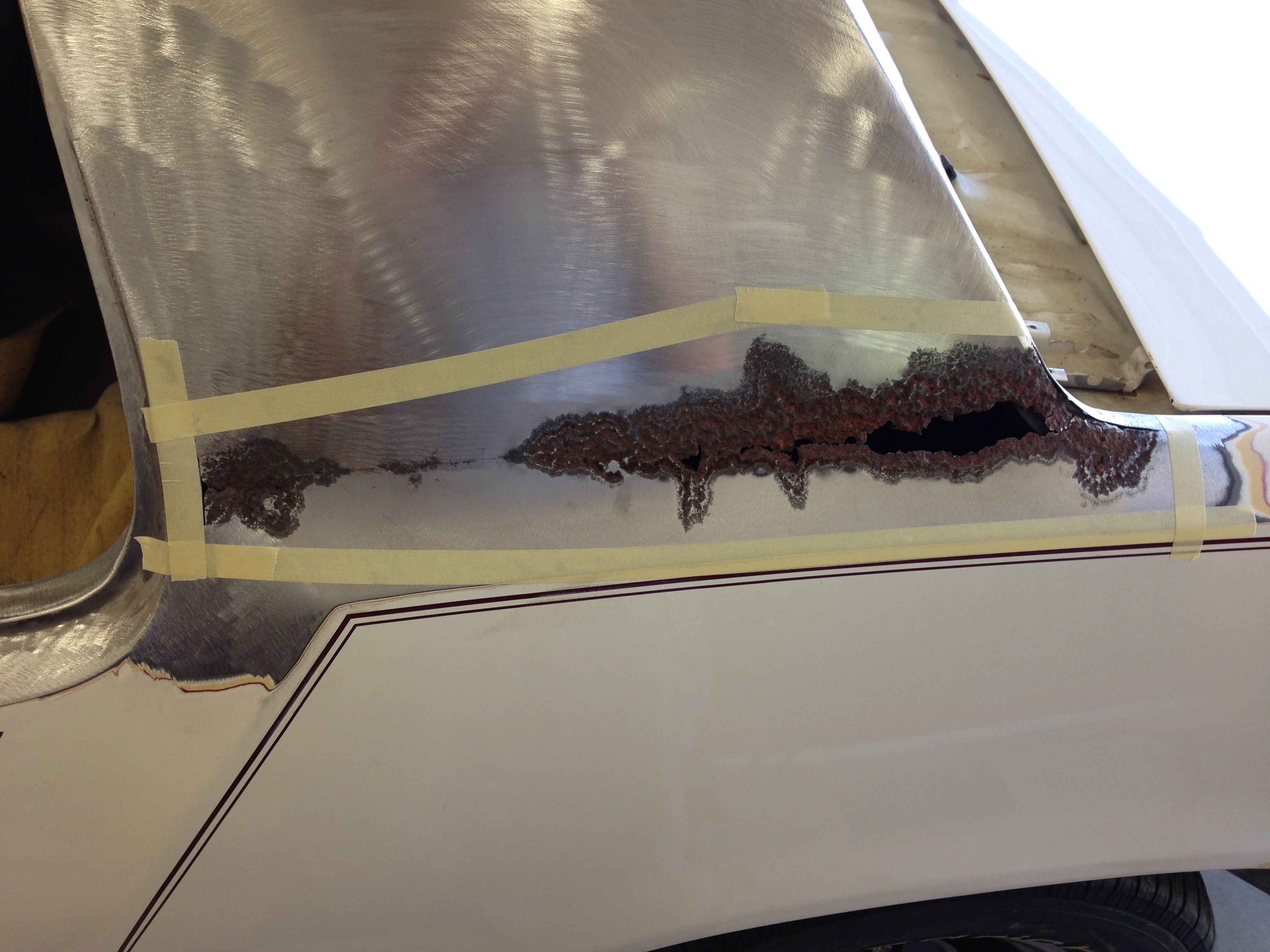

With the last bit of structural sheetmetal around the edges finally replaced, it was time to cut the last of the rust out. This is by far the largest piece, it will also be the most critical to get right and time consuming to complete.

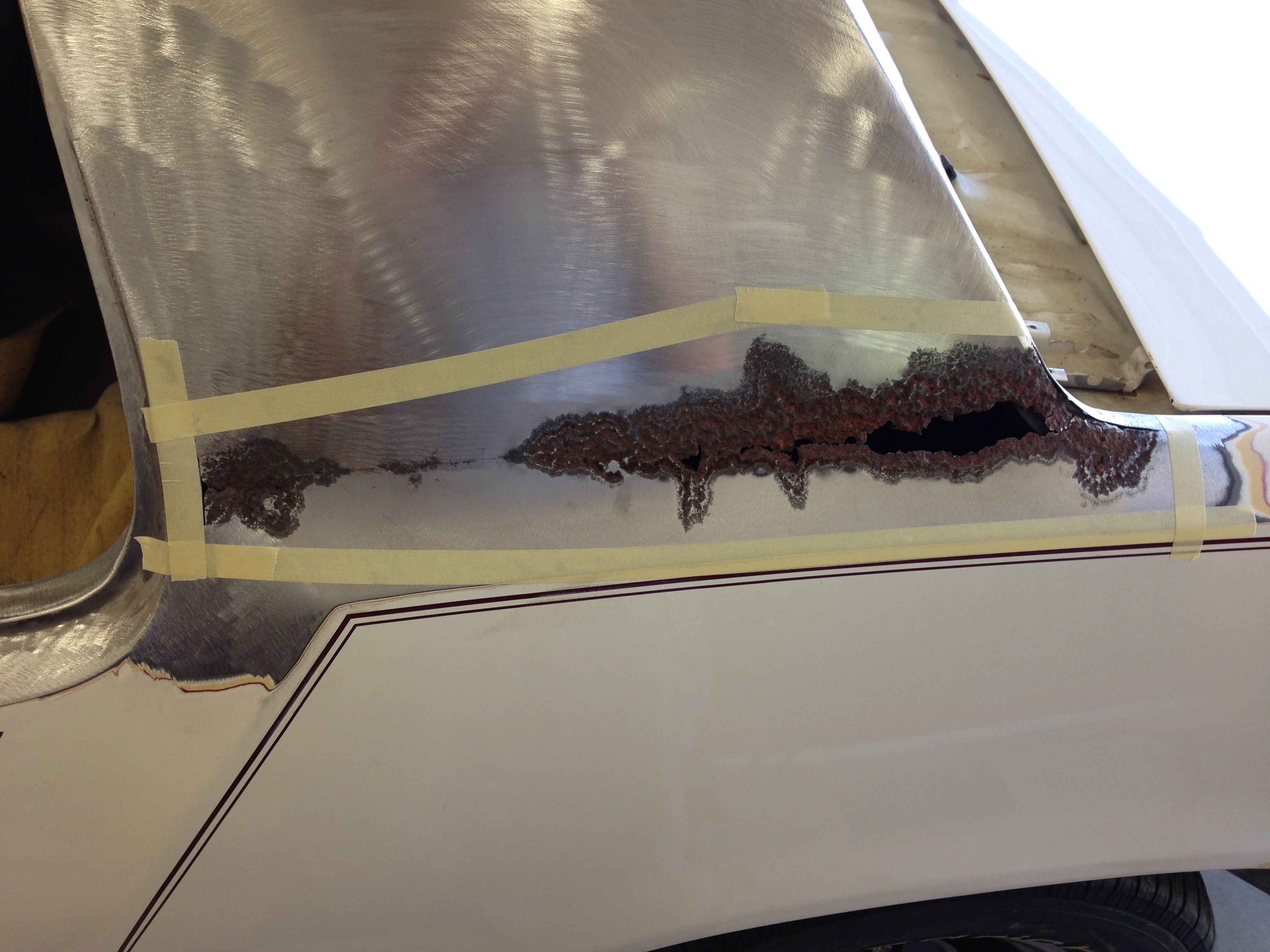

I marked off my cut lines with masking tape...

... then cut it all out in one shot using mostly the body saw. Damn that's a big hole!

I usually prefer to make my patch panels symmetrical and even, but due to the location and pattern of the rust that had occurred, this one ended up looking kinda funny.

I used what was left of the old piece as a template for the new patch...

...then put a slight curve in it to match the transition from the sail panel to the quarter panel.

I don't (yet) own a slip roller, so using a little redneck ingenuity, I gradually formed the curve over my largest fire extinguisher:

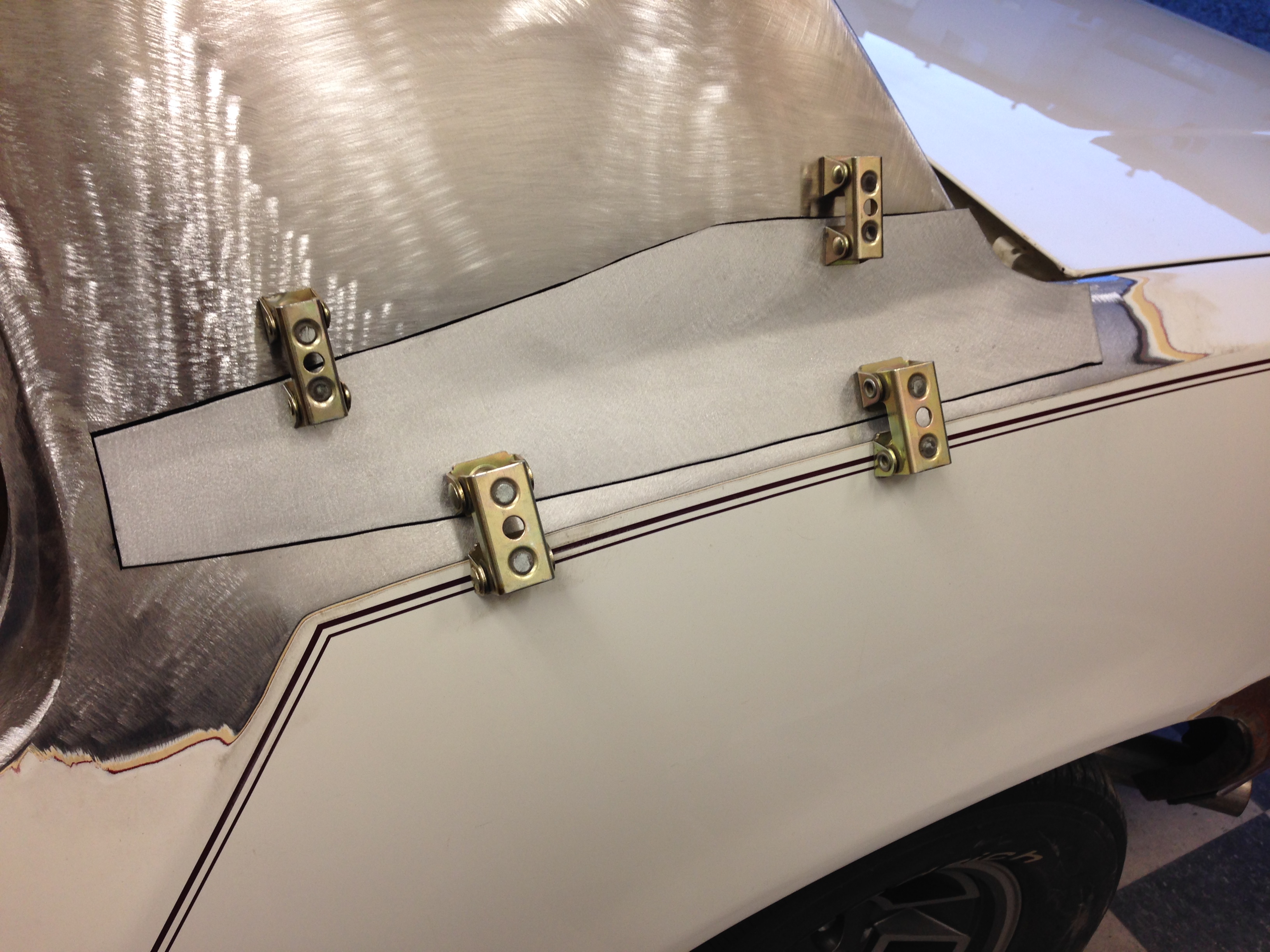

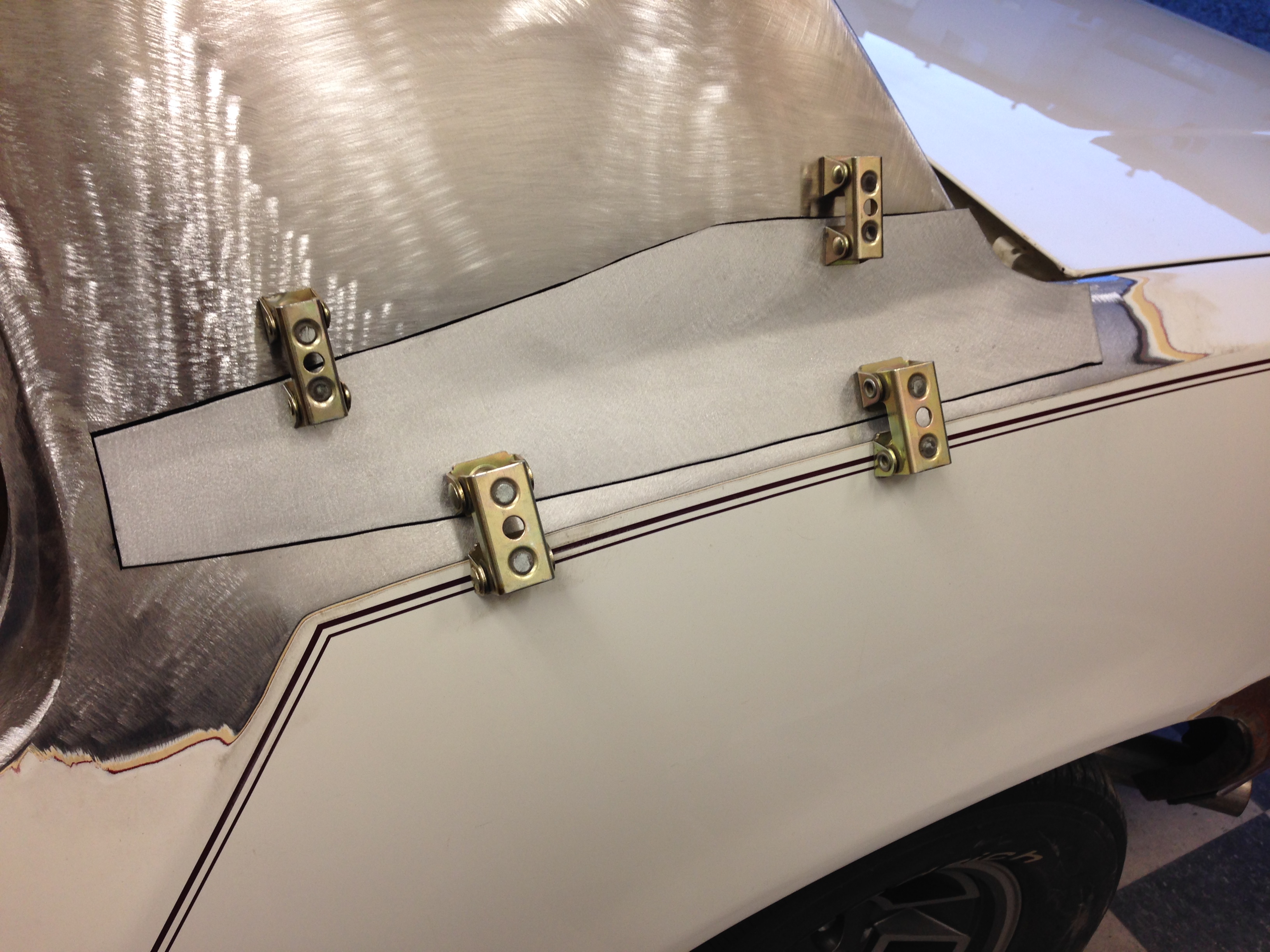

The first test fit in the opening:

Looks pretty good so far!

I'll do a little more tweaking to it before I start to weld it in, I'm not really happy with the "crease" in it towards the back. It's not really a crease, it just looks like it in the pics. It could use a little more finessing tho.

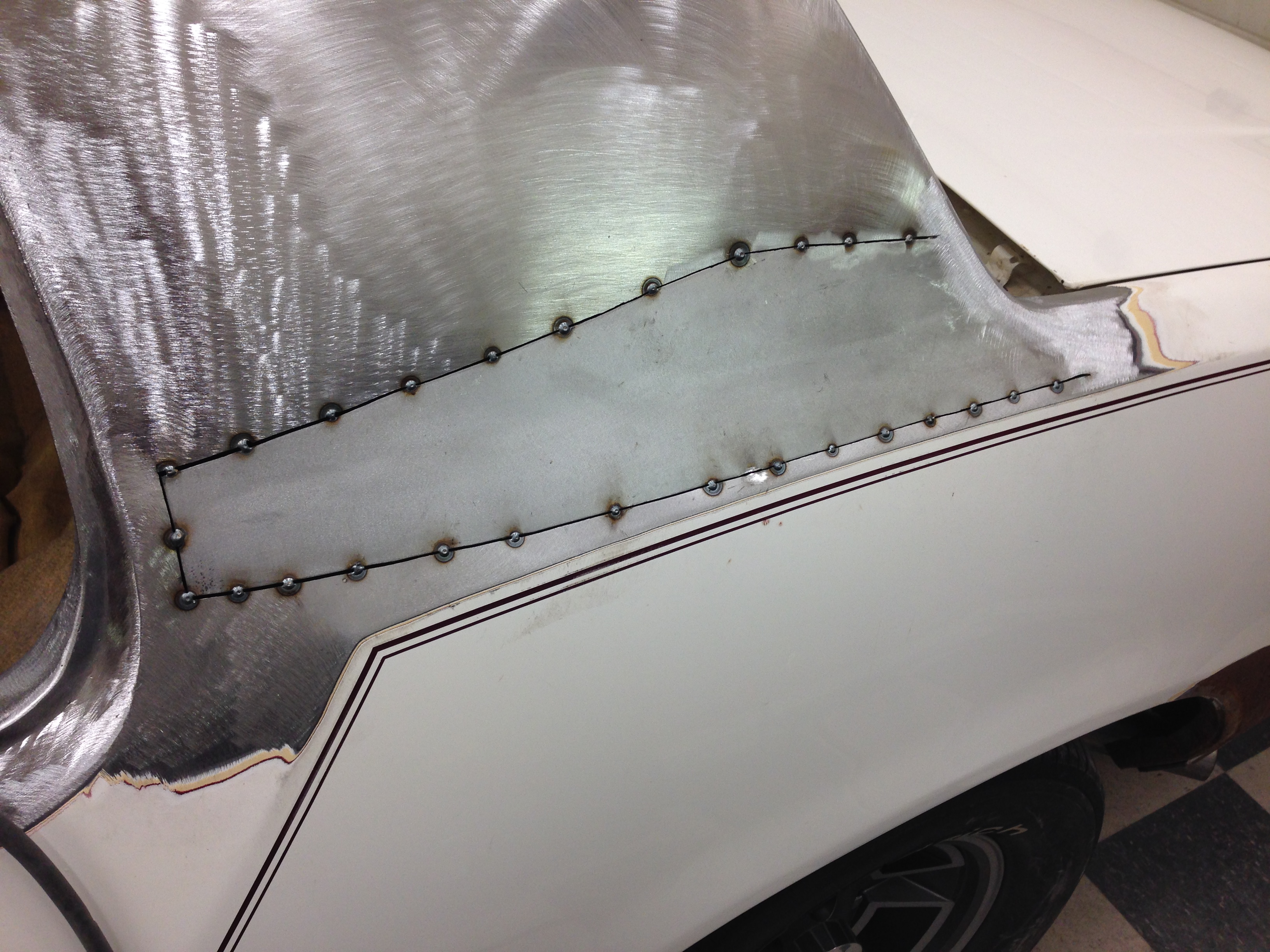

Mocked back up into the opening again, after sanding off the mill scale and spraying the backside with zinc primer:

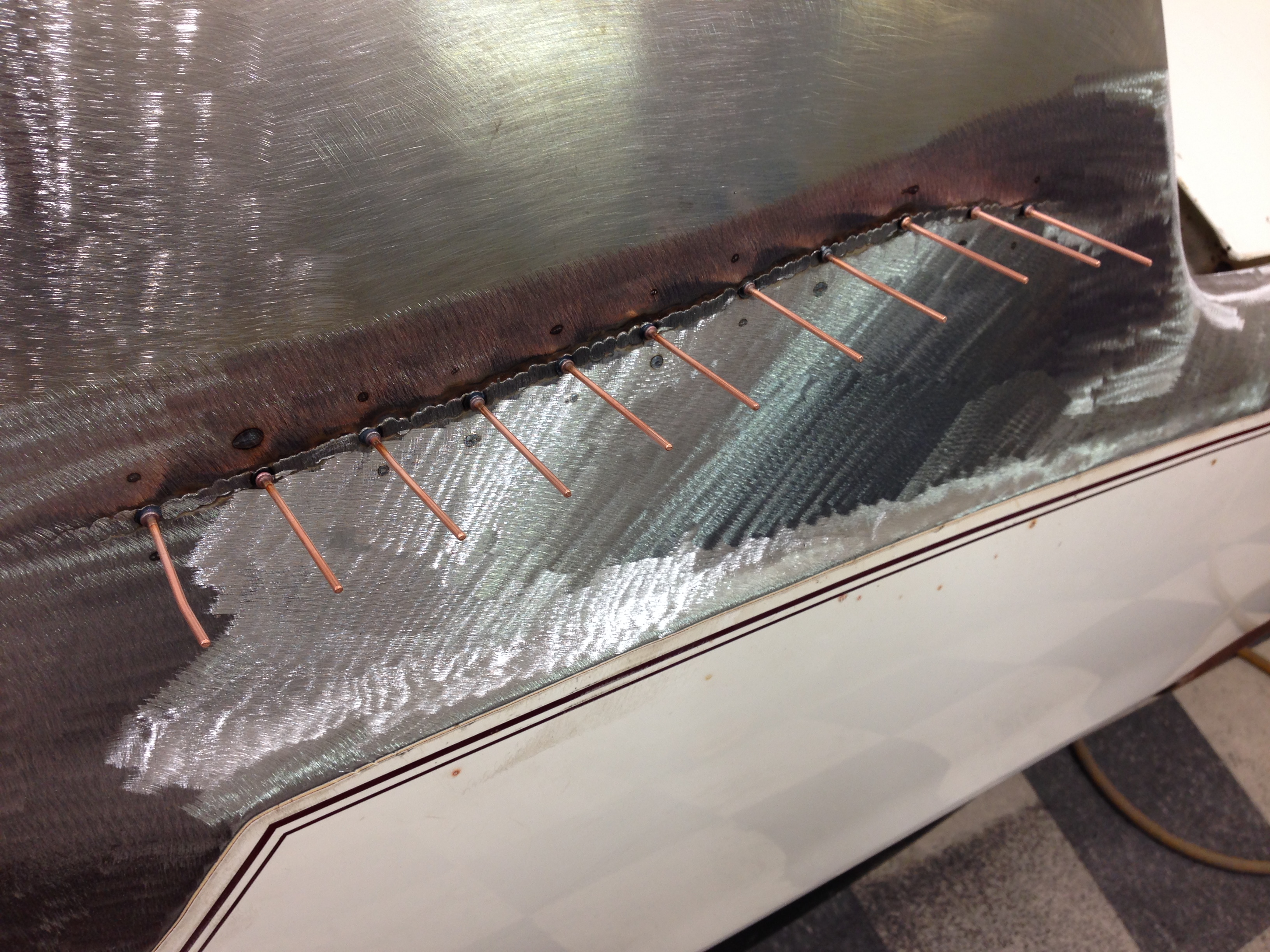

Tomorrow night after work, I'll get back on it, finesse the back a bit more and then start welding it in. It'll be so nice to see this completed, and have no more rust on this side!

Thanks once again for checking back everyone.

🙂

Donovan

I marked off my cut lines with masking tape...

... then cut it all out in one shot using mostly the body saw. Damn that's a big hole!

I usually prefer to make my patch panels symmetrical and even, but due to the location and pattern of the rust that had occurred, this one ended up looking kinda funny.

I used what was left of the old piece as a template for the new patch...

...then put a slight curve in it to match the transition from the sail panel to the quarter panel.

I don't (yet) own a slip roller, so using a little redneck ingenuity, I gradually formed the curve over my largest fire extinguisher:

The first test fit in the opening:

Looks pretty good so far!

I'll do a little more tweaking to it before I start to weld it in, I'm not really happy with the "crease" in it towards the back. It's not really a crease, it just looks like it in the pics. It could use a little more finessing tho.

Mocked back up into the opening again, after sanding off the mill scale and spraying the backside with zinc primer:

Tomorrow night after work, I'll get back on it, finesse the back a bit more and then start welding it in. It'll be so nice to see this completed, and have no more rust on this side!

Thanks once again for checking back everyone.

🙂

Donovan