Yep, Scott nailed it!

Today was an extremely busy one, up at the crack of dawn (no joke) and got down to business in the shop. It was a civic holiday here today, so a long weekend, and I was determined to take full advantage of it.

I started off by finishing the second half of the passenger side headlight bezel. I had gotten the first half done the night previous before I had to call it quits from my fingers being numbed to the bone from sanding.

Now both sides are done:

After that, I reassembled the headlight/bucket/trim ring assemblies, tidied up the shop and put everything away that wasn’t needed. In doing so, I remembered that I hadn’t installed a very important accessory...

Easiest

Install

Ever!

Done procrastinating, I knuckled down and got after the chore I’d been avoiding:

Scuffing the insides of the headlight and grille openings:

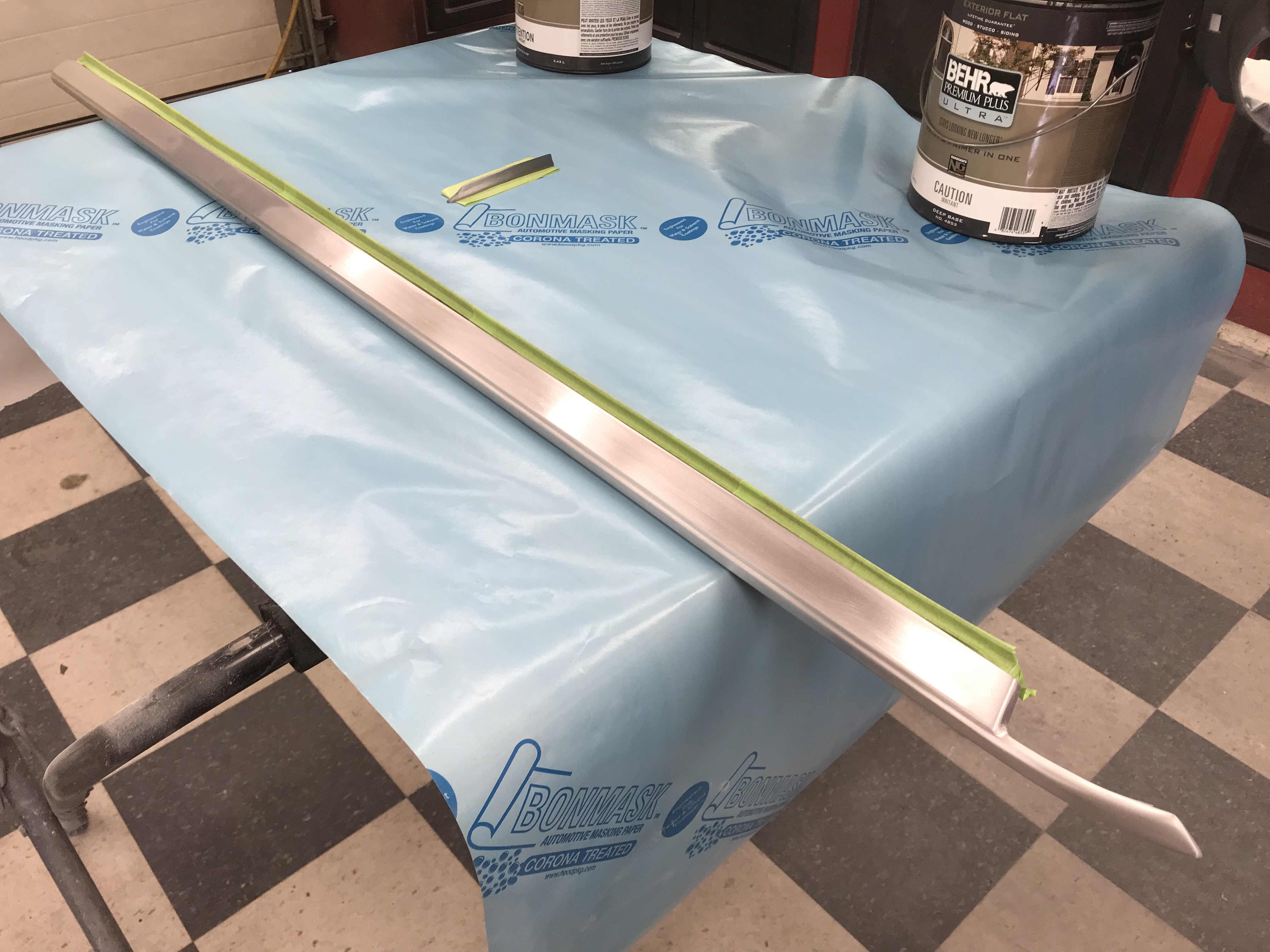

This was the last bit of prep the header panel needed, once that was done Olds Cool got moved outside and the header panel was “professionally” jigged up on the stand (on some old paint cans 😅). Along with the header, I also set up the passenger side belt moulding and the header panel trim spear.

I started the marathon spray session with a blow off and wipe down, then a good coat of adhesion promoter on all the parts.

Now before I go any further, I need to explain what’s going on with the belt moulding. Remember the one that I turned into a pretzel in a fit of rage? That was the second attempt at a passenger side moulding. The first one I had set aside after having similar problems. Thankfully I kept it.

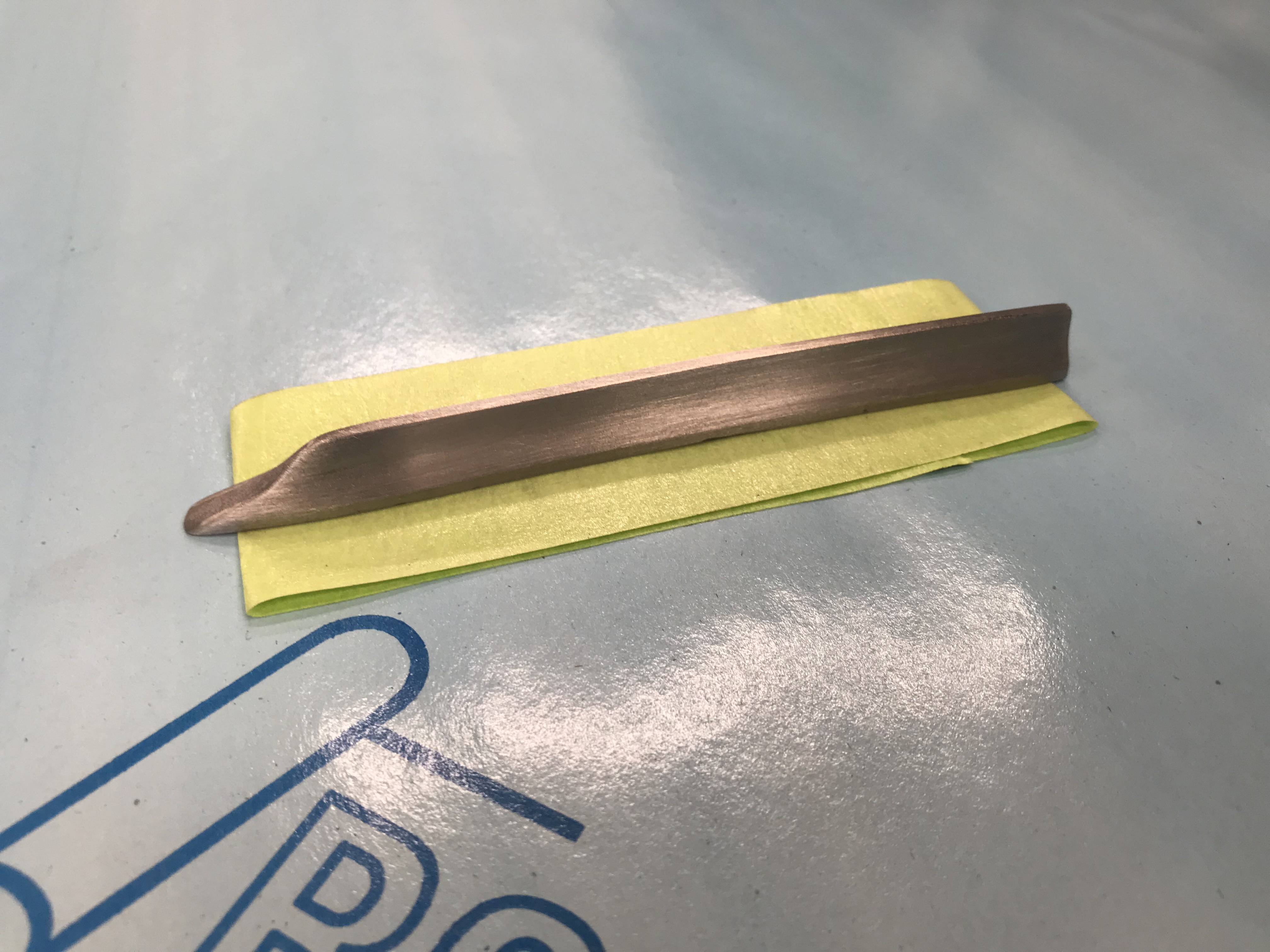

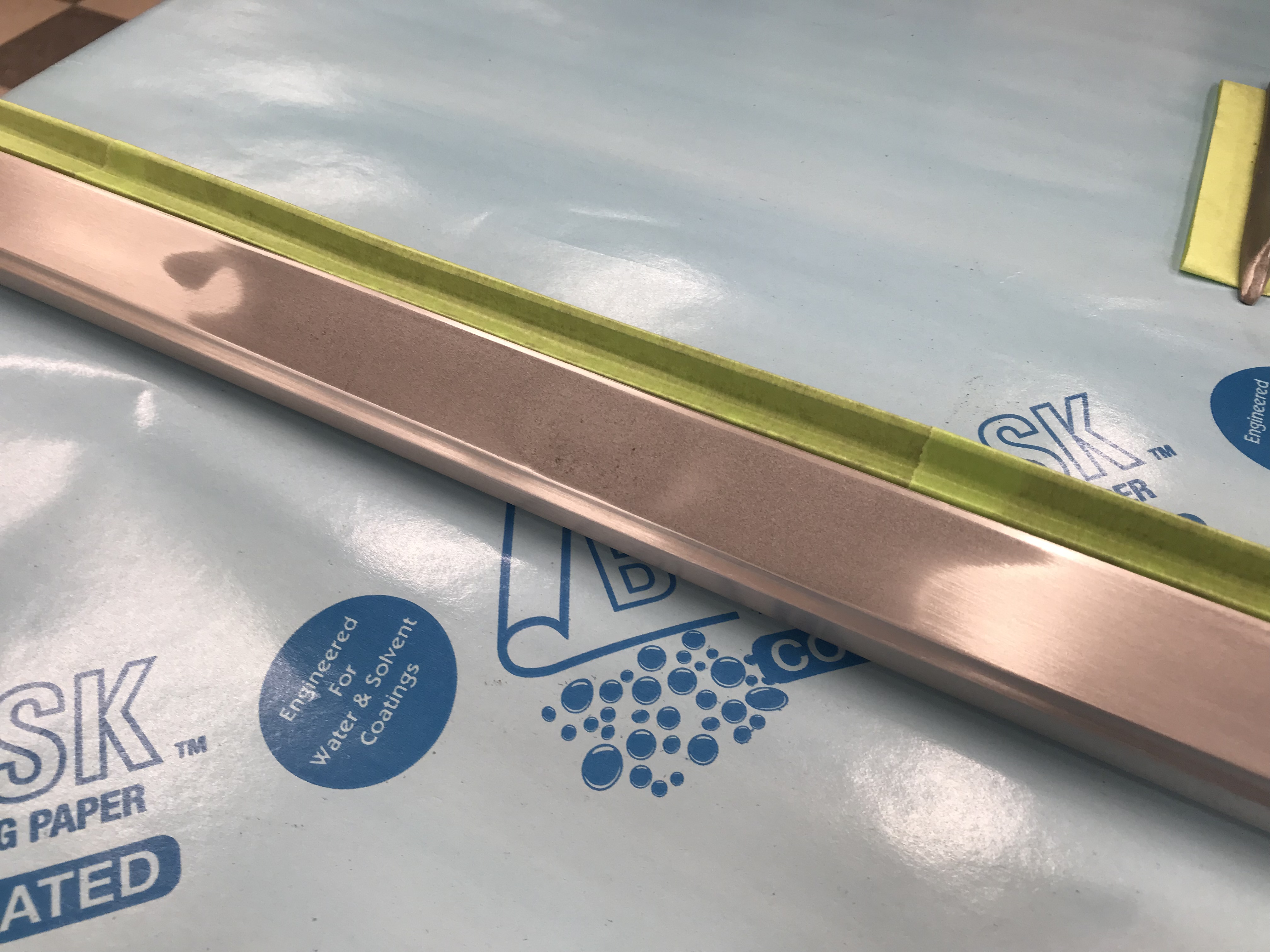

After pressing it back into service, I decided to leave the low spots I couldn’t get to cooperate, and roughed them up with a 60 grit disc on the air angle grinder. From there I just treated the moulding like any other metal panel, and applied some body filler. Not the regular stuff mind you, but some All Metal. I figure it’ll be a little more durable in the long run.

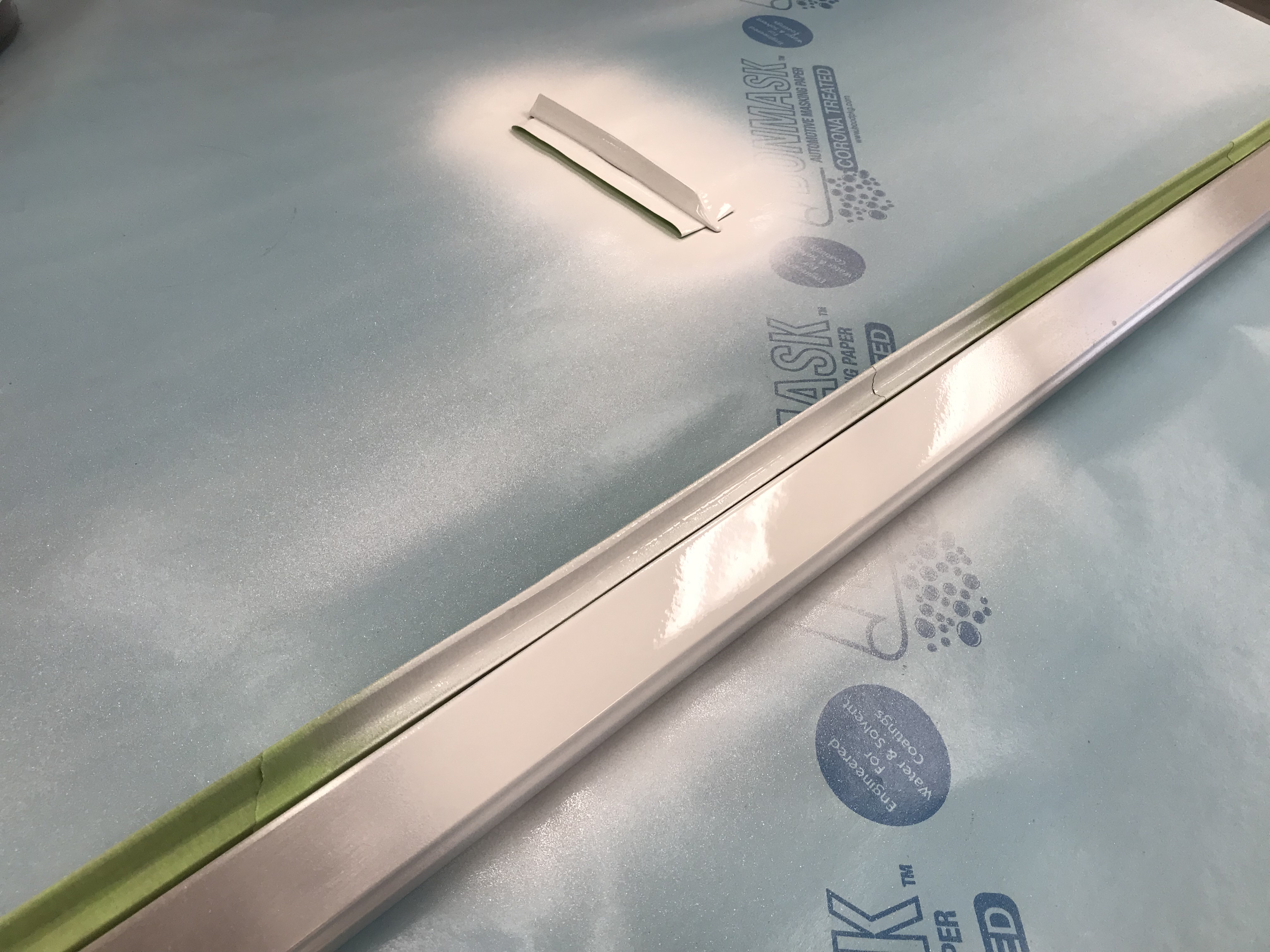

Anyways, after it was block sanded flat and smooth, it was masked up and wiped down in preparation for epoxy primer. This is why I picked up the silver tinter to try and somewhat approximate the color of the trim.

Anyways, here’s the piece masked up and ready for epoxy:

All the parts then got 2 full wet coats of white epoxy, and were left to set for the one hour induction period. My application of the epoxy wasn’t the greatest with a couple of rookie sags in it, but it’ll suffice.

When the hour was up, it was back to it again. This time with 3 medium wet coats of high build primer, but only on the outside of the header panel and the repaired spot on the trim. The trim spear didn’t need it.

My application of the epoxy may have been mediocre at best, but my bodywork on the hood ornament deletion is spot on:

Still not finished quite yet, it was time to clean the gun for a second time and mix up some metallic grey. I’m able to do this because of the curing and bonding properties of the epoxy. It’s a process called “wet on wet” and it saves a ton of time and labor by not having to sand inconvenient areas in between.

The headlight and grille openings were shot next, finally ending the marathon day.

After feeling like I’ve been spinning my wheels and accomplishing seemingly nothing lately, it felt great to get so much done in just one day. I’ll let everything cure for a couple days, then I’ll block sand the moulding and header before a second round of high build.

This gets me back on track again, coming up soon will be some experimentation with paint effects to try and duplicate the brushed finish on the trim.

So stay tuned for that, it should be interesting!

Till then, thanks all.

D.