Yeah the guy said it ran when pulled but you know how that goes. I’m the one that number them though. Another thing I was wondering is if it has been to the machine shop before. If it has what rings do I need to order and stuff like that.Yeah, those are indeed the two styles of rods. The capscrew rods are quite heavier and beefier than the earlier stud and nut rods. you can weigh them all. They have been numbered, so someone definitely cobbled that engine together at some point. The capscrew rods are the better rods, but unless it annoys you, just get everything weighed out and balanced. if it balances fine, leave it i suppose. It ran before, correct?

Buick 350

- Thread starter Street Sweeper22

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

any cheapo digital calipers from the parts store or harbor freight will tell you the bore size. stock bore is 3.800". pin diameter i believe is .942, which is how grand national and 3.0 v6 pistons fit. Just standard cast iron rings, dont need anything fancy, especially if you arent gonna bore it.

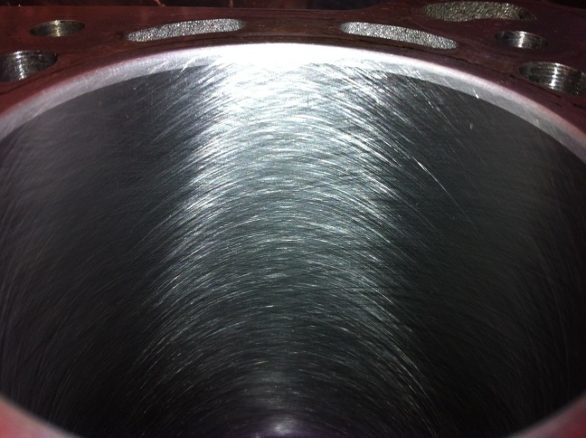

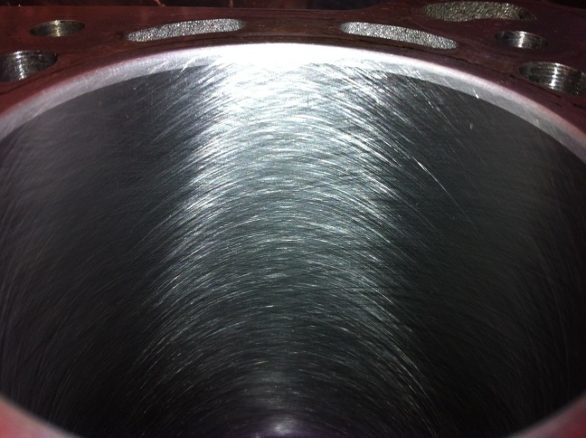

The bore size does measure 3.800. The first pic is about 2 minutes with a 240 grit 3 stone home and the second pic is about a minute. What do you think and is 240 the right grit?any cheapo digital calipers from the parts store or harbor freight will tell you the bore size. stock bore is 3.800". pin diameter i believe is .942, which is how grand national and 3.0 v6 pistons fit. Just standard cast iron rings, dont need anything fancy, especially if you arent gonna bore it.

The grit is determined by the type of rings, see what the ring manufacturers recommendation is. Cast iron is somewhere around 220 grit, moly coated somewhere in the middle and chrome moly rings can be as fine as 400 grit.

That line in that bore is trouble, what does the piston skirt look like?

The first picture looks like you slowed the rotation of the hone before removing it from the bore. Use a slow setting on the drill but it needs to be at full speed when inserting or removing the hone.

The cross hatch pattern is supposed to be 27-45 degrees, it is a factor of the drill speed and the speed you move the hone up and down in the bore. Experiment with it till it looks right.

I prefer the ball type hone. Less to get wrong.

That line in that bore is trouble, what does the piston skirt look like?

The first picture looks like you slowed the rotation of the hone before removing it from the bore. Use a slow setting on the drill but it needs to be at full speed when inserting or removing the hone.

The cross hatch pattern is supposed to be 27-45 degrees, it is a factor of the drill speed and the speed you move the hone up and down in the bore. Experiment with it till it looks right.

I prefer the ball type hone. Less to get wrong.

The grit is determined by the type of rings, see what the ring manufacturers recommendation is. Cast iron is somewhere around 220 grit, moly coated somewhere in the middle and chrome moly rings can be as fine as 400 grit.

That line in that bore is trouble, what does the piston skirt look like?

The first picture looks like you slowed the rotation of the hone before removing it from the bore. Use a slow setting on the drill but it needs to be at full speed when inserting or removing the hone.

The cross hatch pattern is supposed to be 27-45 degrees, it is a factor of the drill speed and the speed you move the hone up and down in the bore. Experiment with it till it looks right.

I prefer the ball type hone. Less to get wrong.

View attachment 219966

I should probably just take it to a machine shop but the problem with that is that I hear they are putting out crappy work and they are backed up a couple of months. That’s the word around Denver. I soaked the pistons in kerosene and they seemed to clean up ok but I don’t know. This is my first rodeo.The grit is determined by the type of rings, see what the ring manufacturers recommendation is. Cast iron is somewhere around 220 grit, moly coated somewhere in the middle and chrome moly rings can be as fine as 400 grit.

That line in that bore is trouble, what does the piston skirt look like?

The first picture looks like you slowed the rotation of the hone before removing it from the bore. Use a slow setting on the drill but it needs to be at full speed when inserting or removing the hone.

The cross hatch pattern is supposed to be 27-45 degrees, it is a factor of the drill speed and the speed you move the hone up and down in the bore. Experiment with it till it looks right.

I prefer the ball type hone. Less to get wrong.

View attachment 219966

You are doing fine. A machine shop will want to overbore and lots of other things making it cost $$$$$.

Say you carry on and for a small amount of $ you build a good running engine that will last 40,000 miles. Nothing to complain about.

Going by your pictures the bore with the scrape in it is also the bore that had weird rod in it?

Say you carry on and for a small amount of $ you build a good running engine that will last 40,000 miles. Nothing to complain about.

Going by your pictures the bore with the scrape in it is also the bore that had weird rod in it?

That bore scrape doesn't bother me. If you can feel it, get some 180 or so grit sand paper and rub it down. Then hone it again, trying to get as close to a 45 degree cross hatch as you can. That pattern holds oil to the cylinder walls, and is critical for ring seal. Do the wrong thing the right way, not the right thing the wrong way. When you install the rings, face the gaps away from the gouge. The rings rotate thanks to that cross hatch anyway, but best to give them a fighting chance.

Thank you for your input. I will be stoked AF to get 40,000 miles out of it. Im going to keep at it and post some more pics as I go.

- Status

- Not open for further replies.

Similar threads

- Replies

- 12

- Views

- 2K

- Replies

- 10

- Views

- 357

- Replies

- 0

- Views

- 128

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.