I f*cking despise this Holley pan. But, after many hours of farting around I think I finally solved it.

View attachment 104815

If you look closely you can see where I had to grind the block... yes, the BLOCK to get the pipe in there. Nothing like laying under the car with metal shavings showering you. FFS, Holley.

View attachment 104816

The DS motor mount and trans mount had to come apart so that I could jack the engine up and get enough room to screw the fitting into the pan. You can see how there is sufficient clearance between the engine cradle and the fitting when it is set back together.

View attachment 104817

View attachment 104818

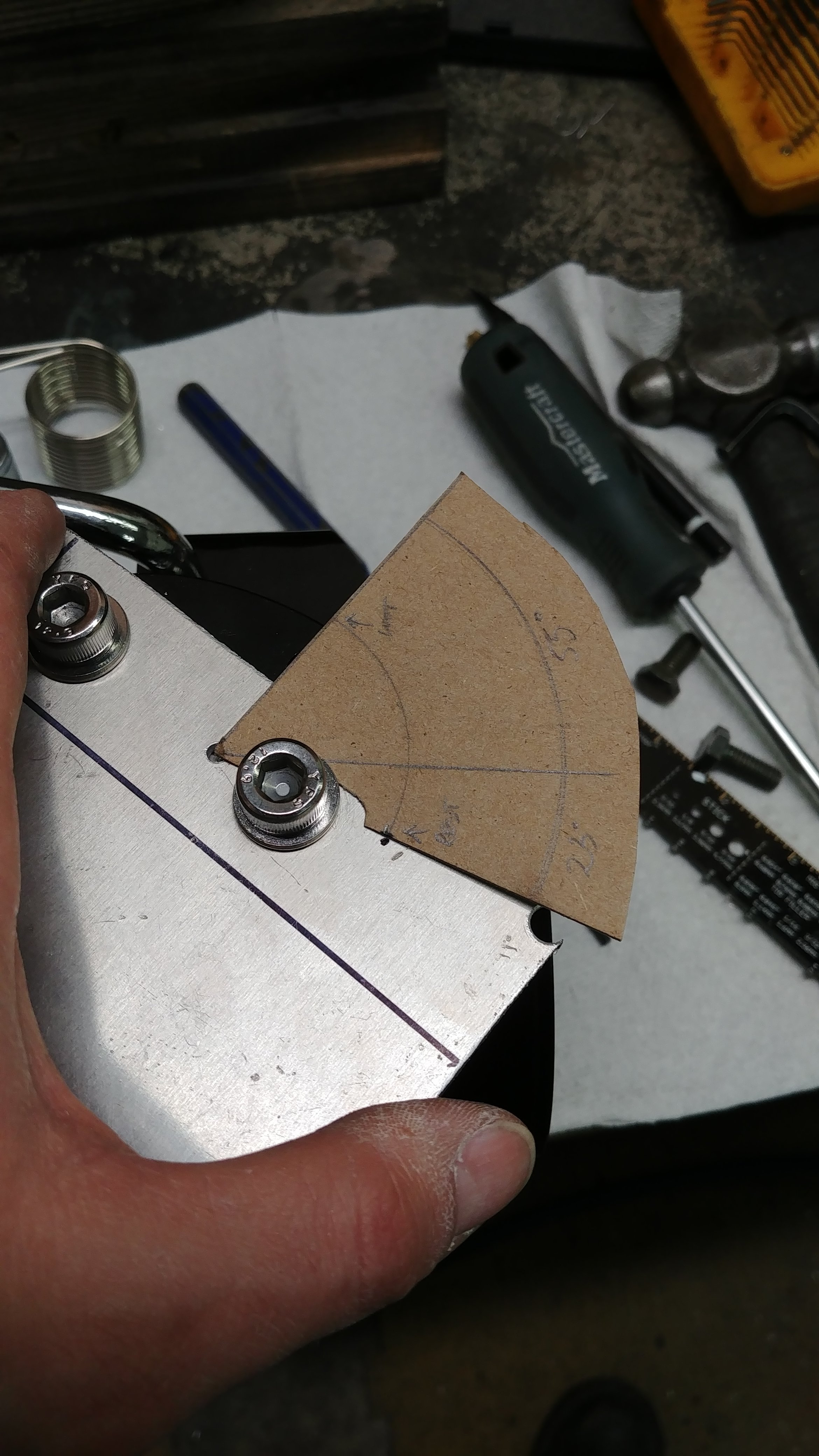

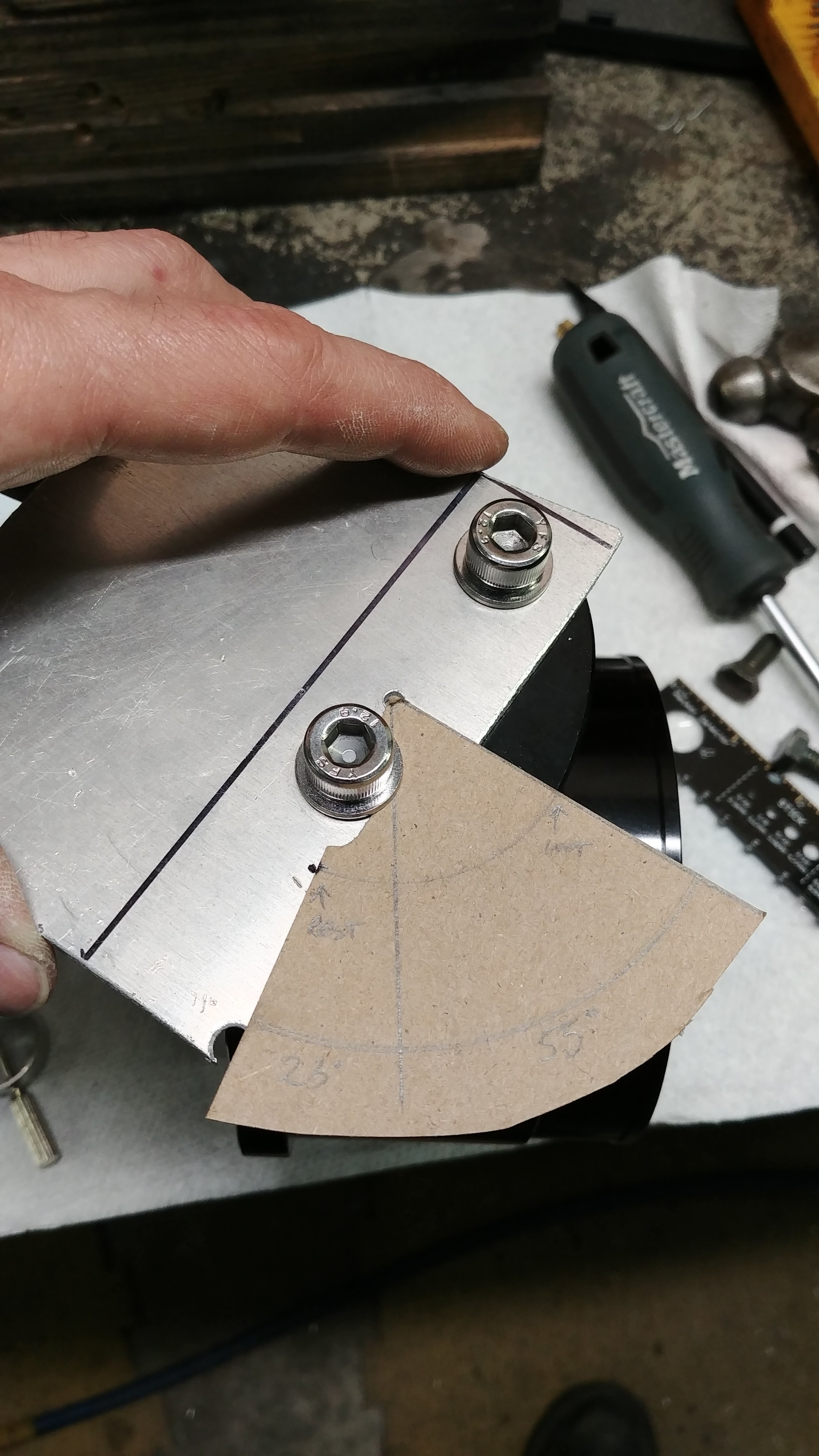

The pan fitting is half of a male and half of a female 1/2" NPT fitting sectioned and welded together. And then lots of grinding. This was the only way to get the fitting low enough to clear the engine cradle. Nothing off-the-shelf other than a banjo bolt (but, I am pretty sure they don't come with an NPT bolt). The pipe is built out of pipe plug, some 1/2" ID steel pipe, a 1/2" bolt, more pipe, and a -10 AN fitting from Vibrant. The whole idea here was to make it modular for assembly and ease of service. The drain hose will pass through the belt, and as such it needs to be serviceable.

View attachment 104819View attachment 104820

So there you go. Just to prove it could work I did it... I shouldn't have. But, I did anyway.

Evidently the banjo bolt exists:

http://rover.ebay.com/rover/1/711-5...0001&campid=5335822911&icep_item=382214007714