Donovan, the Cliff Ruggles book is great and I relied on that book until Mark (Bonnewagon) suggested I get the Doug Roe book. I still use Cliff's book but mostly rely on Roe's book.

At my wits end with this QuadraJet

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Try it you can always go furtherAlright fellas, I made some progress tonight.

I got my hands on the mixture screw adjusting tool and counted the number of turns they were at before removing them.

2 1/4 on the passenger’s side one, and 1 3/4 on the driver’s side. Not great.

I also obtained a copy of Cliff’s book and studied the entire sections on the idle system. I definitely think this is where the problem lies as the idle circuit wasn’t modified for the improvements and changes I made to the engine when the carb was rebuilt.

Going through step by step following the book, I measured and recorded all the sizes of the components I had in the idle system.

Idle tube: smaller than .040 (smallest drill bit I had, should be able to find out exactly tomorrow)

Idle down channel: .048 - .050

Upper idle bleed: .067

Lower idle bleed: .076 - .077

Idle bypass air: .069

Holes under mixture screws: .067 - .069

Holes in throttle plates: None

As you can see by these measurements, several of the components and ports in the idle system were severely undersized, especially when compared to Cliff’s recommendations for a build with a cam similar to mine.

I need to bring my calipers home from work tomorrow to verify and finish up enlarging the rest of the components, but here’s what the new, modified numbers are at now:

Idle tube: Not enlarged yet

Idle down channel: Not enlarged yet

Upper idle bleed: .070

Lower idle bleed: .070

Idle bypass air: .082

Mixture screw holes: .093

Holes in throttle plates: None

What do you experienced guys think of these numbers with my engine combination?

(See earlier in this thread if you don’t recall the particulars)

Thanks in advance.

D.

when you are adjusting the idle screw mixture you can use a vacuum gauge to set them

Aaaaaaand done!

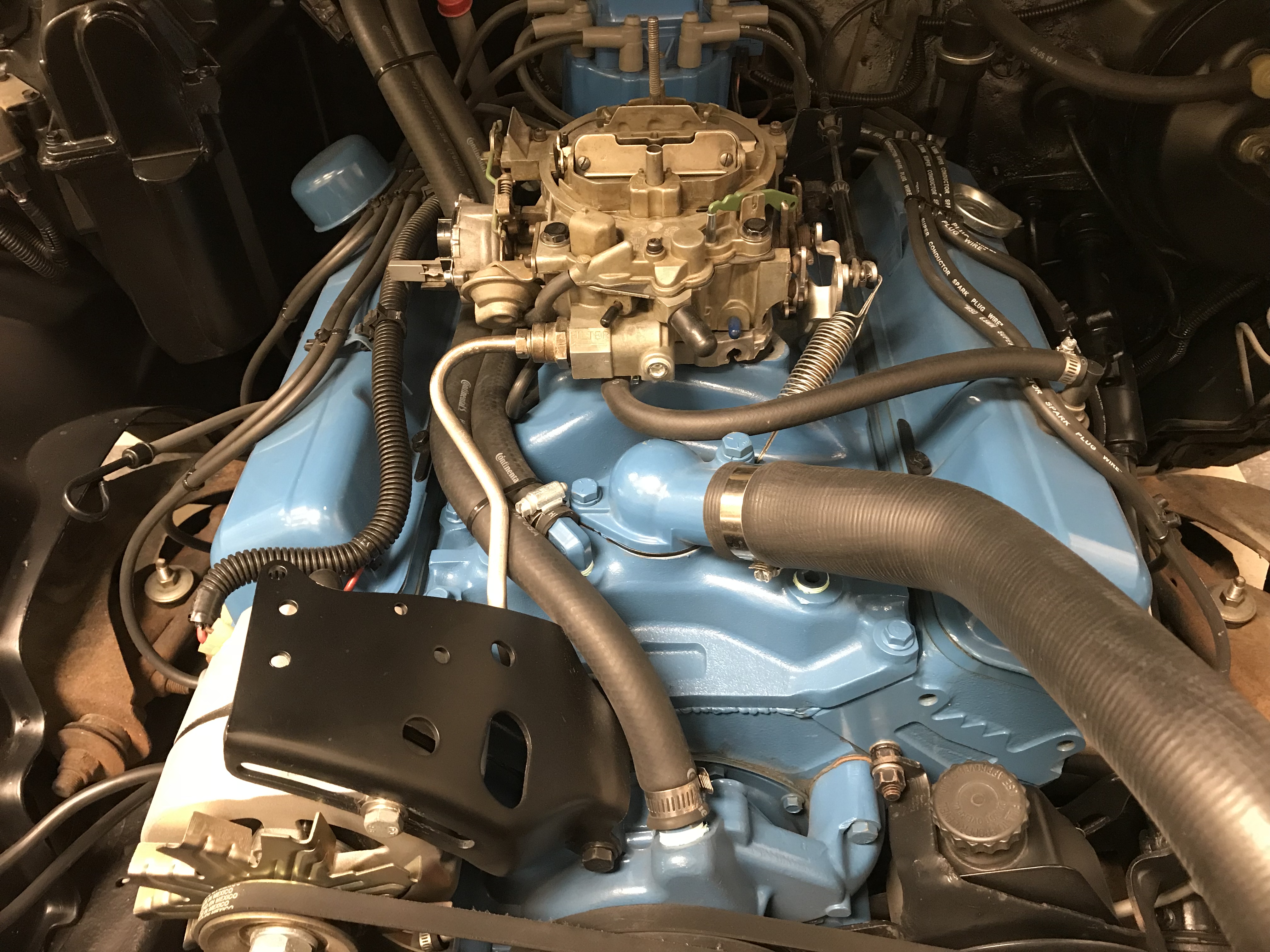

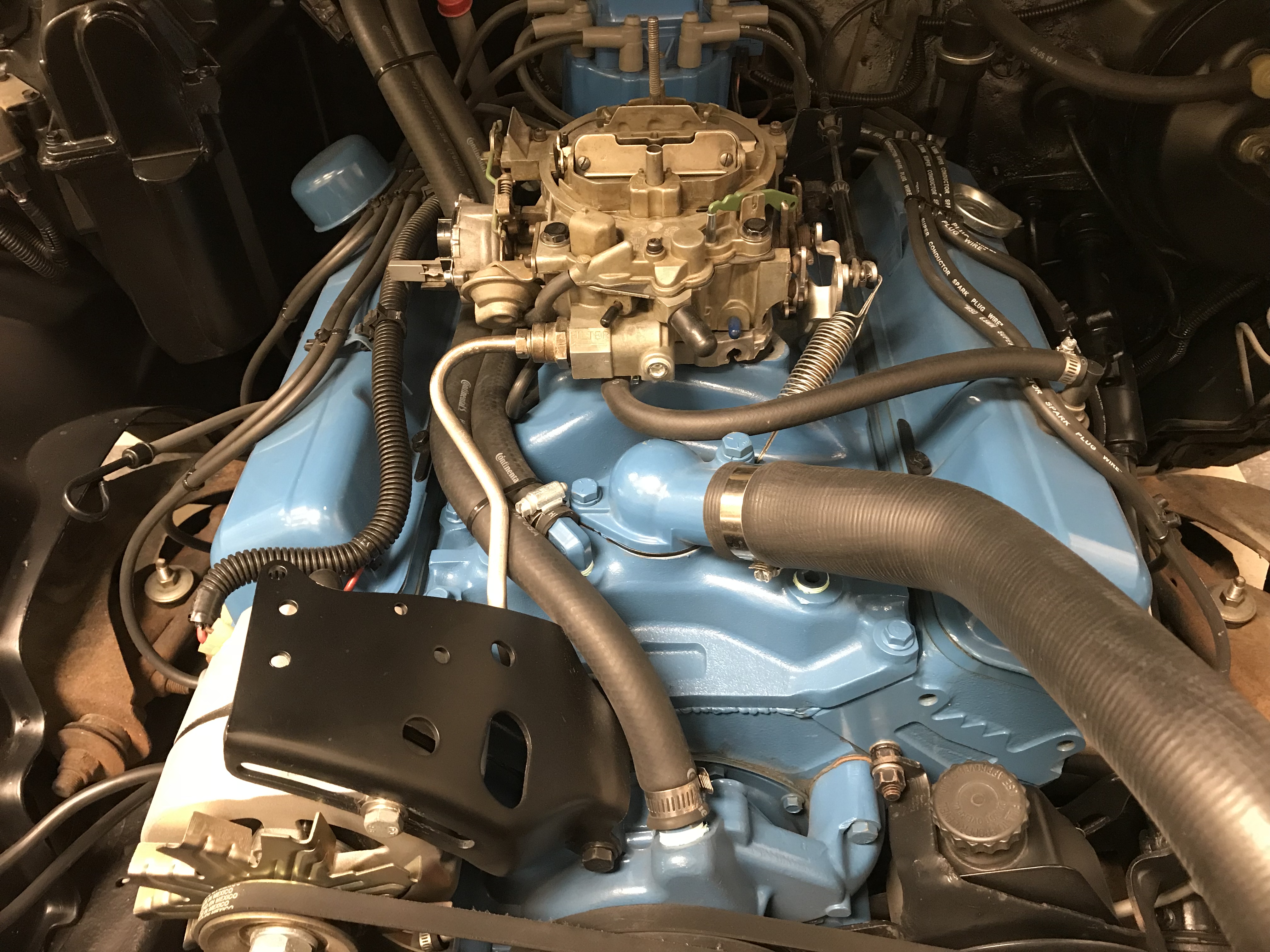

I completed the last of the modifications to the idle circuit tonight, and got the carb reassembled.

It actually all went back together better and a little quicker than I expected.

With a bit of time left in the evening, I reinstalled it on the car and got everything buttoned back up.

I wouldn’t have been able to sleep tonight without knowing whether it’d at least fire or not, so despite the late hour I gave it a shot.

And success! Well, sort of.

The car will fire and run, but now the tuning work will have to begin. It still stalled on me, but the idle screws will need adjusting along with the idle speed and possibly the choke and timing again. So I still don’t really know just yet at this point whether the modifications were truly successful or not.

Tomorrow night will be back to basics getting it tuned right and dialed in again.

Thanks for everyone’s input and help, it was all invaluable and I’m extremely grateful for it. Thank you.

And you guys thought all I could do was only fabrication, paint and bodywork....

😛

I completed the last of the modifications to the idle circuit tonight, and got the carb reassembled.

It actually all went back together better and a little quicker than I expected.

With a bit of time left in the evening, I reinstalled it on the car and got everything buttoned back up.

I wouldn’t have been able to sleep tonight without knowing whether it’d at least fire or not, so despite the late hour I gave it a shot.

And success! Well, sort of.

The car will fire and run, but now the tuning work will have to begin. It still stalled on me, but the idle screws will need adjusting along with the idle speed and possibly the choke and timing again. So I still don’t really know just yet at this point whether the modifications were truly successful or not.

Tomorrow night will be back to basics getting it tuned right and dialed in again.

Thanks for everyone’s input and help, it was all invaluable and I’m extremely grateful for it. Thank you.

And you guys thought all I could do was only fabrication, paint and bodywork....

😛

OK, did I hallucinate that this will idle properly after you drive it a while? But only upon restart it is again too rich, runs like crap?

Though I only know the CCC "well", I don't think you need to enlarge the idle bleeds D if you can tell it is too rich already? My big block was too lean to idle without the speed screw in far enough to crack the primaries. Sounds like a lack of air problem at idle or a too much fuel condition in your case.

Agree on the stoichiometric AFR reader meter gauge if you can get one? Be nice to borrow it since they ain't cheap but not a bad tool to have around.

Please, before you start to carve it up [and I know how frustratingly they can lead one to do that] start from cold start basics and make sure all 3 conditions are working purr-fectly.

EDIT: Sorry, logged on too late. Well, hope it works then . . . 👍

Though I only know the CCC "well", I don't think you need to enlarge the idle bleeds D if you can tell it is too rich already? My big block was too lean to idle without the speed screw in far enough to crack the primaries. Sounds like a lack of air problem at idle or a too much fuel condition in your case.

Agree on the stoichiometric AFR reader meter gauge if you can get one? Be nice to borrow it since they ain't cheap but not a bad tool to have around.

Please, before you start to carve it up [and I know how frustratingly they can lead one to do that] start from cold start basics and make sure all 3 conditions are working purr-fectly.

EDIT: Sorry, logged on too late. Well, hope it works then . . . 👍

OK, did I hallucinate that this will idle properly after you drive it a while? But only upon restart it is again too rich, runs like crap?

Though I only know the CCC "well", I don't think you need to enlarge the idle bleeds D if you can tell it is too rich already? My big block was too lean to idle without the speed screw in far enough to crack the primaries. Sounds like a lack of air problem at idle or a too much fuel condition in your case.

Agree on the stoichiometric AFR reader meter gauge if you can get one? Be nice to borrow it since they ain't cheap but not a bad tool to have around.

Please, before you start to carve it up [and I know how frustratingly they can lead one to do that] start from cold start basics and make sure all 3 conditions are working purr-fectly.

EDIT: Sorry, logged on too late. Well, hope it works then . . . 👍

No worries Garth.

No, that wasn’t the problem. To save me an hours worth of typing, go back and reread my first post. It wouldn’t idle, period. The only way it would was if I fooled the carb into running on the PRIMARY circuit, rather than the idle circuit. THEN it ran pig rich, for obvious reasons.

I do agree however, I think it was running way too lean at idle, causing the stalling issue. Hopefully my modifications have corrected the problem, guess I’ll find out tomorrow night.

Cool!

This part is what confused me: Once it does stay running this way, I can drive the car around for hours through start and stop traffic, and it pulls good throughout the rpm range but as soon as I shut it off and go to restart it the cycle starts all over again.

****ing English language anyway.

This part is what confused me: Once it does stay running this way, I can drive the car around for hours through start and stop traffic, and it pulls good throughout the rpm range but as soon as I shut it off and go to restart it the cycle starts all over again.

****ing English language anyway.

Nice work- it looks great. See? At first everyone is intimidated by a Q-jet. But once you dig in and rebuild one several times it gets easy. Then you wonder what all the fear was for. So once the timing is verified start on the carb. A nice trick is to pull out all the plugs and ground the wires. Then have someone crank the motor while you watch the timing light. Now you can set the timing at like 100 rpm and it will not have any advance interfering. When ready, start out at a fast idle and the let it warm up. Then slowly idle down to where you want it. The final adjustment should be while watching the vacuum gauge looking for the most vacuum you can get at a reasonable idle speed. I am confident you will be successful. EDIT: what is that large object above the float bowl on the pass side? That spot is usually used for a high altitude aneroid, the CCC connector, or on some '80's trucks- an idle enrichment solenoid.

Last edited:

I’m off Friday and light duty tomorrow so I’ll keep an eye on this want to know how you come out

Does it have plastic or brass floatsHey guys, what’s up.

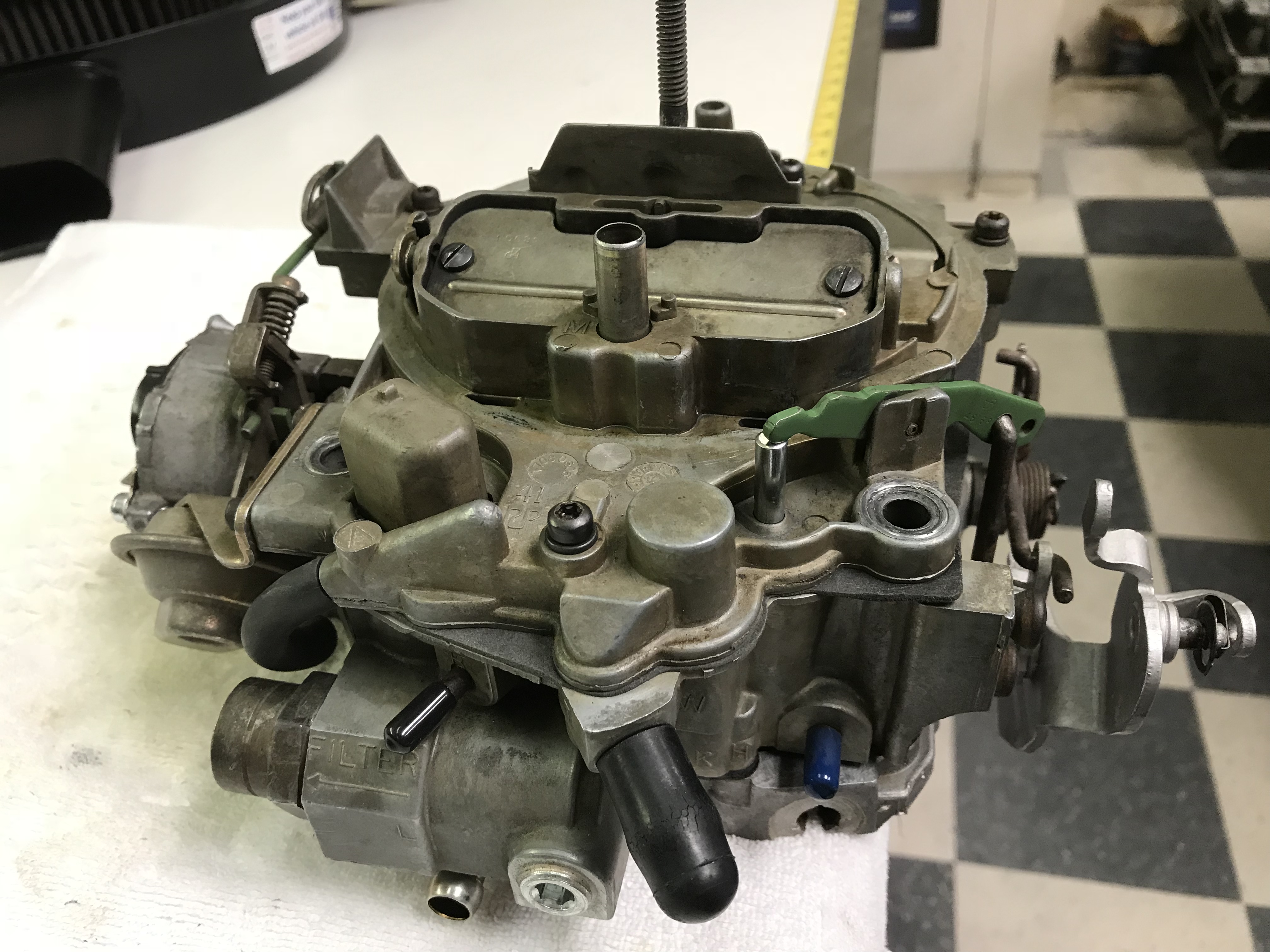

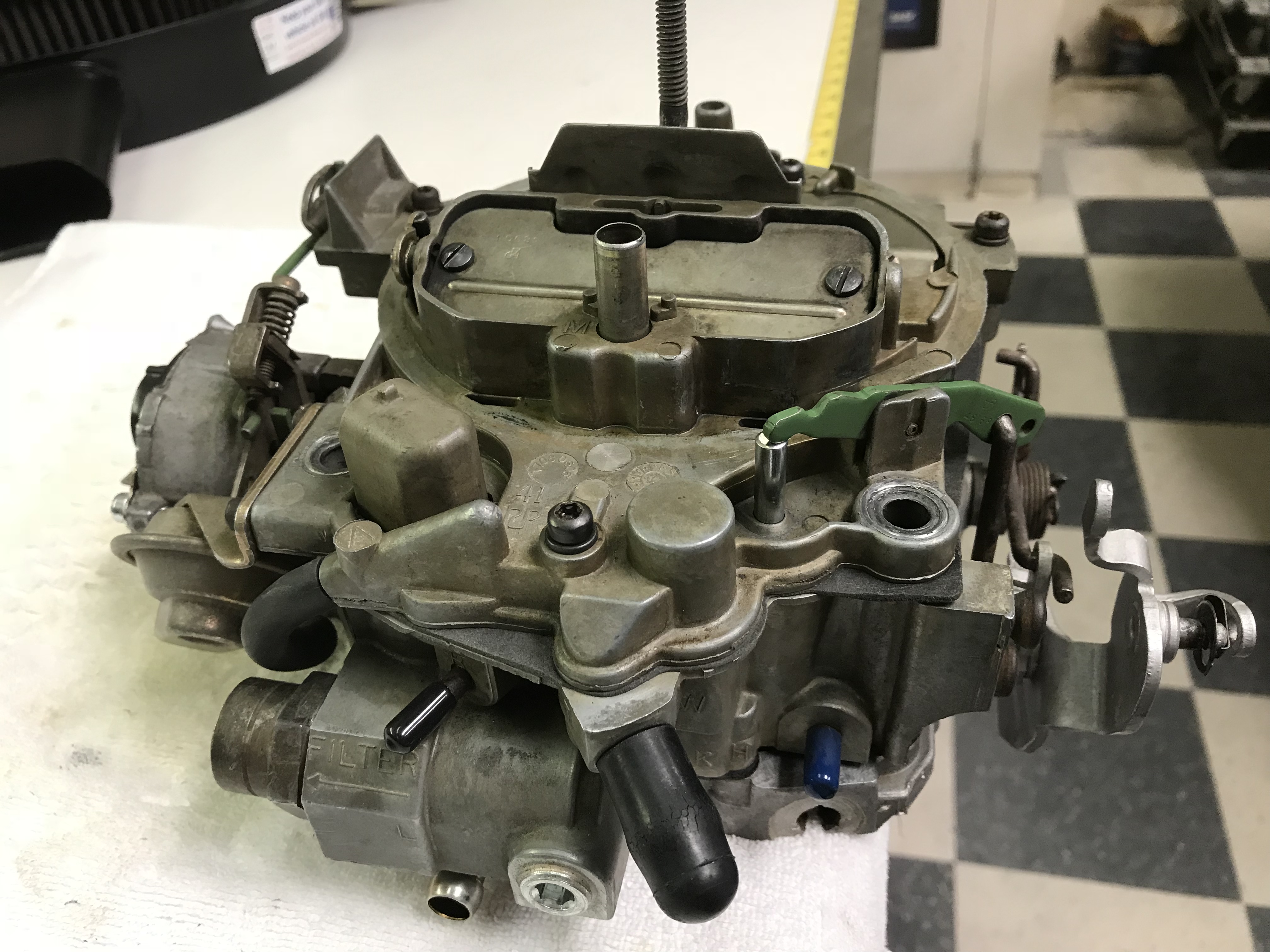

I’ll get into more particulars of my issue with this QuadraJet later in this thread, but for right now, a simple question:

Is it possible to have a QuadraJet run on the primary circuit rather than the idle circuit?

My car WILL NOT idle on its own after starting it, even if it’s already up to operating temperature. It just stalls. If I very carefully feather the gas and hold the rpms around 800-1000 where it should idle, the engine sounds normal and you can hear the lope of the cam as you should.

But as soon as I take my foot off the gas it just stalls.

The only way I can get it to stay running on its own is if I rev it to 3500-4000 rpm, then it’ll stay running but it’s pig rich and doesn’t sound like it should. Revving it to anything less than these rpms won’t keep it running.

Once it does stay running this way, I can drive the car around for hours through start and stop traffic, and it pulls good throughout the rpm range but as soon as I shut it off and go to restart it the cycle starts all over again.

It’s almost as if when I rev it into this rpm range, it fools the carb into running on the primary circuit rather than the idle circuit. Is this possible?

I’ve gone through countless hours and trouble shooting only to find nothing out of the ordinary. It’s recently been rebuilt, no vacuum leaks, throttle shafts have been bushed, tinkering with the timing and vacuum advance pulloff locations has no effect on the problem. It seems to be an issue with the idle circuit, but unable to determine what. The idle mixture screws are turned out the recommended 3-3 1/2 turns.

The carb was thoroughly cleaned and air blown through all the passages when it was rebuilt, so dirt or contamination is highly unlikely. And yes, I have already bought the Doug Roe QuadraJet book. I see no mention of the problem I’m experiencing in it.

Please help before another QuadraJet finds its way onto the scrap heap. I’m at my wits end with it.

- Status

- Not open for further replies.

Similar threads

BUILD THREAD

The never ending 383

- Replies

- 10

- Views

- 432

- Replies

- 22

- Views

- 1K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.