I'd rather be lucky than good.

All day long, anytime.

Sometimes success in a project can come down to nothing more than luck, pure and simple. Such is the case here.

Earlier in the thread, Jared, Kevin and I had tossed around the notion of finding a donor section from a parts car to aid in replacing the rusted out sections that have complex body lines in them. Nothing ever came of that discussion for various reasons, but it did get the rusty old gears in my noodle turning.

Years ago when I bought the parts car affectionately referred to as The Brown Bomber, I had cut off and saved the entire quarter panels for use in the future on a special project slated for The Juggernaut.

When it became apparent that I would need to repair and replace the rusted sections on this car, I had never really given those quarters a second thought. Mainly because I knew that when we cut them off, we had cut them fairly short, not including much of the sail panel. Well, I figured it at least warranted a closer look, if nothing else than to confirm for myself I was right.

Digging the quarters out of the shed, I laid them out on the lawn for a better look:

This is where my bit of luck came in.

A closer inspection of the needed areas was rewarded with a happy surprise...

Not everything I needed was there, but good usable sections on both sides definitely were! I could work with what WAS there, and still not jeopardize my future plans for the quarters.

🙂

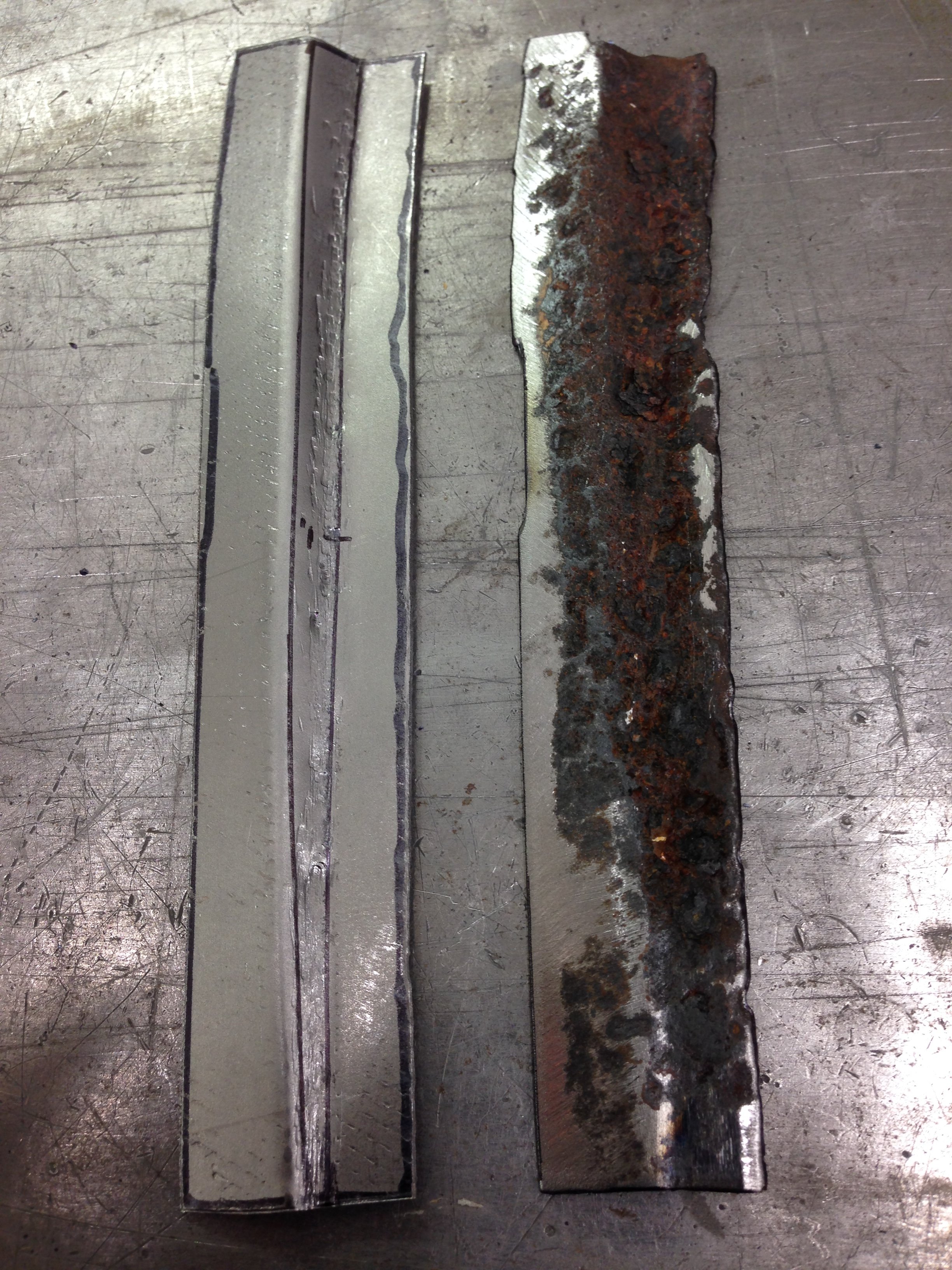

A few minutes and some carefully placed cuts later, I had the sections I needed cut off and on the bench:

Since I'm currently working on the driver's side of the car, I stripped the paint off the driver's side patch in preparation for use:

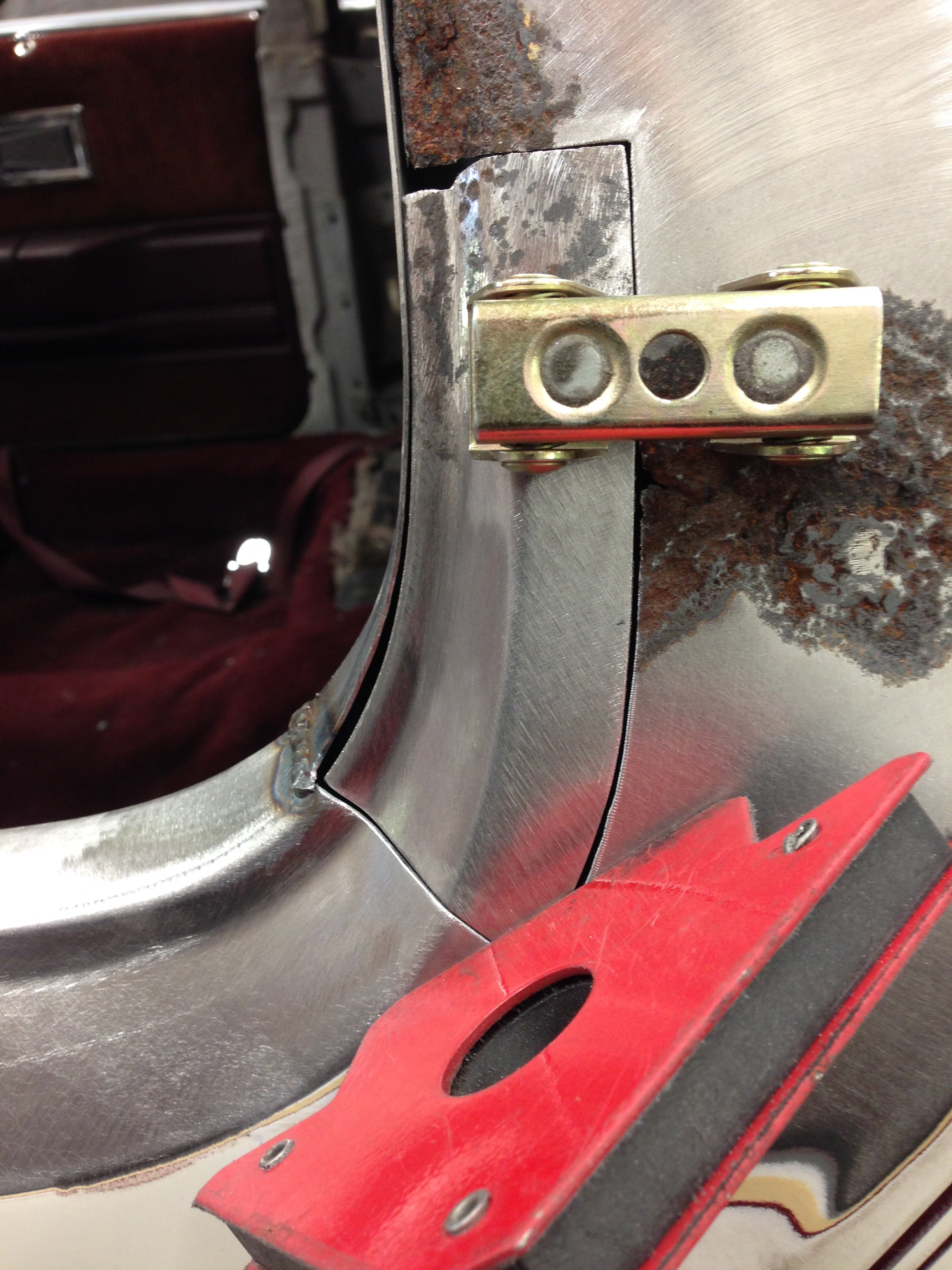

This is the affected area that the majority of the patch would be priceless to use:

Once I had the new patch trimmed down a bit, I held it up for its first test fit:

Looks good, it's going to save me a whole pile of time and complicated fabrication trying to duplicate it!

Next, I traced around where the patch needed to go...

...and then shortened it up a bunch and re-traced it. There was no sense in cutting out all that good unblemished sheetmetal if I didn't have to.

Once I knew where I had to cut on the body, I transferred that line to the patch:

Continued >>>

All day long, anytime.

Sometimes success in a project can come down to nothing more than luck, pure and simple. Such is the case here.

Earlier in the thread, Jared, Kevin and I had tossed around the notion of finding a donor section from a parts car to aid in replacing the rusted out sections that have complex body lines in them. Nothing ever came of that discussion for various reasons, but it did get the rusty old gears in my noodle turning.

Years ago when I bought the parts car affectionately referred to as The Brown Bomber, I had cut off and saved the entire quarter panels for use in the future on a special project slated for The Juggernaut.

When it became apparent that I would need to repair and replace the rusted sections on this car, I had never really given those quarters a second thought. Mainly because I knew that when we cut them off, we had cut them fairly short, not including much of the sail panel. Well, I figured it at least warranted a closer look, if nothing else than to confirm for myself I was right.

Digging the quarters out of the shed, I laid them out on the lawn for a better look:

This is where my bit of luck came in.

A closer inspection of the needed areas was rewarded with a happy surprise...

Not everything I needed was there, but good usable sections on both sides definitely were! I could work with what WAS there, and still not jeopardize my future plans for the quarters.

🙂

A few minutes and some carefully placed cuts later, I had the sections I needed cut off and on the bench:

Since I'm currently working on the driver's side of the car, I stripped the paint off the driver's side patch in preparation for use:

This is the affected area that the majority of the patch would be priceless to use:

Once I had the new patch trimmed down a bit, I held it up for its first test fit:

Looks good, it's going to save me a whole pile of time and complicated fabrication trying to duplicate it!

Next, I traced around where the patch needed to go...

...and then shortened it up a bunch and re-traced it. There was no sense in cutting out all that good unblemished sheetmetal if I didn't have to.

Once I knew where I had to cut on the body, I transferred that line to the patch:

Continued >>>