Ok, enough about panel bond.

Now that I finally had my patch panel created, the next step was to prepare the opening for the patch.

I still had some rough edges and some extra material that needed cleaning up before I could test fit.

Using a fresh sharp blade on an Olfa knife, I deburred the edges of the opening, and ensured there was no adhesive between the roof support and skin that would interfere with the front flange sliding under.

With that done all around, time for the initial test fit.

Here's the results of that:

Again, it's tough to see in the pic, but for the initial test, it fits VERY well. A little more tweaking to the size of the opening will be required, but that's about it.

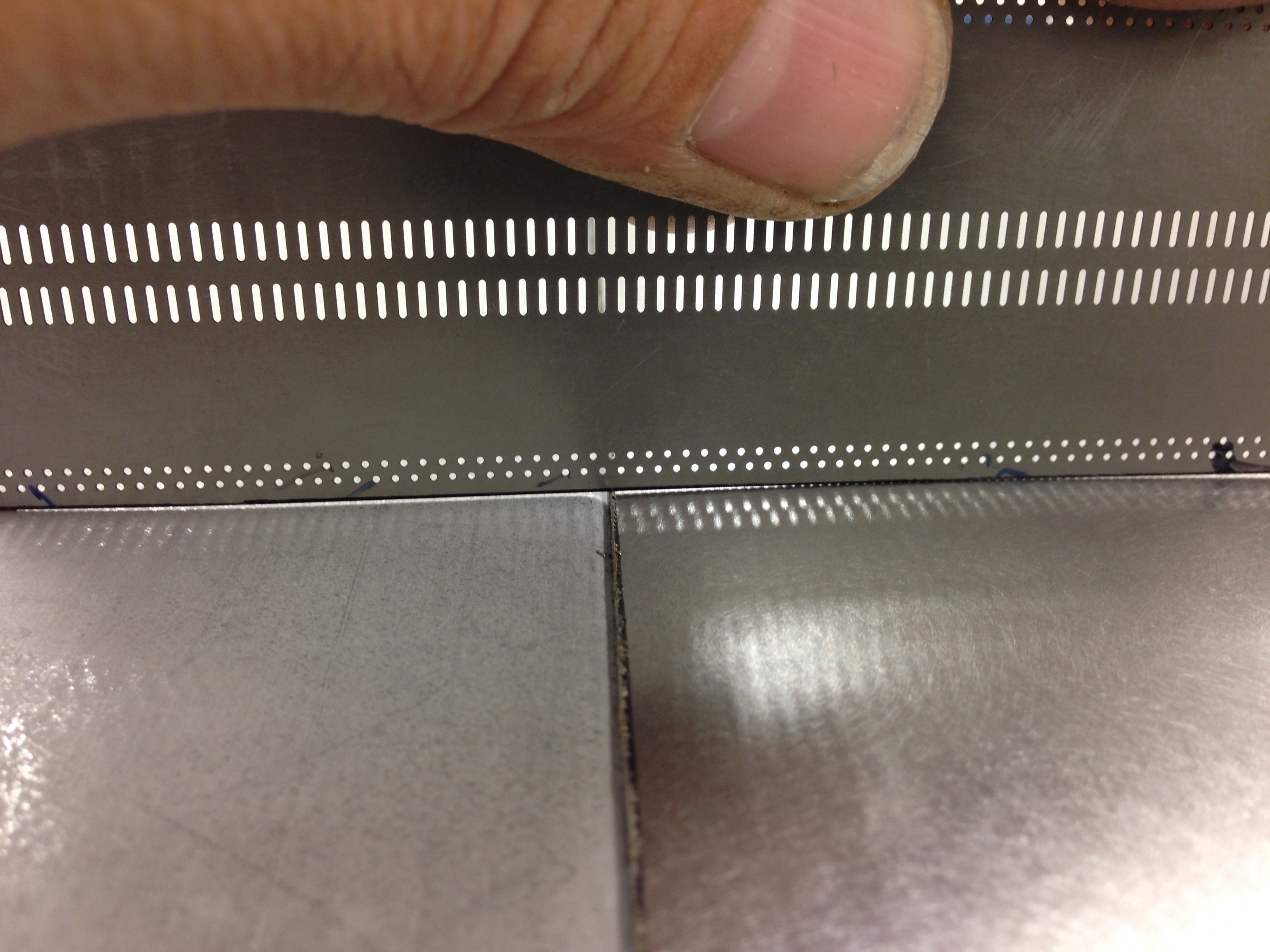

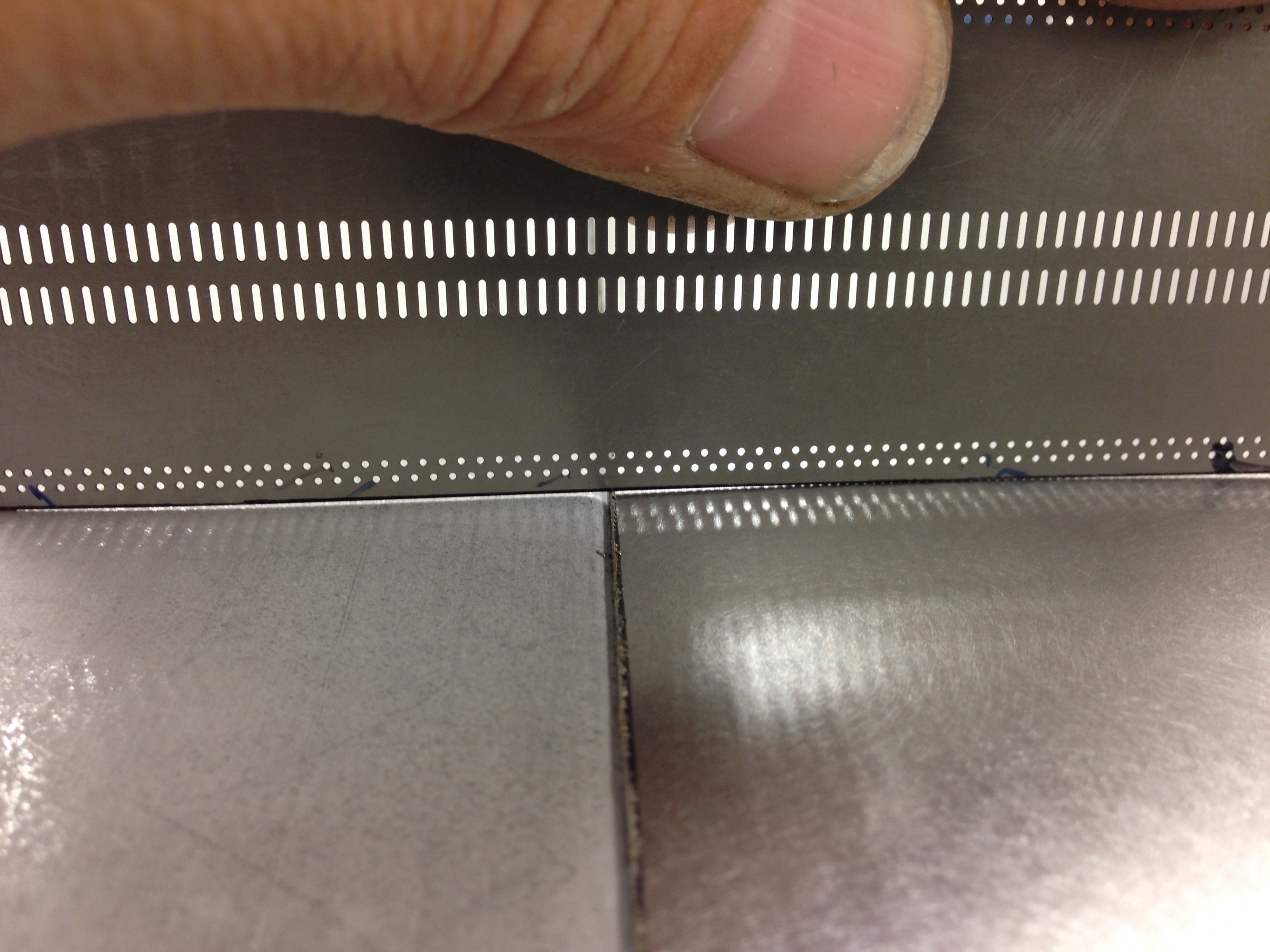

I snapped a couple close-up pics of where the patch fits properly, and laid a straight edge across it so you can see how well it's going to work.

Across the top center of the roof:

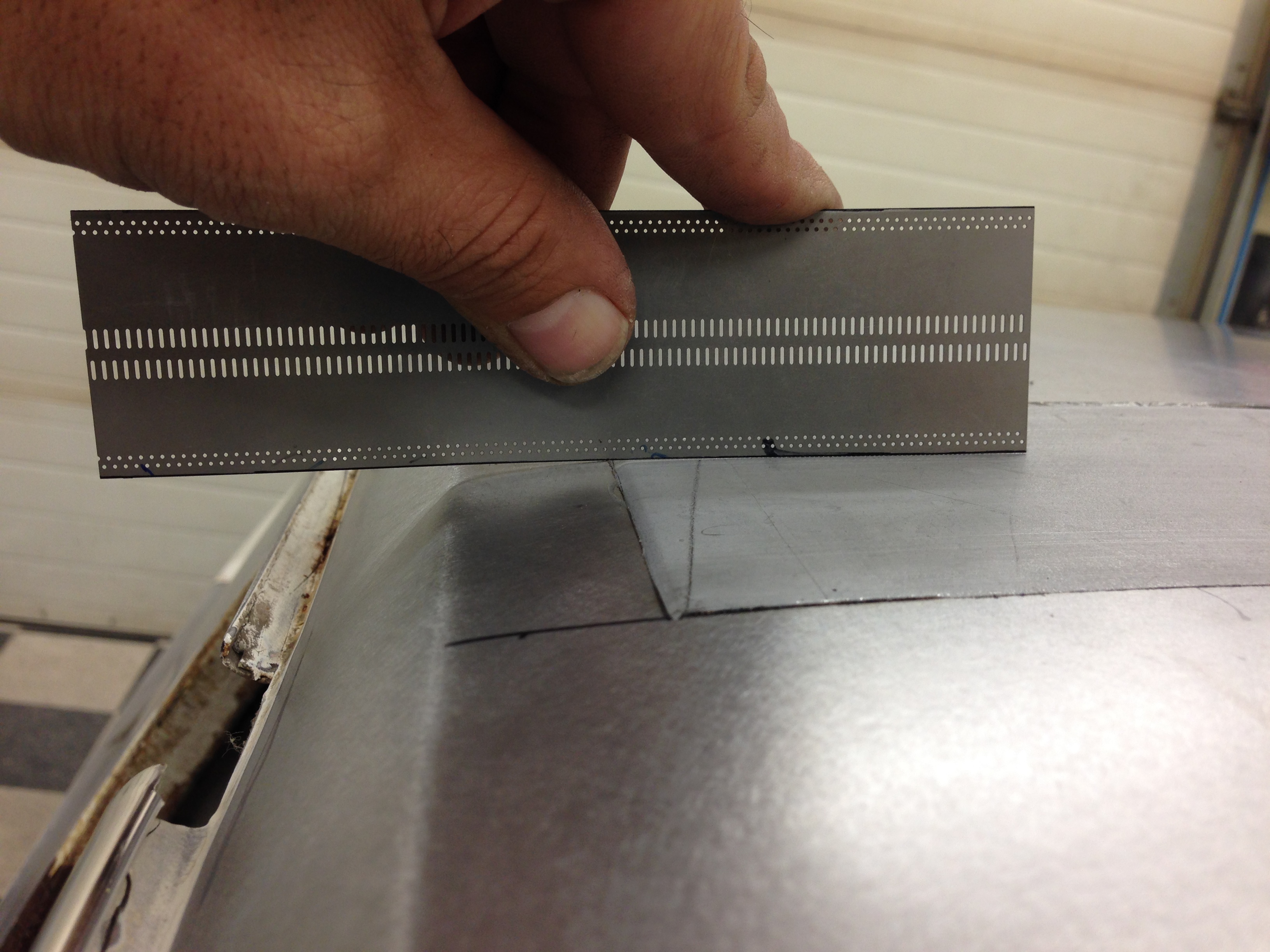

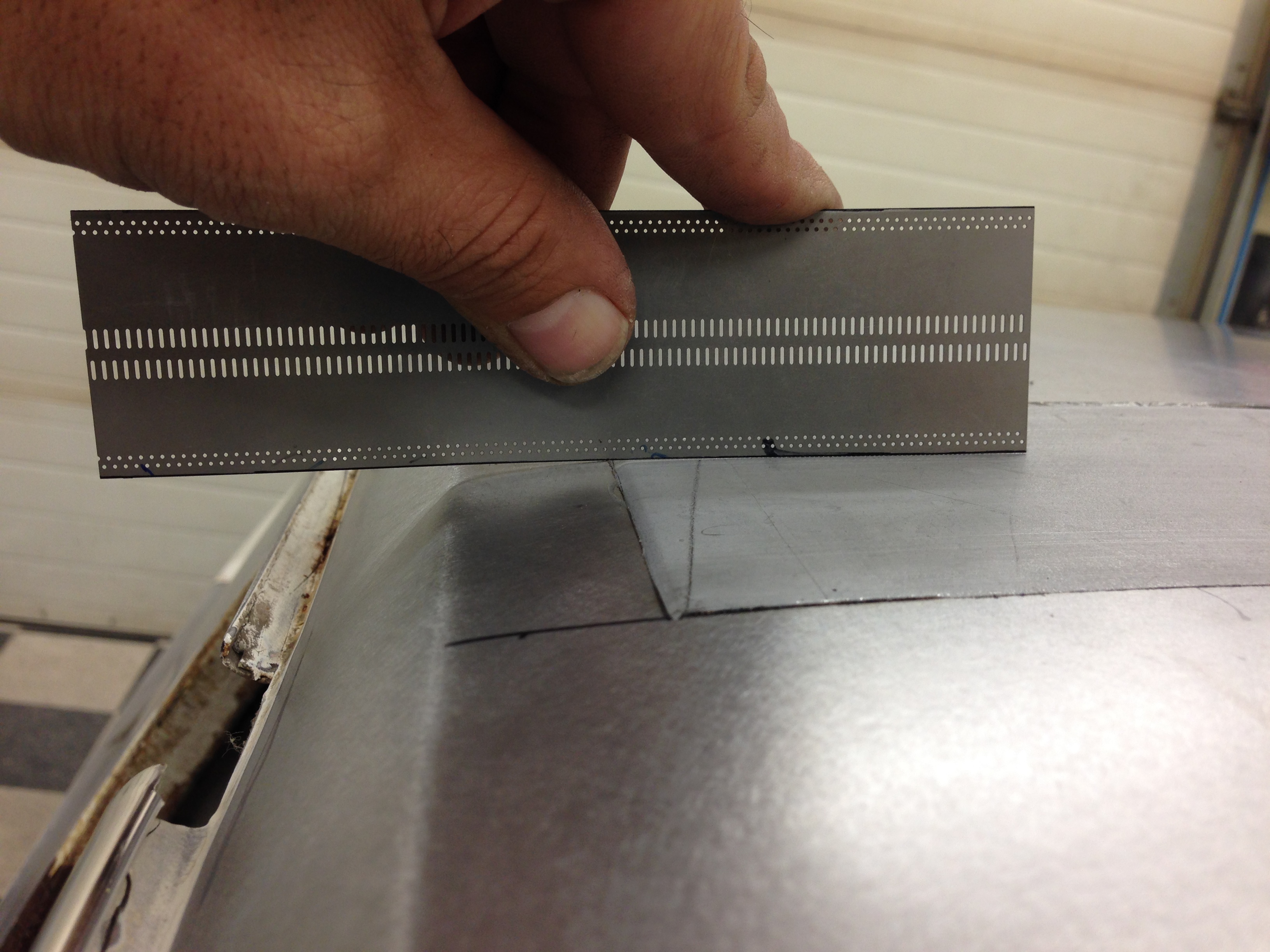

And across the outer edge by the drip rail:

I'm very happy with the results thus far, I really think this is the best way to repair this.

That's it for today's progress, I'll leave you with a couple more, well, just because!

Thanks for checking back everyone!

Another update tomorrow night.

D.

Now that I finally had my patch panel created, the next step was to prepare the opening for the patch.

I still had some rough edges and some extra material that needed cleaning up before I could test fit.

Using a fresh sharp blade on an Olfa knife, I deburred the edges of the opening, and ensured there was no adhesive between the roof support and skin that would interfere with the front flange sliding under.

With that done all around, time for the initial test fit.

Here's the results of that:

Again, it's tough to see in the pic, but for the initial test, it fits VERY well. A little more tweaking to the size of the opening will be required, but that's about it.

I snapped a couple close-up pics of where the patch fits properly, and laid a straight edge across it so you can see how well it's going to work.

Across the top center of the roof:

And across the outer edge by the drip rail:

I'm very happy with the results thus far, I really think this is the best way to repair this.

That's it for today's progress, I'll leave you with a couple more, well, just because!

Thanks for checking back everyone!

Another update tomorrow night.

D.