liquidh8

Comic Book Super Hero

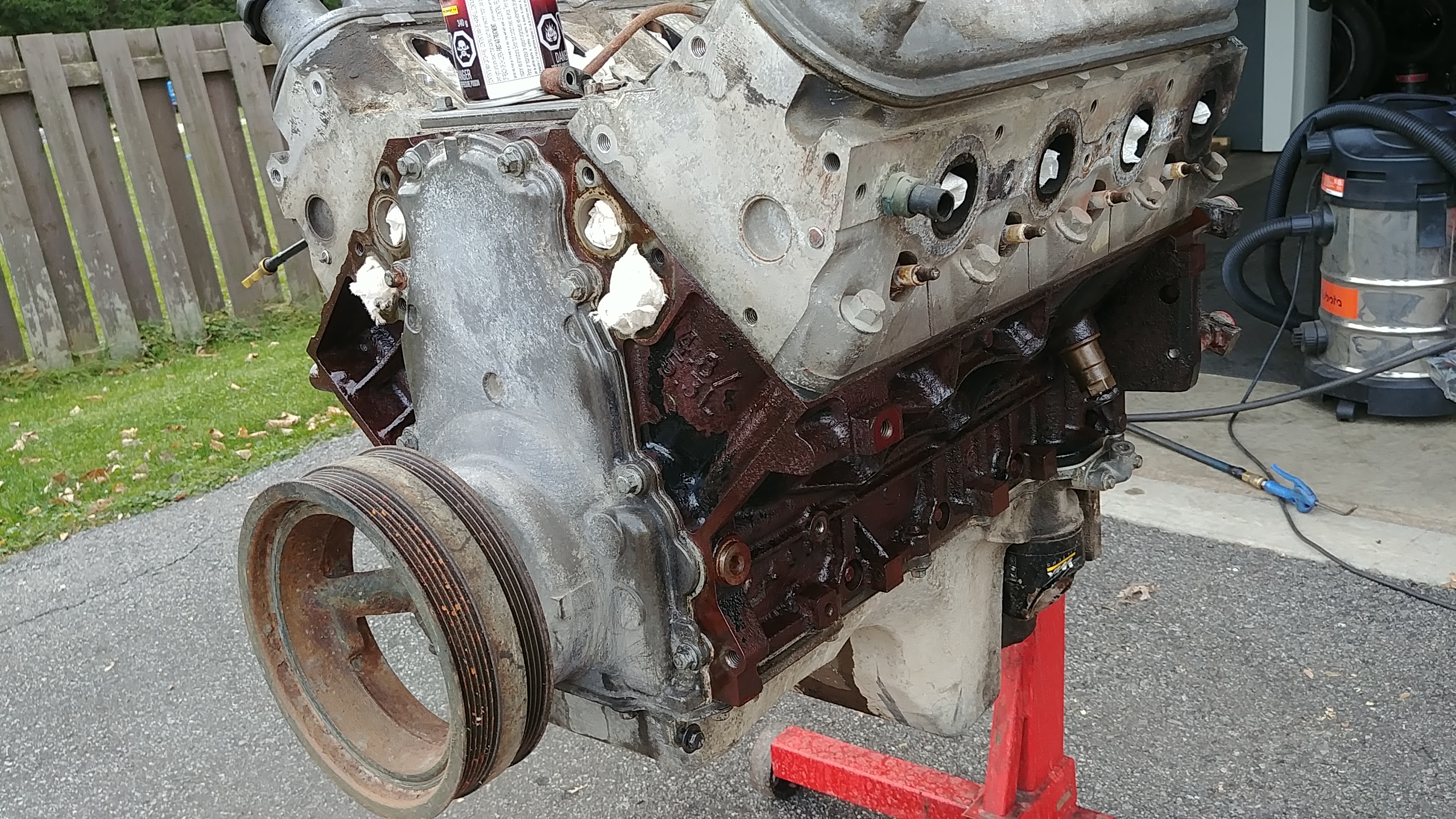

I'd imagine those holes are 1/2" because alot of the aftermarket bushings are 1/2". Meeting the poly bushings and suck on the tubular arms.Did a thing today. Took some time to install the UMI LCA relocation brackets on the 8.5". I made a mock control arm to ensure that the arm sweep was accurate - it also helped to triangulate the brackets. That being said UMI failed horribly in their design. The hole which bolts to the stock ears is way too large, it measures out to about 1/2" when it needs to be 10mm - what this does is introduces a lot of slop into locating the brackets making accurate alignment damn near impossible. What I did to overcome this was cut some bushings that made up the difference and helped centre everything up. I was not impressed. Set the pinion angle to 0*, set the LCA brackets to 0*, tack, weld, repeat, paint, done.

View attachment 75767

View attachment 75768

At least your making progress.