral build up in it so I wasn't to surprised at needed to get a new one. The clutch in the clutch fan also appears to be about worn out so to get rid of the problem I went ahead and ordered a 3 core aluminum radiator with dual electric fans.

Current & Next Tasks

- I pulled out the headers and have already cut them apart and completely rewelded them to be kind of like a block hugger. Eventually Ill probably get a nice set of stainless headers but for now it'll have to do. Need to spray the headers with header paint and then I've got header wrap coming tomorrow.

- Swap out the radiator and install fans (got another water neck on order for the fan temp sender)

- Finish up the cat delete down pipes, and then finish up the exhaust. I'm going with 2.5" pipe, with an x-pipe followed by "Spintech 3000 sportsman mufflers (they have awesome customer service!)" , and then sending the exhaust over the rear axle and exit behind the rear tires.

- Also installed an cheap aftermarket electric inline windshield washer sprayer since I pulled apart my entire wiper system and couldn't find out why It wasn't working. The metal tube for the driver side sprayer nozzle was sheared off so I need to find another somewhere, so for now I just have the passenger side sprayer. Ill clean up the wiring and connections once I get both nozzles spraying.

Attachments

Time for another update.View attachment DSC_0710.jpgView attachment DSC_0703.jpg

Over the past month I've got the car driving and have been driving it everywhere. I drove it without an exhaust for a week or so just for the fun of it. I had to tune on the carb a bit with bigger jets, had to deal with a stuck power valve, and put in 2 degrees of timing or so. It was running great other than a small dead spot in the carb and an issue with dieseling.

The dieseling may be an issue of the fact the car is running at 190 degrees which is causing the left over fuel to ignite when the car shuts off or maybe my plugs are too cold for the aluminum heads and it doesn't burn up all the fuel. Any opinions or other ideas why? After I install the aluminum radiator and fans this issue may be solved though.

Got my exhaust welded on by Joe at T&M Muffler Shop in Archdale NC. Joe does great work and had the exhaust done the next morning. Cant beat the price either since it saved me time and frustration of welding exhaust under the car without a lift in the hot weather. The Spintech Sportsman 3000 mufflers I went with sounds great at idle, don't drone at all and, about the same loudness as a (Dronemaster)Flowmaster 40, but at full throttle they have a little bit of rasp which ill fix by adding in an H pipe connector soon. Also longer down the line I may get the louder 6000 Spintech series muffler after I get floor pans welded in, sound deadening and my door seals.

Track Day

Took the car to the track and made a couple passes, the best being an underwhelming 10.5 on the 1/8 mile. This time only beating my best time with the old 305 by .5 seconds. The times at the 60' and 330' and the same with the old 305 and the current 355. Meaning I wasn't actually picking up speed until after halfway down the track. I'm not surprised or disappointed because I knew my 2:41 gears and stock converter were going to hold me back. (I only use first gear and then get into second gear at the last second). On the last run I had a small exhaust leak start due to the header exhaust flange coming loose a little bit which got tightened down after getting home.

I also may start getting to cutting my bumpers up this week to tuck them in a little bit. I'm thinking 2ish inches shorter on each side to tuck the bumpers in flush

Over the past month I've got the car driving and have been driving it everywhere. I drove it without an exhaust for a week or so just for the fun of it. I had to tune on the carb a bit with bigger jets, had to deal with a stuck power valve, and put in 2 degrees of timing or so. It was running great other than a small dead spot in the carb and an issue with dieseling.

The dieseling may be an issue of the fact the car is running at 190 degrees which is causing the left over fuel to ignite when the car shuts off or maybe my plugs are too cold for the aluminum heads and it doesn't burn up all the fuel. Any opinions or other ideas why? After I install the aluminum radiator and fans this issue may be solved though.

Got my exhaust welded on by Joe at T&M Muffler Shop in Archdale NC. Joe does great work and had the exhaust done the next morning. Cant beat the price either since it saved me time and frustration of welding exhaust under the car without a lift in the hot weather. The Spintech Sportsman 3000 mufflers I went with sounds great at idle, don't drone at all and, about the same loudness as a (Dronemaster)Flowmaster 40, but at full throttle they have a little bit of rasp which ill fix by adding in an H pipe connector soon. Also longer down the line I may get the louder 6000 Spintech series muffler after I get floor pans welded in, sound deadening and my door seals.

Track Day

Took the car to the track and made a couple passes, the best being an underwhelming 10.5 on the 1/8 mile. This time only beating my best time with the old 305 by .5 seconds. The times at the 60' and 330' and the same with the old 305 and the current 355. Meaning I wasn't actually picking up speed until after halfway down the track. I'm not surprised or disappointed because I knew my 2:41 gears and stock converter were going to hold me back. (I only use first gear and then get into second gear at the last second). On the last run I had a small exhaust leak start due to the header exhaust flange coming loose a little bit which got tightened down after getting home.

I also may start getting to cutting my bumpers up this week to tuck them in a little bit. I'm thinking 2ish inches shorter on each side to tuck the bumpers in flush

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 166

- Replies

- 2

- Views

- 233

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.